Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

04-13-2012, 03:18 PM

|

|

CC Member

|

|

|

Join Date: Apr 2000

Location: Austin,

TX

Cobra Make, Engine: ERA 427 SC - #463 - 427 SOHC

Posts: 269

|

|

Not Ranked

Not Ranked

Clutch problem??

Clutch problem??

Replaced the clutch master cylinder on my cobra with a Tilton 7/8" master cylinder.

Everything has been bled.........I have a good pedal.........only thing is it is

REAAAALLLL hard and disengages close to the floor  .

Never been that hard before..............anyone have any ideas??

Did I do something wrong.............did I get the wrong Tilton cylinder.......can I lighten up the pedal???

All thoughts are appreciated.

__________________

Dee Walters/Cammer

Austin Cobra Club

2008 TCC President

|

04-13-2012, 03:20 PM

|

|

CC Member

|

|

|

Join Date: Feb 2009

Location: Greer,

SC

Cobra Make, Engine: ERA #778 427SC Keith Craft FE 428 stroker

Posts: 243

|

|

Neutral

Neutral

What cylinder did you have before? What clutch, pressure plate do you have? All that can make a difference.

Did you change anything else?

Hal

|

04-13-2012, 03:46 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

If it's a Tilton 74-750, or 74-875 it's the right one (I have the 7/8" one). Try backing off the adjustment on the threaded rod so that the clutch fork is not even being touched. Then lightly push the pedal to see if all the resistance is now gone. Obviously that won't fix the problem, but it will tell you if there is some sort of clog in the hydraulics.

Last edited by patrickt; 04-16-2012 at 10:25 AM..

Reason: Clarified Tilton Sizes

|

04-13-2012, 09:05 PM

|

|

CC Member

|

|

|

Join Date: Apr 2000

Location: Austin,

TX

Cobra Make, Engine: ERA 427 SC - #463 - 427 SOHC

Posts: 269

|

|

Not Ranked

Not Ranked

Yes......that's the Tilton that I replaced the old BMW unit with.

All the hoses are new........shouldn't be any clogs.

What's interesting is that after driving the car for a while the distance from the floor that the clutch disengages moves further from the floor.

It is still just as hard.......but I don't have to push it as far to disengage the clutch.

Could there possibly be some air in the lines that expands as it gets hot and moves the pedal up from the floor??

__________________

Dee Walters/Cammer

Austin Cobra Club

2008 TCC President

|

04-13-2012, 09:36 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 2003

Location: Parker County,

Tx

Cobra Make, Engine: LoneStar LS427 , 427 Windsor

Posts: 381

|

|

Not Ranked

Not Ranked

It sounds as if there are two things going on.

The old cylinder was likely a smaller diameter than 3/4" and thereby had more leverage. If you disassemble the old one and find that it is 3/4" or larger, then there must be some kind of mechanical binding with the new one. Pedal effort should be purely a function of cylinder sizes.

The "moving engagement point" is likely due to air in the system. A bubble in the master cylinder itself is tough to get rid of, especially if the master is near level. I would suggest raising the front of the car as high as possible and bleeding the master cylinder at the bleeder near the line connection, then lower the car and bleed the entire system again through the slave cylinder. Make sure the line from the remote reservior is not full of air and re-introducing it under certain conditions.

Keep us posted on what you find.

__________________

Jim

------------

A Gnat! Quick, get a sledgehammer!

|

04-14-2012, 06:25 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Cammer

Could there possibly be some air in the lines that expands as it gets hot and moves the pedal up from the floor??

|

The only real trick to bleeding the ERA clutch is to make sure you have the nose of the car nice and high. What I do is put plastic surgical tubing on the bleed screw of the slave and have the tubing run in to a plastic bottle of DOT-3 or 4 fluid. I think that bleeder screw on the slave is like 3mm. When you crack it and start pumping you should have a really easy pedal push and a nice strong squirt in to the bottle. If you don't, then that tells you the problem is with the hydraulics and is not because of a clutch/pressure-plate/fork geometry issue. |

04-14-2012, 07:22 AM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,011

|

|

Not Ranked

Not Ranked

The original BMW master is 19mm. Almost exactly 3/4". Changing to a 7/8" Tilton will increase pedal release effort by 36%.

