Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

08-05-2003, 07:41 AM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Livermore,

CA

Cobra Make, Engine: ERA #629, BBM Side Oiler Block, 482ci, Richmond 5 speed

Posts: 852

|

|

Not Ranked

Not Ranked

Torque Straps?

Torque Straps?

Well, I now have almost 1000 miles on my 428. As a result I don't have to baby it quite as much as I did during break in. Now that I'm able to get on it a bit every now and then, I've noticed rub marks on the top of the left side pipe and the bottom of the right side pipe (right where the side pipes exit the body). The engine torque is causing the motor to twist enough to allow the side pipes to hit the cutout openings. The gap between the sidepipe and the cutout it about 1 inch. At first I thought the motor mounts weren't tight, but I checked them and they are. The engine is also sitting level. Bob, I have the rubber motor mounts that I purchased from ERA. Do you recommend switching to a solid type motor mount? I'm also considering adding a torque strap. Any suggestions or recommendations?

Chris

|

08-05-2003, 11:29 AM

|

|

CC Member

|

|

|

Join Date: Jan 2002

Location: Morristown,

nj

Cobra Make, Engine: SPF #623 460/4x2

Posts: 858

|

|

Not Ranked

Not Ranked

I have straps on mine and it cured the problem. I found a bolt hole on the block, on the drivers side. (right next to the oil pan smack in the middle, just back from the motor mount) I fabricated a small bracket, and I wrapped a ratcheting tie down around the frame. I would eventually like to have a more professional strap but for now...it works. If you find a better system, please let me know...Thanks.

__________________

Dane

|

08-05-2003, 11:47 AM

|

|

CC Member

|

|

|

Join Date: Mar 2002

Location: so cal,

Cal

Cobra Make, Engine: I used to fix them for a living

Posts: 2,563

|

|

Not Ranked

Not Ranked

you can put as bolt and two fender washers through most motor mounts to make it less stretchy. An aluminum flywheel will make the biggest improvement in eliminating motor torque-over, excluding solid motor mounts. If you use a chain as a torque strap, it will stretch and become worthless in a very short amount of time.

__________________

In a fit of 16 year old genius, I looked down through the carb while cranking it to see if fuel was flowing, and it was. Flowing straight up in a vapor cloud, around my head, on fire.

|

08-05-2003, 11:58 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 1999

Location: New Britain, CT,

Posts: 1,416

|

|

Not Ranked

Not Ranked

Chris,

There is just enough room to put a bolt through the engine mount to limit how much it stretches. I don't have an example handy, but if you mark where the chassis stand supports the mount, you can figure where the bolt fits without interference. Install a stover nut so the bolt has .020"- .050" "looseness".

__________________

Bob Putnam

- E.R.A.-

Please address parts inquiries to eraparts@sbcglobal.net

|

08-05-2003, 12:47 PM

|

|

CC Member

|

|

|

Join Date: Jul 2001

Location: Southwest,

WI

Cobra Make, Engine: Shell Valley, Mopar thingy (small block of course)

Posts: 2,215

|

|

Not Ranked

Not Ranked

I used two straps. One on each side of the back of the block, like a mid-plate, since it was twisting in the tranny mount also. (Fixit, the new motor will have the al flywheel) Heim joints on each end of a lh/rh threaded rod. Easy to preload for a bit of support, no difference in vibration really. Had it not been for the weak tranny mount (Shell Valley, not ERA) I would have done Mr Fixit's bolt through the motor mount thing. Out of sight, simple and effective.

__________________

Brent Dolphin

|

08-05-2003, 05:10 PM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Median of I-40 near Barstow,

Posts: 45

|

|

Not Ranked

Not Ranked

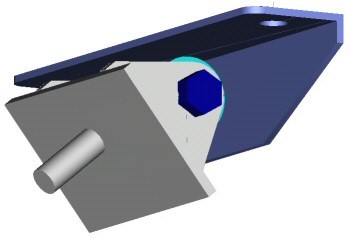

Had similar problem...used a male heim joint and one of the accessory bolt holes in the front of the left side head...then to a 5/8 aluminum hex rod...then to a 3/8 bolt thru two sway bar donuts...to a bracket welded on frame...

I drew this up for peter years ago and suggested he at least make people aware of how to address the problem.....guess he's eaten since then.....

Use GT-40 motor mounts on FIA car...no more problems....but then no torque either...

M

|

08-06-2003, 06:19 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: White Plains,,

NY

Cobra Make, Engine: ERA140, ERA 267, ERA GT2038, ERA FIA 2045, ERAGT2077 ERA2893000EXP

Posts: 1,117

|

|

Not Ranked

Not Ranked

Murt:

On the Farcus Special #02, (I think I'm up to 129.5 miles on the odometer now) my right front Weber "horn" is hitting the hood scoop and putting a slice into the fiberglass. Hard to figure that I've been torquing the motor over that much, after all, I never go over 1400 rpms coming off the trailer. So, what's involved with the GT motor mounts? Is it a straight bolt in? Lord knows I want to have all my guns loaded when I call Peter up on this one and endure the usual slings and arrows...*

Regards to the missus

Morty

*WWhat do you want to do that for? You don't drive the car and you're just going to sell it anyway, etc. etc."

