Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

26Likes 26Likes

02-10-2014, 05:47 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Kevin - they must have done your pads a little different than mine. Mine are sewed to the straps all the way around and there isn't an open sleeve to tuck the ends into. But running them to the back is working OK.

FYI - started on the top yesterday - had it up to 62 deg in the garage. So far though it's the top -1 and Dan -0. After installing the two corner lift-a-dots at the corners behind the doors I found I'm about 3 inches from being able to fasten the second corner down. So I'm going to have to cut some out of the center of the top bows since the adjusters are screwed all the way in. I guess it makes sense they would be a litle long to start with. I'm just planning to do the lift-a-dot fasteners for now. And save the front windshield bow for a warmer day.

|

02-10-2014, 06:08 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: West Chester,

PA

Cobra Make, Engine: ERA #795 427 S/C completed Jan. '14 - '68 FE 427 side oiler

Posts: 1,052

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

Kevin - they must have done your pads a little different than mine. Mine are sewed to the straps all the way around and there isn't an open sleeve to tuck the ends into. But running them to the back is working OK.

|

Hmmm...Mine have a Velcro sleeve that wraps around the straps - not attached to the straps.

__________________

"Anyone who drives faster than you is a maniac and anyone who drives slower than you is an idiot" - George Carlin

|

02-10-2014, 06:32 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

That is a lot different than mine. Mine are sewn onto the staps. Did you order the pads at the same time as the straps - or later?

|

02-10-2014, 07:16 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: West Chester,

PA

Cobra Make, Engine: ERA #795 427 S/C completed Jan. '14 - '68 FE 427 side oiler

Posts: 1,052

|

|

Not Ranked

Not Ranked

I ordered them later. Sounds like you found a good solution to the dangling strap ends, though.

__________________

"Anyone who drives faster than you is a maniac and anyone who drives slower than you is an idiot" - George Carlin

|

02-16-2014, 04:29 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

I started fitting my top and decided to post some progress photos on the process. I may eventually regret starting this as there is no guarantee this is going to end in success. But, I would rather give it a try myself than risk turning the car over to an unknown stranger.

I started out covering the rear deck - this was just the start. I eventually put about 3 layers of tape down around and over the studs (puncturing the tape to fit over them) and then layed towels down also.

These are the tools I used to install the lift-a-dot tabs. I understand there is a special tool that can be purchased to simplify this process but I didn't have any issues with using what I had. An X-acto knife with long, pointed blades was critical.

I read the assembly manual and special owners supplements on the top installation over and over and started by installing the first to dot fasteners right behind the door - at the corners of the top. A hole punch was used to cut the hole in the top, then the bottom plate was layed over the holes as a template and taped in position and the X-acto knife used to cut slits for the tabs. After installing the top and bottom plates I used a punch and small tack hammer to preen the cabs tight. The dot on the tab goes towards the edge of the top.

I installed my top bows and stretched the top over it and snapped down one side and went to the other - but no matter how tightly I pulled, the closest I could get was about 4 inches to the stud. At this point the owners supplemental instructions say to cut some off of the bow where they connect at the center of the car. But, fortunately before I did this I gave Jack at ERA a call. Boy, am I glad I did. He passed on a lot of information that isn't in either the manual or supplemental information and in some cases what he advised was in contradiction to the manual.

First he informed me that the bows were changed to shorter length ones few years ago and gave me dimensions on the current ones. I ordered my top about 2-1/2 years ago and after measuring mine, I found they were the old, longer style. But he said don't worry about that right now - install all the snaps, one at a time from the doors to the center of the deck and leave the bows out for now. He said that after the first tab, install the next 3 or 4 a little above the centerline of the sewn panel around the base of the top. This was to avoid ending up with an exess of material when I got to the center of the rear deck.