I tend to think that the release difference is more a factor of mechanical distances rather than air in the system. Air compression won't be changed significantly with temperature.

|

04-14-2012, 08:43 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

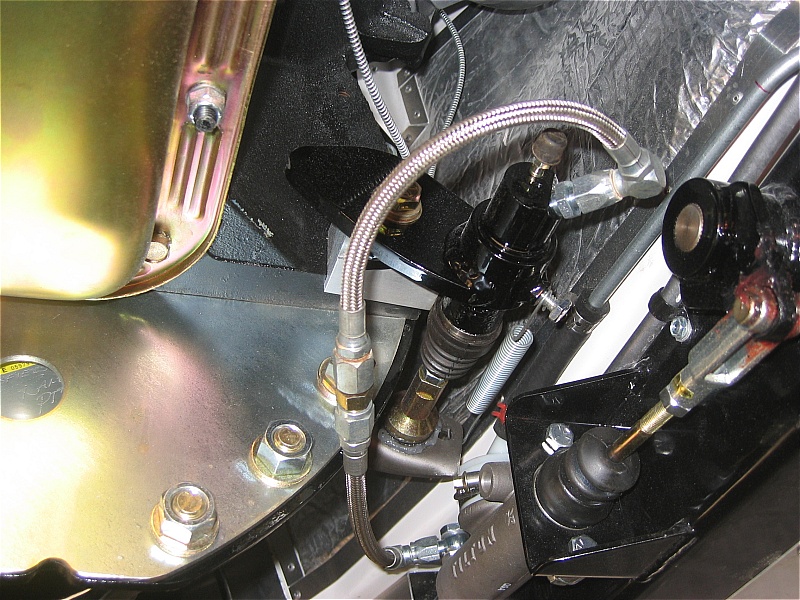

A Helpful Pic...

A Helpful Pic...

Here's a pic, just in case you need it. Note that this shot was taken before I shaved my fork, as per this thread: So, Should I Replace This Part or Not? So, be mindful of your clutch fork clearance on the little plastic reservoir cap.

Last edited by patrickt; 10-28-2016 at 09:05 AM..

|

04-16-2012, 07:50 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Central,

NC

Cobra Make, Engine: ERA #775

Posts: 324

|

|

Not Ranked

Not Ranked

Check the number on the side of the master cylinder that you bought...the 74-750 is a 3/4" cylinder size whereas the 74-875 is the 7/8" cylinder.

Ray

|

04-16-2012, 10:24 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RAO-3

Check the number on the side of the master cylinder that you bought...the 74-750 is a 3/4" cylinder size whereas the 74-875 is the 7/8" cylinder.

Ray

|

You can put either a 3/4" or a 7/8" or a 1" bore Tilton cylinder in place of the the BMW clutch master cylinder. According to the manual, they all just bolt right in and all that is needed is a new hose. You can almost see from my pic that mine is the 7/8". |

05-28-2012, 07:49 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Cobra Make, Engine: 427FE ERA 1966

Posts: 14

|

|

Not Ranked

Not Ranked

PatrickT,

I am considering replacing the BMW MS on my ERA which is a later car, post #750. If I replace with the T 74-750 will the plastic resevoir clear the fork, or will I need to shave it? Also will,I need to shave the after boss on the MS also?

Thanks......and great information in you posts, very helpful.

|

05-28-2012, 08:07 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 66427stow

PatrickT,

I am considering replacing the BMW MS on my ERA which is a later car, post #750. If I replace with the T 74-750 will the plastic resevoir clear the fork, or will I need to shave it? Also will,I need to shave the after boss on the MS also?

