Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

12-27-2009, 09:25 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Broken Dove Rockers ??????

Broken Dove Rockers ??????

I would like to know from those of you that have had or are using Dove rockers.

Have you ever broken a rocker?

What was the cause of breaking the rocker, if known?

What is your lift on the camshaft?

What pressure springs are you using?

Cup size on pushrod?

Ball on pushrod?

I had 2 rockers break that I think is due to too much spring pressure.

Also would like to know what you did to correct it

|

-

Advertising

12-28-2009, 08:18 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Your rockers did not break because of too much spring pressure---your rockers broke because the rockers aren't strong enough for your springs

|

12-28-2009, 11:39 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

Have you ever broken a rocker?

|

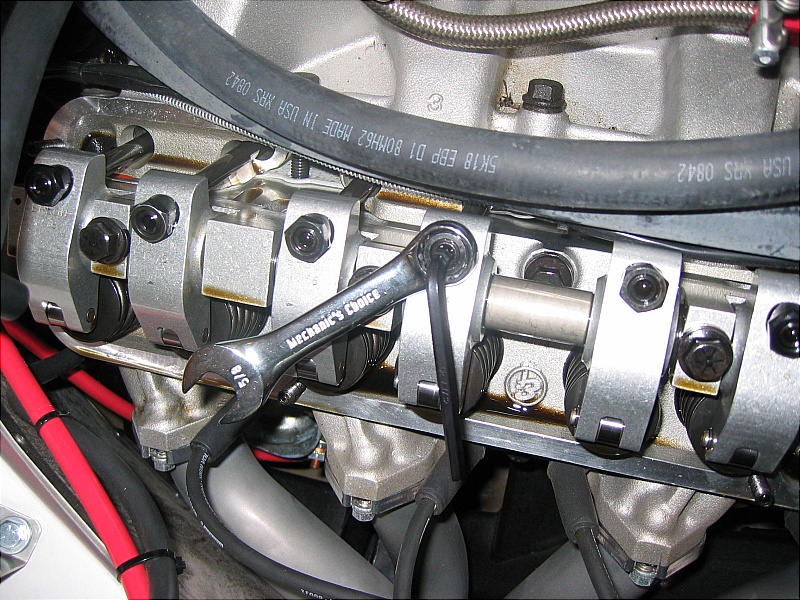

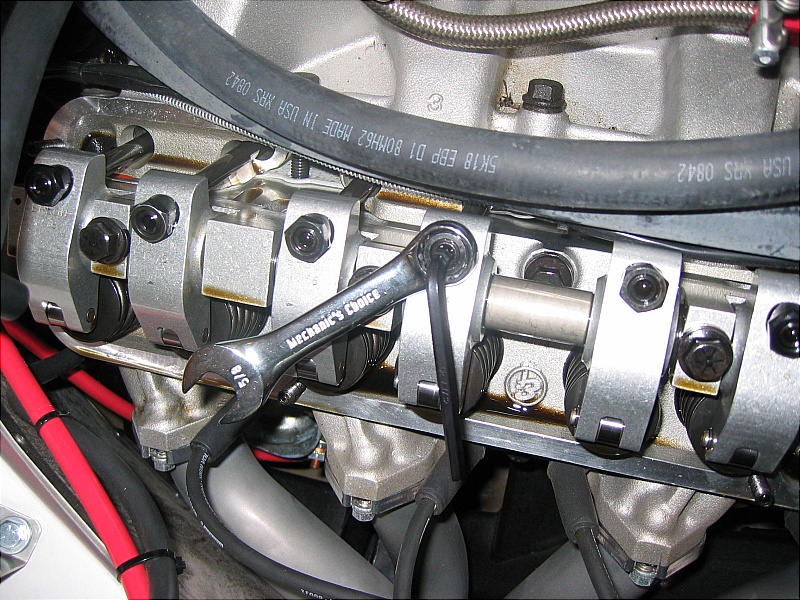

We had a member of the local club break a Dove rocker last year. You can read the thread here: http://www.capitalareacobraclub.com/...ic,7039.0.html and Jim later placed a pic of the sad rocker in his gallery. Here's the pic:

|

12-28-2009, 12:20 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,588

|

|

Not Ranked

Not Ranked

Phil, you may have already done this, but if you do a search on "Dove" and "rockers" or just "Dove" over on the FE Forum, you will see many threads about problems with Dove parts including Dove rockers.

