Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

03-19-2010, 11:25 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

Valve lash questions

Valve lash questions

I need to do my first valve lash adjustment (427FE, solid lifters, "B" cam, iron block and heads, standard bore/stroke, pertronix ignition, 11:1 compression) and have a few questions and unfortunately I just found out that my engine builder passed away in January (RIP Dwight Powell - neat guy if any of you ever had the luck to meet him).

Lash specs for my engine is .025". And I know that the range given by Ford (according to the Steve Christ book) is .025" - .027" with the higher end typically for setting the lash cold, which is how I plan to do it.

So my questions (excuse any dumb questions since this is my first time adjusting the lash):

1) After I set the lash and tighten it with the lash wrench, what is the proper final torque for the bolt? (I will recheck the lash to be sure it stayed in the correct position after torquing the bolt).

2) When finding TDC for each cylinder, is there any problem with backing up the engine a bit if I go to far? Or is TDC not that sensitive? After pulling the plugs, and getting #1 on the compression stroke, my plan was to use a wooden dowel in the spark plug hole to determine TDC for each cylinder. If I feel the piston starting to go back down, can I back it up? Not sure this is even possible, but I have seen it suggested, although I have also read that you should never back the engine up. Thoughts? Suggestions?

3) Lastly, since I can no longer talk to my engine builder and don't know what my spark plugs are gapped at, any recommendations? I will check the gap on all the plugs and can probably figure it out, but thought I'd ask. I have read .035-.040 is a good starting point. Agree?

Feel free to mention anything else that I might be missing.

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

-

Advertising

03-19-2010, 11:48 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

2) When finding TDC for each cylinder, is there any problem with backing up the engine a bit if I go to far? Or is TDC not that sensitive? After pulling the plugs, and getting #1 on the compression stroke, my plan was to use a wooden dowel in the spark plug hole to determine TDC for each cylinder. If I feel the piston starting to go back down, can I back it up? Not sure this is even possible, but I have seen it suggested, although I have also read that you should never back the engine up. Thoughts? Suggestions?

|

You don't have to do all that. The simple, tried and true method that has been done since the Romans lashed their horses is as follows:

1. Rotate the engine until the exhaust rocker goes down to open the exhaust valve. Set the INTAKE lash to your setting.

2. Rotate the engine until the intake rocker comes up to close from its full lift position. Set the EXHAUST lash to your setting. |

03-19-2010, 11:55 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

You don't have to do all that. The simple, tried and true method that has been done since the Romans lashed their horses is as follows:

1. Rotate the engine until the exhaust rocker goes down to open the exhaust valve. Set the INTAKE lash to your setting.

2. Rotate the engine until the intake rocker comes up to close from its full lift position. Set the EXHAUST lash to your setting.

|

If I do that, then I can set 1/2 the valves on the compression stroke for #1 and the rest on the compression stroke for #6, which is obviously a hell of a lot easier. My only issue is that Steve Christ recommends using TDC for each cylinder for higher lift cams, not sure exactly why. I am not quite sure my "B" cam qualifies for that, but wasn't sure.

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

03-19-2010, 11:55 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,591

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

You don't have to do all that. The simple, tried and true method that has been done since the Romans lashed their horses is as follows:

1. Rotate the engine until the exhaust rocker goes down to open the exhaust valve. Set the INTAKE lash to your setting.

2. Rotate the engine until the intake rocker comes up to close from its full lift position. Set the EXHAUST lash to your setting.

|

Yes, I remember the good old days when I had to adjust the solid lifters on my '66 427/425 HP Corvette.

Very nice succinct summary. |

03-19-2010, 11:59 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

If I do that, then I can set 1/2 the valves on the compression stroke for #1 and the rest on the compression stroke for #6, which is obviously a hell of a lot easier. My only issue is that Steve Christ recommends using TDC for each cylinder for higher lift cams, not sure exactly why. I am not quite sure my "B" cam qualifies for that, but wasn't sure.

|

If you do it my way, you absolutely can't make a mistake and you'll be safely on the heel of the lobe. Trust me. Just pay attention that you don't mix up the exhaust and intake valves -- that's easier to do than you think if your mind starts to wander. Remember that the exhaust valves on the FE point to the ends. Meaning, they are EI EI IE IE when you look down at them. |

03-19-2010, 12:19 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

If you do it my way, you absolutely can't make a mistake and you'll be safely on the heel of the lobe. Trust me. Just pay attention that you don't mix up the exhaust and intake valves -- that's easier to do than you think if your mind starts to wander. Remember that the exhaust valves on the FE point to the ends. Meaning, they are EI EI IE IE when you look down at them.

|

Alright makes sense. I am looking for the simplest method and this sounds like it. Any ideas on torque for those bolts? You thought 20-25 ft lb?

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

03-19-2010, 12:24 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

Alright makes sense. I am looking for the simplest method and this sounds like it. Any ideas on torque for those bolts? You thought 20-25 ft lb?

|

I torque my Erson Roller Rockers to 20 ft/lbs. You have a different valve train entirely. If no one gives you a better answer then flip a coin, if it comes up heads torque them to 20 ft./lbs., if it comes up tails then torque them to 25.  |

03-19-2010, 12:29 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

If anyone wants to chime in I have Harland Sharp roller rockers and Ferrea Racing 6000 Series Competition stainless steel valves.

