Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

05-25-2014, 06:15 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Play in clutch and brake pedal

Play in clutch and brake pedal

ERA 797 is running well, with about 800 miles on it so far. Just ironing out some minor issues. One I just noticed is that the brake and especially clutch pedal become a bit loose on the splined shaft under the floorboard. Consequently, there is about a half inch of play on each that should be eliminated. At first I thought it was just a matter of inadequate tightening (they are held on using a set screw that tightens against the spline, with a nut to hold the set screw tight). I tightened both pedals down pretty hard, but after some driving they loosen up again. Since the position of each is good, one solution might be to drill and tap a new hole for a set screw that would go into the splined shaft, instead of against it. Anyone deal with this issue, and have a good solution?

|

05-25-2014, 07:49 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lippy

instead of against it. Anyone deal with this issue, and have a good solution?

|

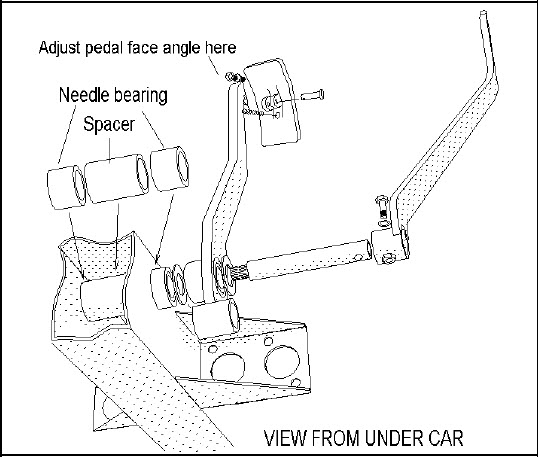

Is the free play side to side or front to back? And is this the correct diagram?

Last edited by patrickt; 10-28-2016 at 09:45 AM..

|

05-25-2014, 11:08 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

Patrick,

The play is mainly front to back but also side to side. The set screw and nut that holds the cylindrical sleeve to the splined shaft becomes a bit loose. That diagram is not exactly correct: the screw that holds the sleeve to the splined shaft sits on the splined shaft but does not go through it.

|

05-26-2014, 12:02 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: PVE,

CA

Cobra Make, Engine: ERA 289 FIA #2027, 65' 289" PS wheels

Posts: 345

|

|

Not Ranked

Not Ranked

check the "shoulder bolt"

check the "shoulder bolt"

After reading your post I am not clear if your problem is play in the splines or if the pedals are loose on the shaft...my car would break the shoulder bolt on the clutch pedal...you could work the clutch pedal fore/aft back and forth as the bolt was only acting to pin the pedal to the shaft after it would break.

I never had a problem with the spline and the bell crank being sloppy, the set screw would loosen occasionally but the problem was the clutch shoulder bolt.

When you push the pedal the rotating load is not taken by the shoulder bolts thick shank...after the play in the hole is taken up the load transfers to the weak threaded section of the bolt...and the bolt snaps at that point.

It doesn't matter how tight the bolt is. The bolt "shoulder" hits the inside of the tube and keeps it from compressing the tube. So the bolt is tight in the sleeve but the tube is not being compressed onto the shaft. When the assembly rotates the tube/sleeve will move until all the play is out of the bolt hole in the shaft. Then the load is transferred to the bolt and it snaps at the threaded section.

After breaking the bolt 3 or 4 times and hating the play in the clutch I ended up drilling out the shaft and tube for a slightly larger bolt...ground off the old nut and welded a larger nut on.

Now the bolt acts to compress the tube and clamp it to the shaft, not act as a "pin"

Used a slightly larger diameter bolt with socket head. No need to use a shoulder bolt now...

Wish I had taken better notes and pictures as I did this several years back. Anyway have not had a problem since. Great to pick up a little more clutch travel as the entire assembly now stays solid.

Hope that made some sense...pictures may help to visualize but a good cross section drawing would make it more clear than I can explain...

Pete

__________________

ERA 289 #2027

|

05-26-2014, 07:15 AM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,021

|

|

Not Ranked

Not Ranked

Pete,

We replaced your design with a spline at both ends in 2010.

The set screw should be pretty effective at taking out any play, but you can try a bolt (and maybe some Loctite Blue on the splines) to firm things up.

|

05-26-2014, 07:18 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

I used thread locker on my set screw (I think Patrick suggested this once). I don't have as many miles on mine yet for any other problems to have cropped up. There is a certain amount of play in the linkage before all the clearances are taken up. Because of my rearward seat mounting I unscrewed the clutch pedal rod until the pedal arm was against the rear of the floorboard opening - basically I have no free play that way (not talking about a minor amount of throwout bearing free play). But, I don't want to move the brake pedal back that far so it still has free play due to the linkage.

The bolt that secures the clutch arm to the shaft should be a through bolt as

Pete describes. I removed my assembly and it was per the diagrapm. The set screw at the clutch bellcrank does just seat into a groove in the splined shaft.

|

05-26-2014, 07:21 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by strictlypersonl

Pete,

We replaced your design with a spline at both ends in 2010.

The set screw should be pretty effective at taking out any play, but you can try a bolt (and maybe some Loctite Blue on the splines) to firm things up.

|

Uh-ohh, I guess I've been superceded by an update since mine was fabricated. |

05-26-2014, 07:37 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,012

|

|

Not Ranked

Not Ranked

I can't say I remember too many examples of that bolt shearing off from the clutch pedal. I think Pete's is the only one I remember. I don't know why you would have slop in the brake pedal either.

|

05-26-2014, 11:22 AM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

I guess I'll try some Loctite blue on the set screw. If that doesn't work I may consider drilling and tapping another hole into the splined shaft

|

05-26-2014, 07:08 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lippy

Since the position of each is good, one solution might be to drill and tap a new hole for a set screw that would go into the splined shaft, instead of against it.

|

Lippy - this would seem to be a good solution and not too difficult. It would certainly lock it in place on the splined shaft. |

04-27-2015, 09:15 PM

|

|

CC Member

|

|

|

Join Date: Apr 2012

Location: Bay Area (Peninsula),

CA

Cobra Make, Engine: ERA 427, 427/487 side-oiler

Posts: 1,248

|

|

Not Ranked

Not Ranked

As an update, after almost 3k miles, I still have this problem. I have the splined shaft on both ends (latest design) and I've tightened the set screw and nut several times, with blue Loctite. Every time it loosens after about 20 mi. It won't come off the splines so it's not dangerous, but there is extra play, both front/back and side/side. I think what's happening is that the set screw sits on the peak of the "triangles" on the spline, and that peak deforms. Not a great design.

Someone suggested I take the shaft out and drill a small pocket where the set screw sits on the shaft so the set screw has something better to clamp against. What do you think?

|

04-28-2015, 06:10 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Seems reasonable to me - can't see how it could cause a problem as long as the spines are de-burred so it can't hang up on reassembly. Should be some scoring of the spline from the set screws that says - drill here.

All of which means you probably need a second opinion.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 11:23 AM.

Links monetized by VigLink

|