Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

05-18-2008, 12:40 PM

|

|

CC Member

|

|

|

Join Date: Nov 2007

Location: Westford,

MA

Cobra Make, Engine: ERA, 427 side oiler

Posts: 6

|

|

Not Ranked

Not Ranked

ERA 452 -- crushed brake-fluid supply lines

ERA 452 -- crushed brake-fluid supply lines

I noticed a small puddle of brake fluid under my ERA 452. I found a leak in one of the rubber hoses that carries brake fluid from the underhood reservoir to one of the master cylinders under the car. The leak was in a portion of the hose that's routed through the inside the car, against the firewall. The leak was caused by the clutch pedal "crushing" the hose against the area where the floor meets the firewall. It took 12 years to crush it enough to create the leak.

Turns out that both brake-fluid supply hoses showed evidence of crushing, so I replaced both of them. I attempted to re-route the hoses to avoid the clutch pedal, but the retaining clamp under the car seems to make it impossible to change the path the hoses follow from the underhood reservoir to the undercar master cylinders.

While working on the car, I also noticed that the clutch slave cylinder is weeping a little, so I think it's time to rebuild or replace it.

Two questions:

1. Does anyone know of a better way to route my brake-fluid supply hoses to protect them from being crushed in the future?

2. What's the best approach to resolve my slave cylinder drippage?

Your counsel and advice are sincerely appreciated.

-- Dan Somers

Cobra Dream

|

05-18-2008, 01:22 PM

|

|

CC Member/Contributor

|

|

|

Join Date: Feb 2000

Location: Greenville,

SC

Cobra Make, Engine: 70 Shelby convertible, ERA-289 FIA, 65 Sunbeam Tiger, mystery Ford powered 2dr convertible

Posts: 12,736

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Exit32

2. What's the best approach to resolve my slave cylinder drippage?

Your counsel and advice are sincerely appreciated.

-- Dan Somers

Cobra Dream |

Dan,

Don't bother rebuilding it, replace it.

Bill S.

__________________

Instead of being part of the problem, be part of a successful solution.

First time Cobra buyers-READ THIS

|

05-18-2008, 04:51 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Glendale,

AZ.

Cobra Make, Engine: Cobray-C3, The 60's body lines on todays chassis technology

Posts: 2,302

|

|

Not Ranked

Not Ranked

The master cylinders most often can be rebuilt but at a cost of 41% of a new replacement ...? Many are made of aluminum and the bore becomes pitted from the moisture/water absorbed by the fluid. If pitted honing the bore for proper seal fit is more difficult but it can be done in most cases.

Making a short steel line for each old rubber line may reduce the diameter enough to stop interference with the pedals as a guess??? Can you get to area well enough to fab steel lines past the problem area, you mentioned re-routing was not an option? You will find a fix I am sure.

|

05-18-2008, 06:46 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2006

Location: McKinney,

TX

Cobra Make, Engine: ERA GT #2077, 331 SBF, Webers, Gurney Eagle heads

Posts: 1,275

|

|

Not Ranked

Not Ranked

Outside the Footbox

Outside the Footbox

Dan, the later 731+ cars route these lines from the reservoir along the top of the frame rail and then just at the front of the footbox, they make a 90 deg turn and then another 90 deg turn into the front of the clutch/brake box. They do not go inside the footbox at all. If you want a pic, I will take one for you. But the lines are steel, changing to rubber hose just at the ends.

Good thing they are steel, because they pass about 1" from a header! I don't know if this will ever be an issue, but I wonder ...

