Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

02-16-2009, 04:25 AM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

VIC

Cobra Make, Engine: Classic Revival CR 3505, LS1, T56 6 Speed, VE 3.45 LSD Rear, 6 Spot AP Fronts, 4 Spot Wilwood Rears

Posts: 1,121

|

|

Not Ranked

Not Ranked

Seperate Swirl Pot

Seperate Swirl Pot

Hi everyone.

I am after some opinions and advice on an external fuel swirl pot etc.

My tank is a custom aluminium job that doesnt have baffles and has an external fuel pump - very noisy Bosch job.

I have a bit of a problem with fuel starvation when the tank is getting down to about half full and you go up a hill or accellerate hardish.

I reckon I need a low pressure pump and swirl pot prior to my high pressure pump.

I have seen a couple of posts on this, just wanted to get the latest advice.

Also any good sources/recommednations for where to get one (also made) and suggestions for low pressure pump (and a quieter high pressure one)?

Thanks

Rgds

Gregg

|

-

Advertising

02-16-2009, 05:38 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Paradise Point,

Qld

Cobra Make, Engine: Absolute Pace

Posts: 1,205

|

|

Not Ranked

Not Ranked

Noisy Pumps

Noisy Pumps

HI Gregg,

I have used a Carter Lift Pump to fill the swirl pot and they do the job nicely.

http://www.rocketindustries.com.au/d...partno=FMP4070

If you find a quite replacement for the Bosch 044 I would be interested as well.

Phil

__________________

Not all driveways reach the street!

|

02-16-2009, 05:59 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Location: Virginia Beach,

va

Cobra Make, Engine: BDR #250

Posts: 234

|

|

Not Ranked

Not Ranked

Gregg,

I struggled with this for a couple of years. I had the exact same conditions that you are having. For pumps I used Mallory from Summit Racing, they are quiet and don't drawl much current. For the high pressure pump I used a Mallory 4060EFI pump it has a max pressure of 55 psi, flows 60 gallons per hour (227 liters per hour) and only draws 7.5 amps. For the low pressure pump I used Mallory 4070M w/a max pressure of 6 psi, flows 70 gph (264 lph) and only draws 2.5 amps. I am very happy with theses pumps as them a quiet, I mounted them on rubber grommets. They are being used on a 590 HP engine up to 7000RPM with no fuel starvation problems. With the low current draw I ran them on the same circuit in parallel with a 12 amp fuse. Hope this helps.... Mac

|

02-16-2009, 05:59 AM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Cobra Make, Engine: 347 Stroker Morrison Injection. Registered.

Posts: 1,440

|

|

Not Ranked

Not Ranked

Hi Gregg, Im not sure what others have done but Im using the commodore tank with the standard in tank pump which pumps fuel under constant pressure into a swirl pot located under the rear guard. It then goes through an aeroquip fuel pump up to the fuel rails. Any unused fuel is then returned to the fuel tank.

Hope it works!

Regards.

__________________

Mando

Last edited by Mando; 02-16-2009 at 11:00 PM..

|

02-16-2009, 06:09 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Location: Virginia Beach,

va

Cobra Make, Engine: BDR #250

Posts: 234

|

|

Not Ranked

Not Ranked

Gregg,

I forgot to include the fuel system flow. From the main tank, to the low pressure pump, to to the swirl pot, to the high pressure pump, to the engine, return fuel goes to the surge tank and over low goes back to the main tank. The swirl pot has 4 fitting. Also the Mallory 4060EFI pump has a air bleed fitting the needs to be tied into the fuel return line. I used two fuel filters from Earls that I put them after both pumps. Hope this helps..Mac

|

02-16-2009, 01:28 PM

|

|

CC Member

|

|

|

Join Date: Jan 2007

Location: Melbourne,

VIC

Cobra Make, Engine: Harrison, 6.0L Chev

Posts: 2,513

|

|

Not Ranked

Not Ranked

Gregg, I'm using the VZ Commodore Crewman pump which has a single fuel line to the engine, internal reg and swirl pot and sits in tank - couldn't be any simpler. Since the L98 injectors flow around 39lb/hr and a stock LS1 only 26lb/hr, I assume this pump would give you a bit of headroom if you needed to increase fueling later. More info on injector flow/pressure rates here.

Sambo |

02-16-2009, 02:00 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

VIC

Cobra Make, Engine: Classic Revival CR 3505, LS1, T56 6 Speed, VE 3.45 LSD Rear, 6 Spot AP Fronts, 4 Spot Wilwood Rears

Posts: 1,121

|

|

Not Ranked

Not Ranked

Thanks everyone for you great advice.

