Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

8Likes 8Likes

04-01-2016, 10:48 AM

|

|

CC Member

|

|

|

Join Date: Oct 2010

Cobra Make, Engine: Superformance

Posts: 663

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

Here's the fun part. I'd like to sit down with the engineer who designed the FE intake setup....maybe put my arm around him....tightly....and explain a few things to him.  |

Get in line. You could also add to that skull session Ford using a separate eccentric to drive the mechanical fuel pump (vs. the more stout and reliable Chevy arrangement with a push rod off an extra cam lobe). What a PITA to fix (i.e. ripping apart the entire front end of the motor and dropping the pan). Or the timing cover that requires additional seals for coolant passage to/from the water pump (vs. directly to the block). Having worked on both Fords and Chevys, I give Ford a thumbs-up on the front-mounted distributor though. But not much beyond that.

Enjoying the build (as always). Keep at it! |

-

Advertising

04-01-2016, 02:10 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

redmt, there's usually a parts misalignment....LOL

As Lippy says, if all the parts come from the same place, they usually fit together. When you snag heads from one vendor, an intake from another vendor, a block from another vendor, then you have to cross your fingers that it all plays well together. Most of the time it doesn't.

I rebuilt a 428CJ for a GT500 restoration a few years back. The cast iron intake came in at 78 lbs. Fun stuff.

Was working on my customer's 289 today and found out that Ferrea sent titanium exhaust valves with hardened tips, when they should have been short and used lash caps. They also cut them with a square groove instead of a radiused groove. Just the exhaust valves ran $800. They screwed up, so they're eating it. However, I'm another week away from assembling the heads, which puts me in a slight bind.......SOOOOO..............

I washed and painted Chris' timing cover and the goal is to have the timing cover, oil pan, and some other assorted goodies mounted tomorrow.

Oh yeah, pushrods came in too.

Last edited by blykins; 04-01-2016 at 02:13 PM..

|

04-01-2016, 07:14 PM

|

|

Senior CC Premier Member

|

|

|

Join Date: Nov 2004

Location: SoCal,

CA

Cobra Make, Engine: CSX #4xxx with CSX 482; David Kee Toploader

Posts: 3,574

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ACademic

Get in line. You could also add to that skull session Ford using a separate eccentric to drive the mechanical fuel pump (vs. the more stout and reliable Chevy arrangement with a push rod off an extra cam lobe). What a PITA to fix (i.e. ripping apart the entire front end of the motor and dropping the pan). Or the timing cover that requires additional seals for coolant passage to/from the water pump (vs. directly to the block). Having worked on both Fords and Chevys, I give Ford a thumbs-up on the front-mounted distributor though. But not much beyond that.

Enjoying the build (as always). Keep at it!

|

Don't forget that pesky "7-8" firing order too!

__________________

All that's stopping you now Son, is blind-raging fear.......

