You thinking about this setup Mando?

The car was engineered with this setup and passed OK.

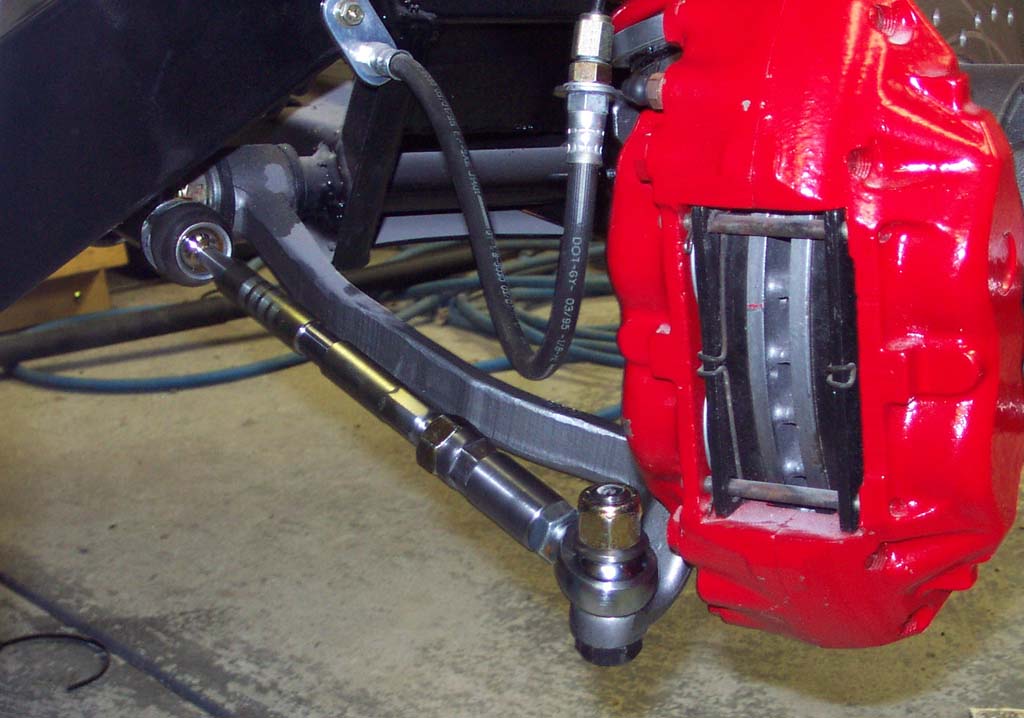

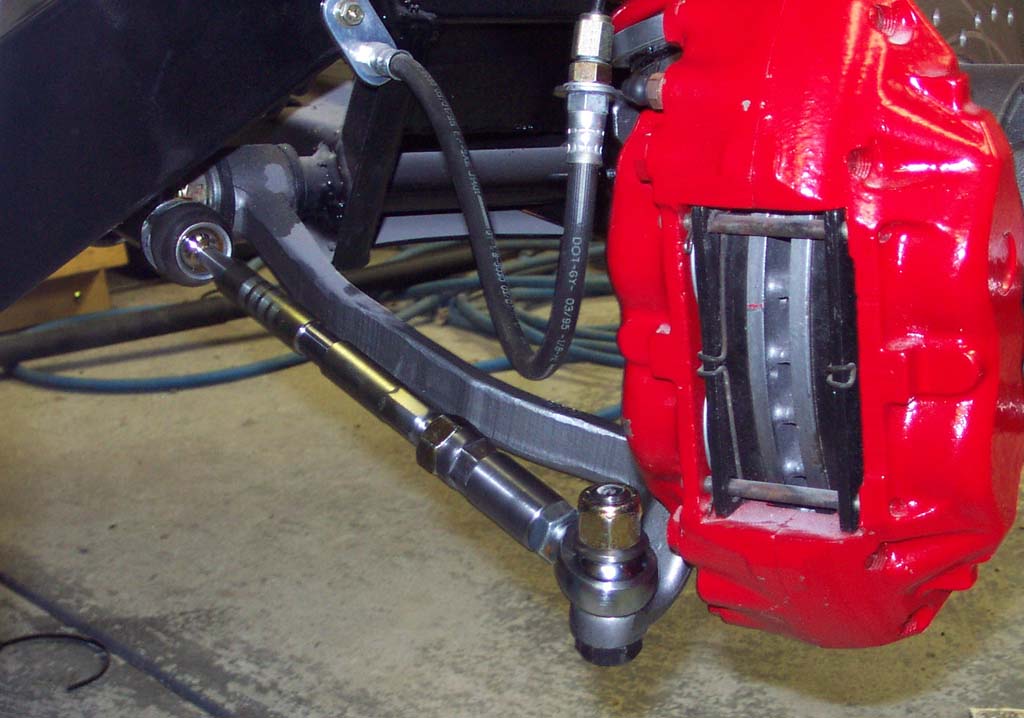

I used VP commodore rack ends which are thicker than the VL and VN ends. The screw straight into the end of the rack as they use the same ball joint on the end. The thread they use for the tie rod end is 16mm fine rather than 14mm for the VL VN ends. I shortened them and ran the thread futher along.

I then machined up some sleeves that have a 16mm fine thread in one end and a 5/8 UNF Left hand thread in the other end. Most of the readily available good quality rod ends are in imperial sizes so it was easer to go 5/8 Left hand.

The tapered hole in the arm I drilled out to 5/8" and ran a High tensile bolt through. There are a couple of conical shaped washers I machined up to ensure the rod end has full range of movement. If I did it again I'd probably buy the high angularity rod ends.

To adjust the toe you just loosen off the 2 lock nuts and rotate the sleeve. One of the things I like about it is for 1 turn of the sleeve you get double the movement. It means you can set it up so you have a big wange of adjustment whilst maintaining maximum thread engagement.

With this setup you dont need to drop the rack. moving the rod ends to the tops of the arms gets rid of a lot of the "droop steer" as Ian calls it. I've still got to do some proper measurements to prove it though.

It also solves the problem of the ball joint on the end of the rack getting pushed beyond it's max angle at full droop.

Cheers

Linear Mode

Linear Mode