I have no personal experience with Dove. Sorry.

|

12-28-2009, 12:27 PM

|

|

CC Member

|

|

|

Join Date: Sep 2009

Location: Sacramento,

CA

Cobra Make, Engine: ERA 707, 446ci FE

Posts: 1,115

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodKnock

Phil, you may have already done this, but if you do a search on "Dove" and "rockers" or just "Dove" over on the FE Forum, you will see many threads about problems with Dove parts including Dove rockers.

|

This thread is virtually a repeat of the still-live one on the same topic, started by the same OP. I'm not sure why.

__________________

= Si Opus Quadratum vis, angulos praecidere noli. =

|

12-28-2009, 12:34 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gunner

This thread is virtually a repeat of the still-live one on the same topic, started by the same OP. I'm not sure why.

|

Yes, but by starting a new thread he prodded me in to remembering that we had a similar experience locally just last year.  |

12-28-2009, 12:38 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

I just wanted to see how many others purchase this rockers thinking that the would hold up to normal driving.

These Dove rockers are obvisouly junk.

My resolution is to move to Erson. Now, I hope this solves my problem.

As you can see from the thread (link) from Patrickt Dove stated it was backed for life.

The removed this statement from there website. Go figure!

|

12-28-2009, 01:26 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

I've been running Dove rockers for a few years now and many thousands on miles. I doubt spring pressure is the problem. My old cam was a solid roller, motor would turn 7,000 rpm. Dual springs with a damper spring (three total), pretty high pressure springs, never had a rocker arm problem.

|

12-28-2009, 01:27 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

My resolution is to move to Erson. Now, I hope this solves my problem.

|

I love my Ersons, thank you very much.

Last edited by patrickt; 10-31-2016 at 01:45 PM..

|

12-29-2009, 10:37 AM

|

|

CC Member

|

|

|

Join Date: Sep 2009

Location: Sacramento,

CA

Cobra Make, Engine: ERA 707, 446ci FE

Posts: 1,115

|

|

Not Ranked

Not Ranked

Ewwww! Warn us if you're going to post pix of open-head surgery.

__________________

= Si Opus Quadratum vis, angulos praecidere noli. =

|

01-01-2010, 11:09 AM

|

|

CC Member

|

|

|

Join Date: Nov 2001

Location: Prineville,

OR

Cobra Make, Engine: Contemporary / FE

Posts: 130

|

|

Not Ranked

Not Ranked

Hello Priobe

May I make some points of consideration.

First of all I do not advocate any brand or detract from any brand. I have used Dove, Erson, Precision Oil Pumps, and T&D. I have not had any problems with any of them that I believe was attributable to the rocker arm itself. But the problems I have experienced are relative to two things. (The below is pursuant to high spring pressures. To quantify 250# closed and 620# over the nose.)

1. If the lash adjustment screw is screwed where more than two threads are below the body of the screw hole this will put excess leverage on the body of the rocker arm thus causing breakage. Make your pushrods to the length to accommodate this.

2. Pushrod whip. If the pushrods are not stiff enough then when they whip this puts tremendous load on the rockerarm during opening ramp excelleration.

3. When using Dove rockerarms I change the adjusters to ones supplied by Smith Brothers for Chryslers that have a 5/16" ball. Changing your pushrods to work with the 5/16" ball also lets you move the pushrod cup closer to the rockerarm.

I hope this helps.

|

01-01-2010, 11:44 AM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by concobra

1. If the lash adjustment screw is screwed where more than two threads are below the body of the screw hole this will put excess leverage on the body of the rocker arm thus causing breakage.

|

You may be on to something there. wow. thanks.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

|

01-01-2010, 12:44 PM

|

|

CC Member

|

|

|

Join Date: Jan 2009

Location: Hutchinson,

KS

Cobra Make, Engine: Spf Shelby alu block

Posts: 25

|

|

Not Ranked

Not Ranked

I have two sets of the Dove HD rockers (1.200” wide). with end stands. The oldest set is in a 427 that has 850 # of open spring pressure and the engine has seen 8500 RPM on the tach. I did pay close attention to the push rod length and had a custom set of manton pushrods made. No issues after 5 years. The second set is in a 427 that only truns 7200 RPM with 550 # of open spring pressure two years old, no issues. Custom manton push rods in this engine also.

SPF 2551 Lyle

|

01-06-2010, 09:27 AM

|

|

CC Member

|

|

|

Join Date: Apr 2003

Location: Central Texas,

TX

Cobra Make, Engine:

Posts: 88

|

|

Not Ranked

Not Ranked

Besides the pushrod being too short and creating some extreme leverage issues when the valve starts to open, two other things come to mind for the Dove (and similarly designed) aluminum rocker arms. The first is the age. Ten years of use is what I see as the limit before the rockers are 'fatigued' and just simply break. The other is side clearance. If the side clearance is inadequate, then when the rocker heats up and expands this creates a significant drag at the sides and puts it in a bind. I like a minimum of 0.030" of sideplay for the rockers.

