Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

11-26-2011, 11:32 PM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: Arkadelphia, AR,

AR

Cobra Make, Engine: Kirkham 427 brushed aluminum with Keith Craft 527C.I. all aluminum FE

Posts: 992

|

|

Not Ranked

Not Ranked

I would like to chime in here and say that this is only second Eagle crank we have had break in an FE. I can also say that this is to many. We are using the Scat cast steel and 4340 steel crank as well as the RPM 4340 steel cranks. We try to test this stuff the best that we can before we use a lot of it. I have used the 460 cranks in engines up to 800 HP with no problems up till a few years ago we had one of them break for no real reason.

I had one drag engine come back that broke a Scat cast steel crank but it was 4 yeaers old and it was built before the 4340 steel crank was available. We could use either a billet steel FE crank for about 2800.00 or the cast steel crank at that time at about 500.00. The customer decided to go the cast steel crank.

I hate when any part breaks and if we were getting the price of a NASCAR engine for this stuff we could double check everything and use the best parts available but we are not getting that money nor do many epople want to pay 50,000.00 for an FE engine. I do feel that all the parts we use in the engine will hold up to their intended use or we would not use them. I have used these cranks in stuff up to 700Hp and 6700 rpms over the years with just the few problems mentioned above.

I hope that there is something that we can do to help with this bad situation. I have gotten little help from ost part suppliers over the years. You know these parts are for high performance use and there for we do not warranty them, I have heard this several times. These are the things that make this engine business so tuff.

I have told several people that when you handle as many parts as we do you are more likely to get some bad parts. As far as the Eagle rods go I have really good luck with them. Most of the problems I have seen with them is a oiling problem or people not having the clearances right. Most people do not know that detonation is very hard on the crank and rods.

I will talk with Eljaro about some options he has. I would like to see the block as well because I have fixed a lot of aluminum part myself. If it can be fixed we can fix it.

Thanks, Keith Craft

__________________

Keith C

|

-

Advertising

11-27-2011, 05:59 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

I know you are busy but couple of quick questions

I know you are busy but couple of quick questions

Keithc8 Keith I guess that the problem with Scat cranks breaking if the questionable materials they use and machine processes done. Here's the questions

Like you been racing a long time, I know that theses companies are still around, LAE, Callies, Hank the crank, and Velesco. I know they cost about 3-500.00 more. Is there a problem with dealing with them???

Do the companies (above) get their blanks from China too?

Do the companies above do a different process and treatment to the crankshafts after all the machine work is done to extend the life?

maybe it's time to reinvent the FE crank to work with a thicker snout, shorten the length, and maybe widen the bearing area to support the loads. The other idea is about having the dampener reworked to help with harmonics. I have seen cranks break at idle and 7,000 rpms, and for MOST applications think a cast crankshaft is alot more forgiven than a billet one. The more solid they are the more chance of breaking and not flexing. Hopw you had a nice holiday. Rick L.

|

11-27-2011, 10:42 AM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

Several years ago I was talking with an engineer about harmonic balancers. In the discussion he told me that the fluid type dampeners were terrible at taking out bending harmonics, and caused many broken crankshafts. Seems like the old rubber OEM style dampener is very good at taking out both torsional as well as bending harmonics. I am guessing the long, and small diameter snout on the FE engine is not helping this problem. The FT is a large snout version of the FE...

|

11-27-2011, 10:53 AM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Location: Belleville, 15 miles East of St Louis MO,

IL

Cobra Make, Engine: Classic 427, I purchased it May 2005, the kit was bought in 1991. I'm not sure when it was completed! Installed GMPP Connect & Cruise 376/525 with T-56 S/M 3.55 gears about 2 years ago! 1/4 miles is with old setup!

Posts: 281

|

|

Not Ranked

Not Ranked

I'm more into Chevy's but I also don't like Scat cast or forged! I have had and know of others that have had problems with them going back 10 years or more. According to my machine shop they also seem to take a lot more balancing (more heavy metal). They like the FE builder above will only use them if the customer insists and if it breaks they are on their own! Also beware of E-Bay sellers reguardless of what the say many are selling "BLEMS"! Scat will tell you to bad for you, we sold it to your supplier as a blem and it's between you and them! Been there done that! Flat Lander Racing are the ones that burned me! Forged BBC 4.25" it took a ton of heavy metal to balance but was never right. It had very strange thrust wear after a few thousand miles, had to replace the crank and the block.

