Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

03-04-2010, 12:16 PM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Kalamazoo,

mi

Cobra Make, Engine:

Posts: 234

|

|

Not Ranked

Not Ranked

Lower radiator hose....help

Lower radiator hose....help

Hey gang

I have a 427FE and the AFCO radiator from FFR in my Factory Five roadster and I am looking for a lower radiator hose.

I have seen on the ERA website that you can cut a GY or Gates hose and use an aluminum center section for the straight away and piece together a hose, but I don't know what that aluminum straight away piece is from.

What has worked for you guys? I would like to keep something clean and origional looking and RUBBER hose.

Thanks

|

-

Advertising

03-04-2010, 12:31 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

It is just a piece of aluminum tubing with pieces of formed hoses on each end. Very easy to fabricate.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

03-04-2010, 12:39 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

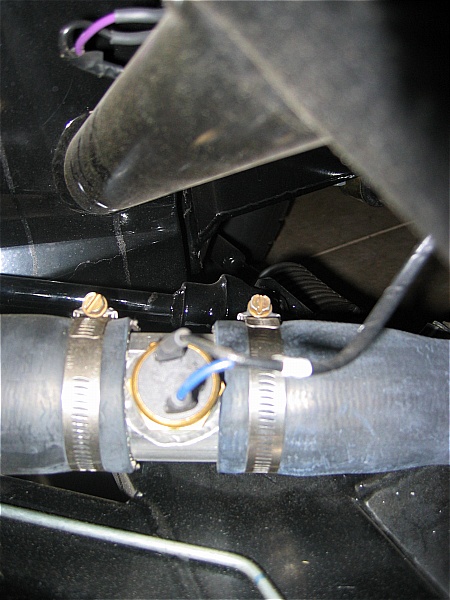

Often parts of two different formed hoses are used on the end of a piece of straight aluminum tubing. I had an unusual situation that required creating a "Hard tube" from several pieces of mandral bent aluminum tubing, it works quite well. Click on the picture for larger version.

[IMG]  [/IMG]

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

03-04-2010, 12:41 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,004

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dlotz

I have seen on the ERA website that you can cut a GY or Gates hose and use an aluminum center section for the straight away and piece together a hose, but I don't know what that aluminum straight away piece is from.

|

On ERA cars the lower radiator tube also houses the thermo-switch for the fans. It's just a steel tube though. If you can't find a perfect fit hose you could easily duplicate the ERA setup without the thermo switch and the tube would not be noticable.

Last edited by patrickt; 11-02-2016 at 12:32 PM..

|

03-04-2010, 01:33 PM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Kalamazoo,

mi

Cobra Make, Engine:

Posts: 234

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

On ERA cars the lower radiator tube also houses the thermo-switch for the fans. It's just a steel tube though. If you can't find a perfect fit hose you could easily duplicate the ERA setup without the thermo switch and the tube would not be noticable.

|

I think that is what I am going to do. I needed to find a location for my fan switch anyway!!!! I think that tube with the fan switch is a summit part. Does anyone have the part number? |

03-04-2010, 03:03 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2001

Location: Florence,

AL

Cobra Make, Engine: RCR GT 40 & 1966 Fairlane 390 5 speed

Posts: 4,511

|

|

Not Ranked

Not Ranked

I have a Lone Star with a small block. I drove my car with the hose under the frame for years but I was afraid it would hit something and leave me on the side of the road.

A couple of years ago I routed my lower hose over the steering rack and frame with two 1 1/2" copper 90's and and three short pieces of copper pipe.

I brazed the 90's back to back so I could route the hose up and over the frame. Works great.

Dwight

__________________

''Life's tough.....it's even tougher if you're stupid.'' ~ John Wayne

"Happiness Is A Belt-Fed Weapon"

life's goal should be; "to be smarter than inanimate objects"

|

03-06-2010, 08:23 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: San Jose CA,

CA

Cobra Make, Engine: SPF_R_/BRG/FRBoss302/327CI/FordEFI/Under_Car_Exh/

Posts: 2,523

|

|

Not Ranked

Not Ranked

We usually get aluminum tubing from "metal-Supermarkets" cut them to size, clean them up and even mill a hose clamp landing in them.

works great.

__________________

Steve SPF 2734 MK3 / Brock Coupe #54- panavia.com

|

03-07-2010, 12:14 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2008

Location: Jacksonville,

FL

Cobra Make, Engine: VSE alum. frame, FFR carbonfiber body (under construction)

Posts: 293

|

|

Not Ranked

Not Ranked

Get a piece of aluminum tubing, cut to length, then take it to a (hot rod) shop and have them put a bead around each end (so your rubber tubing can't pull off) with a bead roller.

Or try this:

http://www.pegasusautoracing.com/gro...COOLGAUGEADAPT

Last edited by COBRANIP; 03-07-2010 at 12:20 AM..

