Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

08-09-2014, 04:24 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,001

|

|

Not Ranked

Not Ranked

Dan, my OEM AC-Delco 60 amp alternator is only $40 from Amazon. My puller fan draws 16 amps, my pushers draw 8 amps, the lights draw 10 amps, and the ignition draws 1 amp per thousand RPMs.

[ame="http://www.amazon.com/ACDelco-334-2099-Remanufactured-Alternator/dp/B000C9PJE6"]Amazon.com: ACDelco 334-2099 Remanufactured Alternator: Automotive@@AMEPARAM@@http://ecx.images-amazon.com/images/I/517CdyaSxrL.@@AMEPARAM@@517CdyaSxrL[/ame]

|

08-09-2014, 06:37 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

I think this is a Powermaster 65 amp alternator from memory. They are pretty common around here at most FLAPS for not much money. I'll check on one tomorrow.

|

08-09-2014, 07:27 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,001

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

I think this is a Powermaster 65 amp alternator from memory. They are pretty common around here at most FLAPS for not much money. I'll check on one tomorrow.

|

I've measured the current on each circuit of my car. These cars hardly use any juice at all when running. When I'm "cruising" down the interstate during the day, none of my fans are running, my lights are all off, and the total amperage drain on the system is less than four amps. That's like a 60 watt light bulb. That's it. In town, in hot weather, only my puller fan runs -- so my total running draw is under twenty amps. Unless someone has monster-killing fans, a huge stereo, heavy duty electric fuel pumps coupled to a microwave oven in the trunk, you barely need an alternator at all.  |

08-10-2014, 04:28 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Some poor info here Dan

Some poor info here Dan

DanEC Dan first off IF your motor is running a 65 amp alt without under driven pulleys, this output is fine. Here's a basic list of draws in the charging system in amps. It's not perfect but close

Electric fan (1) high speed 8-16 amps

twins fans in front of car 7-15 amps

wiper motor depending on speed and load 5-12 amps

lights headlight, (Old style) 2-6 amps

Stock ignition with oil coil about 2-4 amps

rest of electrical draw about 2 amps running max.

The biggie, CHARGING of the battery, upto MAX of the output of alt.

voltage may go to 16.0v depending on battery and condition

The wiring setup for the cobra was to run a 45-60A alt setup.

Today is different with alot more power users in the car

MSD ignition system may pull upto 10amps alone

Electric fuel pumps depend on unit 15-18 amps

Some guys have AC in their cars, add another 30+amps

High power HID lights, They are all over the place with load.

At idle you need about 30 amps to power the system and recharge the battery. Any thing less and you are looking for problems. I went through this many years ago. Main problem was underdriven motor pulleys and killing the battery at idle. I also started to melt the end at the Alt, just like yours. The worst part was the insolators on the amp gauge in the dash. They where melted too. I couple of guys here have melted there wiring harness and it not a good thing. You could loose the whole car.

Here's what is in my car and what I did to fix all the problems,

PAperformance sells a couple kit for cobras with a 95 amp setup. This is more than enough power for all the acc to run at idle. It has a old style regulator box and Alt. Change 2 wires and you are done. The other issue is to replace the Amp gauge with a volt meter. The 2 wires that are connected to the guage should be spliced togeather and add 150 amp maxi fuse to protect wiring system. Swap the pulley off old Alt. Been running this system for 5 years and no problem. Still can run the under drive pulley from march on the crank shaft. I went to a 1-1 ratio with crank and water pump for another problem. My system runs 35-38 amps at idle and 14.12 volts on the gauge. when all the electric is on still in the 12.7 volts.

Power load to my car, FI system with injectors, 2 fuel pumps (electric) MSD ignition system with HVC coil, 6 cooling fans, 3 for the motor, and 3 for removing hot air from under the hood and down the trans tunnel. Total load is about 48-52 amps depend on temp of the day. This can be a 2-4 amp extra.