|

04-02-2016, 07:57 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

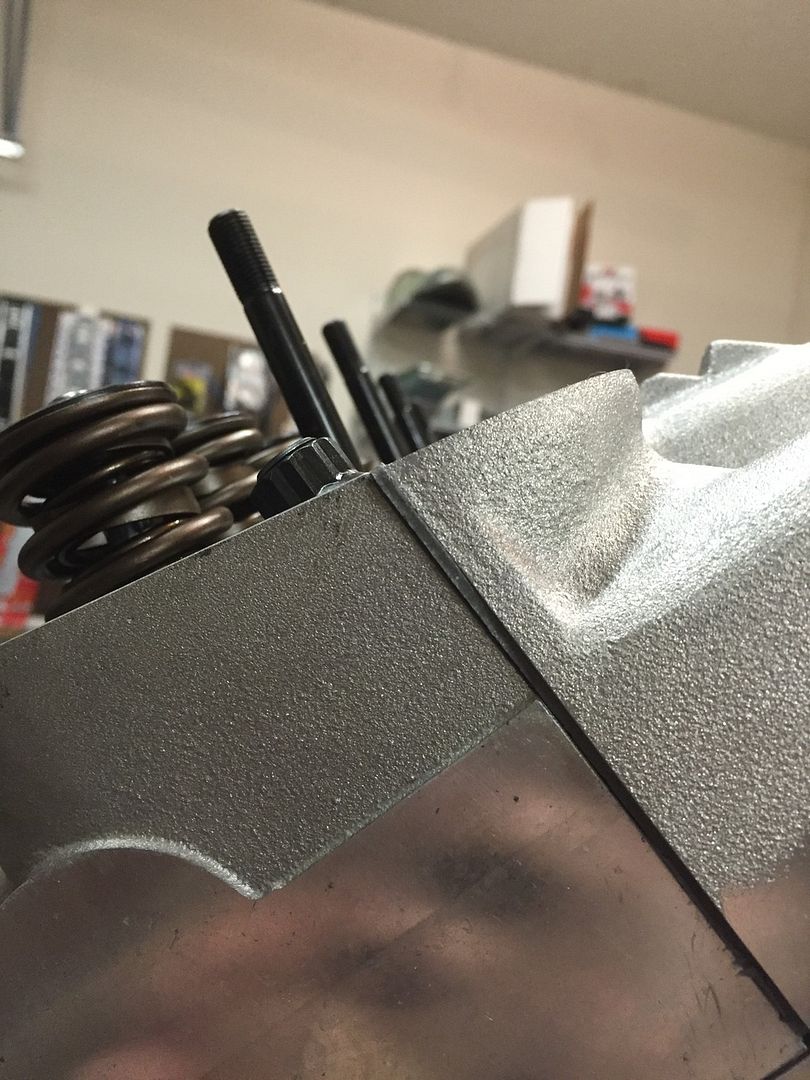

Refurbished a factory timing cover, installed a new seal, and gave it a nice coat of paint. When you use a Ford Racing one piece fuel pump eccentric, they often get close to the timing cover and there are some factory ribs that can interfere. I ground them off...

I install the timing covers with a special tool that centers it on the crankshaft. The tool is quite handy...it fits the seal bore on an FE with one end, and the seal bore on a SBF with the other. Some guys use the balancer spacer to align the cover. Nothing wrong with that at all, I've just found this way to be easier for me.

