Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

12Likes 12Likes

02-11-2014, 06:28 PM

|

|

CC Member

|

|

|

Join Date: Feb 2000

Location: Enfield, CT,

Posts: 542

|

|

Not Ranked

Not Ranked

Re your brake caliper installation: Way back when, I swapped out the Jag rear for the ERA outboard setup in my old (#50) 427 car. Being the "creative" engineer, I adapted AP calipers, solid mount, all around. Racers used them, and so would I. First lap at the Glen, something weird was happening. The pedal seemed to fall off on first hit. Must be a little air, I'll re-bleed it later. Really starting to get into it in the toe of the boot and flat down to the heel....pedal is on the floor and I'm pumping like crazy and it comes back. I learned to left foot tap the pedal just before I braked. All this story telling is leading back to the point here. If you are running the Jag ball bearing setup in the hub, your gonna get rotor kickback and a crappy pedal. Choice here is floating calipers or taper bearings with adjustable preset. My cheap fix was an inline valve to hold 5psi in the caliper and hope the pistons floated back and forth. Sold the car that fall and never really got the chance to sort it out. Damned 'ole Bob knew what he was doing, he spec'd floating calipers right from the start.

edit: Just REALLY looked at the hub pic's and see a taper bearing race. So.....never mind.

Last edited by a427sc; 02-11-2014 at 07:27 PM..

Reason: jumpd the gun

|

02-11-2014, 10:38 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by a427sc

Re your brake caliper installation: Way back when, I swapped out the Jag rear for the ERA outboard setup in my old (#50) 427 car. Being the "creative" engineer, I adapted AP calipers, solid mount, all around. Racers used them, and so would I. First lap at the Glen, something weird was happening. The pedal seemed to fall off on first hit. Must be a little air, I'll re-bleed it later. Really starting to get into it in the toe of the boot and flat down to the heel....pedal is on the floor and I'm pumping like crazy and it comes back. I learned to left foot tap the pedal just before I braked. All this story telling is leading back to the point here. If you are running the Jag ball bearing setup in the hub, your gonna get rotor kickback and a crappy pedal. Choice here is floating calipers or taper bearings with adjustable preset. My cheap fix was an inline valve to hold 5psi in the caliper and hope the pistons floated back and forth. Sold the car that fall and never really got the chance to sort it out. Damned 'ole Bob knew what he was doing, he spec'd floating calipers right from the start.

edit: Just REALLY looked at the hub pic's and see a taper bearing race. So.....never mind.

|

Way cool - big thanks.

We are taking some risk engineering wise. The adaptation of the rear brakes is a concern. Will be disappointing if we cannot get it sorted.

Nearly everyday we speculate on how fast it will run. There is an older gent that runs a Lotus (Elise?) Spyder at PIR. This is a very light, full aero, track car with a blown Toyota 4 - 240 hp. He runs 1.24. Last time out I was running 1.33 in my Mustang. I will be very happy if we can run with the Lotus. I will be very disappointed if we cannot stomp the Mustang.

We swapped Wilwoods all around into the Mustang last summer and it dropped lap times like noting else. I love multi piston calipers which is why I decided to go for it. The risk is that the Mustang front and rear kits were developed by very capable companies who develop and race what they build. I knew what I was purchasing.

We are adapting on a bit of a prayer. If it works it will be beautiful. If not I will have wasted two very nice ERA uprights.

