Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

390Likes 390Likes

08-05-2019, 11:43 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Glen,

The strap looks better in your last photo, less stress on the lid end of the strap.

Gary

|

08-06-2019, 12:19 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by hauss

hurry up already! your killing me.

|

Wish I could oblige, hauss. It's frustratingly slow progress, but I'm doing the first FIA with street dash in Australia....and the dash is completely my design (as far as manufacture goes).

As far as I know there's only one other FIA bodied car in Australia, and that's another AP car ( BJ's Snake, which is a replica of Ken Miles' 398 USRRC car), and its body came from the splash mould taken from my car.

There's some warped satisfaction there though, in that I'm frustrating at least one other person....apart from my wife

Cheers,

Glen |

08-06-2019, 12:25 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gaz64

Glen,

The strap looks better in your last photo, less stress on the lid end of the strap.

Gary

|

Agreed, Gary...but unfortunately, doing it that way caused interference with the fill-in panel that I need to cover the top of the horizontal structural crossmember.

Doing it the way I ended up doing it means there's only one thickness of strap being sandwiched when it's closed rather than two thicknesses.

Glad you're paying attention though

Cheers,

Glen

Last edited by xb-60; 08-06-2019 at 01:23 AM..

|

08-06-2019, 03:48 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xb-60

Agreed, Gary...but unfortunately, doing it that way caused interference with the fill-in panel that I need to cover the top of the horizontal structural crossmember.

Doing it the way I ended up doing it means there's only one thickness of strap being sandwiched when it's closed rather than two thicknesses.

Glad you're paying attention though

Cheers,

Glen |

I meant the bottom photo in your most recent photo uploads shows the strap with less bend when the lid is open.

Looks less stressed to me while the lid is open.

I hope that is what you meant by your "4th".

Gary |

08-08-2019, 03:33 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Something I started on some time ago (drilled the holes) but left it as access looked like a 'challenge' for me and my jigsaw.....the footwell cutout for pedal box.

Turned out to be not as hard as imagined

Cheers,

Glen |

08-08-2019, 04:31 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,505

|

|

Not Ranked

Not Ranked

Glen,

Nice job. Yes, cutting out panels in hard to reach areas can be challenging. In addition, there is the fear of the "Oops!" mistake where the saw veers off path and you are left with an ugly mess. my most recent experience with this was having to cut two electric outlet boxes into the ends of the island in the kitchen for my new house. Had to cut into the finished ends of the cabinets and any mistake would be glaring at everyone that walked into the house. Both turned out fine, but it was nerve wracking.

Jim.

__________________

|

08-08-2019, 07:42 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

I know what you mean Jim. Been there myself (with house mods).

With the footwell, lucky I have long arms...also a requisite when driving an older Alfa

Cheers,

Glen |

08-10-2019, 02:19 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

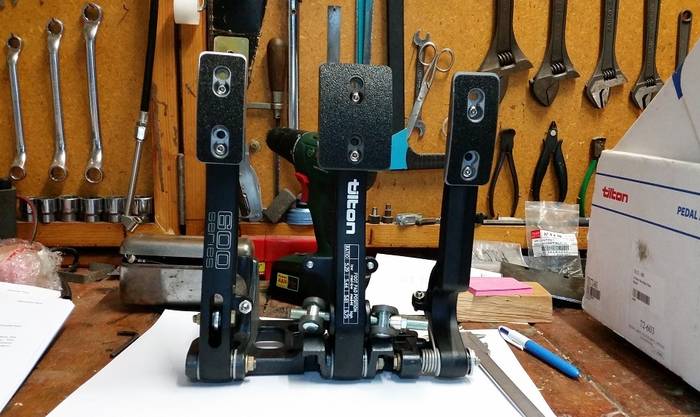

So, have the footwell cutout done, attention turns to the pedals...