Sambo I wish I had of thought about this sooner and done the "all-in-one" VZ option you have. Saves a lot of external plumbing.

Phil - I think my noisy pump is made worse by the fact that it is attached to a mounting bracket on the Fuel tank - nice speaker box effect I think

I think I will put some rubber around it and see if that helps.

Carter lift pump sounds like the go.

I think I read Shaun Mellish does Swirl Pots (I got my Water Header Tank and Radiator pipes from him he did a good job), I'll have to have a chat to him.

From a Fuel flow perspective I have a single line going from the rear to the engine fuel rail so I am thinking the following:

- Fuel tank to low pressure lift pump

- lift pump to swirl pot

- swirl pot to high pressure pump

- high pressure pump return (after regulator) to Swirl pot (currently goes back to Fuel tank)

- swirl pot overflow to Fuel Tank.

I think that what Mac VABCH mentioned.

Rgds

Gregg |

02-16-2009, 02:14 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

My set up is very similar to Mando, I have factory commodore tank fitted with a factory V8 (VN I think) lift pump, this feeds to the back of the L/H rear guard where I have a factory VT fuel pump in a swirl pot (supplied by Aussie Mike). The lift pump supplies fuel to the swirl pot, the main pump is connected just as it would be in a VT commodore (even has all the factory hoses with push on connections), So like the commodore it only runs a single line to the front of the car (although when building my car I did install a return line for use later when a larger motor is fitted).

And with the factory hoses at the back and VT pump as main feed, this is all built with inbuilt regulator and inbuilt return line that feeds back into the swirl pot.

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

02-16-2009, 03:13 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Brisbane Australia,

QLD

Cobra Make, Engine: RMC under re-construction, GenIV with tremec 600, Jag 3.31 L/S diff

Posts: 3,318

|

|

Not Ranked

Not Ranked

Here is a swirl tank available in Melbourne from EFI hardware. Sounds like it is not unlike that which boxhead had described.

http://www.efihardware.com/

Has a holden pump fitted and comes with the push on fittings, costs about $500.00.

__________________

It's impossible to soar like an eagle when you're surrounded by turkeys.

|

02-16-2009, 03:47 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

Yes that is same design as my setup.

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

02-16-2009, 05:50 PM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Darwin,

nt

Cobra Make, Engine: Classic Glass 302 Windsor

Posts: 101

|

|

Not Ranked

Not Ranked

The only thing I would suggest is to not return your fuel to the surge tank but return it back to the tank. The reasons for this is that you are retuning hot unused fuel back to the surge tank and then sending it back to the engine for consumption or recirculating. If you think that your lift pump is not capable of maintaining a full surge tank either your tank is to small or your lift pump is to small. The advertised flow ratings for most pumps is in US gallons (3.75 litres) per hour at what ever restriction required to achieve a rated pressure, when you remove the restriction and the pump is in free flow the volume is greatly increased, Make sure that the surge tank has the same size return as supply.

|

02-16-2009, 07:06 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

VIC

Cobra Make, Engine: Classic Revival CR 3505, LS1, T56 6 Speed, VE 3.45 LSD Rear, 6 Spot AP Fronts, 4 Spot Wilwood Rears

Posts: 1,121

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by C0braed

The only thing I would suggest is to not return your fuel to the surge tank but return it back to the tank. The reasons for this is that you are retuning hot unused fuel back to the surge tank and then sending it back to the engine for consumption or recirculating. If you think that your lift pump is not capable of maintaining a full surge tank either your tank is to small or your lift pump is to small. The advertised flow ratings for most pumps is in US gallons (3.75 litres) per hour at what ever restriction required to achieve a rated pressure, when you remove the restriction and the pump is in free flow the volume is greatly increased, Make sure that the surge tank has the same size return as supply.

|

Can you get non-return valves as I would want to plumb the high pressure return and the "low pressure" Surge Tank overflow back to a single outlet in the Fuel Tank? |

02-17-2009, 12:37 AM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Alice Springs, central Australia,

NT

Cobra Make, Engine: Classic revival kit (CR3181), gen III engine, T56 6 speed box, AU XR8 lsd diff

Posts: 5,699

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by C0braed

The only thing I would suggest is to not return your fuel to the surge tank but return it back to the tank. The reasons for this is that you are retuning hot unused fuel back to the surge tank and then sending it back to the engine for consumption or recirculating. If you think that your lift pump is not capable of maintaining a full surge tank either your tank is to small or your lift pump is to small. The advertised flow ratings for most pumps is in US gallons (3.75 litres) per hour at what ever restriction required to achieve a rated pressure, when you remove the restriction and the pump is in free flow the volume is greatly increased, Make sure that the surge tank has the same size return as supply.

|

I agree with you there, I initialy only set it up that way wanting to be able to get every last drop of fuel from the tank, and I have similar issues as Gregg is describing in hi speed cornering and accelerating when the tank is below about 1/4 full, I was thinking that by returning the fuel to the swirl pot then atleast it is not getting sloshed around in the tank and missing the intank pick up.

