Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

8Likes 8Likes

08-16-2008, 05:10 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by tuska

Looks great! Where did you get your header tank from? Is it brass? could you chrome it? cheers glen

|

Glen,

The tank came from ERA. Its a brass unit that has been painted black. Apparently, chroming these tanks makes the brittle and they tend to crack and leak. I kind of like the look of the black tank's contrast against the polished aluminum. What do you think?

- Fred |

08-16-2008, 06:00 PM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine:

Posts: 3,077

|

|

Not Ranked

Not Ranked

Incredible!!! You are setting a new standard. Are the sidepipes stainless steel? I would be afraid to drive it.

|

08-16-2008, 06:33 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by madmaxx

Incredible!!! You are setting a new standard. Are the sidepipes stainless steel? I would be afraid to drive it.

|

Yes. the sidepipes are polished stainless steel. |

08-18-2008, 12:01 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: taihape,

nz

Cobra Make, Engine: keith craft 427, tko600, very shiney pile of parts

Posts: 45

|

|

Not Ranked

Not Ranked

I have seen some chrome header tanks around.... but as you say the contrasting gloss black is great...if there's poss that they crack best not go there!

|

09-02-2008, 08:13 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: St. Charles,

MO

Cobra Make, Engine:

Posts: 22

|

|

Not Ranked

Not Ranked

Wheel Positioning

Wheel Positioning

fkkemmerer,

Are you having the same problem as #747 & #757 are having with the location of the front wheels with respect to wheel openings? I am going to ERA next Tuesday to check out my #768 and want to make sure I don't have the same issues.

Thanks,

Clyde

|

09-03-2008, 04:28 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Clyde,

Yes, I'm seeing this same issue. I want to get my car done and readjust the ride height to spec. before deciding if I need to fix anything here. It looks to me like the car may be OK now the that motor is installed. I can't set the final ride height yet becuase I'm waiting on a set of rear wheels from ERA.

- Fred

|

09-03-2008, 05:53 PM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: USA,

MI

Cobra Make, Engine:

Posts: 327

|

|

Not Ranked

Not Ranked

Fred,

Great looking color on your car. What can you tell me about the paint specs.

|

09-03-2008, 06:45 PM

|

|

CC Member

|

|

|

Join Date: Apr 2007

Cobra Make, Engine: # 757 ERA 427 SC , 482 Al. big block

Posts: 896

|

|

Not Ranked

Not Ranked

Fred , Beautiful car !! I talked to Doug a while back and he said he had never seen so many wires as yours had !

I have ERA # 757 and have been working on the tire clearance issue for mine . I`m running the Avon 245`s on the front , not 235`s ,and do have contact with the inner rear fender lip on a left turn at full suspension droop ( car is still on ERA shop stands ) after one turn of the steering wheel . No problem with right turn under the same conditions . I have the fast ratio box , so I only have about another .3 turns to full lock . With no load on the suspension , the tires are at their widest point on the diameter and my thought , like you , is that when the engine etc is in , suspension set and aligned and the car on the ground , the wheels/tires will be far enough up due to loading ( smaller part of the tire diameter ) that this may not be an issue ... if it is , I`ll just clearance the inner lip some. I discussed this with ERA before getting the tires and was told up front that it could be an issue .... but being stubborn , decided to do it anyway .

|

09-03-2008, 07:36 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Meriden,

CT

Cobra Make, Engine: ERA 427 SC s/n 718, 428 FE

Posts: 1,731

|

|

Not Ranked

Not Ranked

You should have the steering rack centered with wheels straight so as to have equal steering radius (left and right) for each wheel. If one wheel steers sharper than the other you may have a rub. You must also have the wheel/spring compressed to correctly check for alignment (and rubs). Just make sure you do all these basic adjustments. ERA has built close to a thousand Cobras without these tire issues.

|

09-04-2008, 12:03 PM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Central,

NC

Cobra Make, Engine: ERA #775

Posts: 324

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ZOERA-SC7XX

ERA has built close to a thousand Cobras without these tire issues.

|

Is this possibly something that relates to the updated body, or possibly the steering and mounting system changes?