They don't look exactly as original, but at least they don't hang down

Cheers,

Glen |

08-23-2019, 05:06 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

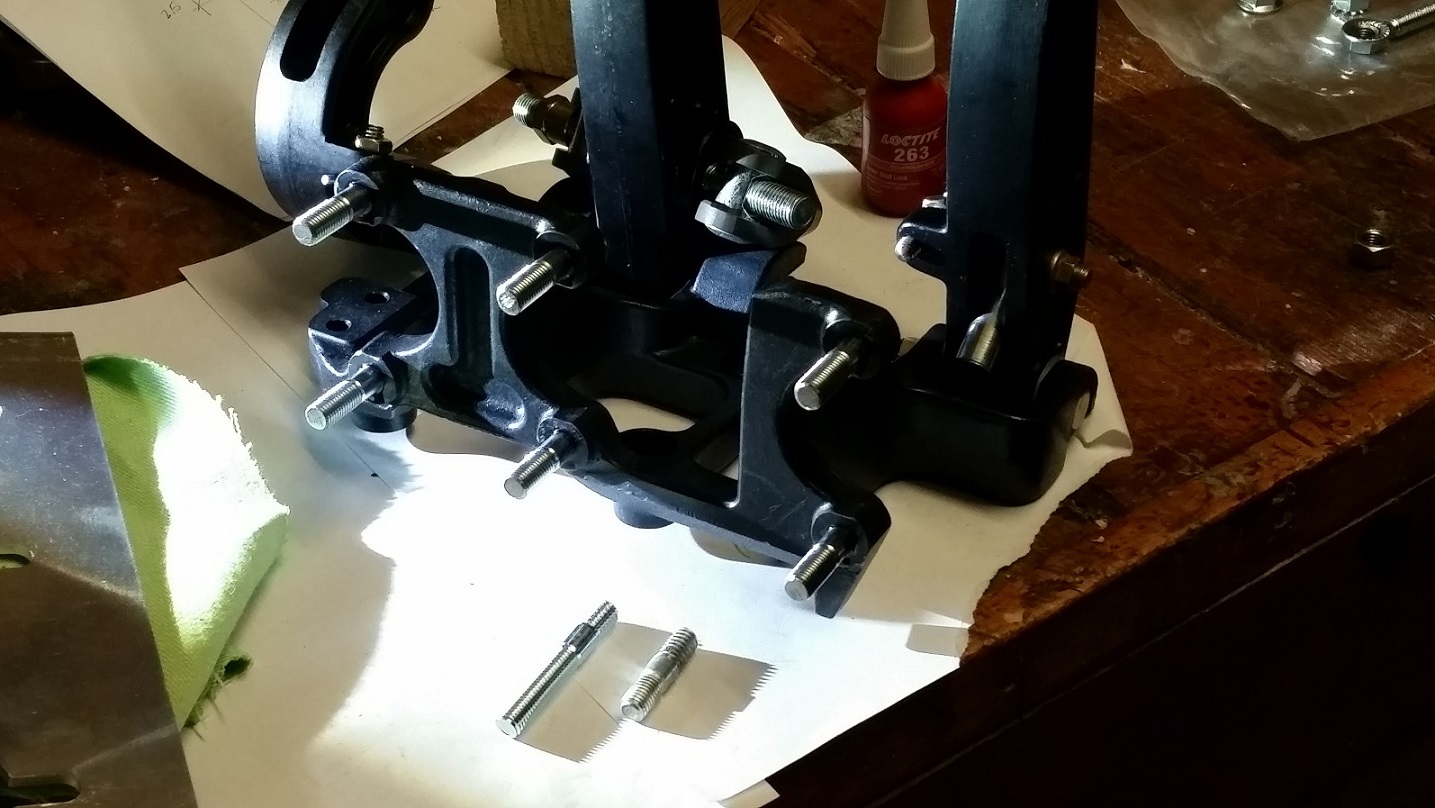

At the moment, feels like one step forward, five steps backwards and then slow advance to gain back that one step ahead again.

The six studs for the three master cylinders (clutch/brakes rear/brakes front) on the Wilwood pedal box were too short, enabling an engagement of only half the nut thickness....which is obviously NBG.

Found some longer studs (needed to be 5/16" UNC one end and 5/16" UNF the longer end, but they needed shortening. That's OK - can do. Done.