On your setup - were the AP brakes lug or radial mounted?

chr

|

02-12-2014, 03:07 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

|

02-12-2014, 04:34 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,528

|

|

Not Ranked

Not Ranked

Lots of room in that engine bay. Thats disgusting actually.  |

02-12-2014, 05:05 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

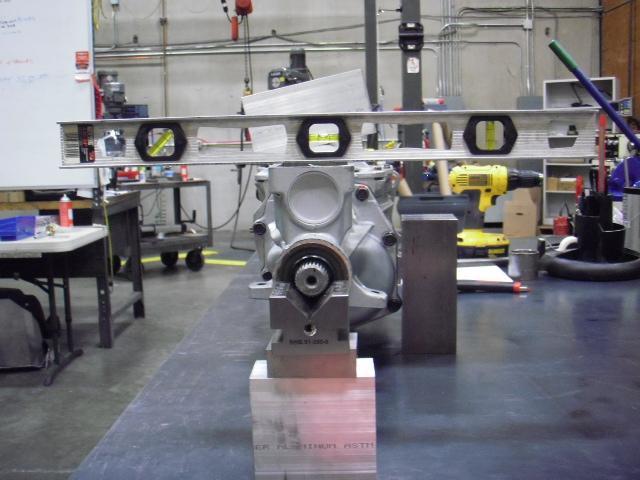

Check out this foo-pa

Look at the trans mounting foot. No fill on the left side (?)- sand it and ship it.

chr |

02-12-2014, 05:51 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Gonna use sold motor and trans mounts?

__________________

Chas.

|

02-12-2014, 06:18 PM

|

|

CC Member

|

|

|

Join Date: Feb 2000

Location: Enfield, CT,

Posts: 542

|

|

Not Ranked

Not Ranked

Small Blocks.....so much hp, so little weight, so little size. It isn't any fun if you can change out header gaskets in less than 4 hours. The AP's were lug mounts, adapted to the mounts for the Corvette's. What is that trans? Looks like a very short tailshaft. Oil pan is just about right height. If you put a belly pan in there (part of the aero package to manage air/air out), it will also take most all the damage going agricultural (short of a pointy rock). Besides, the oil pan will push the junk away from the bell housing. I ran a windshield very similar to yours. At final trim, it put the air stream about an inch above my faceshield and the helmet was very solid.

Really like what your doing, I'm sure you'll kick that Lotus's butt. |

02-12-2014, 10:18 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

Gonna use sold motor and trans mounts?

|

They are copies of 289 mounts, but lock up. There was a thread here some time a go about motor mounts developed for FSB hot rods. They are designed to allow vibration at idle, but have steel in them that lock them up if too much rotation is encountered. I did not keep the boxes. I would have to research to tell you where I got them. I am hoping you know of the ones I am speaking of. I am using poly for the trans mount. |

02-12-2014, 10:37 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

a427cs - The trans is a t5. We had to fabricate a mount for it, but the drive shaft that fit the 3550 fits this one. I want to run an alum drive shaft. We verified the length so will be ordering soon.

I have been pulled a way from bottom aereo, but am headed there. Would very much like to hear your ideas when I can get back there.

x-chr

|

02-12-2014, 10:45 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Please look at the picture of the screwed up foot. It appears to be some sort of mold closure problem that left the foot undersized on one side. The builder will take care of it, but I am wondering if it is worth it to replace the tail shaft housing if a properly sized spacer could solve the problem.

Would a properly sized spacer be mechanically sound? There is 1/2 " between the two sides.

Do I really need to break open a new, sealed box to repair a casting problem?

x-chr

|

02-13-2014, 04:46 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA2076

Would a properly sized spacer be mechanically sound? There is 1/2 " between the two sides.

Do I really need to break open a new, sealed box to repair a casting problem?

x-chr

|

My fear would be that the short side casting is inherently less strong. And a spacer would not add strength-only contact area for the fastener. That's just a total WAG, 'cause I never had the problem.

But you'll be putting torque through that with sticky tires...

__________________

Chas.

|

02-13-2014, 08:38 AM

|

|

CC Member

|

|

|

Join Date: Feb 2000

Location: Enfield, CT,

Posts: 542

|

|

Not Ranked

Not Ranked

The left side mount should be ok as it's shorter length decreases leverage as it is pulled up. Right is in compression and longer for a more stable set-up (if you have movement in the motor mounts). I use solid motor mounts to control rotational movement in the driveline and a flexable trans mount to absorb some movement vertically. The different heights of the trans pads have no effect in my setup since movement is up/down.