Anything much over stock go with a good forged rotating assembly, it's cheap insurance in the long run!

Just my 2 cents!

__________________

Al

I want to do right, Just not right NOW!

|

11-27-2011, 11:07 AM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Location: Belleville, 15 miles East of St Louis MO,

IL

Cobra Make, Engine: Classic 427, I purchased it May 2005, the kit was bought in 1991. I'm not sure when it was completed! Installed GMPP Connect & Cruise 376/525 with T-56 S/M 3.55 gears about 2 years ago! 1/4 miles is with old setup!

Posts: 281

|

|

Not Ranked

Not Ranked

Again I don't know much about FE motors. Was it internal or external balanced? On HP SBC/BBC I will only do internal! To me external balancing is like sitting on your washer during the spin cycle! ;-)

Just me!

__________________

Al

I want to do right, Just not right NOW!

Last edited by Lightingrod; 11-27-2011 at 11:11 AM..

Reason: add

|

11-27-2011, 11:29 AM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Location: San Marcos california,

CA

Cobra Make, Engine: 1989 KCC from South Africa Right Hand Drive

Posts: 1,605

|

|

Not Ranked

Not Ranked

I can't tell you how many times I have seen guys tighten the v belt so tight that it puts a huge amount of stress on the very long Ford crank snout. That nthong sits in the garage with all that sideways pressure on the crank snout. Primarily this is a design flaw of these tors. A multi robbed belt with very little tension would be beter.

|

11-27-2011, 12:02 PM

|

|

CC Member

|

|

|

Join Date: Jun 2005

Location: Belleville, 15 miles East of St Louis MO,

IL

Cobra Make, Engine: Classic 427, I purchased it May 2005, the kit was bought in 1991. I'm not sure when it was completed! Installed GMPP Connect & Cruise 376/525 with T-56 S/M 3.55 gears about 2 years ago! 1/4 miles is with old setup!

Posts: 281

|

|

Not Ranked

Not Ranked

^^Very True^^

I had a Vortech S-trim SC on a 454SS truck. Vortech had used a very small pulley on the supercharger due to size and low rpm of TBI 454 BBC. They had a fitting for a 1/2" breaker-bar on the SC bracket so you could torque the heck out of it! It would still slip. Not with a stock cast crank! I had a custom crank pulley about 1 1/2" dia. larger made so I could also use a larger SC pulley to achieve the same boost level with a lot less belt tension! No more belt slip even when I stepped the boost up about 10%! The pulleys worked great, the 10% increase not so much! It went lean on a real hot day at the strip and I broke a forged piston! A fun setup, more torque than the tires (BFG drag radials) and I knew what to do with!

__________________

Al

I want to do right, Just not right NOW!

|

11-27-2011, 12:29 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Lightingrod

If your crank took a ton of heavy metal but was never right should show you that your shop don't know what they are doing

|

11-27-2011, 05:17 PM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: Arkadelphia, AR,

AR

Cobra Make, Engine: Kirkham 427 brushed aluminum with Keith Craft 527C.I. all aluminum FE

Posts: 992

|

|

Not Ranked

Not Ranked

All of the FE cranks we do are internally balanced or zero balanced. I have never had a problem with a billet crank in an FE. I have used the Valasco, Scat and a few other with no problems. I have used SB Ford billet cranks and made 2500HP with some of the turbo and blower stuff. You on who will do a billet crank for the FE engine as well.

I have used the factory 391 truck crank turned down in some of the Super Stock FE 428 engine when we could not get a good crank. Turned the journals to the 2.200 BBC size and stroked to 3.997. We made about 750 HP with these engine and turned them 8200 rpms. I have had them last decent but have also cracked them. You did not know if the crank had 50,000 or 100,000 miles on it. All you could do is crack check it and go from there.

I know the billet stuff is going to be much stronger than any cast crank we can get. The cast stuff will flex some and the billet stuff is stiffwer but a lot stronger. Have never had a problem with the snout on them. The Scat and Eagle cast stuff is forged over seas and the Scat stuff is turned here, Eagle stuff comes in done over seas.

