Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

06-26-2011, 10:18 AM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Neutral

Neutral

My first FE malady

My first FE malady

OK, I was going to take my newly finished Cobra to work after lunch because some of my friends there wanted a look and you gotta give the fans what they want right? When I started the 468” FE it sounded sick on the pass side, as though it were missing consistently on one cylinder. I shut it down immediately (it ran for maybe 45 seconds and oil pressure was about 85 psi) and pushed it inside to check things out. The first things to check were the spark plug wires, but for me to get my hands down there I have to pull the huge Holman Moody VCs off. When I got the vc off I saw that I was missing a rocker adjusting nut on the #4 intake and it was nowhere to be found on top of the head. So I started peering down into the lifter valley with a light to no avail. Then I removed the rocker assy. and push rods to get a better look. At this point I was still thinking “Oh, it’s not too bad. I’ll find this little bastage, fish it out with a magnet and I’ll be home free.” Right? Wrong-O o diseased yak breath! The thing was nowhere to be found in the lifter valley.

So I knew that I had to pull the pan and my mood was growing darker. Then, whilst standing there looking at the head trying to come up with a reason NOT to do this, I noticed that the valve stem on the offending valve wasn’t protruding from the retainer as much as the other valve stems were. In fact, it was damn near flush with the retainer and it looked like the retainer had come in contact with the rocker. Go over to the bench to look at the underside of the rocker and there’s a nice silver half circle showing where the retainer did indeed hit the rocker. WTF!? Now the head has to come off as well and I want to get it to the machine shop that assembled them before they close on Friday afternoon. So I thrashed to get the head off and to the shop where they to initially scratched their heads like I did. It looks like the keeper had somehow collapsed down inside the retainer and was slowly getting pulled down through it allowing the retainer to rise higher and higher on the valve until it came in contact with the rocker. I think this is when I first heard something wrong with the engine because this valve wasn’t operating properly. So they’ll be disassembling the head to check it out. Right now “WTF over?” is still going through my head.

But I digress; back to the rocker nut saga we go. So I get back from the machine shop and start my quest for the “F-ing” nut again. You know what? Pulling an oil pan on a BB Cobra can be just as much of a hassle as pulling a head that’s retained by studs in the same car. When I installed the op I used “The Right Stuff” on the pan side of the gasket and nothing on the block side thinking that if I did have to pull it later that this would make it easier. Right? Wrong-O again o diseased weasel breath! I must’ve pushed every flat blade screw driver that I own (that would fit up in there at least) between the block and pan before I could get that f-ing thing popped loose. When it finally does come loose, again I see no nut and again I think “WTF!?” At that point I set about cleaning the pan while straining everything that came out through a stainless mesh to ensure that I don’t miss anything. While getting into the baffles and trap doors I see something that looks like a small piece of rubber belt or something of that nature. But when I rotate the pan it sounds metallic and when I fish it out I find that it’s a piece of the wayward nut. I wound up finding 2 more pieces that together I’m pretty sure constitute the whole thing. So this nut came off the rocker, fell into the lifter valley, through the reciprocating mass, got chopped up in the process and came to rest in 3 pieces in the pan. The crank and rods are a KC stroker kit and fill the block pretty well. In looking at the assy. I can find nothing that would show that nut’s passage from up top to the pan. The whole reciprocating assembly looks (for lack of a better way to say it) perfect. Really, it looks better now than when I buttoned it up with all that assembly lube and junk on it. Just for the heck of it I checked the #4 rod bearing and it’s perfect as well. Except for the fact that there is oil all over everything in there you can’t tell that the engine has ever been run. Of course it only has about 200 miles on it to.

So now I’m waiting on the machine shop to tell me what they think happened with the valve. I’m tempted to rip apart the rest of the motor to see if I can find any damage that might have been done by the nut but I really don’t think that I’d find any.

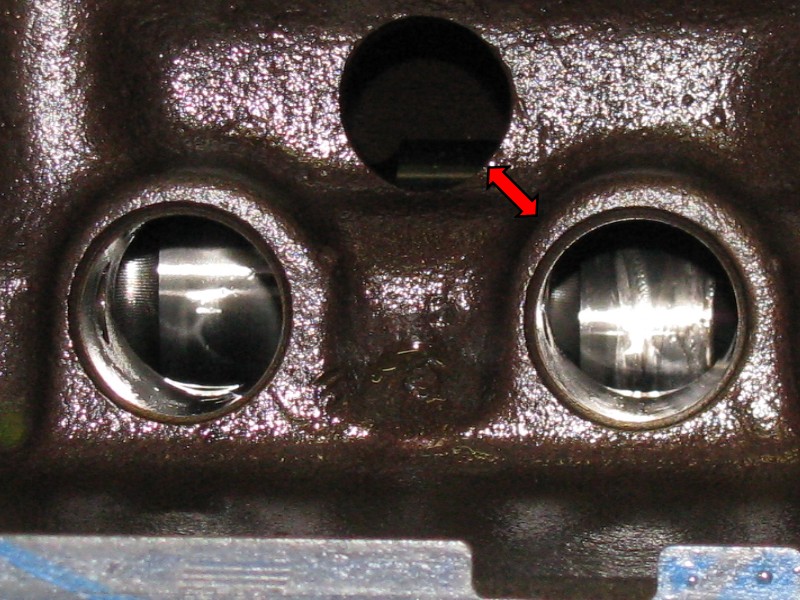

The offending nut:

The rockers during assy.