How common does this appear to be? |

09-04-2008, 09:41 PM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: Arkadelphia, AR,

AR

Cobra Make, Engine: Kirkham 427 brushed aluminum with Keith Craft 527C.I. all aluminum FE

Posts: 992

|

|

Not Ranked

Not Ranked

I must say that the car is looking very nice and the detail and time you have taken to do it to this level is amazing. I know what it takes to do some of these cars right and nice you have taken it up a notch. I hope that eveything goes to your liking and look forward to you getting the engine running and the car driving. You may be running out of time this year but that will just give you more time to make it even nicer. Good luck, Keith Craft

__________________

Keith C

|

09-05-2008, 05:28 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ROSS WEAVER

Fred,

Great looking color on your car. What can you tell me about the paint specs.

|

Ross,

The Red is basically a stock 2007 Chrysler Red Metallic. The silver is also a stock color. Here's the paint code information:

Silver Blue Metallic

Diamont from R&M

"FM", Stock #79775

Blaze Red

CUS PRH

AY112AR/STD

Dark Maroon Undercoat (mix of Maroon and Black)

This process is a base coat + clear coat one.

The real story out the paint and body work is Ron Randall at Metalmorphous. Ron spent a great deal of time preping and painting the car. Ron has alot of experience with cobra and I think it really shows in his work. |

09-05-2008, 05:32 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RAO-3

Is this possibly something that relates to the updated body, or possibly the steering and mounting system changes?

How common does this appear to be?

|

As far as I can tell, all of the instances of this problem to date are with cars that do not yet have engines installed and/or are not at proper ride height yet. I'm certainly in the latter state at my stage. When I get my final wheels installed I'll set the car at ride height, set the final alignment and see where things are. The interference issue, if its still there, is not so great that it cannot be fixed with some pretty minor clearancing. I think things like this are all part of the process of building custom cars. I don't think I've ever worked on a project like this where I did not encounter one or two things like this. I am sure that ERA will address these issues if they are there on all of their turnkey cars. |

09-05-2008, 05:34 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Keithc8

I must say that the car is looking very nice and the detail and time you have taken to do it to this level is amazing. I know what it takes to do some of these cars right and nice you have taken it up a notch. I hope that eveything goes to your liking and look forward to you getting the engine running and the car driving. You may be running out of time this year but that will just give you more time to make it even nicer. Good luck, Keith Craft

|

Thank you very much Keith. I have to say that a good measure of credit for the way my car is turning out goes to you and your team. You really built an outstanding engine for me and it is clearly one of the best points of the car.

- Fred |

09-05-2008, 07:03 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

Regarding rear wheel availability. Could these issues have anything to do with Trigo having been sold? The new owners sure seem to keep a low profile.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

09-05-2008, 07:43 AM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Millbrook,

NY

Cobra Make, Engine: ERA 758 KC Pond 482

Posts: 391

|

|

Not Ranked

Not Ranked

Rick-

There is a delay on these wheels from Vintage. For the ERA, the fronts need to be machined for correct backspace, and for some reason, the rears are hard to get now. I was quoted 5 weeks and from what I heard from Peter, this may be optimistic. I ordered mine 5 weeks ago and no sign of them so far.

Fred also has Vintage wheels.

|

09-05-2008, 07:57 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Central,

NC

Cobra Make, Engine: ERA #775

Posts: 324

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by fkemmerer

As far as I can tell, all of the instances of this problem to date are with cars that do not yet have engines installed and/or are not at proper ride height yet. I'm certainly in the latter state at my stage. When I get my final wheels installed I'll set the car at ride height, set the final alignment and see where things are. The interference issue, if its still there, is not so great that it cannot be fixed with some pretty minor clearancing. I think things like this are all part of the process of building custom cars. I don't think I've ever worked on a project like this where I did not encounter one or two things like this. I am sure that ERA will address these issues if they are there on all of their turnkey cars.

|

Thanks Fred, I appreciate your input! I'm sure that ERA will be on top of it, but was thinking of putting this on my checklist.

Ray |

09-09-2008, 05:56 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Just an update on where I am with my Cobra project. First, ERA has indicated that they expect a shipment of pin drive wheels from Vintage in the near future. I'm hoping to get the rear wheels for my car as part of this shipment.