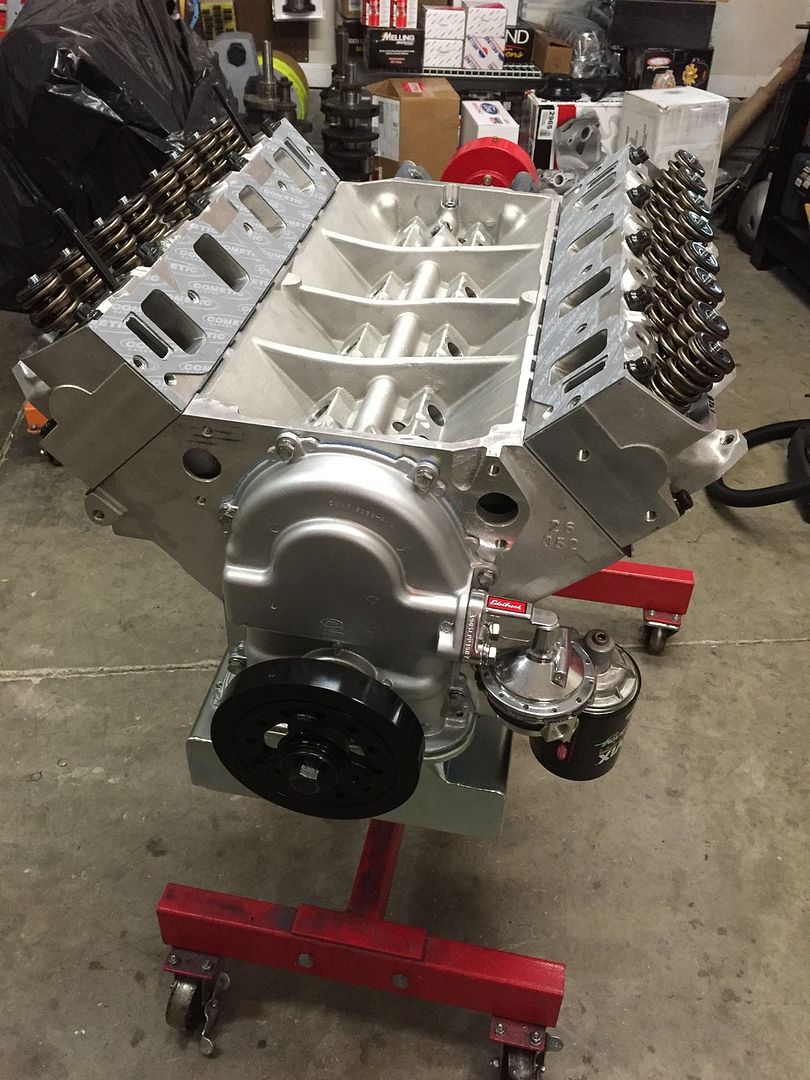

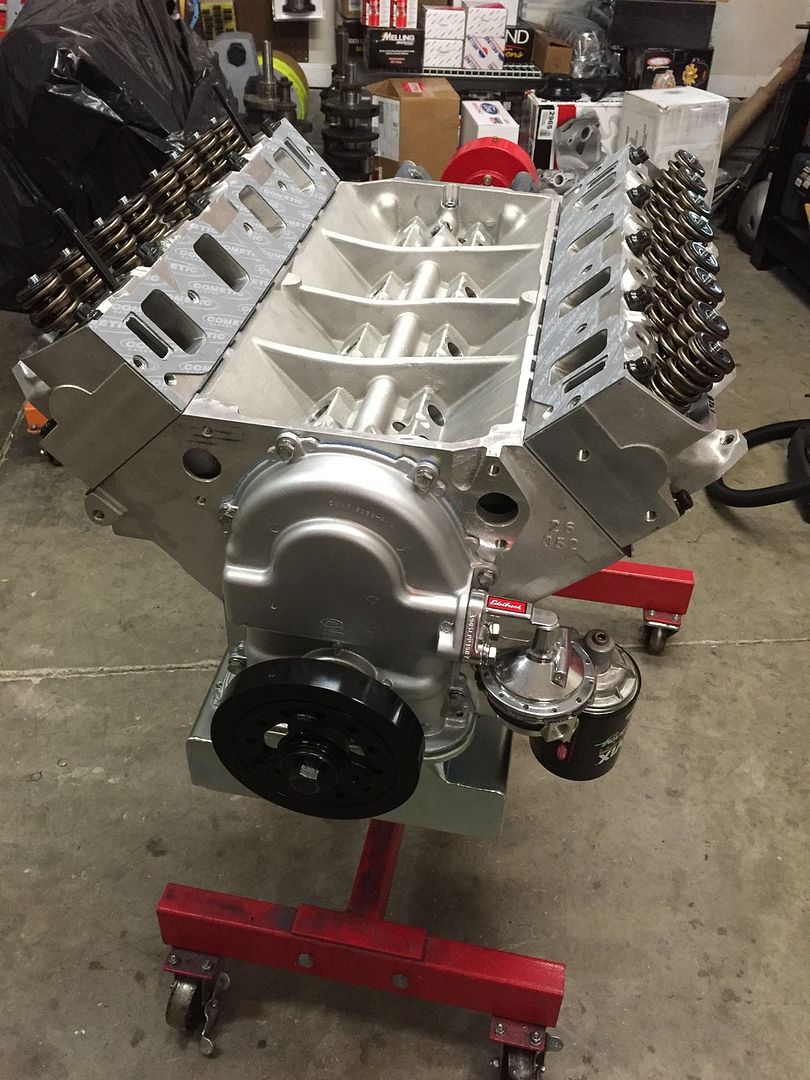

Timing cover, fuel pump, and harmonic balancer installed.

Oil

Oil pump pickup clearance checked, Moroso oil pan installed.

|

04-05-2016, 07:37 PM

|

|

CC Member

|

|

|

Join Date: Oct 1999

Location: Stoneville,NC,

NC

Cobra Make, Engine: Factory 5 mk4 445 FE

Posts: 1,623

|

|

Not Ranked

Not Ranked

The oil pan you are using. What is the real amount it holds. I hear different things |