I would check out the wiring behind the dash at the amp meter. Make sure the insolators are not burnt or off color. Any possible thought, REPLACE THEM or the gauge.

Only other thing I did was add a fusible links to the main power wires. If you have a dead short they will save the rest of the wiring. Need about a 125 amp. This is what I run. Gives piece of mind. Good luck Rick L.

|

08-10-2014, 05:09 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

Thanks Rick and Patrick. My ERA is a pretty rudimentray Cobra replica - HD puller fan, points ignition, no stereo, mechanical fuel pump, etc. I do liike to run the lights when cruising around even in daytime. I used an alternator with a part no. for a 1970 428 Mustang (probably cross references to a lot of V8 Fords) and it seemed to be doing a good job until it decided to take advantage of a loose connection to change careers and become an arc welder.

|

08-10-2014, 09:53 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

Dan, i'm sure you have the problem licked.

just an observation from the pic of "the fix" you posted.

the eyelets seem to bottom out on the black, what i call "insulator"

giving a false sense of tight. as the wire cycles hot and cold it may shrink expand, get hard or all of the above, and may slowly be loose by itself.

i would place a washer on the alt stud first then attach the eyelets on the stud, when you then tighten the nut it will firmly bottom on metal and not catch the black insulator. i had to do this on both my powermaster starter and my one wire alternator

__________________

Fred B

|

08-10-2014, 11:02 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,001

|

|

Not Ranked

Not Ranked

Now You Should Perform a Voltage Drop Test

Now You Should Perform a Voltage Drop Test

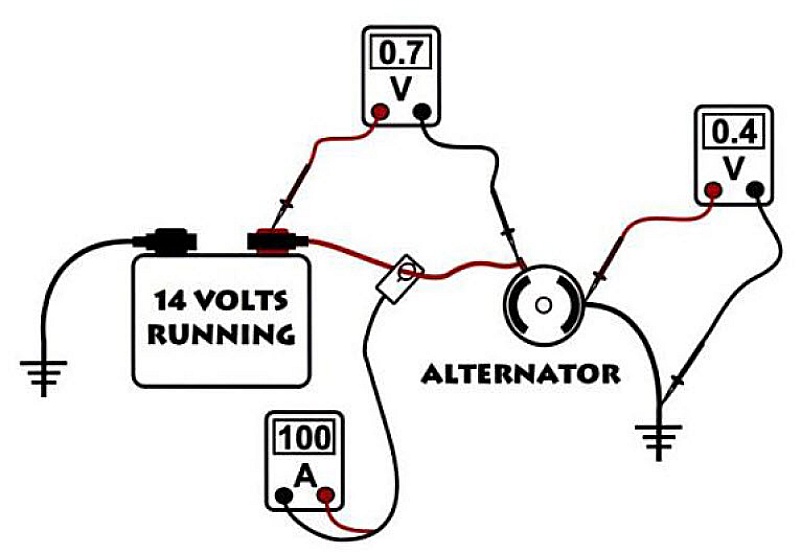

Since you're replacing the wires, connectors, and alternator itself, once you get the new stuff in you should take five minutes and perform a voltage drop test on the charging circuit (both positive and ground). It will tell you if you have a problem anywhere along the circuit. The picture that I'm posting below shows a 100 amp charge, so the potential difference between battery and alternator is acceptable at 700 millivolts. For your 65 amp alternator, I would only expect 400 millivolts or less both on the positive side and the ground side. Dan, I know you hate any sort of electrical test, but this one is not only the easiest, but it's the best. Just put your VOM's leads as shown, with the car running, and measure the voltage just like you see on the pic. If you register a number that's larger than .4 volt, on either the positive side or ground side, then you have more work to do. If it's less than that, all is well. You can do this.