So, I guess the tail housing is a custom piece, what about the internals? straight cut gears/dog clutches? I run this one with a mag tail housing with a 350 hp 302 in a 2100# car JT5 Enduro 5 Speed |

02-13-2014, 10:09 AM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

G Force case - Astro internals.

|

02-13-2014, 03:37 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

It spins freely at 3.700 BS - not so much at 3.890.

Inside tire clearance on a 10" rim.

|

02-14-2014, 04:46 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Finally getting to the front hubs.

|

02-17-2014, 06:49 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

8" rim width. Still messing with the backspace.

|

02-18-2014, 10:13 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

My machinist is giving me crap about my mounts so I had to look them up -

MightyMounts - FM132

How they work

How they work |

02-21-2014, 05:58 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

We went ahead and fit the transnission. Seems my tail housing is what it is. The builder measured several and they were all the same. We are 3/8" high to ERA spec so we will have to do some more fitting to get it right but at least we are getting towards working weight.

With the trans installed I have been working on ride height with the taller tires. After messing with the thing for a year I have to say the frame is rigid. We were working on something and needed the frame to move 1/8" vertically. We put a 1500 lb ratchet strap on it and then watched as force was moved around the frame but we could not close the gap. It finally dawned on me we should use a standard 3 point system to establish a horizontal plane for the frame. We used the front frame rails and the middle of the rear cross brace to establish our working plane. This puts any frame flatness error into the rear of the car. We have a very ruff measurement of .180 between the rear frame rails when sitting on 3 points.

We welded washers to the bottom of the frame so we can locate the same every time.

Once we had the datum established I went back to setting the front end up. I have run circle track analyzer hundreds of times on the front suspension. I am going to run the lower control arms parallel to the ground. If the car is lowered below horizontal the roll center drops below ground quickly which increases the roll couple. What really caught my attention was how fast and how far the roll center moves in the transverse direction. I only ran it out to 2 degrees of roll.

With the arms horizontal - if I could reduce roll to 1.5 degrees max and run 1 degree of negative camber the tire would be flat on the road at the max cornering speed. The only reference I have is Allens car. I swiped a picture of it auto-crossing and ran some lines to determine the amount of roll which appears around 3 degrees(+-?).

I am running much less un-sprung weight, more wheel rate, and possibly less roll couple so it is not an apples to apples comparison, but I am wondering what is a typical roll angle for an FIA. Is Allen's car representative in this picture?

With the 26.50 tire, 3/4" extended ball joints, and the arms parallel, the front of the car sits 4.875 (+1/8" from ERA manual) form the frame rails to the ground. I wish I could get the 1/8 back easily (CG), but I cannot see how.

Anyway once we got the thing on 3 points I realized how out of square the rack is so we pulled the car and squared the rack. Since we can start running next month we put the Mustang back on to install the splitter.

Working around the car we all notice how light it feels. With it sitting on the floor I decided to give it a cursory weigh. I piled as much disconnected stuff as I could think of into the cock pit.

No fuel - When I took possession of it, it weighed 2440 lb with a half tank.

I am encouraged -

|

02-21-2014, 06:58 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

That 1 degree neg is very apparent.

PS-Allen's car is the one I told you to check for Weber hood clearance a while back.

__________________

Chas.

|

02-21-2014, 10:46 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Actually that is 2 on the drivers side. Once I get it back on the rack I will set it to 1.

I don't think there is any problem running a 302 block with Weber's and no scoop. It is astonishing how far down it sits compared to the 351. Brent has a pretty tall Edelbrock manifold on it and it sits down there.

What about the body roll? Does the pic seem typical? I ask because I may need to stiffen the bars some.

x-chr

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:52 AM.

Links monetized by VigLink

|