Thanks......and great information in you posts, very helpful.

|

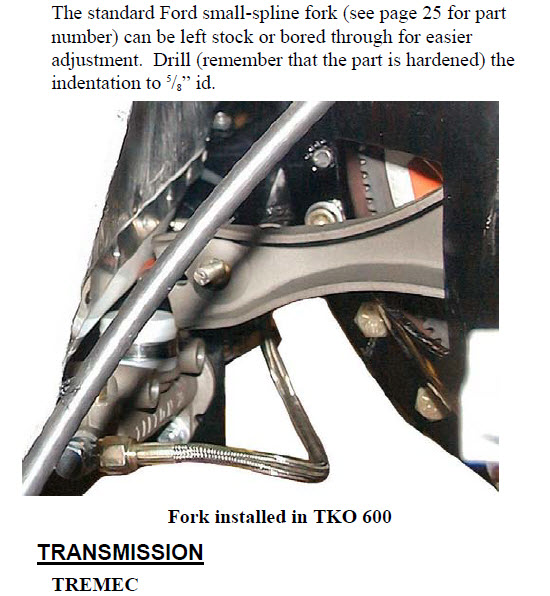

The tolerance between the fork and reservoir is tight... really tight. Of course it rubbed on mine, but not enough to rub through; but damn, damn close. If you look on page 34 of the most current ERA Assembly/Service Manual you'll see the picture that I've ripped below. You know I love ERA to pieces, but man that's a tight tolerance. So..... I'm going to say there's a strong chance you'll have to buzz the fork, as per my thread on it. It's not nearly as bad a job as you might think, though... and you might get lucky and have enough room that you don't even need to do it. I do believe the Tilton requires a little grinding to fit the stock bracket, but, again, that's no big deal. Here's the rip from page 34. Tight.

Last edited by patrickt; 10-28-2016 at 09:06 AM..

|

05-29-2012, 09:06 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Cobra Make, Engine: 427FE ERA 1966

Posts: 14

|

|

Not Ranked

Not Ranked

PatrickT,

thanks again, solid guidance and wow your right that tolerance is extremely tight. I'll do a little grinding to play it safe....between metal and plastic we know who wins  . Funny my chassis number is 760 and it is out fitted with the BMW MC. Most of the ERA documentation I have seen references the Tilton MC as spec for chassis since #700 on the FEs. My issue is the filler line to the Girling has popped out of the rubber fitting on the BMW MC twice and I am loosing confidence in that set up.....

appreciate all the help. |

05-30-2012, 10:04 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 66427stow

PatrickT,

thanks again, solid guidance and wow your right that tolerance is extremely tight. I'll do a little grinding to play it safe....between metal and plastic we know who wins  . Funny my chassis number is 760 and it is out fitted with the BMW MC. Most of the ERA documentation I have seen references the Tilton MC as spec for chassis since #700 on the FEs. My issue is the filler line to the Girling has popped out of the rubber fitting on the BMW MC twice and I am loosing confidence in that set up.....

appreciate all the help. |

The only reason I can think of for using the BMW master cylinder is the clearance issue -- or maybe it's a little lighter on the foot. I think the Tiltons are just a tight fit in that tunnel area. Plus, it's not like your drivetrain stays perfectly still; it torques over like pretty much everything else in the car. But I remember somebody in the "ERA family" recently telling me that ERA had a new clutch fork design. I have not seen it with my own two eyes, so I don't even know it to be true, but maybe they now grind a little bit away from where the fork would rub the reservoir when the fork is just sitting there in the shop? Removing the end of the fork with the fork still in the bellhousing was not a huge deal. It's just basic, typical, Cobra PITA work because there is so damn little room to do anything and the cutting wheel does make a good bit of sparks and you don't want it to kick back in to something, like your nose. Eye protection, face protection, etc. goes without saying. I put a welding blanket back behind it as well. Now if you were doing that in your workshop with the fork out of the car it would be pretty much nothing -- you could relax and watch a SpongeBob cartoon while you worked on it.  Here's a picture of Godfather's fork that he posted maybe two or three years ago (I happened to remember it last evening). I was able to find it in the Gallery by doing a search with his username and it honestly looks like his does not touch the reservoir. So, I think when it comes to the Tilton MC in the ERA cars it's kind of a "roll the dice and see if you get lucky" type of thing.