I figured I was not chassing every single last bit of HP so the small loss due to warm fuel did not bother me.

All feed and return lines to and from surge tank are the same size, being 8mm ID

__________________

Cruising in 5th

---------------------------------------------

Never be afraid to do something new, Remember, Amateurs built the Ark: Professionals built the Titanic.

|

02-17-2009, 02:18 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2007

Location: North Gold Coast,

Qld

Cobra Make, Engine:

Posts: 820

|

|

Not Ranked

Not Ranked

the best setup is to have as minimal connecti0ns as possible

now the problem u have is half the guys that make these tanks do not ask enough questions

no one these days asks why where how or what

ive been doing conversions for 15 years and u have to look 50 steps forward

even though its just a fuel tank they should be asking u what enigne is it what is the std fuel system setup like

surge tanks are ok if u got a premade tank but in a cobra with minimal room best to go internal

now if u are getting custom tank made up why not get the thing made to exactly how need it

these fabricators should be asking what can we do to mak eit easy

anyway best setup is

std holden vt to vz fuel pump assembly directly into the tank then u will have the most minimal amount of connections and possible leaks

i have these neat fuel filters with a pressure reg already inside them

they work a tread

another need to know the fuel sender resistance to get a matching gauges

so i always tell people to ask many questions when getting things made up

if u can afford the cobra to be off the road for a week or so

get a std holden pump setup and drop the tank out and get it modded to suit the new pump

|

02-17-2009, 04:11 AM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Ipswich,

QLD

Cobra Make, Engine: Harrison Cobra, SC540 Roadster

Posts: 359

|

|

Not Ranked

Not Ranked

The Harrison cobras have a setup that utilises the fuel pump from a BA/BF Falcon(similar to the VT/VZ Commodore) straight into the fuel tank the way Sideshow discribed. Mine was one of the first few tanks they started to use this idea which used a commodore pump before they changed over to one from a falcon. I used a V8 ute pump which fitted a bit easier.

I would fit the falcon pump over the holden pump as the falcon unit is a lot easier to fit. The falcon uses five screws to hold it in position with a cork gasket and holden uses a large O ring and circlip.

In the picture of the swirl tank and pump that Rebel attached, the pump is a BA/Bf falcon unit.

Warren

|

02-17-2009, 04:50 AM

|

|

CC Member

|

|

|

Join Date: Jan 2007

Location: Melbourne,

VIC

Cobra Make, Engine: Harrison, 6.0L Chev

Posts: 2,513

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by WKB

I would fit the falcon pump over the holden pump as the falcon unit is a lot easier to fit. The falcon uses five screws to hold it in position with a cork gasket and holden uses a large O ring and circlip.

|

Warren, here's a picture of my VZ Crewman pump. Sounds very similar to the Ford unit you're describing - certainly no O ring or circlip involved. More pics in my gallery.

|

02-17-2009, 05:30 AM

|

|

CC Member

|

|

|

Join Date: Aug 2001

Location: Melbourne, Australia,

Vic

Cobra Make, Engine: G-Force Mk I, 5L Windsor, TKO 600, enhanced Jag / Koni suspension & LSD Diff.

Posts: 2,303

|

|

Not Ranked

Not Ranked

Gregg

Somewhat the same as Paul's I had Marty retro mod my GForce steel tank to accept a BA V8 pump with self swirl pot.

Top of tank needed some funny work cause of the design but pump inside the swirl pot sits flat on the bottom of the tank. Had no issues though I don't think I had the tank absolutely low in the period I was driving.

Only difference I will make when I get a new tank fabricated is to have the swirl pot sit in a lowered section for full collection.

I had a Bosch 044 in a rubber mount and it was still noisy.

If you can go in tank do it!!

Cheers

__________________

slowy

|

02-17-2009, 02:01 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

VIC

Cobra Make, Engine: Classic Revival CR 3505, LS1, T56 6 Speed, VE 3.45 LSD Rear, 6 Spot AP Fronts, 4 Spot Wilwood Rears

Posts: 1,121

|

|

Not Ranked

Not Ranked

Slowy, I think in tank is defiinitely the go for getting rid of noisy external Bosch 044 pump.