Reason: additional information

|

03-07-2010, 06:35 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Cheaper and not as pretty

Cheaper and not as pretty

dlotz You can also use exhaust pipe for this and it is cheaper and easier to get at any auto store, 3 things to do if using steel pipe, double clamp it 180 degress apart on both ends. Lite coat of grease on each end. If you can get someone to roll the ends 1 clamp will be fine. The other thing is to get a universal exhaust hanger for that size pipe and hook it to the frame and the pipe. This will take the load off the pipe and stop vibrations and have something come loose and could leak or break off. If you have a torch setup you can make your own pipe with a bead lock on it by cutting about 1/4" off the end and heating it until it expands and slides over the end of the pipe. Let cool and it will lock on. Blaze a coulpe of spots and it is good for life. Exhaust shop can do this too. Rick L.

|

03-07-2010, 09:36 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

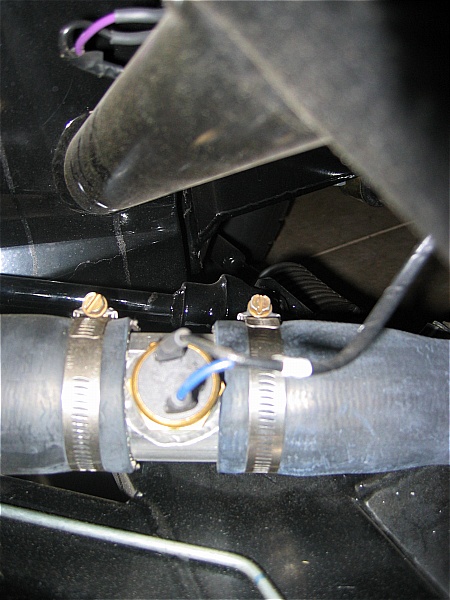

Each connection has the potential for a leak or failure, be sure they are secure. If you can't put a raised ring on each end of the metal tubes (sometimes difficult to find someone with "That" tool), put 4 "Dots" of weld material around the end perimeter of the tube which will prevent the hose clamp from sliding off. You can also put the fan switch in the RH lower radiator tank. I use the same 22mm fan switch pictured above, they are used on VW, Porsche and others.

[IMG]  [/IMG]

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

Last edited by Rick Parker; 03-07-2010 at 09:23 PM..

|

03-07-2010, 11:15 AM

|

|

CC Member

|

|

|

Join Date: Nov 2002

Location: Flanders,

NJ

Cobra Make, Engine: Classic Roadsters 351 Windsor 405 HP

Posts: 1,043

|

|

Not Ranked

Not Ranked

Check Jegs they have tubing and connecting pieces!

|

03-07-2010, 04:19 PM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Kalamazoo,

mi

Cobra Make, Engine:

Posts: 234

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by COBRANIP

|

This is what I am looking for but I cannot find it bigger than 1.5" I need at least 1 7/8"

Anyone know where I can get a bigger one? |

03-07-2010, 07:22 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

Dan that's an easy one for me to make for you if needed.

|

03-07-2010, 09:13 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

03-09-2010, 08:37 AM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Kalamazoo,

mi

Cobra Make, Engine:

Posts: 234

|

|

Not Ranked

Not Ranked

WOO HOO, more fabrication time!

WOO HOO, more fabrication time!

Ok

So I am going to make my own adapter here at work on the lathe. Here is my drawing/dims. Anything look wrong to you guys?

1/4 wall should be enough, but I am wondering if the barb should be deeper than 1/8"?

Should I make the O.D. on the adapter slightly larger than the I.D. on the hose say maybe 1/16" wider on each side (1/8" total) so that the hose has to stretch a little to get over the barb?

http://i108.photobucket.com/albums/n...radadapter.jpg |

03-09-2010, 08:59 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

I would make the OD of the tube the same as the ID of the hose, check the hose size is it 1.875" or 1.750? Check the part number of the lower hose with the manufacturer for sizing. You may have to start with 2" aluminum thick wall tubing. The barb does not have to be .125 deep to allow for retention of the hose .065-.080 is plenty, eliminate the sharp corner on the barb.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

03-09-2010, 09:16 AM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Kalamazoo,

mi

Cobra Make, Engine:

Posts: 234

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Rick Parker

I would make the OD of the tube the same as the ID of the hose, .

|

Meaning the O.D. of JUST the hose not including the extra for the barb depth?

Yes, I plan to round the edges. Didn't want to get too technical with MS powerpoint and paint! lol |

03-09-2010, 09:46 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

You're on the right track. I like these stainless ones and I just weld an appropriately threaded fitting in where needed.  |

03-09-2010, 11:23 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Edinburg,

TX

Cobra Make, Engine: Everett Morrison, All aluminum small block ford.

Posts: 436

|

|

Not Ranked

Not Ranked

Making the fitting slightly larger then the hose i.d. is a good idea. On your barb... .125 high barb is ok..but make sure you take the sharp edge of the inside lip. When the hose goes over that barb and you tighten it down with a clamp you can in time cut the hose if it has to make too sharp of a bend...especialy if there is 90* corner. Just my opinoin.

__________________

" If it wont break em loose in 3rd gear, it aint enough power "

|

03-09-2010, 11:26 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Edinburg,

TX

Cobra Make, Engine: Everett Morrison, All aluminum small block ford.

Posts: 436

|

|

Not Ranked

Not Ranked

forget what i said...someone else already said it.

__________________

" If it wont break em loose in 3rd gear, it aint enough power "

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:23 AM.

|

[/IMG]

[/IMG]

Linear Mode

Linear Mode