Last edited by patrickt; 10-28-2016 at 09:48 AM..

|

08-10-2014, 11:21 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

The OEM's use crimping exclusively but for low volume production or 1 offs such as ours, mechanical connection (crimping) and solder have a lot of merit. Anticipated current loads for individual circuits, taking into consideration any future changes or additions will dictate the gauge of wire being used.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

08-10-2014, 12:04 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

You can do this.

|

I'm not sure I need to. I've run the car since the incident and it was charging and running fine. I'm convinced it never actually shorted - just got real hot - like the solder melted and ran out of the terminal hot.  |

08-10-2014, 12:16 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,001

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

I'm not sure I need to. I've run the car since the incident and it was charging and running fine. I'm convinced it never actually shorted - just got real hot - like the solder melted and ran out of the terminal hot.  |

No, a voltage drop test will check the resistance in your new circuit that comes from the new wires and connections being less than what they should be. You are replacing the charging wire, the connectors on the end, and the connections to the fuse panel along with the alternator itself. There are two ways to confirm the integrity of your work (and the circuit): 1) Just eyeball it and say "yeah, those connections look pretty tight and the wire looks pretty good and nothing looks loose" or 2) Perform a simple voltage drop test. |

08-10-2014, 05:05 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

No, a voltage drop test will check the resistance in your new circuit that comes from the new wires and connections being less than what they should be. You are replacing the charging wire, the connectors on the end, and the connections to the fuse panel along with the alternator itself. There are two ways to confirm the integrity of your work (and the circuit): 1) Just eyeball it and say "yeah, those connections look pretty tight and the wire looks pretty good and nothing looks loose" or 2) Perform a simple voltage drop test.

|

Hmm - I don't remember this being part of Bob's electrical manual instructions or primer for wiring up and starting the car. I'll see - nothing I like doing better in 95 deg heat and 60% humidity than leaning over a hot engine taking voltage checks.

New ,rebuilt alternator is in place and UPS is showing the wire from ERA to arrive tomorrow. I decided to bit the bullet and un-wrap the harness, pull out the old wire and then install the new one and re-wrap everything. Everything will back to 'As-New" condition then.

Check those alternator hot leads. FWB is pretty much on the same page as I - planning to install a small washer before the terminal and then use a serrated lock washer between the nut and the terminal. I think I'm even going to stick a cut down vacuum cap over the exposed end of the terminal connection just for another precaution. |

08-10-2014, 09:12 PM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

Hmm - I don't remember this being part of Bob's electrical manual instructions or primer for wiring up and starting the car. I'll see - nothing I like doing better in 95 deg heat and 60% humidity than leaning over a hot engine taking voltage checks.

New ,rebuilt alternator is in place and UPS is showing the wire from ERA to arrive tomorrow. I decided to bit the bullet and un-wrap the harness, pull out the old wire and then install the new one and re-wrap everything. Everything will back to 'As-New" condition then.

Check those alternator hot leads. FWB is pretty much on the same page as I - planning to install a small washer before the terminal and then use a serrated lock washer between the nut and the terminal. I think I'm even going to stick a cut down vacuum cap over the exposed end of the terminal connection just for another precaution.

|

yes the vac cap sounds good, its damn close to the head...in my mind i see an arc jumping to it.........still looking for the GM type alt wire boot that would fit over the red cover and make everything nice and tidy

i ran heat shrink right down to the eyelet and resin coated fiberglass loom.

from mcmastercarr......takes something like 1200 degrees before it poofs

__________________

Fred B

|

08-11-2014, 04:07 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

Yes, I wish it had one of those GM style hoods for the alternator lead also. It is close to the head. I didn't realize until shopping for the replacement alternator that they sell at least two versions of this Ford alternator with the rear case (and connections) clocked 120 degrees differently. The first two I looked at had the terminals down low and inside (about 8 O-clock) to the motor - nearly impossible to get to, and sure to short on the dipstick tube or motor. Finally found what I had before with the terminals at about 4 O-clock which provides better access and clearance.

|

08-11-2014, 07:28 AM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: Patchogue. NY,