I do like the external swirl pot mentioned by Rebel1 and Boxhead as this is quite neat having the pump/reg inside it . Means I have to do some slight re-plumbing but not too bad.

I need to have a look at the depth of my tank to see what options I have. I am suspicious that my tank might be too shallow.

Slowy or Paul -do you happen to know the dimensions of the VZ or BA in tank pump?

Thanks for the suggestions.

Rgds

Gregg

|

02-17-2009, 02:25 PM

|

|

CC Member

|

|

|

Join Date: Jul 2007

Location: Sydney Australia,

NSW

Cobra Make, Engine: RMC with 6 litre 307KW LS2, Comp Cam, 348rwhp & 532.5 ftlb of torque with 6L80E Tiptronic Transmission

Posts: 1,400

|

|

Not Ranked

Not Ranked

Gregg,

This may help you out and is exactly what Sideshow is talking about.

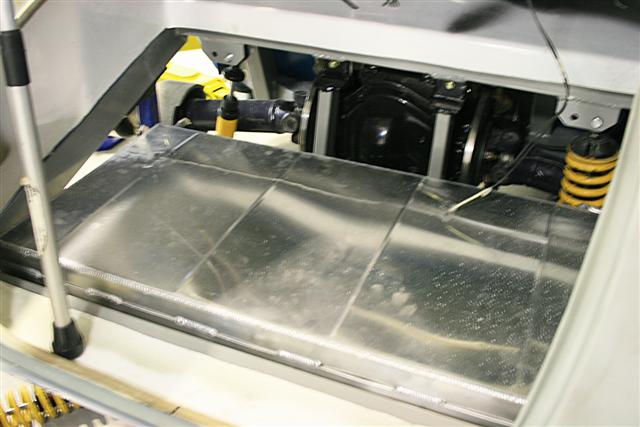

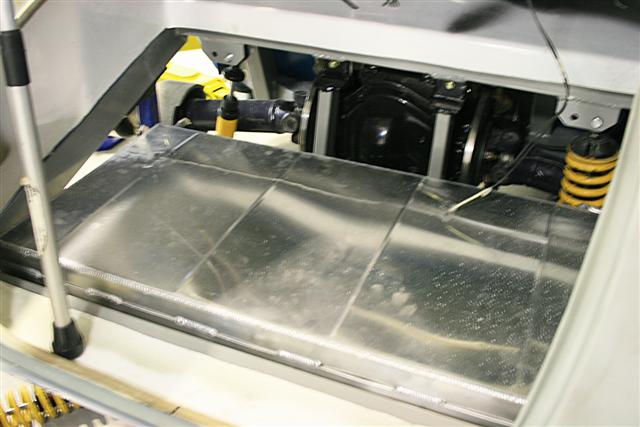

My tank is aluminium with a 75 litre capacity. I retreived the VDO Fuel Pump, Sender Unit an Swirl Pot from a VS V8 Commodore. The Swirl Pot was fitted to the base of the tank and the Fuel Pickup Line goes straight to the bottom of that Swirl Pot. This setup is part of the Sender Unit and this is what you see in the accompanying photo.

Two Fuel Lines are connected to that Sender Unit and they both go to the adjustable Fuelab Fuel Regulator which is set to 60 lbs pressure. The top hose goes through the Fuel Regulator ton a single line to the engine while the bottom hose goes into the Fuel Regulator then returns to the Swirl Pot if the pressure increases to more than 60lbs.

We selected this setup as it is far quieter and hopefully more reliable than having an external Swirl Pot and Fuel Pump.

Baz

|

02-17-2009, 03:51 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Ipswich,

QLD

Cobra Make, Engine: Harrison Cobra, SC540 Roadster

Posts: 359

|

|

Not Ranked

Not Ranked

Gregg,

The tank in the 540 is 200mm deep and fits the BA/BF pump. The tank in my Harrison is 210mm deep and uses a VZ Commodore Ute pump(the pump from the sedans are longer), although I had to shorten the sprung loaded locoating tubes a bit to fit.

If you use a Falcon pump and require a fuel sender the ute pump has the sender attached to the pump, the sedan pump is just the pump as it uses a remote sender. The Holden pump has the sender attached.

Paul,

The VZ ute pump looks completly different to the crewman pump. From the picture of the pump in your gallery it looks as though the

flange around the top of both pumps are the same. The fabricator of the tank come up with a good idea in the way he held the pump down without using the O ring and circlip.

Warren

Last edited by WKB; 02-17-2009 at 04:36 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:35 AM.

|

|

Linear Mode

Linear Mode