Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

10-20-2011, 04:56 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

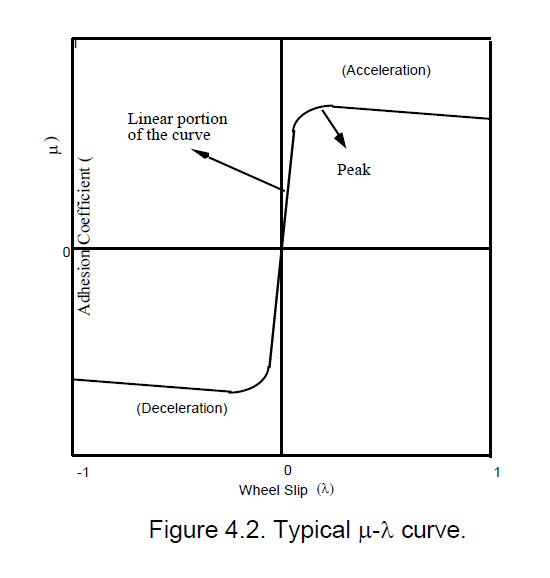

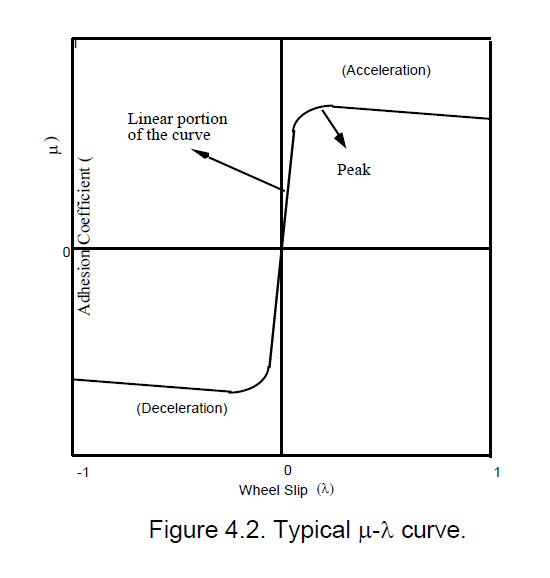

Here's a Graph

Here's a Graph

Rick, I still want someone to explain why I would want a clutch that held more than the PEAK point plus a small safety margin. I think Brent is on record here stating that as clutches go up in "hold" ability, so does the chatter on the street.

Last edited by patrickt; 11-02-2016 at 01:11 PM..

|

-

Advertising

10-20-2011, 06:19 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,285

|

|

Not Ranked

Not Ranked

It's more than the clutch's ability to hold a given horsepower/torque. The "stupid sliding weights", are pretty much useless, 'cept when you push in the clutch for a fast 5500 rpm shift and the weights keep the disc firmly pressed to the flywheel. Ask me how I know...

As far as strength goes, I've found a good OEM clutch (not parts store special) to have better clamp than CF's Dual Friction. I've had several run-ins with CF with my small and big block Chebbies.

For the OP, I run the aluminum SFI RAM flywheel on my KC Pond 482 with a single disc RAM 2600lb long style clutch and a sintered iron disc. I'm part of Rick's 600/600 club and have put 8000 miles on the setup with never a slip. Engagement it pretty smooth too. I also run drag radials all the time and have been know to lift a front tire or two

FWIW, it was the KC's clutch of choice when I bought the setup. I do think that if I was to do it now I'd go with one of Rick's dual disc setups. You just can't beat the grip, coupled with the s-m-o-o-t-h engagement. They're 2+ times the cost though.

__________________

Too many toys?? never!

|

10-20-2011, 06:23 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Forget Centerforce for the moment (and yes we removed those little gimmicky weights). Is there a benefit to having a clutch that has a hold ability that is greater than the peak point on the graph? And if so, what is it?

|

10-20-2011, 07:01 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

I usually aim for the engine's horsepower + 10%. That way if the customer decides that he/she wants to hit it one time at the strip with drag radials or slicks, the clutch will hold.

You're right, as the clutch disc's coefficient of friction goes up, the possibility of clutch chatter goes up as well. However, the weight of a Cobra really helps out here (as does a lower rearend gear ratio) and I can usually match a Cobra up with a sintered iron clutch disc and not have any issues. Where I really have to watch my P's and Q's is when I spec a clutch for something like a Galaxie or Fairlane with a 3.00 gear.

|

10-20-2011, 07:10 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

You're right...

|

Well, that answers that. And I was thinking that I was gonna have to challenge Undy to calculate the slope of the tangent line on that there curve.  Bet he was sleeping that day, though.  |

10-21-2011, 05:27 AM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Blitchton Ga,

Ga

Cobra Make, Engine: Superformance aluminum427

Posts: 188

|

|

Not Ranked

Not Ranked

Starter Ring

Starter Ring

I have a 484 BB FE motor with a Meleod aluminum flywheel that has a bad place on it where the starter won't engage have any of you guys had to replace the flywheel starter ring. Looks like the easest way to replace is pull the motor. What do yall recomend replace starter ring or new flywheel. Its a SPF Cobra

|

10-21-2011, 05:34 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by flipscobra

Looks like the easest way to replace is pull the motor. What do yall recomend replace starter ring or new flywheel. Its a SPF Cobra

|

If it were me, I wouldn't pull the motor -- just unbolt it off the back of the crank while the engine was in the car (now I don't know SPF tunnel configurations, but if you can remove the bellhousing while the motor is in the car there's clearly enough room to remove the flywheel). And if that flywheel was kind of funky to begin with, I'd just toss it and buy a brand new one. I wouldn't screw around with changing the ring. |

10-21-2011, 05:55 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by flipscobra

I have a 484 BB FE motor with a Meleod aluminum flywheel that has a bad place on it where the starter won't engage have any of you guys had to replace the flywheel starter ring. Looks like the easest way to replace is pull the motor. What do yall recomend replace starter ring or new flywheel. Its a SPF Cobra

|

I'd replace the starter ring....lot cheaper. |

10-21-2011, 10:24 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Any chance of seeing a picture of the damage?