I am also knee deep in electrical work on my car. I am using a FAST XFI system and I've opted to build a custom wiring harness for the FAST XFI computer in my car to get a good fit and to ensure that there's not alot of visible excess wire from an over length wiring harness. I'm also using and MSD ignition system and I am implementing a number additional electrically controlled features based upon what my MSD Digital 6 Ignition and the XFI Computer can do. These include:

1) Using the red ignition indicator dash light on my ERA as a shift light controlled by the FAST XFI computer. This keeps the dash looking "stock". A hidden switch under the dash allows me to also use this light as a "Service Engine Soon" indicator from my FAST Computer. I will start the car with the light in the SES mode to check for any problems and then switch the light to be a shift light when I'm driving the car.

2) Using the 2-step REV limiter on my MSD Digital-6 and a shifter mounted button to implement a REV limiter for launching the car

3) I am connecting a driveshaft speed sensor to the XFI to implement electronic traction control as well as to implement recording of vehicle speed, tire slippage and gas mileage.

4) I am using a digital controller for my fuel pump which runs the fuel pump at a lower speed below 2,400 RPM to keep the fuel cool and improve fuel pump life.

5) I am also connecting a fuel pressure sensor to my FAST XFI computer so that it can monitor the fuel pressure on my car

6) The FAST computer can store up to 4 seperate programs for the fuel injection system. ERA made a custom control panel that is hidden under the dash which allows me to select which program to use. This lets me have different tunes in the car for street use, track use, and emissions and select the one I want with a flip of a switch.

7) I using the FAST XFI computer's internal data logging features to implement an on-board data logging system. This will include logging of all of the engine control functions as well as the driveshaft sensor and fuel pressure. This should be me a good platform to fine tune the car and deal with any problems that might come up later.

Here's a picture of the custom switch bracket which is hidden under the dash. These switches let me control all of the functions listed above from the driver's seat:

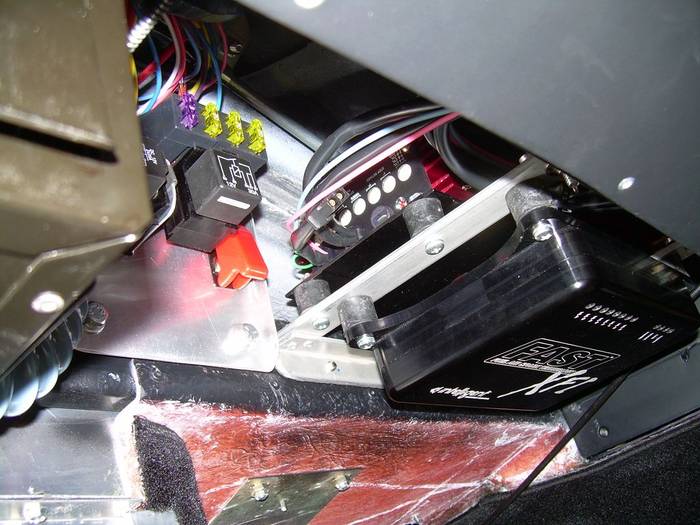

The following is a picture of the custom bracket that Doug at ERA made for my car. It mounts the FAST XFI computer (the black box), the MSD Digital 6 ignition box (the red box) and all of the fuses and relays associated with the FAST XFI computer (these are installed in the picture but not yet connected to the wiring harness). This computer is mounted face down so that the indicator lights on the FAST computer are easily viewed by looking under the dash. The entire assembly can be removed with 2 wing nuts to allow the settings on the MSD box to be easily changed.

Doug built a nice custom aluminum panel which mounts the FAST XFI program selector switch, an arming switch which allows the FAST XFI computer's software program to be updated, and an auxillary fuse block and Fuel Pump relay. This panel is hidden under the dash next to the XFI computer - again, we were able to add all of the extra electrical components to the car in locations which are not visible.

The final picture shows how all of these components are mounted together under the dash on the passenger's side of the car. This picture was taken before all of the wiring (and the XFI program selector) switch were installed. As you can see, everything is neatly hidden. Doug did a really outstanding job with this!