Last edited by Jim Holden; 08-06-2003 at 06:25 PM..

|

08-07-2003, 06:30 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 1999

Location: New Britain, CT,

Posts: 1,416

|

|

Not Ranked

Not Ranked

Jim,

We haven't used the old-style mounts for 10 years but we may still have the tooling. They are a direct replacement for the standard mounts.

__________________

Bob Putnam

- E.R.A.-

Please address parts inquiries to eraparts@sbcglobal.net

|

08-07-2003, 07:33 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: White Plains,,

NY

Cobra Make, Engine: ERA140, ERA 267, ERA GT2038, ERA FIA 2045, ERAGT2077 ERA2893000EXP

Posts: 1,117

|

|

Not Ranked

Not Ranked

Bob:

But do they do as Murt sez: prevent the motor from "torquing" over so much?

Jim

|

08-07-2003, 11:47 AM

|

|

CC Member

|

|

|

Join Date: May 2002

Location: Median of I-40 near Barstow,

Posts: 45

|

|

Not Ranked

Not Ranked

Morty....I have a set if Bob can't find any....they were a set I was saving for myself....the last ones I had...very special...

Considering we don't want to short a "team car"...I'll consider parting with them...assuming I can find them.

or

I can sell you the ones currently in the car...but you have to buy the whole car...

MF

|

08-07-2003, 12:40 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 1999

Location: New Britain, CT,

Posts: 1,416

|

|

Not Ranked

Not Ranked

They use a round urethane bushing that's only 3/16" thick. There's not a whole lot of room to move in any direction. I suspect that the stock mounts don't compress that much but they may stretch a bit.

__________________

Bob Putnam

- E.R.A.-

Please address parts inquiries to eraparts@sbcglobal.net

|

08-07-2003, 01:28 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: White Plains,,

NY

Cobra Make, Engine: ERA140, ERA 267, ERA GT2038, ERA FIA 2045, ERAGT2077 ERA2893000EXP

Posts: 1,117

|

|

Not Ranked

Not Ranked

Murt:

I realize that every little itty bitty thing you've got is an extra, they ain't mak'n any more, special, one of a kind, it's gona cost ya, and I ain't given it up until you beg and plead and grovel, heirloom item. (Gee, this sounds just like what I have to go through to get Peter to part with any of his junk too.)

So, if I can't get Bob to come across with a set, I'll be back to you. Just let me know how many Pintos ya need to get for them.

Morty

|

08-07-2003, 01:54 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Aug 2000

Location: Mckinney,

TX

Cobra Make, Engine: Lone Star Classics #89 Keith Craft Genesis 427 so, stroked to 482, 649 hp. Sabre GT 40 #16 351W stroked to 408, 527hp, TWM stack injection, Fast XFI, G50/50.

Posts: 537

|

|

Not Ranked

Not Ranked

Ok here's what I did. I took the adjustment rod from a March alternator bracket. It was about 10 inches long with a heim joint at each end. One end bolted to the front drivers side head. The other end bolted to bracket I made and attached to the frame. It looks good and has worked well.

Let me know if you want to see a pic. I can probably take one this weekend.

John

|

08-07-2003, 05:50 PM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Livermore,

CA

Cobra Make, Engine: ERA #629, BBM Side Oiler Block, 482ci, Richmond 5 speed

Posts: 852

|

|

Not Ranked

Not Ranked

John,

I thought about doing something similar. I found this one on the internet: http://www.engine-swaps.com/frames/f...rquestrap.html I could do something similar I suppose, but I think I'm just going to try the bolt through the motor mount trick that a few people mentioned. That sounds pretty simple and inexpensive.

Chris |

08-08-2003, 02:35 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Aug 2000

Location: Mckinney,

TX

Cobra Make, Engine: Lone Star Classics #89 Keith Craft Genesis 427 so, stroked to 482, 649 hp. Sabre GT 40 #16 351W stroked to 408, 527hp, TWM stack injection, Fast XFI, G50/50.

Posts: 537

|

|

Not Ranked

Not Ranked

Hey Chris,

that is very similar to what I did except I had a much smaller bracket that bolts to the under side of the frame. I wanted a simple bolt on that would be adjustable. I thought about Drilling an bolting the motor mounts but I did not want to deal with supporting the motor while the mounts were out.

Good luck

John

|

08-12-2003, 10:33 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Aug 2000

Location: Mckinney,

TX

Cobra Make, Engine: Lone Star Classics #89 Keith Craft Genesis 427 so, stroked to 482, 649 hp. Sabre GT 40 #16 351W stroked to 408, 527hp, TWM stack injection, Fast XFI, G50/50.

Posts: 537

|

|

Not Ranked

Not Ranked

here's a picture if I can get it to work.

John |

08-13-2003, 03:23 PM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Livermore,

CA

Cobra Make, Engine: ERA #629, BBM Side Oiler Block, 482ci, Richmond 5 speed

Posts: 852

|

|

Not Ranked

Not Ranked

John,

Thanks for the photos. That looks like a pretty clean set up. If I was going to do something similar, I think I'd change the bottom connection from an eyelet type connection to a rod type connection. I'd use sway bar link kit type bushings on the rod end. That would allow the engine to flex just a bit but I think I'd be able to control how much based on how tight I tighten the bushings.

I think I'll try installing the bolts through the motor mounts this weekend. I should be able to support the engine (with a Canton pan) using a floor jack. If not, then I guess it's plan B which is your setup.

Chris

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:39 AM.

Links monetized by VigLink

|