I ran the bronze bushed aluminum rockers many years ago and had breakage issues from the start when using them with roller valve spring pressure requirements. I subsequently went with the Dove's and that particular issue went away but the breakage issues resurfaced when the rockers got several years worth of running on them. Just food for thought.

__________________

Ted Eaton.

Fe's are fast but "Y-Blocks" are fun when they run in the 9.60's at 135 mph.

|

01-06-2010, 09:50 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by spf2551

I have two sets of the Dove HD rockers (1.200” wide). with end stands. The oldest set is in a 427 that has 850 # of open spring pressure and the engine has seen 8500 RPM on the tach. I did pay close attention to the push rod length and had a custom set of manton pushrods made. No issues after 5 years. The second set is in a 427 that only truns 7200 RPM with 550 # of open spring pressure two years old, no issues. Custom manton push rods in this engine also.

SPF 2551 Lyle

|

SPF 2551,

Is this a drag motor... pressure at 850 open is pretty agressive. Also how old are these rockers.

After the first rocker broke I rechecked everything( not saying I am perfect) I really dont think it was a push rod length issue because everyone I spoke to including Dove said to make sure you have 3 threads out.

Now, I finally switched to the Erson and noticed just by changing to the Erson rockers I had 5 -6 threads at the bottom of the rocker. Many have said it should be fine and I probably would not have a problem.

Well, I decided to remeasure the pushrod length and to have the 2 -3 threads on the bottom of the rocker with the Ersons. I then cycled the motor several times to make sure the cup is not touching the bottom of the riocker.

It will cost me an additional $200 but will save me a possible tow home.

Its funny, since I had down time I decided to check a few things. If my push rods were at 8.926 and I had 5-6 threads at the bottom. Each thread being .050 I could have easily add .100 to my existing push rod .

My final pushrod length needed for me to have 2-3 threads were 9.037 (EA) or 9.197 for a overall length

|

01-06-2010, 02:41 PM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Location: West Bloomfield,

MI

Cobra Make, Engine:

Posts: 717

|

|

Not Ranked

Not Ranked

Sorry I could not get back to you on this - I found myself badly tangled up in non-work stuff for a few days.

I think you did the right thing on pushrod length. 5-6 threads is more than I like to see - I prefer 2-3. I measure my pushrods "bottom of cup" - using a modified pushrod length checker with a flat at the cup end and a 12" dial calopier.

__________________

Survival Motorsports

"I can do that....."

Engine Masters Challenge Entries

91 octane - single 4bbl - mufflers

2008 - 429 cid FE HR - 675HP

2007 - 429 cid FE MR - 659HP

2006 - 434 cid FE MR - 678HP

2005 - 505 cid FE MR - 752HP

|

01-06-2010, 08:36 PM

|

|

CC Member

|

|

|

Join Date: Jan 2009

Location: Hutchinson,

KS

Cobra Make, Engine: Spf Shelby alu block

Posts: 25

|

|

Not Ranked

Not Ranked

The rockers are 8 years old but have only been used the last 5 years. I just pulled the engine to freshen it up and the rockers look fine. The engine is in a street car. You can never have enought cam.

SPF2551 Lyle

|

01-07-2010, 06:52 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,380

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by spf2551

You can never have enought cam.

SPF2551 Lyle

|

Just curious,

What is your cam spec to be running those types of spring pressures? |

01-07-2010, 08:04 PM

|

|

CC Member

|

|

|

Join Date: Jan 2009

Location: Hutchinson,

KS

Cobra Make, Engine: Spf Shelby alu block

Posts: 25

|

|

Not Ranked

Not Ranked

I have found running a lot of spring pressure keeps the valve from bouncing on the seats and keep harmonics in the valve train down. I do run stainless valves 2.25 & 1.75 which are a little heavy. I also have tapered chrome moly push rods 7/16 x 3/8 which are a little heavy also. if you are going turn a little RPM you need to have good part. since it is just street toy I did not go with titanium parts so the heavy springs. Lift in. 774 ex.739

dur @50 in. 290 ex. 298. 15.7 to 1 compression two HP 950's over 800 HP

SPF2551 Lyle

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 11:15 PM.

|

Linear Mode

Linear Mode