Obviously all of this involves an significant amount of custom wiring work. At this point I have about 50 hours in this part of the project. To give you a feel of the amount of work involved, there are over 100 wires that need to be terminated to build the FAST XFI wiring harness alone! At this point, all of the wiring for the ignition box and all of the in-car control features are done. I'm about 70% done with the custom harness for the FAST XFI computer and I plan to install the computer and the custom harness in the car for the last time this weekend. I was able to build the FAST XFI harness off the car thanks to the really neat removable bracket assembly that Doug created for the FAST computer and the MSD box. All of this may seem a bit complicated but the key to making a system like this work well and be reliable is to 1) use good electrical practices to build everything such as soldering connections, using heat shring tubing and high quality sealed connectors everywhere, etc. 2) test all of the components as you go (for example, I've tested the entire ignition system, fuel pump controller, tach, etc using an MSD ignition tester which lets me generate signals that trigger the MSD box and all of the PRM activated features; I've also brought the XFI computer up on the bench and verified that its working with the custom harness and that it can talk to my laptop, and 3) carefully document everthing via diagrams and tables so that you can remember what you've built later if there's a problem. At this stage, I need to put connectors on all of the wiring to the engine and to the driveshaft and fuel pressure sensors and I can fire her up! I think that I should be to this point by the end of this weekend if all goes well. I will post some pictures of the completed wiring to give everyone a feel for what was involved. A great deal of what I am doing is defintely not needed on most EFI equipped Cobras. Most folks would do fine to use a pre-built harness from FAST and would not try to utilize all of these electrical features that I am using. I'm trying to take maximum advantage of all of the capabilities that the electronics in my car can provide and also create a neat, custom installation that is completely hidden.

- Fred

Last edited by fkemmerer; 06-03-2009 at 08:11 AM..

|

09-09-2008, 07:02 PM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine:

Posts: 3,077

|

|

Not Ranked

Not Ranked

Wow!!!!! what takes you 50 hours would take me 200 hours. I cannot wait to here how it all works together.

Thanks for the entertainment!!

|

09-18-2008, 04:25 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

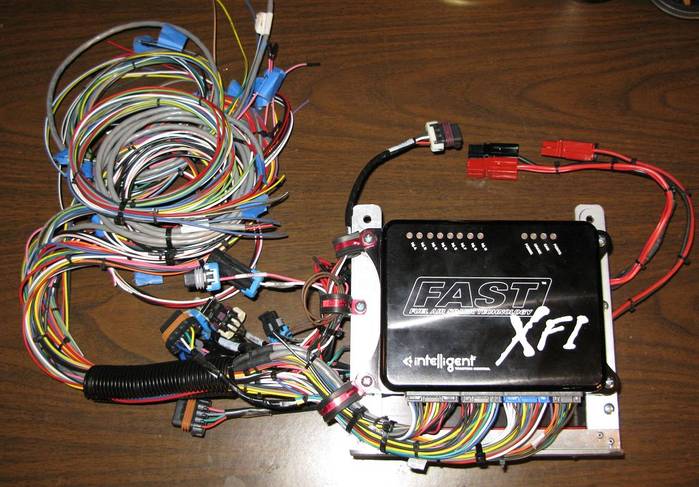

Just an update on my electrical journey. I've completed all of the wiring harness work (power circuits, grounds, relays, fuses, etc) that I can do off the car. The attached is a picture of the FAST XFI computer and ignition box assembly. As you can see, I still have a few wires left to connect  .

All of this remaining wiring goes to two basic places: 1) to the sensors in the transmission tunnel for the driveshaft speed sensor for electronic traction control and fuel pressure monitoring and 2) to the engine for all of the fuel injection associated sensors and controls. I've completed all of the terminations and connection for the driveshaft sensor and fuel pressure monitoring. Here's a picture of that part of the project:

The button on the shift control the 2-step rev. limiter on my MSD box.

All that is left is to make the connections to the engine. To give those who might consider trying to build their own EFI harness a feel for what's involved in this, the engine connections include:

1) CAM and Crank trigger connections to the distributor

2) MAP Sensor connections (measures manifold vacumn)

3) Air Temperature Sensor

4) Coolant Temperature Sensor

5) Throttle Position Sensor

6) Idle Air Control Motor

7) Wide Band O2 Sensor (in the passenger's sidepipe)

8) Fuel Injectors (there are 8, one in each intake port)

Obviously, most folks would opt to use an off the shelf harness which would not require all of this work. The advantage of building a custom harness is that everything fits perfectly with no excess wire to hide.

I think one more weekend will do it ....

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:19 AM.

Links monetized by VigLink

|