So, trial fit of the pedal box with master cyls attached in the car footbox, and in the recommended mtg location, my knees are hitting the bottom of the dash panel. Seems to me I can mount the pedal box assy further forward with some adjustments to mtg hardware (and no negative effects), so currently investigating that....but still not back to "square one" yet.

Cheers  !

Glen |

08-23-2019, 07:36 AM

|

|

CC Member/Contributor

|

|

|

Join Date: Sep 2016

Location: (Beautiful) Sequim,

WA

Cobra Make, Engine: Pacific Roadster, 347 cu.in. 5-speed

Posts: 2,007

|

|

Not Ranked

Not Ranked

First off Glen, Beautiful work as always  Floor mounted pedal's just fall readily to your feet (Alfa Style). I spent time with a friends Contemporary big block, (floor mounted pedal's) and what a joy to drive, heel & toe easy as pie. Mine unfortunately has top mounted pedal (Doable) but not near as much fun. But the Sideoiler is fired & running so in a little way makes up for the other shortcoming  Cheers Tom. |

08-23-2019, 07:03 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Thanks Tom. Yeah, floor mounted pedal's should fall readily to your feet, and when I’ve set them up to suit me, that'll be the case. I’m 6’ 1˝”, and with the distance from the pedals to the master cylinders’ mtg faces at around 5” to 6” (adjustable within limits), that chews up valuable real estate down in my footbox. I’ve seen out tougher challenges than that.....it'll work out OK with a bit of thought

Cheers,

Glen |

09-14-2019, 01:37 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

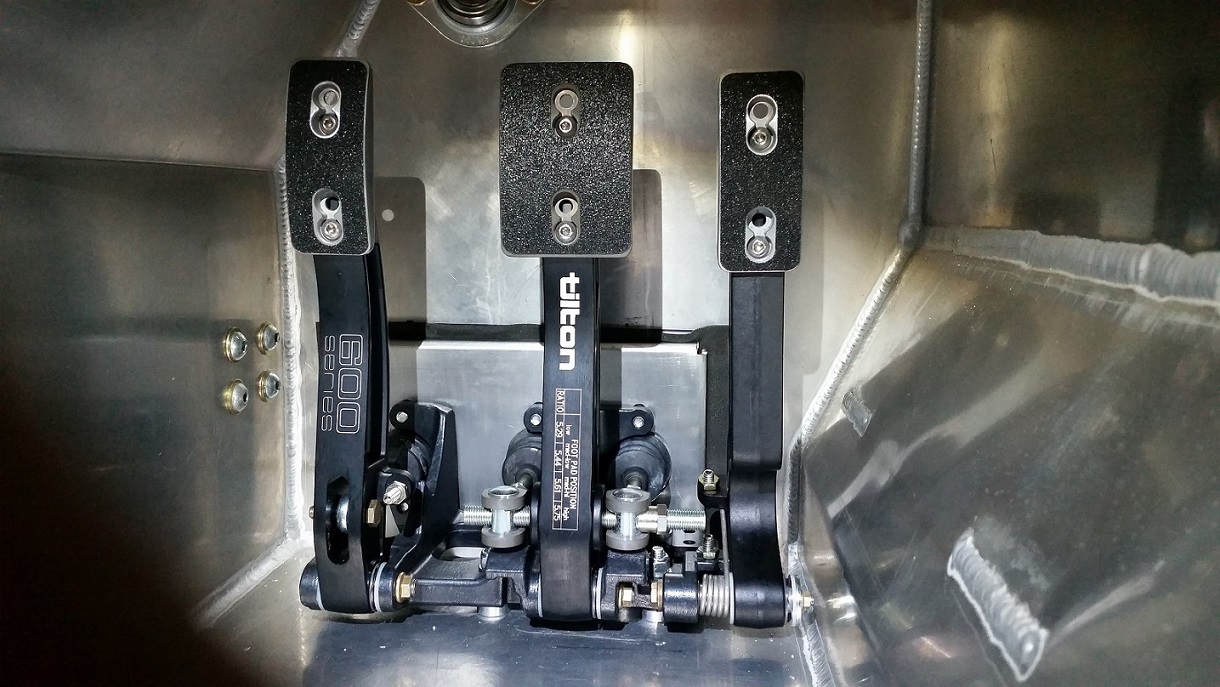

Pedalbox installation update....