Any chance of seeing a picture of the damage?

Flipscobra Any picture of the damage. Does your bellhousing have a block plate? What kind of starter do you have? If you are running a mini starter without trimming the block plate you will have only about 1/2 or 3/4 complete contact of the stater gear to the fly wheel. I had this problem with a mini starter. Something to check. Some guys machined the starter housing down .060" to help with engagement. If the flywheel was balanced with the motor, repair it, shop araound and compare repair against replacement of the flywheel. What condition is it in?? Rick L.

|

10-21-2011, 10:38 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

pressure plate load was how clutches where sold

pressure plate load was how clutches where sold

PatrickT. Pat in the old days clutches where light duty, heavy duty, and hauling or towing rate. 11- 12" clutches where a standard and in some cases still are for diesels. Gas cars have gone to twin disc with GM V8 motor stick cars. I ran 2,600 pound pressure plates in my CJ5 jeeps with stock motors, race motors went to 2,800 lbs. All ran organic discs. Never like metal ones or solid hubs. There where stronger, but no my favorate. I don't know what the street twin pressure is but with 2 10.5" discs, that's alot of holding surface. You can also run a pressure plate with 1,800 pounds of holding power. I'm guess but think the gold centerforce pressure plate is 22-2,400 pound of holding without the weights adding force to act as a lockup under high RPM's. I had nothing but problems over 3,400 rpms with shifting with the weights. I believe that some cobra manufactures sell there car with Centerforce but remove the weights. I learned to back in 98 and 6,000.00 dollars later. That was the price of 2 trannies. I do like your chart but it is not real life or street. Theory is just that. Have a good weekend. Last question, do you have 4 years to spare, looking for a sharp guy to run for the white house.  WE NEED A GUY LIKE YOU.  Rick L. ps have a nice weekend.  Undy would vote for you too. You have 3 votes and not even started.

|

10-21-2011, 10:40 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RICK LAKE

|

I would never make it past the vetting process.  |

10-21-2011, 11:17 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RICK LAKE

PatrickT. Last question, do you have 4 years to spare, looking for a sharp guy to run for the white house.  WE NEED A GUY LIKE YOU.:MECOOL |

Rick-kill yourself.

__________________

Chas.

|

10-21-2011, 01:05 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

I would never make it past the vetting process.  |

They would just have to change it to a Cobra-ing process...................  |

10-21-2011, 03:07 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Blitchton Ga,

Ga

Cobra Make, Engine: Superformance aluminum427

Posts: 188

|

|

Not Ranked

Not Ranked

Starter Ring

Starter Ring

Hi Rick my car is running a mini starter a Mcleod, I found out it was not engaging when I took it off, it looks like it was engaging about half to 3/4 its still got teeth at the back of the flywheel, do not have pictures, if it would go in about a 1/4 inch more probaly would not have to do anything. Thanks

|

10-21-2011, 03:15 PM

|

|

CC Member

|

|

|

Join Date: Jun 2007

Location: Blitchton Ga,

Ga

Cobra Make, Engine: Superformance aluminum427

Posts: 188

|

|

Not Ranked

Not Ranked

Starter Ring

Starter Ring

Hi Patrick, looks to me like its easier to pull the motor than have to open the cover, I would rather do it your way but looks like a lot more trouble, I haven't made up my mind yet as to wich I am going to do it. It still will crank as long as it does'nt stop on the bad place, thanks for the comment. Flip

|

10-25-2011, 03:32 PM

|

|

CC Member

|

|

|

Join Date: Oct 2011

Cobra Make, Engine:

Posts: 11

|

|

Not Ranked

Not Ranked

I was going to mention what would be better for the street the aluminum or steel inertia wise. One thing I was wondering should a guy have his driveshaft checked for balance since he should have the engine rotating assembly balanced? Bob.

|

10-26-2011, 10:45 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Few thoughts/comments

Yes driveshaft turns at engine speed so should be balanced, u-joints in proper phase and straight--also with such a short shaft , u-joint angle is critical

We have a customer with original Shelby gt500 mustang that we built a stroked center oiler for--he used a centerforce(I am a long time friend/fan of Bill Hays) aluminum flywheel and is on his third one in a little over a year---starter ring gears aren't shrink fitted to the wheel but are fastened with 3 tabs around the outside--now they have gone to 6 tabs--these keep coming loose----

The sprung hub clutch discs have various numbers of hub springs and some are dampened with rubber slug inside the spring--this will kill off the chattering on engagement

Lots of chatter comes from hanging the trans by the input shaft during install bending the disc so that it doesn't made full disc contact upon engagement

same deal on having difficulty engaging gear at a standstill---clutch won't fully didengage because its bent

From my days of top fuel/funny car and pro stock racing I have a container (tank/artillery shell) full of matched springs grouped by pressure, adjustable stands, and a tool box full of weights, arms, etc---I'll try to get a pic of some of the stuff, altho it doesn't apply to this, it will maybe open some eyes as to what these things do to the clutch operation

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:23 PM.

|

Bet he was sleeping that day, though.

Bet he was sleeping that day, though.

WE NEED A GUY LIKE YOU.

WE NEED A GUY LIKE YOU.

Linear Mode

Linear Mode