Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

10-19-2010, 04:09 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Meriden,

CT

Cobra Make, Engine: ERA 427 SC s/n 718, 428 FE

Posts: 1,731

|

|

Not Ranked

Not Ranked

I had to cut my hardened fork to clear the tunnel flange but could not get the cutoff tool in there, so I used a Sawsall. Worked like a charm and didn't have to take anything apart. After you get your required clearance, mix up some epoxy and apply it to the worn area.

__________________

"Paint It Black, Black As Night"

|

10-19-2010, 05:29 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2001

Location: Santa Barbara, Ca.,

ca

Cobra Make, Engine: R.U.C.C. with a 427FE, toploader

Posts: 1,435

|

|

Not Ranked

Not Ranked

Just put in a small block and you won't have that problem!

__________________

Mike Z

Nothing sucks more than that moment during an argument when you realize you’re wrong.

|

10-19-2010, 08:45 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 2003

Cobra Make, Engine: ERA #698 428 Toploader

Posts: 292

|

|

Not Ranked

Not Ranked

Maybe if someone holds the clutch pedal to the floor the fork will move enough to get a cutoff wheel or grinder in there. Then just leave the master alone if its not leaking.

|

10-20-2010, 08:31 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

Maybe you could remove the slave cylinder rod to allow the spring to pull the fork as far forward as possible. Then if it moves forward enough you could get in there with a small cable drive Dremel attachment & grind the end of the fork the required amount.

With the fork in place you would be able to move it by hand back into position & check for clearance.

Craig

|

10-20-2010, 09:33 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

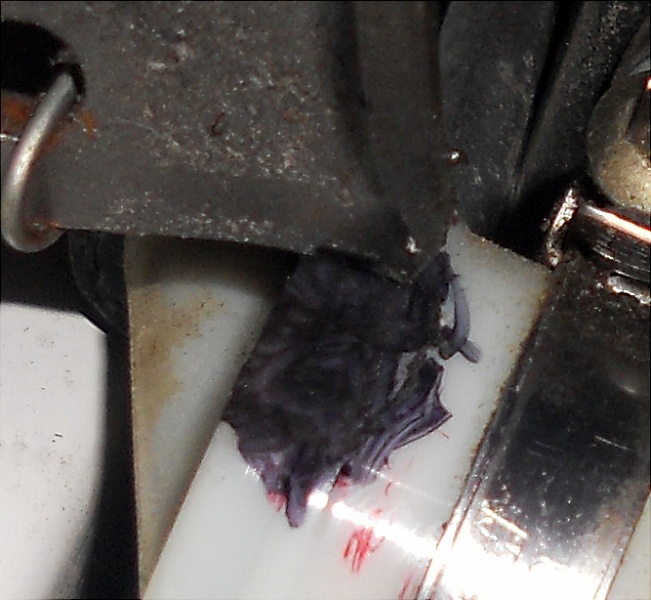

Here's a better shot of the rub. The previous photo was a little deceptive on the angles. It will be impossible to grind/cut the end of the fork without removing the master cylinder first, and it doesn't matter whether the fork is forward or back in that regard. What I ended up doing for now, while I wait for a new plastic inlet from Tilton, is to mark the rub area with a black magic marker to see if it is still rubbing or not. I'll try and get the car out for run when the weather improves.

Last edited by patrickt; 10-26-2016 at 01:28 PM..

|

10-20-2010, 10:06 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

The plastic looks very, very think in that top picture.

It's probably worse at a low rpm than at a higher rpm or higher load, because of the way the engine moves under load.

|

10-20-2010, 10:07 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

As you get older and shrink, maybe you when you're 6'2" or less, you can move the master cylinder back where it should be.

Why not make this a Winter project for yourself and R&R the whole thing? |

10-20-2010, 10:18 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Boston,

MA

Cobra Make, Engine:

Posts: 361

|

|

Not Ranked

Not Ranked

is the additional roll bar causing this rub?....sorry...maybe i should just say yes...i'd replace it!...it can't more then a $20.00 piece of plastic that would cause nothing but grief when it brakes

Last edited by kgs365; 10-20-2010 at 10:34 AM..

|

10-20-2010, 10:42 AM

|

|

CC Member

|

|

|

Join Date: Jan 2009

Location: Dallas,

TX

Cobra Make, Engine: ERA #776, 445 FE

Posts: 55

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

I think that's probably exactly what I'm going to do. I only need to cut a piece of the fork about the size of a thumbnail.

|

I did the same thing on mine with a cutoff wheel. It was a bit of a pain getting the correct angle without cutting something I didn't want cut, but it worked out fine without taking anything apart. |

10-20-2010, 11:01 AM

|

|

Full Blown Member

|

|

|

Join Date: Sep 2008

Cobra Make, Engine: KMP 427 S/C, Twin Paxton 511 FE

Posts: 2,594

|

|

Not Ranked

Not Ranked

Way better picture. That nylon is down to the quick. You know what you need to do. Remove the entire drivetrain.

