Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

06-05-2006, 11:35 AM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Coming Soon to a Breakfast Near You :)

Coming Soon to a Breakfast Near You :)

Spent the weekend wiring. About 1 more weekend, a visit to custom alignment, and it's off to the BAR. I'm getting excited. 4 years in the making now...yikes.

|

06-05-2006, 02:48 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Sunnyvale,

CA

Cobra Make, Engine: Superformance #1048, 392w

Posts: 122

|

|

Not Ranked

Not Ranked

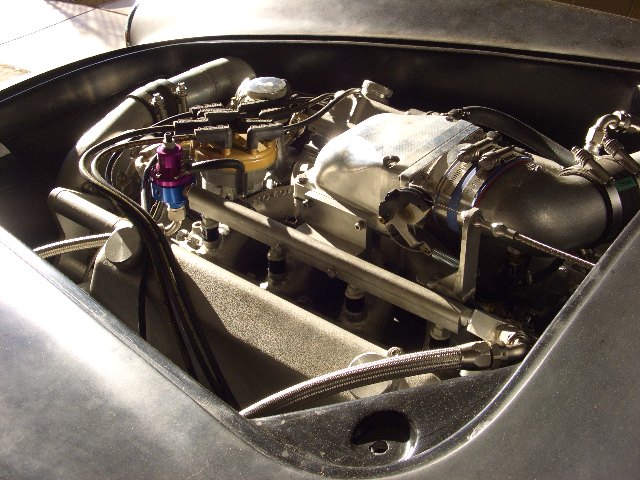

that engine compartment looks crazy - i like how everything looks custom machined...

good luck keeping it attached to the ground.

|

06-05-2006, 03:32 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Yeah, that will be a problem.

Yeah, that will be a problem.

Quote:

|

Originally Posted by nblumberg

that engine compartment looks crazy - i like how everything looks custom machined...

good luck keeping it attached to the ground.

|

I've been working on this for years and fab'd a lot of the parts. Pulleys, blower mount, crank adapter, intake mods, intake hat, rails, brake mounts, trans parts, power distribution panel, digital dash, etc. The project started as a frame and body from a good friend Charlie Bruno's estate. I'm sure Charlie would approve of what I've done to his car.

Even with 360/710-17's on the back, I'm afraid it will have the capability of destroying any amount of tire...you're absolutely correct. Simulation data says well over 900ft-lbs of torque at 10psi and it's capable of 14 on this engine so Vortech says. The weak link is the transmission; and I've seen 1000hp through a Viper T56 on Vipers...so hopefully it'll last a while.

The power is managed by the boost control valve and/or the blower pulleys. It's a small big block 385 series engine; 435" and low compression; 7.88:1. If I back the boost down, I can hold the power back to 400rwhp or even less. Initially, it's pulleyed to get a dyno number. We'll see how drivable it is. It has every indication of being extremely streetable. I don't know what it'll make; but if it's not 800 to the tires I'll be suprised. The goal was 1000fwhp on pump gas when the project started; we shall see if I made the number or not. Whatever it makes, it sure sounds sweet with that big cog pulley and impeller humming away up front.

Anyway, I plan on having it drivable and legal by my birthday; July 13th; and if I make it...perhaps I'll see you guys on the 15th at breakfast with the car.

Oh, and... all the project pics are on http://www.racesystems.com/cobra if you want to see the rest of it. They are not in order...havn't taken the time to sort by date.

Byron

Last edited by ByronRACE; 06-05-2006 at 03:35 PM..

|

06-05-2006, 03:45 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Sunnyvale,

CA

Cobra Make, Engine: Superformance #1048, 392w

Posts: 122

|

|

Not Ranked

Not Ranked

you mind if i bring my helmet along for the ride you are going to take me on?

Did you do the fabrication yourself or spec the stuff out to machine shops? If so, who?

-nathan

|

06-05-2006, 04:09 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Fab work

Fab work

Hehe, I need some break-in miles and a lot of solo time before I'll attempt any stunt driving with a passenger, but I'll drive folks around in it sanely, sure. I'm honestly very afraid of this thing. The first time I fired it, it became clear who was boss.

Some of the stuff I did myself using equipment at work. Some of it I did in my garage at home. Some of it I farmed out to water-jet shops. Some of it I had cut on a buddy's CNC machine in up in Oregon (I'm half owner).

The long-block was built at Mustang Ranch in Santa Clara; it was a team effort of several people. The 4-bolt main conversion, block prep, align-hone, and other critical stuff was done by Teddy/Techcraft (now Craig Hill owns them, right?). Some of the chassis fab work like the trans mounts and engine mounts and dropping the big parts into the chassis was done there as well.

Advanced waterjet in San Jose cut the flat engine plates for the blower drive from my cad input.

Design-It Prototype cut the EFI intake adapter elbow from my cad input. That was work in trade; I did efi work for them.

Shumway Machine in Oregon cut the brake parts from my cad input.

Advanced Circuits did the PCB Fabs from my cad input.

Most of the rest of it was done at home in my 2-car garage or at work where I have access to a machine shop.

I'll be soliciting help again to hang the doors. Then again for body/paint, and lastly interior.

Byron

Last edited by ByronRACE; 06-05-2006 at 04:13 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:46 PM.

Links monetized by VigLink

|