Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

04-28-2011, 02:06 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Since the QT has smaller amount of surface area, the unit area impact force is greater--

The force is more concentrated.

I have a Kieth Black Alum hemi that I'll get some pics of the bell housing end---it has 11 or 12 fasteners instead of stock 6, also have a blank motor plate and an Lakewood housing for some examples of mods, etc.

Problem is I have a new camera and I'm having problems downsizing pics for uploading.

|

-

Advertising

04-28-2011, 08:49 PM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Rockford / Mesa, AZ,

IL

Cobra Make, Engine: FFR, 347, 462 hp, 4 barrel

Posts: 487

|

|

Not Ranked

Not Ranked

Hi Jerry, I was speaking about the velocity of the parts of the flywheel or the input load. Now to address the strength of the bell housing and the fact one is a smaller diameter. The smaller diameter bell housing has an advantage in hoop strength assuming the same wall thickness.

This is very general and the specifics of the design and mounting can make a HUGE difference.

By the way we have to pass a containment analysis to qualify our equipment.

Lee

|

04-29-2011, 07:47 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Lee---I was extremely glad to see you join this thread as I know that the stuff you work on has some similar concerns---

Since in a clutch coming apart, most of the stuff will leave the explosion on a tangent line, the lakewood with its larger size will have a better deflection angle to slow the parts down. Also since the QT is closer to shape of the clutch assy, it will funnel all the parts to a more concentrated area along the front edge and it will get there at a higher velocity, causing more strain on the existing holes for starter and clutch arm openings.

This design was created as a replacement for a bellhousing in a vehicle and I applaud the effort in doing this, whereas the Lakewood was designed as a Scattershield for multi disc clutches in dragsters and actually got a big boost when SFI banned the Llum Donovan units, even with the steel liners. The requirement for scattershields in the bodied cars equipped with starters was when Lakewood started putting the starter pocket on them , however they remained round, and closed with the front plates bolted with 25 (I think) bolts to the can.--this is where the QT comes up short---out of all there units, only a very few have all the fasteners, and of those that do, ground clearance will suffer.

I am going to take a bunch of pics today of a lakewood from one of my pro stocks and also a couple of block plates plus a 1/4 7075 alum mid plate like is used in real race cars, plus the back of a few blocks to show how race blocks vs oem blocks are

Lee--this wasn't all directed at you, sorry if it reads that way---see you thursday??If your coming maybe I can bring all the parts and you as a engineer can help with the proper terminolgy and photos

Last edited by Jerry Clayton; 04-29-2011 at 07:50 AM..

|

04-29-2011, 09:50 AM

|

|

CC Member

|

|

|

Join Date: Jan 2005

Location: Rancho Cucamonga,

ca

Cobra Make, Engine: SPF 239

Posts: 820

|

|

Not Ranked

Not Ranked

Jamo,Ron,

I have walked away from the fight!

I hope this is ok? Not trying to be disobedient. Just asking a question…

Jerry and Lee,

What is your position on the net affect of the significantly higher tensile strength/lower ductility of the QT housing?

My belief is that it is more resistant to deformation and therefore transfers a larger portion of the total energy into the block mounting points.

Jason

Last edited by D-CEL; 04-29-2011 at 10:04 AM..

|

04-29-2011, 10:41 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Jason

I hope it isn't appearing that this is a fight about these bell housings, but a little enlightenment---I have said that I have had 2 failures over the years--one on my 1955 ford back around 1960 and one on my 64 Cyclone while at the drag strip in Pheonix City Ala. The 1955 was a stock bellhousing and flywheel--guess it was only a matter of time til it came out but at that point in time you had to weld fab 1/4 steel over and around your clutch/trans for riles and that didn't keep anything from coming out---just protected driver/pass

My 64 Comet cyclone with hp 289 toploader was a factory housing that was sorta accepted for super stock comp---it failed and the floor /dash was just strong enough to slow the pieces that they didn't exit the roof--

In both cases, bolt bosses were blown out of the block-----and the 63 broke 2 ears off the toploader---

Moving ahead to top fuel--some of you know that I was involved in NHRA,AHRA top fuel racing---couple of pics in my gallery--

They used to weld up a piece of lke 12 inch steel pipe(maybe pipeline type?)with a flat piece on the back to hold a bearing for the input shaft-- then Ed Donovan made a hydroformed aluminum canthat was much nicer and of course lighter.Later SFI (or whoever)required a chromemoly 1/8 liner with some method of anti rotation plus a engine plate between the can and block--up to that time the mounting plates were just that--plates to mount the engine into the rails of the dragster and most(all) had the big cut out so you could remove the plate without taking off the flywheel(important then for engine changes) The new motorplate also was only allowed the had 2 small holes in it for air to the clutch(slipper clutches get very hot)and to retain debries inside the can in event of explosion.