I followed these instructions - although I may have gone a bit too far above the center of the panel and I think I went possibly one tab too far on this pattern before transtitioning towards the lower part of the panel. I got to I think the 5th tab and after installing on both sides, had a heck of an effort getting the top to stretch to where they could snap into position. I had the top laying flat on the deck and eventually realize that it needed to be leaning up towards the windshield in order to pull the center of the top back over the center studs. So I propped a board on top of the windshield and back to the rear deck to raise the top and I was again in business and got all the tabs in and secured OK. Most of the rear tabs install pretty close to the bottom of the top panel. If I can get them sanpped in place in a 60 deg garage I figure that out in the sun they should fit pretty easily.

On the first few tabs from behind the doors it's safe to install both opposing tabs at a time for the first 3 or so. I never did more than one new tab per side before re-fitting the top to check fit and mark where the next stud hit the top. As I got to where the big turn in the studs starts, I found it was best to install a tab on one side, re-fit the top and mark where to punch the hole for the opposing tab on the other side. I would re-fit the top and snap it down and pull the top into position on the other side and mark on tape stuck to the top of it, where the next stud was pressing on the top. After removing the top and before punching the next hole, I double checked the dimension between the stud for the tab I was fitting, and the previous stud and compared it to what I marked on the top. I constantly measured ahead to make sure I wasn't running out of top dimension as I neared the center and in fact found that I had to typically punch the next hole about 1/16 inch shorter than the measured distance between the studs. But with a bit of a tug and lifting under the top and pushing back on it, it fastened OK. I guess this 1/16 inch just compensated for slack in the loose top. Also, on the ERA there are a couple of studs where the dimensions between them are different from driver to passenger side. I suspect this mimics the originals - not sure. It's definately a measure 2 or 3 times before punching the hole process.

Then to protect my paint - I glued two strips of 1/8 inch thick felt all the way around the underside of the panel and over the lift-a-dot tabs, I punched holes in the felt for the studs to pass through.

That is all for now. The next step per Jack's instructions is to set the main bow and remove the back bow or tie it up out of the way. Install the top on all of the studs and then pull the forward part over the bow, stretching and lifting to get the bow in position at the sewn in crease in the top. This is going to have to wait for a warmer, sunny day to work on. Since I've confirmed I have the older, longer bows I know I'm going to have to shorten them, going slow in small cuts. He also advised that when first pulled to the windshield I should not be surprised to have large gaps behind the side curtains. There is a trick to deal with this that isn't in the manual.

Hopefully this doesn't all end in a disaster.

Last edited by DanEC; 02-16-2014 at 05:06 PM..

|

02-16-2014, 05:01 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Jack fitted my top, along with the longer bows, and it fits like an absolute glove, but it is a big-time *itch to put up. The instructions from the original 427 manual give the best steps for putting up a top, but mine is so tight, that it is a real chore to get it up. I finally stumbled on a shortcut that makes doing it much, much easier. I put the top on the car without the aluminum bows in the car, then I put one bow in the slot, then insert the second bow in to the first and slip it in to it's slot while I push the bows up in to place. If the top is cold, this is about the only way I can get it completely installed. After I found this method, the top now looks as good as any "modern" top. I've never read this tip anywhere, so I thought I'd pass it on to you -- maybe it will help you on the installation.

Last edited by patrickt; 10-26-2016 at 12:40 PM..

|

02-16-2014, 05:17 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Thanks Patrick - I'll remember that. Your top does look good and tight. Mine is real tight around the studs. There isn't any slack. I probably could have crowded the first stud a 1/8 inch or so further forward which might have helped a little. I anticipate it's best to install the finished top out in the sun at high noon.

|

02-16-2014, 05:30 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

The problem with the Cobra soft top design is that when you insert the holding pins in to the slot on the windshield frame, then fasten the side clasps but don't cinch them down, the next step is to get the two back lift-a-dots fastened. If the top is tight, and cold, then when you pull down on the top to try and get the two back lift-a-dots down, the pins pop out from the top of the windshield frame. I can't tell you what a PITA it is. What is really irritating is when you do manage to get the two back ones down, then you alternate around, and you're almost done, and you pull hard, and the damn pins up front pop out.

|

02-16-2014, 07:22 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

|

A. Why are your hood latches pointed forward with the hood closed?

B. I hate to say it but the beige looks like a stool sample under garage lights...

C. You're being very helpful to Dan. But it seems to defy logic that a top, needed for cold weather can only be erected when it's 60+ degrees. ?