We have a problem getting people to pay 3000.00 for a crankshaft of these engines and most of time they are not needed, like I said before we have done a lot of engine with the cast cranks and had very few problems. We have had no problems with the over seas 4340 forging and it mis only about 500.00 more than the cast crank and is what we should just make standard in the engines and go up that much on price.

You then have a guy shopping price and he sends over all of these spreads sheets from other guys so you give him a quote with those parts. You then tell him the up-grade prices and they make the decision from there. Price does matter to most people in the end. This mechanical stuff just does break some times.

Thanks, Keith

__________________

Keith C

|

11-29-2011, 06:46 AM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Location: West Bloomfield,

MI

Cobra Make, Engine:

Posts: 717

|

|

Not Ranked

Not Ranked

I agree with Keith 100%

We have a lot of street race type engines running at and over 600-700 horsepower with Scat cast cranks and have had a breakage rate of damn near to zero. I might have seen one or two but could usually trace that to another root cause - like no oil.

We try to steer people to a forged crank at the 700 HP or road race level because they are a lot harder on parts. Until recently the only options were a factory 391 with work - or an RPM part that required some "lovin'" before it could be used - both ended up around a grand. Recently Scat brought out their own forging that looks a lot nicer than the RPM parts for a hundy extra - well worth it from what I can tell.

Billet stuff was and is the best from a quality and strength perspective. As Keith noted - very spendy and it takes a certain type of customer to both appreciate and afford that kind of item.

So far I have built LOTS of FE engines for a very long time and have yet to personally handle one with a broken snout - probably cursing myself with that line right there...

__________________

Survival Motorsports

"I can do that....."

Engine Masters Challenge Entries

91 octane - single 4bbl - mufflers

2008 - 429 cid FE HR - 675HP

2007 - 429 cid FE MR - 659HP

2006 - 434 cid FE MR - 678HP

2005 - 505 cid FE MR - 752HP

|

11-29-2011, 07:37 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

I asked for info on the dampner and I mentioned how driveline harmonics could break a crank at the front----

of the number (probably 30-40) of cranks I've seen broken over the years, could be traced to contributing factors that weren't crankshaft---probably one of the primary reasons a circle track car breaks a crank is that it either hit a wall or possibly a tire to tire with another car a couple of weeks earlier that killed the dampner(especially a fluid dampner)

Wrong flywheel used ( external/internal problem) will break the front as its the weak point.

I've seen a few top fuel/funny cars break center main(usually without center counterweights that strengthen it there)

Seen a few early chrysler 392 types break in the relieve groove at the front journal--a lite hammer tap to ring the crank will show this up--if it rings your good, if it thuds, its cracked.

Crank designers talk about 8 or 9 different orders of vibration?????

The old guys that ran the flat cranks-----

when you see something besides the crank broken, look for another reason----

|

11-29-2011, 09:57 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

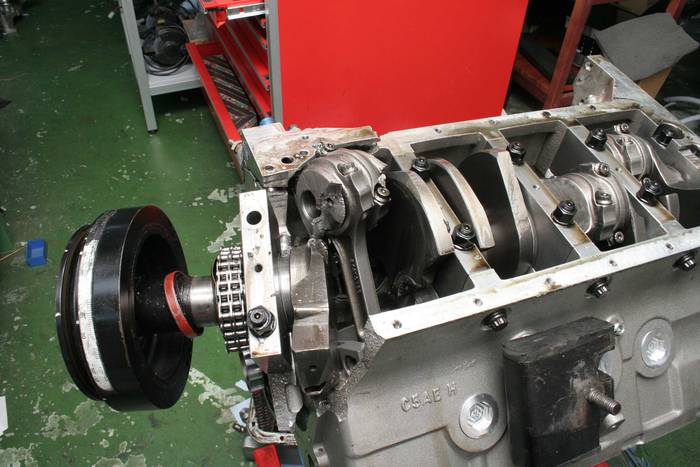

I have been looking at the picture magnefied many times and looks like the top half of the main bearing insert is hanging out forward---

|

04-10-2012, 10:44 PM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

pics of the disaster

pics of the disaster

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

04-10-2012, 11:07 PM

|

|

CC Member

|

|

|

Join Date: Apr 2008

Location: Melbourne,

Vic

Cobra Make, Engine: Some polish thing... With some old engine

Posts: 2,286

|

|

Not Ranked

Not Ranked

Ouch that hurts.