Last edited by lovehamr; 06-26-2011 at 02:36 PM..

Reason: spelling

|

-

Advertising

06-26-2011, 10:42 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

Hmmm, I've had adjusters come loose before.......detonation will do this sometimes, or simply they just come loose, it looks like it split then fell off the rocker, .......overtightened? maybe ......maybe not......

in any event the nut did get mushed by something, the rocker, a spring,

down in the lifter valley somewhere. if the machine shop doesn't find a place of impact you should go on a fact finding disassembly. pull the intake first...

inspect every valve train component....

i can empathize with your frustration, i'm in " lost a roller lifter" sadness myself........

__________________

Fred B

|

06-26-2011, 10:47 AM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

FWB, intake's off, head's off, all the lifters out and cam lobes inspected.

What type of roller lifter did you loose? Sux.

|

06-26-2011, 11:08 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

freakin comp cams......had 6500 miles on a new set.......i now have a thousand dollar date........no comp cams anything will go back in my motor.

i'm looking at isky and crower for lifters....and the jury is still out for a camshaft......in shopping for lifters comp cams is the cheapest, prolly a reason for that.....seems every cam manufacturers tech says the roller lifter failures they have seen seem to be comp cams......a red flag should have gone up when i got a set of 460 lifters boxed wrong as a FE set....

so with your day-mare....no signs of impact? could the nut have wedged between the rocker and the retainer? i would also be looking at the cam, see from underneath if any wedge impact with the cam and the underneath of the block in the lifter valley area.....it had to fall thru the hole between the intake and head.....if it fell into the head around the springs it would have still been there when you pulled the cover...so impact was either on the retainer or with the cam and block....or a crank throw and the block

__________________

Fred B

|

06-26-2011, 11:58 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Mismatched angles on the locks/retainers?

|

06-26-2011, 12:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: Arkadelphia, AR,

AR

Cobra Make, Engine: Kirkham 427 brushed aluminum with Keith Craft 527C.I. all aluminum FE

Posts: 992

|

|

Not Ranked

Not Ranked

Got to love this damn engine stuff. All it takes is one little part failure to cause a lot of problems. Hope that everything is ok. It sounds like you have a handle on most of it. If the camshaft and other parts look ok you may be fine. I would wonder why it did this in the first place. If the nut got loose and the adjuster backed of it cold have had quite a bit of lash and been popping the valve around on the seat and knocked the lock out. Just hard to tell which happened first.

Good luck, Keith Craft

__________________

Keith C

|

06-26-2011, 06:29 PM

|

|

CC Member

|

|

|

Join Date: Jun 2011

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

We have come accross quite a few instances where the locks pull through the retainers and nearly every time it's a valve spring problem. Either wrong springs fitted or incorrect spring height giving insufficient pressure leading to valve bounce. Don't dismiss it as an option, valve bounce will destroy most things, even loosen adjusting nuts like your's.

The worse case we had was on a Cleveland, wrong springs gave only 40 lb seat pressure, by the time the locks had pulled through it had 15 lbs, yes 15 lbs seat pressure.

I am sure yours will check out OK, but I know that's the first thing I would be looking at.

Mike

P.S. that said, we have also had retainers with no heat treat, make sure they're not Chinese !

Last edited by Mike Huddart; 06-26-2011 at 06:32 PM..

|

06-26-2011, 06:43 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Thanks for the ideas guys. Keep'em coming.

Steve

|

06-26-2011, 06:56 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

The odds are on that you left that nut loose while adjusting valves

|

06-26-2011, 07:08 PM

|

|

CC Member

|

|

|

Join Date: Jun 2011

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jerry Clayton

The odds are on that you left that nut loose while adjusting valves

|

But that wouldn't cause the locks to pull through the retainers.

Mike |

06-26-2011, 07:44 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jerry Clayton

The odds are on that you left that nut loose while adjusting valves

|

Of course that is a distinct possibility. I did check all the others after this and it would be the only one though. |

06-26-2011, 08:04 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

or-- you could of over tightened a nut that had a flaw!!!!