__________________

Chas.

|

02-16-2014, 08:01 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

A. Why are your hood latches pointed forward with the hood closed?

B. I hate to say it but the beige looks like a stool sample under garage lights...

C. You're being very helpful to Dan. But it seems to defy logic that a top, needed for cold weather can only be erected when it's 60+ degrees. ?

|

A) I rarely latch the hood when it's in the garage. I tighten them before I take her out though as one of our local club members lost his hood on the highway by forgetting to latch.

B) Well, at least you hate saying it....

C) I could get it up in the cold, I think, but certainly not quickly. When AC was designing the original car I'm sure the top was the very last thing they thought of -- and it was barely more than an afterthought. There is zero chance I could get it up quickly with a thunder storm coming up on me (I keep a tarp in the trunk for that). To do a really nice job getting it up, so that it looks and fits perfectly, takes me about twenty minutes in the garage. Maybe a little longer if my thumbs start to go numb from the lift-a-dots.  |

02-16-2014, 08:37 PM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: West Chester,

PA

Cobra Make, Engine: ERA #795 427 S/C completed Jan. '14 - '68 FE 427 side oiler

Posts: 1,052

|

|

Not Ranked

Not Ranked

Dan,

I appreciate the details since I'll be attempting to fit my top when it warms up. Regarding your noting that the studs are not all equal distance, I spoke with Jack when I was thinking of buying a used top that was already fitted to an ERA. Jack indicated that the studs are not the same on any two cars and that a fitted top would not fit another car. I didn't quiz him on whether they use a template to install the studs but I followed his advice and passed on the used top.

Kevin

__________________

"Anyone who drives faster than you is a maniac and anyone who drives slower than you is an idiot" - George Carlin

|

02-16-2014, 10:41 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

A) .... one of our local club members lost his hood on the highway by forgetting to latch.

|

Is that possible? Very surprising.

chr |

02-17-2014, 04:58 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Patrick - keep the installation tips coming. So, if I understand correctly, you put the front bows in the windshield slots and loosely secure them. Then you start with the center lift-a-dots - and this is before installing the bows? If I understood the earlier comment you assemble the bows, insert one side in the ferrell, and the pushing up on the center of the bows (and top) swing the other end around and get it inserted in the other ferrell?

And I still kind of like the color - just haven't warmed up to the rollbars yet. One reason I'm tackling my own top is that I don't have a roll bar to work around which will simplify things a little. Not sure it would make doing it myself a no-go, but it would definately add another dimension. But, I guess from recent polls I'm way into the rollbar minority - somewhere around having a death wish and having little regard for my wife/passenger safety.

ERA Chase - the relationship between the weather needed to install the top and the weather when you need the top, hasn't exactly escaped me. I figure the top either goes on, on a warm Fall day and stays on until Spring - or it will probably stay in the trunk while the car hibernates in the garage through the winter. Not sure yet - may vary from year to year.

Kevin - I would have figured ERA has a template they use to drill the stud holes. Surely they do, but it may have been revised a few times slightly over the years. I didn't record the stud to stud measurements but I did find two that had a 1/2 inch difference from side to side - and I assume there may be two more with a 1/2 inch difference the other way to get back on center towards the back??? As I mentioned there has been some change in the bows over the years according to Jack. My top is made by Robbins and I wonder if the pattern on it (or even the supplier) may have slightly changed over the years too? After doing the lift-a-dot tabs, and seeing how carefully they have to be installed, I would have to agree that using a top fitted to another car would be a real high risk.

Last edited by DanEC; 02-17-2014 at 06:17 AM..