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

03-19-2010, 12:43 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

If anyone wants to chime in I have Harland Sharp roller rockers and Ferrea Racing 6000 Series Competition stainless steel valves.

|

Harland Sharp Roller Rocker instruction sheet: http://www.harlandsharp.com/pictures...%20webpage.pdf |

03-19-2010, 12:51 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

Perfect, thanks! Guess I could have done that search, but appreciate the help.

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

03-19-2010, 12:53 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

Perfect, thanks! Guess I could have done that search, but appreciate the help.

|

That's the only way I can provide help that ERAChas doesn't rag on me....  |

03-19-2010, 12:56 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,591

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

That's the only way I can provide help that ERAChas doesn't rag on me....  |

I think the appropriate term is "fact checker." |

03-19-2010, 01:02 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

Thanks! Appreciate the help.

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

03-19-2010, 01:05 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Steve Christ is talking about "valve overlap". On some really wild cams both the intake and exhaust valves can be slightly open at the same time. If I was writing a book I'd put that "disclaimer" in there as well, every valve at TDC for adjustment. That way the advice is bullet and lawyer proof, even if it only applies to the rare situation.

|

03-19-2010, 01:10 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

Steve Christ is talking about "valve overlap". On some really wild cams both the intake and exhaust valves can be slightly open at the same time. If I was writing a book I'd put that "disclaimer" in there as well, every valve at TDC for adjustment. That way the advice is bullet and lawyer proof, even if it only applies to the rare situation.

|

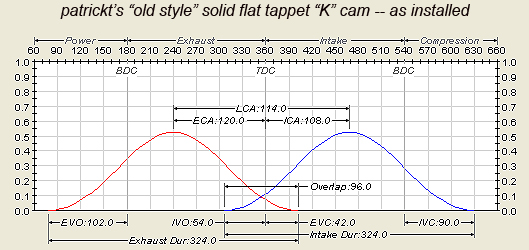

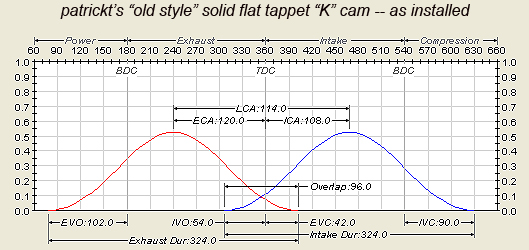

Doug's old "B" cam has a fair amount of overlap -- like 112 degrees, if memory serves. He has the step up from my "K" cam, which has 96 degrees of overlap, seat to seat. |

03-19-2010, 01:31 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

How do I determine overlap and can I use the simple method or do I need to use TDC for each cylinder?

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

03-19-2010, 01:39 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by dcdoug

How do I determine overlap and can I use the simple method or do I need to use TDC for each cylinder?

|

The simple method will work on every cam known to man, no matter how wild, or how much overlap you have. That's why it's the safest method to use. To calculate your overlap, you need to graph your cam events, like this:

|

03-19-2010, 01:44 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodKnock

I think the appropriate term is "fact checker."

|

Very helpful advice from my often abused and occasionally correct antagonist.

dc,

Don't get hung up on the adjuster torque, just get them as even as you can. A good tool for the job:

http://www.jegs.com/p/Proform/Profor...48239/10002/-1

You must know the size of the jam nut and screw slot to order.

DO check the torque of the bolts (or studs) on the center and end stands. Shoot for 45 LbFt. Work from center out. .025 is fine for cold adjustment.

If your Pertronix has no spark box (like an MSD) .035 is fine. If you do have a capacitive box, be around .045 to .049. When you get carbon stripes on the insulator, go back down a few thousandths.

__________________

Chas.

|

03-19-2010, 02:12 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

Don't get hung up on the adjuster torque, just get them as even as you can. A good tool for the job:

http://www.jegs.com/p/Proform/Profor...48239/10002/-1

You must know the size of the jam nut and screw slot to order.

DO check the torque of the bolts (or studs) on the center and end stands. Shoot for 45 LbFt. Work from center out. .025 is fine for cold adjustment.

If your Pertronix has no spark box (like an MSD) .035 is fine. If you do have a capacitive box, be around .045 to .049. When you get carbon stripes on the insulator, go back down a few thousandths. |

I have a similar wrench and the right wrench for the screw slot, need to verify the nut size and have emailed Harland Sharp about it.

I don't have a spark box for my Pertronix, so will go with .035. Actually, this brings up a question - when I took delivery of the engine, it still had points and the installer switched out the points for the Pertronix points replacement solution. Should the plugs have been re-gapped or would the required gap remain the same (not sure what they did)?

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

03-19-2010, 02:20 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Gap is the same as points-type- .035 is pretty close.

Also, did Dwight give you the cam card with the engine?

__________________

Chas.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:03 AM.

|

Linear Mode

Linear Mode