But it's creeping over time, don't you think? It's not like the fork took all that off at one time. Plus, the nut doesn't seem centered on the fork anymore.

rodneym |

10-20-2010, 11:05 AM

|

|

CC Member

|

|

|

Join Date: Jan 2005

Location: Hillsboro,

OR

Cobra Make, Engine: Scratch built CSX style frame, Carbon fiber body, 393 Stroker, T-bird IRS, T5

Posts: 1,623

|

|

Not Ranked

Not Ranked

Patrick,

I have a Wilwood unit which I think is the same one as the Tiltons use. You don't have much plastic left there as you probably already know.

If you need one, I have a couple spares. I could drop one in the mail for you if you need it quickly.

Bob

|

10-20-2010, 11:06 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Three Peaks

I could drop one in the mail for you if you need it quickly.

|

Thanks Bob, but Pegasus has already shipped one out to me. I know I have to take everything apart and replace it. But...

Quote:

Originally Posted by cdnus

... you could get in there with a small cable drive Dremel attachment & grind the end of the fork the required amount.

|

Craig, I stuck "can my Dremel cut through case hardened steel" and this little blog popped up with photos. http://blog.daveduncan.ca/?p=2274 Having a relatively small, easily controlled tool like my Dremel could make this job a heckuva lot easier than I first thought.... |

10-20-2010, 11:16 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Edinburg,

TX

Cobra Make, Engine: Everett Morrison, All aluminum small block ford.

Posts: 436

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by rodneym

Way better picture. That nylon is down to the quick. You know what you need to do. Remove the entire drivetrain.

But it's creeping over time, don't you think? It's not like the fork took all that off at one time. Plus, the nut doesn't seem centered on the fork anymore.

rodneym |

You need to pay real close attention to this post...he's right that did not happen in one swipe. Something is moving side to side down there that is probably going to get worse as time goes on.

Good catch Rod.

__________________

" If it wont break em loose in 3rd gear, it aint enough power "

|

10-20-2010, 11:33 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Z-linkCobra

You need to pay real close attention to this post...he's right that did not happen in one swipe. Something is moving side to side down there that is probably going to get worse as time goes on.

Good catch Rod.

|

I went back and checked my archives. It's been doing this for years. I just caught it though on my inspection this week. Here's a shot from when the car was literally brand new. What also irritates me is that I bet I've looked directly at that wear a couple of dozen times and still didn't see it.

Last edited by patrickt; 10-26-2016 at 01:28 PM..

|

10-20-2010, 11:35 AM

|

|

Full Blown Member

|

|

|

Join Date: Sep 2008

Cobra Make, Engine: KMP 427 S/C, Twin Paxton 511 FE

Posts: 2,594

|

|

Not Ranked

Not Ranked

Good catch Rod.[/quote]

FINALLY!!!

My head hurts. |

10-20-2010, 11:42 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Craig, I stuck "can my Dremel cut through case hardened steel" and this little blog popped up with photos. Having a relatively small, easily controlled tool like my Dremel could make this job a heckuva lot easier than I first thought....

|

I use a cut-off wheel in my rotozip all the time. 30,000 rpm = knife through butter.

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

10-20-2010, 11:44 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

I use a cut-off wheel in my rotozip all the time. 30,000 rpm = knife through butter.

|

It would never have occurred to me that my Dremel would cut through my clutch fork. Makes me appreciate the fact that Jamo hasn't kicked me off this forum....  |

10-20-2010, 12:10 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Personally, I would sell the car. Too many issues.

|

10-20-2010, 12:11 PM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

Those little buggers will cut almost anything steel, but are VERY fragile.

They will explode in a heartbeat if jammed up at all, be sure to wear protection  (for your eyes )

If you have access problems with the dremel, have a look at the cable drive attachment. It will get in much tighter places.

Craig |

10-20-2010, 12:40 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodKnock

Personally, I would sell the car. Too many issues.

|

I'm shocked you're not praising me for having the eagle eye to have spotted this before it left me stranded.

Quote:

Originally Posted by cdnus

Those little buggers will cut almost anything steel, but are VERY fragile.

They will explode in a heartbeat if jammed up at all, be sure to wear protection  (for your eyes )

If you have access problems with the dremel, have a look at the cable drive attachment. It will get in much tighter places.

Craig |

Got it. I think I'll have plenty of room once I remove the master cylinder, and I think I would probably do that anyway to get that plastic inlet on the top of it. Uhhh, I guess I should take pics?  EDIT

EDIT -- Cable Drive, hmmm... Man, I love an excuse to buy a new tool.

Last edited by patrickt; 10-20-2010 at 12:45 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:31 PM.

Links monetized by VigLink

|