I'm sorry to see... I hope for the best with regard to a positive outcome. |

04-11-2012, 02:44 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Eljaro

What do you have to say to this?

|

Use a Scat crank.... |

04-11-2012, 03:15 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: York Co. Maine USA,

ME

Cobra Make, Engine: ERA 427 S/C W/Holmon Moody Original Nascar build #508 Iron Block/heads (C5AE-H) Bal/Blu 427 Sideoiler; 780 Holley Dbl. Pump; 4 Speed Top Loader; AP Racing Bks; IRS; 15" Trigo pins

Posts: 391

|

|

Not Ranked

Not Ranked

Photo's  What Blykins said. USE A SCAT CRANK Or mabe use a 385 series engine. You can get 600/600 hp/tq easy! with off the shelf parts for less than $10,000 US. Well, here anyway.

Last edited by Silversmith; 04-11-2012 at 03:19 AM..

|

04-11-2012, 04:23 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Save the block for a spare

Save the block for a spare

Eljaro Is this block aluminum?? If yes and you have all the pieces, it can be repaired with a good machinist and welder. You would need to add a gridle to the mains for support and drop the rpms in range to 6,000. Block would need to be welded and tubed for the oil side. Camshaft bearing area would need to be welded and recut. Crankshaft is done. Need to check rods and pistons. Bores for being still square. Front 2 cylinders get sleeves. This block has seen the end of race days. What fluid dampener are you running? I don't see any spacer on the nose of the crankshaft. Some fluid dampeners need to be allowed to warm up before driving. I have this problem with my ATI. The weiht doesn't move in the thick silicone at the start and the motor has the shakes. By the time the oil pressure drops to 75 psi the vibration is gone. If you have silly money to spend on a custom dampener, One company will send a guy out to do a vibration test and custom the weights and fluid to best match and reduce vibrations at a certain rpm range. Sorry for the breakage. Will look at the other pictures. Rick L.

|

04-11-2012, 09:51 AM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

I have a little SFA experience and in my opinion, the red arrows show where the break started. This would appear to be right at the edge of the machined journal. Seems to be some heat scoring marks on the journal itself (dark lines), possibly from an increase in bearing temps? Those wouldn't have happened after the break because the engine would have stopped rotating almost instantly given the carnage.

Terrible situation Eljaro.

EDIT>> What balancer is that you were running? Fluid or SFI?

Last edited by elmariachi; 04-11-2012 at 09:55 AM..

|

04-11-2012, 11:19 AM

|

|

CC Member

|

|

|

Join Date: Oct 2002

Location: Eagle,

Ne.

Cobra Make, Engine: 1966 Lone Star 427SC.

Posts: 4,310

|

|

Not Ranked

Not Ranked

What can be said,.........so sorry !

I'll pray to the car God for you.

__________________

Regards,

Kevin

|

04-11-2012, 12:15 PM

|

|

CC Member

|

|

|

Join Date: Oct 2010

Cobra Make, Engine: Superformance

Posts: 663

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RICK LAKE

Eljaro Is this block aluminum?? If yes and you have all the pieces, it can be repaired with a good machinist and welder. You would need to add a gridle to the mains for support and drop the rpms in range to 6,000. Block would need to be welded and tubed for the oil side. Camshaft bearing area would need to be welded and recut. Rick L. |

Rick, honest question. You would trust all of that block work to all the new ($$) internal parts you would have to throw inside? You have a much higher faith and trust in your block repair guy than I would. From a confidence perspective, to me it's a total do-over with all fresh components.

Eljaro, good luck with whichever direction you take...that was a tough one to look at. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:26 AM.

|

What Blykins said. USE A SCAT CRANK

What Blykins said. USE A SCAT CRANK Or mabe use a 385 series engine. You can get 600/600 hp/tq easy! with off the shelf parts for less than $10,000 US. Well, here anyway.

Or mabe use a 385 series engine. You can get 600/600 hp/tq easy! with off the shelf parts for less than $10,000 US. Well, here anyway.

Linear Mode

Linear Mode