NY

Cobra Make, Engine: Midstates 351W tremec

Posts: 60

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by FWB

yes the vac cap sounds good, its damn close to the head...in my mind i see an arc jumping to it.........still looking for the GM type alt wire boot that would fit over the red cover and make everything nice and tidy

i ran heat shrink right down to the eyelet and resin coated fiberglass loom.

from mcmastercarr......takes something like 1200 degrees before it poofs

|

Dorman Products 85684 Dorman Electrical - Wiring Accessories - Free Shipping on All Orders @ JEGS

this might work for you! |

08-11-2014, 08:18 AM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,011

|

|

Not Ranked

Not Ranked

I'm not sure about this, but it may be possible to "re-clock" the back plate of the alternator by removing the long screws that keep everything together.

|

08-11-2014, 11:03 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by strictlypersonl

I'm not sure about this, but it may be possible to "re-clock" the back plate of the alternator by removing the long screws that keep everything together.

|

I think it could be possible also. And I suggested to the counter guy at Advance that I would try that if he told me he was OK with it. But it had been awhile since I was last in an alternator and I knew there were leads from the magnet to the brushes, etc. and it could damage it. I think he decided he didn't like the idea of taking the risk so he decided to refund my money instead and I went to NAPA and found one like I needed.

Interestingly Advance had two listing for two different clocked rear cases and they had both in stock. But upon examination they were both the same with termiinals at 8 O'clock.

BUT - I think by removing the 3 case screws the front case can be rotated 120 degress leaving the rear case and magnet assembly together. |

08-11-2014, 10:01 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Keller,

TX

Cobra Make, Engine: Lonestar Classics LS427. Self-built 408W, AFR 195 heads, Performer RPM Intake, Quick Fuel 750, 407rwhp, 479rwtq

Posts: 549

|

|

Not Ranked

Not Ranked

I just re-clocked my alternator. It was a TuffStuff alternator and came with instructions on how to clock it.

|

08-12-2014, 05:38 AM

|

|

CC Member

|

|

|

Join Date: Aug 2010

Cobra Make, Engine: RUCC, SB 331 Stroker

Posts: 171

|

|

Not Ranked

Not Ranked

Clocking the alternator is easy...lots of instructions on the Net.

You can get the charge wire boot at Summit and probably many other places as well: http://www.summitracing.com/parts/RNB-85684/ |

08-14-2014, 04:59 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,519

|

|

Not Ranked

Not Ranked

All fixed back to original and functioning. I still plan to order a boot or something to go over the terminal.

New video - those with sharp ears will detect a header leak at the collector on the right side. Another project for next winter.

[ame]https://www.youtube.com/watch?v=7Dntx6wfo0U[/ame] |

08-14-2014, 06:20 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Dan

Ya know I love you...

but will you just DRIVE THE DAMNED CAR???

Over 4K RPM. With your undercar system, no one on the street will be scared. Carry RPM in the gears.

Stop gawking at it. Get with a local club (any make) who rents track time or autocrosses. You don't have to race, just tour the track lap after lap at a medium pace and work up to sh!tting yourself.

You have no idea at your usage level how wonderful an ERA is to get in rhythm with. Especially one you slaved years to perfect. You are using 20% of the car's dynamic envelope.

Let it wheeze, piss and niggle the details but you're missing the entire other half of the experience. Of course the self build was rewarding. But now whip it and raise your personal bar. You have no idea yet how much more rewarding it is when you press it hard and trust your craftsmanship dynamically.

Like you I was anally obsessed, but always with the vision that I'd pull it's hair out or have it kill me. It didn't and that's the entire other reward - you are that good a builder too. And it will always be as docile as your wife wishes when you're not pressing it.

Two decades from now it will be just as good as this minute-because you're a capable guy who can have perfection and performance.

Here's how I know:

Rant over---pal.

__________________

Chas.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:45 AM.

Links monetized by VigLink

|