Reason: fixed my own editing

|

02-17-2014, 06:32 AM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,021

|

|

Not Ranked

Not Ranked

Excuse me if this has been mentioned before...

The trick to installing the top is to screw the bow height adjusters all the way in first, then fasten the back Lift-a-Dots, then the front bows. Once everything is cinched down, adjust the height adjusters so that the top is tight.

|

02-17-2014, 07:06 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Top Steps

Top Steps

My bows are screwed all the way down, and stay there, always. Maybe that's why ERA went to shorter bows.... Anyway, Dan -- here are the steps from the original 427 manual, paraphrased by me, with my annotations and insights. On a hot summer day, I do not have to use my "bows go in last" method. On a cold day, I do. Regardless, for me, putting the bows in last is now my preferred installation method. Everything comes out smoother, more even, and looking more fitted.

1) Carefully push the sun visors down using your fingers on the metal hinges only. If you just pull on the plastic visor itself it’s likely to break. Join together the two aluminum bar braces and insert them in to the sockets on each side of the cockpit. Unscrew them down so they are as low as possible. The folding piece goes towards the rear of the car, but leave it straight up and down for now.

2) Lay the top across the aluminum bar braces, hold the soft top front metal frames near the center and then insert the center holding pins, that are on the metal frames, in to the slot that is in the middle of the top of the windshield. Do one side at a time and pull the frames towards the sides of the car to engage the holding pins in to the channel that runs along the top of the windshield. Make sure the frames are positioned down along the top of the windshield so that they are completely fitted over the windshield’s frame. Make especially sure they are fitted over the screws that attach the sun visor mounts to the windshield frame. Pay attention to the middle space between the two bows. Make sure the top fabric is folded under this spot and that it looks neat. Engage the outside windshield clamps, but don’t cinch them down yet.

3) Push down the two lift-a-dots at the rear of the top (note that there are four lift-a-dot spikes on the back of the car between my two roll bars, but the soft top only fastens to the inside two, the outer two are not used). Alternate from one side of the car to the other as you fasten down the lift-a-dots; move the felt lined flap on the bottom interior of the top upwards from the inside of the car so it does not interfere with the lift-a-dots. Leave the last two lift-a-dots on each side (towards each door) unfastened for now. Cinch down the outside windshield clamps – the clamps should cinch down easily, if it requires a monumental effort then the top frames are not positioned correctly on the windshield.

4) Inside the car, push the folding hoop backward to tighten up the top, then button the tabs that go around that brace. Push down the remaining four lift-a-dots that are on each side of the top and carefully raise the sun visors by touching the metal hinges only. Note that the knurled knobs on the ends of the aluminum bar braces will now raise everything for a tighter fit, if needed.

My newer method is exactly the same as above, except you do not put the bows in until the very last step, and you do cinch down the clamps, and leave them that way, as you fasten down the lift-a-dots. You then put the bows in, one at a time, and kind of "wiggle" the second bow in as you do it.

|

02-17-2014, 07:08 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by strictlypersonl

Excuse me if this has been mentioned before...

The trick to installing the top is to screw the bow height adjusters all the way in first, then fasten the back Lift-a-Dots, then the front bows. Once everything is cinched down, adjust the height adjusters so that the top is tight.

|

It hasn't been mentioned here yet Bob. I have thought about if I should fit my top with the adjusters screwed out a little so that I could generate some slack later. Right now I have them screwed all the way in and they are way too long and will have to be shortened in the middle. I should have asked Jack that question. I will probbably be calling him again. |

02-17-2014, 07:19 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

3) Push down the two lift-a-dots at the rear of the top (note that there are four lift-a-dot spikes on the back of the car between my two roll bars, but the soft top only fastens to the inside two, the outer two are not used).

|

Read the owners manual - well that would be logical. Mickmate is probably wondering why I bought that reproduction in the first place.

If I understand what you are saying, because of your two rollbars, one rear LAD tab on each side of your top is not there because of the modification/patch to fit around the rollbar(s).