Then they required steel housings!!!!!!Donovan freaked quit making them and Joe Shubeck at Lakewood made them ---they were 3 times as heavy but did the job--later someone made them from titaium which were mainly $$$$$$

When people needed them for the bodied classes--Joe added the starter pocket-but they were still big barrels---later they started modding the shape to fit vehicles bodies floorboard ---

Now Quick Time comes along and I think originally that he was a sprint car /modified type racer who made a nice adapter bell housing---as he added various applications they didn't get tested/approved but in my opinion there were enough people buying them it didn't matter so they made them---I think that the people fixing up there cars, adding TKOs,etc wanted a bell housing and that somewhere it got lost that these weren't fully what most people thought they needed, but bought anyway or was done by the installers.

I am going to try to take some pics today of a Kieth Black alum hemi, a Lakewood, some engine plates and a midmount plate of 1/4 7075 Alum.

So stay tuned

|

04-29-2011, 02:17 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Got the pics taken, now got to download them, resize them and get them posted

Well I got them loaded into my gallery but couldn't get them here--they are IMG 0122thru 0137

I thought i hade description with them but can't get it now--they may be there so if one of the Mods can help I would appreciate it.

Jerry

Last edited by Jerry Clayton; 04-29-2011 at 03:41 PM..

|

04-29-2011, 05:35 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

|

04-29-2011, 06:09 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

[img]img_0122_640x427_[/img]

|

04-29-2011, 07:30 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

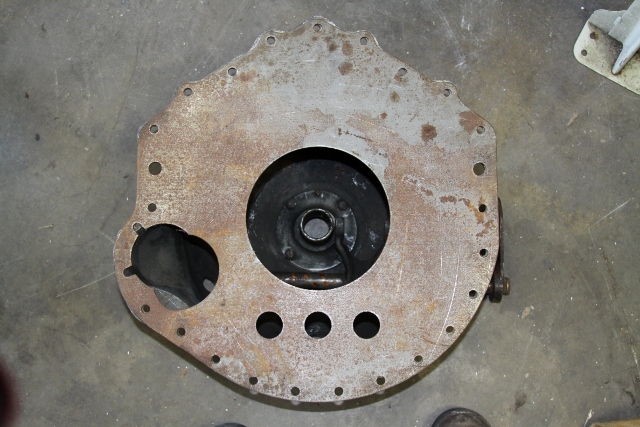

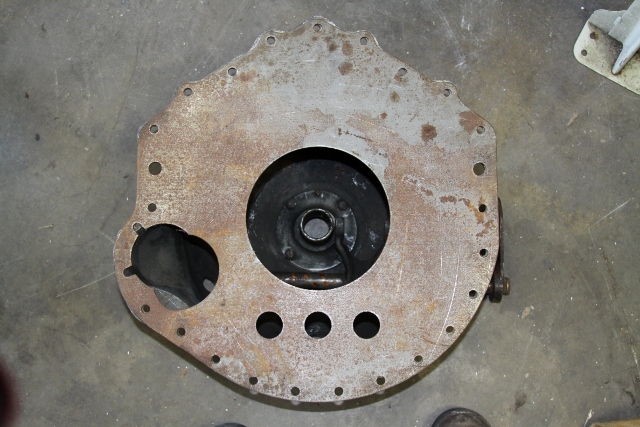

This is a Lakewood block plate for a Ford big block--notice the number of bolt holes around the outer edge and also the 3 holes for air and the starter pocket ring.