Mike----the locks are forced thru the retainers by aone or a combination of several factors--soft retainers or locks, coil bind, and possibly just by the pressure of the spring being held by the locks just push thru---Manleu and possibly other companies have and sell a lock/lash cap set up where the cam / rocker pressure pushes on the locks/retainers instead of wholly on the valve tip--- I referred to this system some months ago when someone else was having a problem such as this

|

06-27-2011, 10:54 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,287

|

|

Not Ranked

Not Ranked

I'm afraid, if it were mine, that the other head would come off and the heads would go to a reputable machine shop for a thorough checking and subsequent R&R.

For instance, if the wrong locks/retainers were used (6 deg versus 10 deg or visa versa) then I wouldn't trust one friggin' thing that shop/builder did...

__________________

Too many toys?? never!

|

06-27-2011, 01:04 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

I would change the pretty blue rockers.

Either you do it now in your garage or you will do it later possibily some place else.

I choose to do in my garage.

|

06-27-2011, 04:42 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by priobe

I would change the pretty blue rockers.

|

Why would you do that? |

06-27-2011, 04:55 PM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lovehamr

Why would you do that?

|

who's rockers are they? dove? crane?

__________________

Fred B

|

06-27-2011, 05:23 PM

|

|

CC Member

|

|

|

Join Date: Jun 2011

Cobra Make, Engine:

Posts: 30

|

|

Not Ranked

Not Ranked

Have to say, from you're photo', both the third from back and third from front, both exhaust, the geometry looks way off. The contact is right at the back of the valve stem, or is it an optical illusion, might just need longer pushrods.

You didn't say, which valve had the sinking locks.

Mike

|

06-27-2011, 05:36 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Mike Huddart

Have to say, from you're photo', both the third from back and third from front, both exhaust, the geometry looks way off. The contact is right at the back of the valve stem, or is it an optical illusion, might just need longer pushrods.

You didn't say, which valve had the sinking locks.

Mike

|

Actually I did, #4 intake. And yes, it is an optical illusion.

More on the post mortem in a little bit. |

06-27-2011, 06:20 PM

|

|

CC Member

|

|

|

Join Date: Jan 2005

Location: Auburn,

ca

Cobra Make, Engine: Unique 289 FIA HiPo 289 with Shelby dual quad intake

Posts: 187

|

|

Not Ranked

Not Ranked

any chance the nut found its way into the valve spring after it came loose? that would cause some major spring bind and possibly damage the retainer at the same time it was trashing the nut.

|

06-27-2011, 08:02 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Crap!

Crap!

OK, hereís what I have so far. To me it looks like Mike called it a few posts back. When I bought this cam back in 08 I remember getting a cam card with it but Iíll be damned if I know where the heck it is. And as much as it pains me to say it, I probably gave the machinist errant information. At any rate, when the machine shop assembled the heads, the springs were inadequate for the cam even then but they didnít have the cam. Fast forward to today and when talking with the machinist he wanted to know the cam specs because it looked like the keepers had been crushed on that valve and the same thing had started on another as well. He tested the spring pressure at 80# installed @ 2Ē. Now for the good part, when talking to KC they found my info but didnít know exactly which cam I had. So going off of what info they gave me I measured the lobe lift with a dial indicator at lunch today and came up with right at .370Ē which gives me .651Ē with a 1.76 rocker ratio. I was under the impression (senility?) that the lift was well under .600. With this much larger cam my machinist believes that the valves had to be bouncing to cause the damage to the keepers and has ordered some springs to give more like 160# on the seat. Brent and other have asked about the keeper/retainer angles and they are 7 degree on each. Since these are being changed anyway he thought it would be good to go with 10 degree parts as heís had better results with them. These should be here Wednesday. He believes that this bouncing could also have caused the rocker adjusting nut to come loose. Having never seen that before, hey, makes as much sense to me as anything else.

On to the f-ing nut. I finally found the moving part that apparently pulverized the little thing. This evening I wanted to do whatever I could to make sure that I wasnít going to have any more problems on assembly. So I had my son slowly rotate the crank a quarter of a turn at a time while I used a light down the lifter bores. This was the second time that Iíve had the lifters out and looked in all the lifter bores but the first time I had someone rotate it while I looked with a good light. Hereís what I found;

Those marks on the cam lobe are only right at the nose of the lobe which is probably why I missed it before. Looking at any other place on that lobe it looks fine and the lifterís roller shows absolutely no hint of anything wrong, even under magnification. So Iím thinking that it couldnít have run for very long at all after that happened.

Going by the forensic evidence It appears that:

the nut was jarred/broken loose by the valve bounce,

fell through the opening between the intake and head,

went down that hole over the cam,

got swung around by the cam lobe,

then crushed between the lobe and the block,

and fell the rest of the way to the pan.

Prolly got kicked a time or two by the recip assy on the way down too.

Well, thatís what I come up with anyway.

Iíll probably know more tomorrow when I get the cam out. You guys see any lapses of logic?

Steve

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:56 AM.

|

Linear Mode

Linear Mode