|

05-30-2012, 11:34 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

If the solution is to move the end of the fork to the rear a little, past the hydraulic cylinder interference point - to some extent that can be done (with the transmission out) by altering the pivot adjustment inside the bellhousing. Have to remember to do that prior to bolting up the transmission however. Not much help once it's all installed.

|

05-30-2012, 12:41 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,011

|

|

Not Ranked

Not Ranked

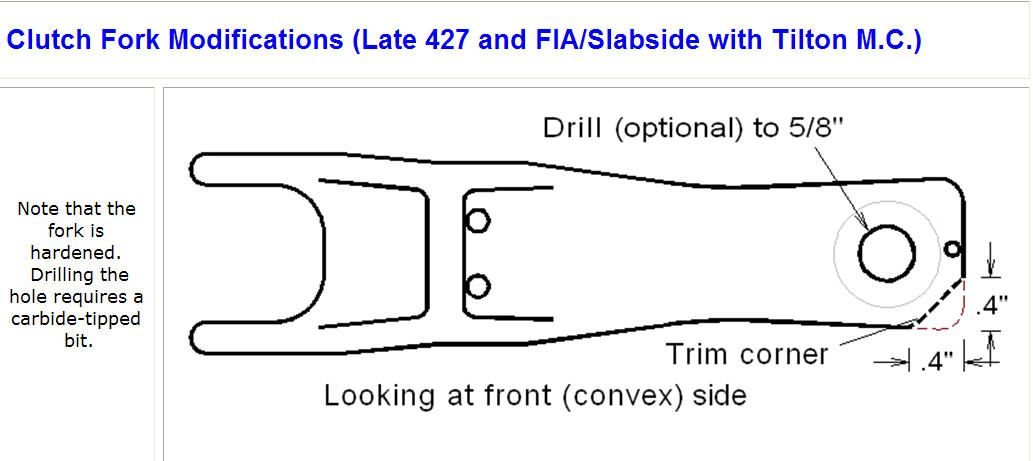

Somehow the fork mods didn't get into the later manuals. (Couldn't have been my fault.)  I'm uploading them to the site now. In addition, there's a web page with the information:

Fork Modifications |

05-30-2012, 12:47 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by strictlypersonl

Somehow the fork mods didn't get into the later manuals. (Couldn't have been my fault.)  I'm uploading them to the site now. In addition, there's a web page with the information:

Fork Modifications |

Well that is one damn fine fork mod.

Last edited by patrickt; 10-28-2016 at 09:08 AM..

|

05-30-2012, 09:40 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Lake Havasu City, AZ,

AZ

Cobra Make, Engine: Arps/Burroughs/Hurricane/428FE

Posts: 1,346

|

|

Not Ranked

Not Ranked

Maybe I don't understand the problem here but, " going back to basics" is the place where I would start.

. Make sure nothing is rubbing that would prevent the clutch arm from moving freely.

. Bleed the system of any air, looks like it should be easy due to the short amount of

line between the master cylinder and the slave cylinder.

. Push the rod in the slave cylinder back into the slave cylinder with the bleed valve

open so the piston retracts into the back of the slave cylinder.

. Close the bleed valve. Now the piston will have the maximum amount of travel when

the brake is operated.

. Adjust the push rod so the clutch arm pushes the throwout to contact the clutch forks,

leave a slight amount of clearance..not much.

. Now check to see if the clutch operates properly.

This method has always worked well for me, good luck.

Bill

Last edited by Bill Bess; 06-02-2012 at 01:38 AM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:32 AM.

Links monetized by VigLink

|