Thanks |

02-17-2014, 08:04 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

If I understand what you are saying, because of your two rollbars, one rear LAD tab on each side of your top is not there because of the modification/patch to fit around the roll bar(s).

|

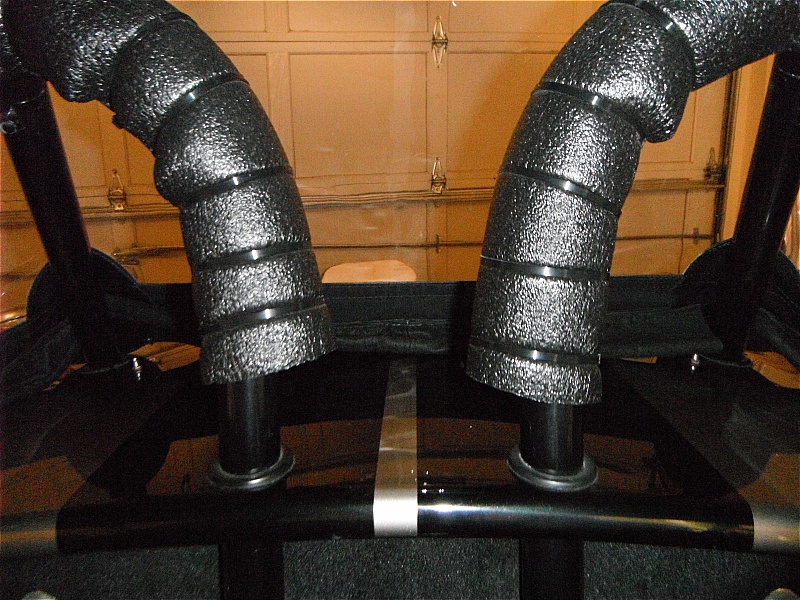

Here you go. Chas loves it when I post pics -- it brightens his day.

Last edited by patrickt; 10-26-2016 at 12:41 PM..

|

02-17-2014, 10:26 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

There goes my last good eye...................................

__________________

Chas.

|

02-17-2014, 10:54 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Dan,

Just sharing some thoughts as I know you're far along in this project and ain't goin' back.

Early on with my car, I loved the look of the up top-and still do. Makes it a real little English roadster. But as I advanced my project with planned upgrades, I kept putting the top at the back of the list.

Roll bar, oil cooler, big brakes, Sideoiler, bulletproof rear, ad infinitum. The function of everything was of greater importance to me. And I found, I was frequently in and out of the car, tweeking or adjusting something.

On the longer drives, I just naturally took to enjoying the accessibility and open air freedom. I began to think I would get a top and install it just for parking shade on the hottest days. I knew my driving style would cost me the top if I went to the expense and trouble. 100 MPH+ everytime in the car was my drug of choice. And I think the top is gone or hurting things over about 70.

Now you are a different owner and I appreciate that. But with the effort involved to use both the top and the car, I think you will restrict your driving pleasure. Compounding that, are the side curtains which make ingress and egress a delicate process when they are on board.

If you plan to just putter to the shopping center on Friday nights with the guys and soak up the ooh's and ahh's with the full display, so be it.

If touring in anything colder than 50 degrees is for you, you may find it's not as pleasant as you think enclosed like that.

Early on with the 428, I too drove in Feb with temps in the 30's and 40's-open mind you-and that was all I could stand for a 1/2 hour at 70 MPH.

I later learned more and found that I shouldn't have been the limiting factor; the fact that the temp gauges never came off their pegs should have been.

When I did the SO, I knew that temps should always be up and no amount of blocking BOTH rads made a difference.

So in the NE, I just learned to use the car in a different way to get maximum longevity out of my new bullet-which is STILL going strong.

You're a meticulous craftsman and that is your pleasure and curse. It makes you do complex projects like this for satisfaction. My car taught me that feeling well so I understand.

Lecture over / resume normal toiling...

__________________

Chas.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:25 AM.

Links monetized by VigLink

|