Last edited by Jerry Clayton; 04-29-2011 at 07:32 PM..

|

04-29-2011, 07:36 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

This is the block plate for a Chev--notice the same setup as for extra bolts as the Ford. It is also laying in place on the Lakewood

Last edited by Jerry Clayton; 04-29-2011 at 07:38 PM..

|

04-29-2011, 07:46 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Here you can see how the bottom was allowed to be trimmed for ground clearance and also the clutch crossshaft and throwout bearing |

04-29-2011, 07:50 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Here you can see just how much was trimmed and the 2 holes that were drilled for extra bolts to fit the minimun spread measurement |

04-29-2011, 07:54 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

This is the SFI 6.2 sticker that was issued AFTER the mods were done!! you can also see the cover for the hole to adjust/change clutch weights/arms/levers |

04-29-2011, 07:57 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

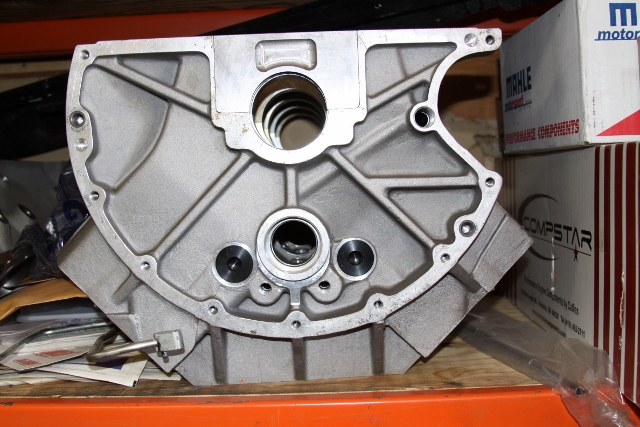

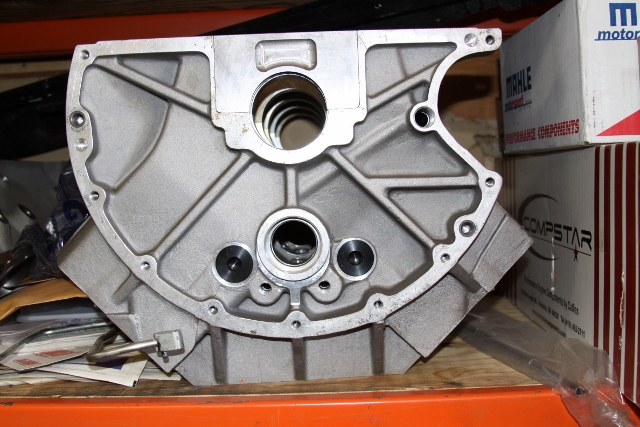

This is a rear view of a Kieth Black Hemi that shows the extra bolt holes for fastening the scattershield |

04-29-2011, 08:00 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

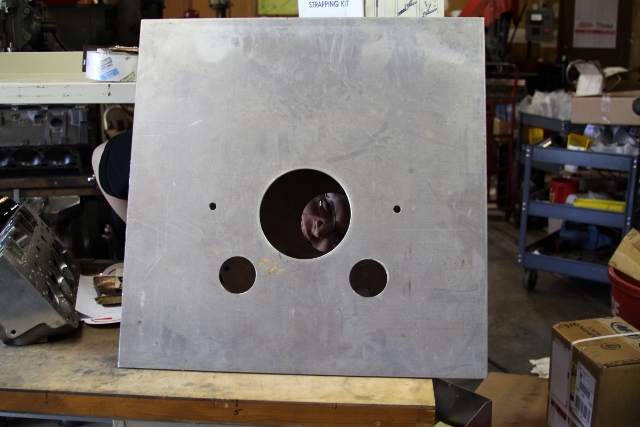

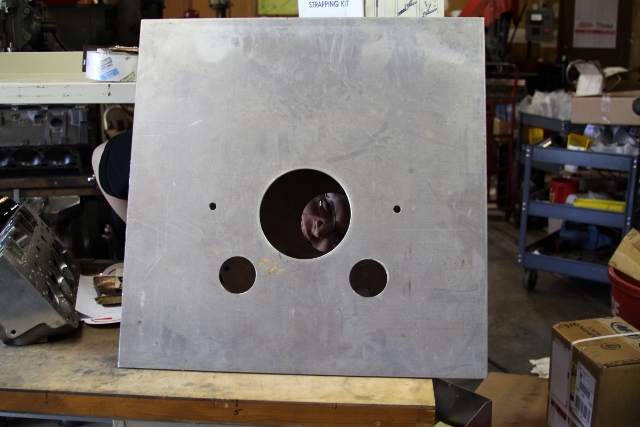

This is a pic of the 1/4 inch 7075 t6 alum blockplate required between the engine and scattershield--visable are the 2 holes allowed for venting