Sam

|

05-18-2008, 07:23 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,014

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by SSSammy

If you want a pic, I will take one for you. But the lines are steel, changing to rubber hose just at the ends.

|

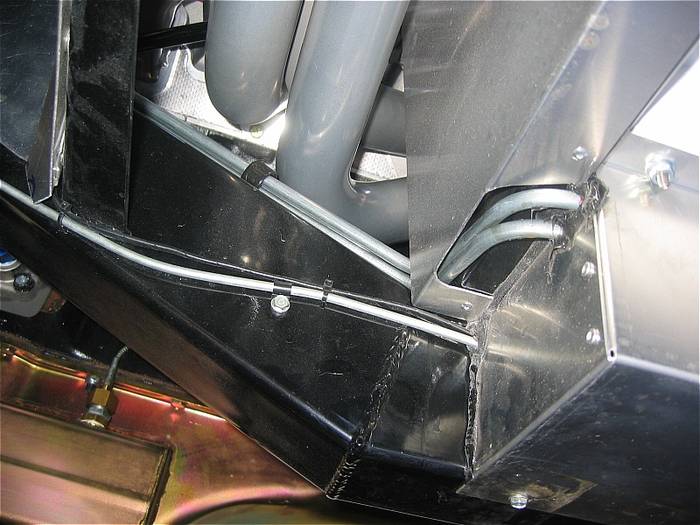

Here's a shot of mine.

|

05-18-2008, 07:36 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,014

|

|

Not Ranked

Not Ranked

Since it's a slow night...

Since it's a slow night...

... I'll post a couple more to give you a better idea of the proximity issue to the primaries (no problems yet, tho). And a shot of how it feeds out to the splitter that feeds the calipers.

|

05-18-2008, 09:44 PM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,605

|

|

Not Ranked

Not Ranked

Those pipes are way too close to the exhaust! You won't have a problem until its too late and you crush the front of the car. Put a stop under the pedal if you have to!  |

05-19-2008, 07:29 AM

|

|

CC Member

|

|

|

Join Date: Nov 2007

Location: Westford,

MA

Cobra Make, Engine: ERA, 427 side oiler

Posts: 6

|

|

Not Ranked

Not Ranked

I really appreciate all your replies, and I'm not surprised to learn that ERA has re-routed the brake-fluid supply lines in their newer cars (thanks for the update, SSSammy). Like CHANMADD, I'm also concerned about the close proximity to the headers shown in patrickt's excellent photos. I can envision boiling brake fluid inside the line after a long cruise on a hot day.

So far, I think the best solution for me is the one proposed by vettestr: "... a short steel line for each old rubber line may reduce the diameter enough to stop interference with the pedals ..." With two short steel lines inside the car, I can create a jog to avoid contact the bottom of the clutch pedal. This solution eliminates the need to drill holes in the brake box under the car and keeps the lines far away from hot headers.

At this point ol' ERA 452 is running fine, so there's no rush for me to tackle this project. If anyone has other suggestions, I'm listening. Guess I'll take mrmustang's advice and order a replacement clutch slave cylinder from ERA, too.

Thanks,

Dan Somers

Cobra Dream

|

05-19-2008, 07:35 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2006

Location: McKinney,

TX

Cobra Make, Engine: ERA GT #2077, 331 SBF, Webers, Gurney Eagle heads

Posts: 1,275

|

|

Not Ranked

Not Ranked

Just a thought

Just a thought

Your brake supply lines are rubber, so easy to cut some longer ones and just "S" them to the side a bit so they do not get struck by the pedal.

Sam

|

05-19-2008, 07:45 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,014

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by CHANMADD

Those pipes are way too close to the exhaust! /

|

That helps boil the moisture out of the lines.  Seriously, my previous shot was a little deceptive. There is about 3/4 of an inch between the supply lines and the lowest primary. Here's a better shot:

|

05-19-2008, 01:48 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,021

|

|

Not Ranked

Not Ranked

The proximity of the tubes doesn't concern me for two reasons:

1/ Heat will tend to rise from the pipes, so only radiant heat is a factor, mitigated by airflow. Note that the plastic-coated metal clamp still looks OK.

2/ Hot fluid doesn't flow into the master cylinder except under rare conditions. Namely, only after a major system leak has already occurred. Otherwise the hot fluid stays over a foot away.

Don't Worry. Be Happy!

|

05-19-2008, 01:50 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,021

|

|

Not Ranked

Not Ranked

Double Double Post Post...

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:57 PM.

Links monetized by VigLink

|