Finally got the pedalbox the way I want it. Took quite a bit of fitting in a tight space but eventually got it right with a bit more leg (length) room

edit: thought I might need a left foot rest, but...nah, the setup is quite OK as-is

Cheers!

Glen

Last edited by xb-60; 09-14-2019 at 01:40 AM..

|

09-14-2019, 03:19 AM

|

|

CC Member

|

|

|

Join Date: Jun 2012

Location: Naracoorte,

SA

Cobra Make, Engine: CR Cobra 3169

Posts: 818

|

|

Not Ranked

Not Ranked

I had to shop for some skinny runners to fit in my CR. No workboots, that's for sure. JD  |

09-14-2019, 04:46 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

No, no room for work boots in a Cobra.

Hey Jaydee - I thought you went to Mildura....you're a Swan Hill local now?

Cheers!

Glen

|

09-14-2019, 06:56 AM

|

|

CC Member

|

|

|

Join Date: Jun 2012

Location: Naracoorte,

SA

Cobra Make, Engine: CR Cobra 3169

Posts: 818

|

|

Not Ranked

Not Ranked

No. I've moved to Naracoorte now. Hopefully a bit more interesting driving the Cobra around here. JD

|

09-15-2019, 07:40 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Relatives in Mt Gambier, so we head down there often. The south east of SA is a beautiful (and largely undiscovered) part of the country!

Cheers,

Glen

|

09-18-2019, 03:03 AM

|

|

CC Member

|

|

|

Join Date: Jun 2016

Location: Basel,

Bas

Cobra Make, Engine: Hawk 289 USRRC, 302 Ford

Posts: 42

|

|

Not Ranked

Not Ranked

The best Thing for such work is a Multitool (Bosch, Fein). This is the best all-in-one i ever bought

There is no need to drill holes in the corners etc. |

09-24-2019, 05:37 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

I was a little surprised that my jigsaw was able to do the job....as access was a real challenge, but it managed to do the job OK.

Corner holes can be an advantage , however. They eliminate stress concentrations in the corners, and these cars can certainly shake and vibrate a little.

Cheers!

Glen

Last edited by xb-60; 10-20-2019 at 04:49 PM..

|

10-21-2019, 03:58 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

At this stage, I can't upload pictures, which makes it just a little boring.

Here goes anyway....

Currently working on the firewall, and specifically, the wipers. There is nothing in my AP manual about the wipers installation, so I'm winging it somewhat.

I looked at an older build of the first AP 427 that was documented, a build by Cobra01, and I found some pictures there. Cobra01 mounted the wiper motor on the "inside" of the firewall on the left hand side of the car, but I can't do that because of my glovebox (remember, mine's a RHD car).

So, asked my learned and very experienced friend Tim for some pics of the wiper install. on his very nice ERA 289FIA. Surprise (not really) ....the wiper motor is mounted on the LHS footbox, as on the original 289 cars.

Looking at my firewall and footbox, that seems to be a sensible thing to do.

First hurdle - the holes for the wiper spindles on my car are mounted around 12mm (1/2") too far apart compared to the supplied tubing that carries the wiper drive spiral to the two spindles.

So, looking at my options to work around the problem. Need some 6mm ID / 8mm OD tubing.

Be nice if at some stage soon, a task that I start on could be yep, one step forward , and done!

Any ideas for the inability to load more pics? I'm wondering if it's that my $ contribution has run its time, and my picture upload allowance has shrunk. Comments?

I'm not necessarily keen to renew my subscription if I can't see any value in it, or any interest in the forum from its owner

Cheers!

Glen |

10-24-2019, 06:16 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

This is a trial post. I'm using image hosting as I can't upload progress pictures directly into CC Gallery.

....seems to work OK.

It's the windscreen wiper spindles (mis)alignment.

Cheers,

Glen |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:00 AM.

Links monetized by VigLink

|