the 2 little holes are for the alignment dowels in the block. |

04-29-2011, 08:03 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

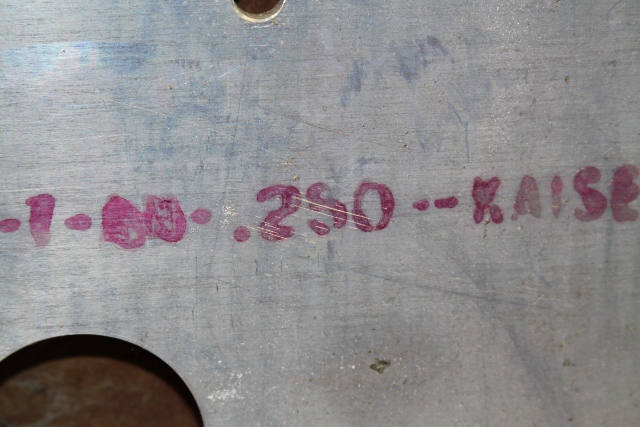

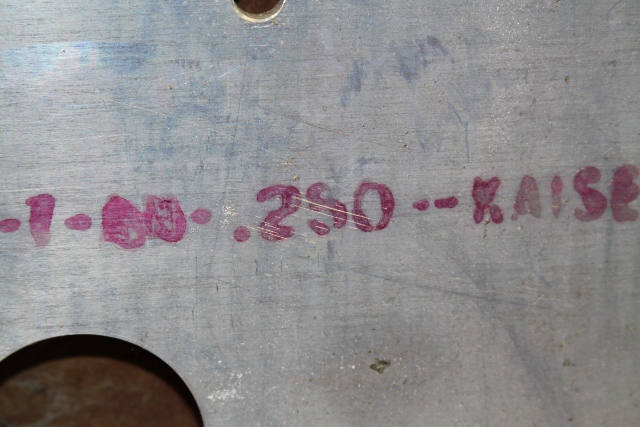

This is the alloy grade marking that can't be removed ---7075 t6 |

04-29-2011, 08:05 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

this is the thickness marking that can't be removed .250 supplier Kaiser |

04-29-2011, 08:09 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

And this was totally destroyed 9-11-2001 in a test of the design used in the World Trade Center Twin Towers

N612UA Flew it many times and several countries |

04-29-2011, 10:17 PM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Location: Rockford / Mesa, AZ,

IL

Cobra Make, Engine: FFR, 347, 462 hp, 4 barrel

Posts: 487

|

|

Not Ranked

Not Ranked

D-Cel you asked:

"What is your position on the net affect of the significantly higher tensile strength/lower ductility of the QT housing?

My belief is that it is more resistant to deformation and therefore transfers a larger portion of the total energy into the block mounting points."

My reply:

The short answer is no. The best material selection would be high strength and high ductility. That is one reason why the block bolts material failed in the photos, i.e. low ductility of cast iron. The reason is you want the material to absorb the most energy. Think of it as similar to the crush zone in our modern cars, absorbing the energy of a crash in the least distance.

If I were to design a bell housing, my goal would be to contain all parts within the bell housing. However that may mean the supports, if cast iron, may fail. As long as the casting and the bolts do not become projectiles then that would be acceptable. Holes in walls or injury to people are not acceptable.

I am reminded of an old saying about design. The main issues are to design for performance, reliability and cost. If you only concentrate on two of the three, then it is like designing a three legged stool with two legs. It does not work. I say this because the above are very simplest points to designing a bell housing, many many more issues have to be determined and the company must make money to stay in business also.

D-Cel, that is a good question and thanks for the chance to reply. I hope this helps explain the reasoning why hi strength and ductility are the better material for this application.

Note, where I work we must do containment analysis in case our rotors fail. Think of a 78 lb rotor at 16000 rpm and what could happen.

Jerry, no problem. I did not see anything you said that could possibly bother me. I will not likely be there Thursday, but am going to car show Sunday and likely the one on May 15. Hope to see you soon. Oh yeah, I know that airplane and am very familar with some of the parts, like the IDG.

Lee

|

04-30-2011, 03:33 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Up kinda late Lee??

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:23 PM.

|

Linear Mode

Linear Mode