04-15-2016, 05:18 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

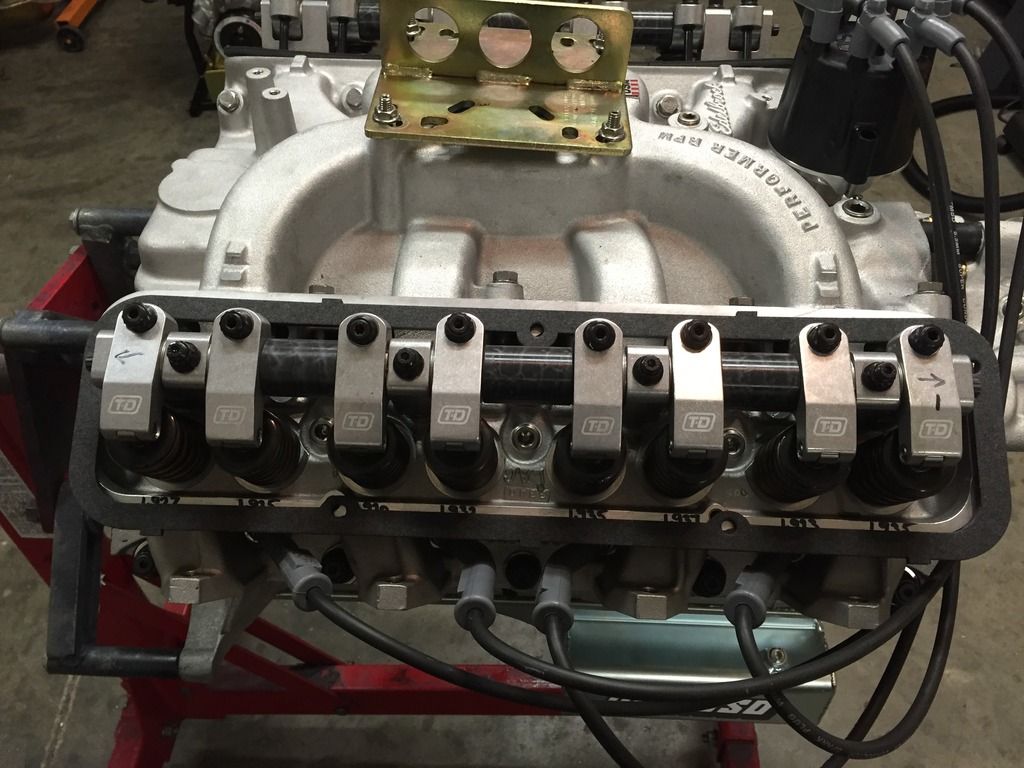

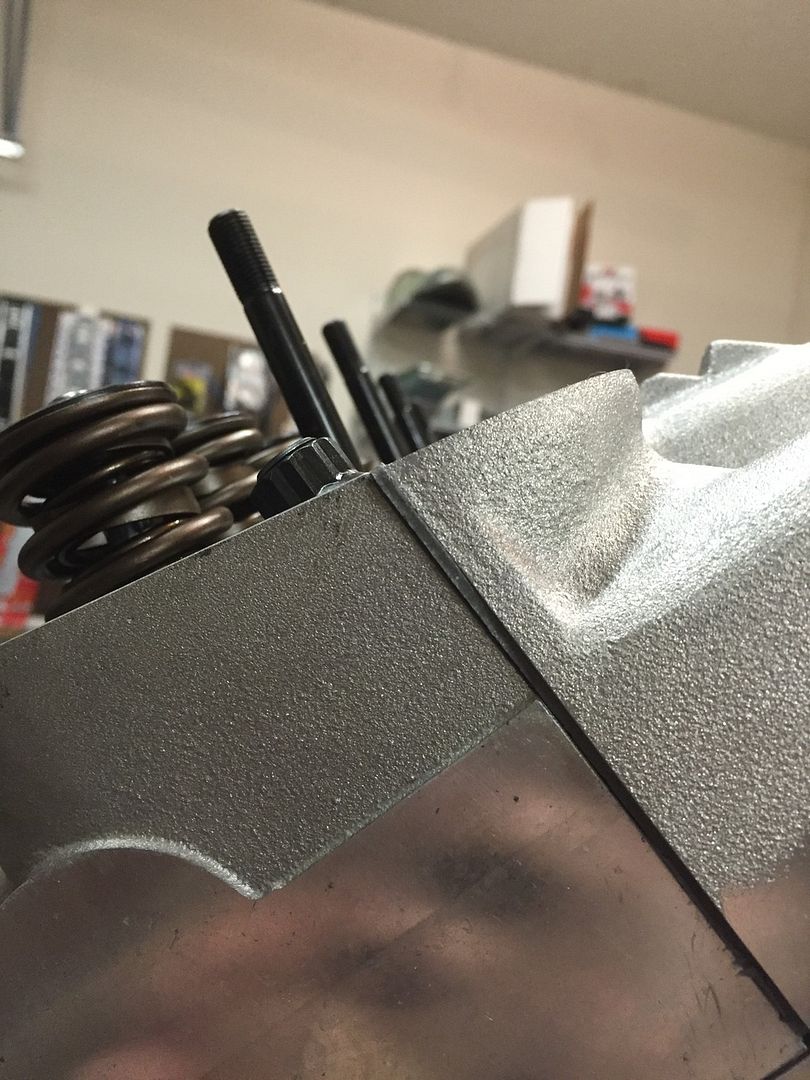

Intake has been cut.....

Much better.

Sealed it up this morning.

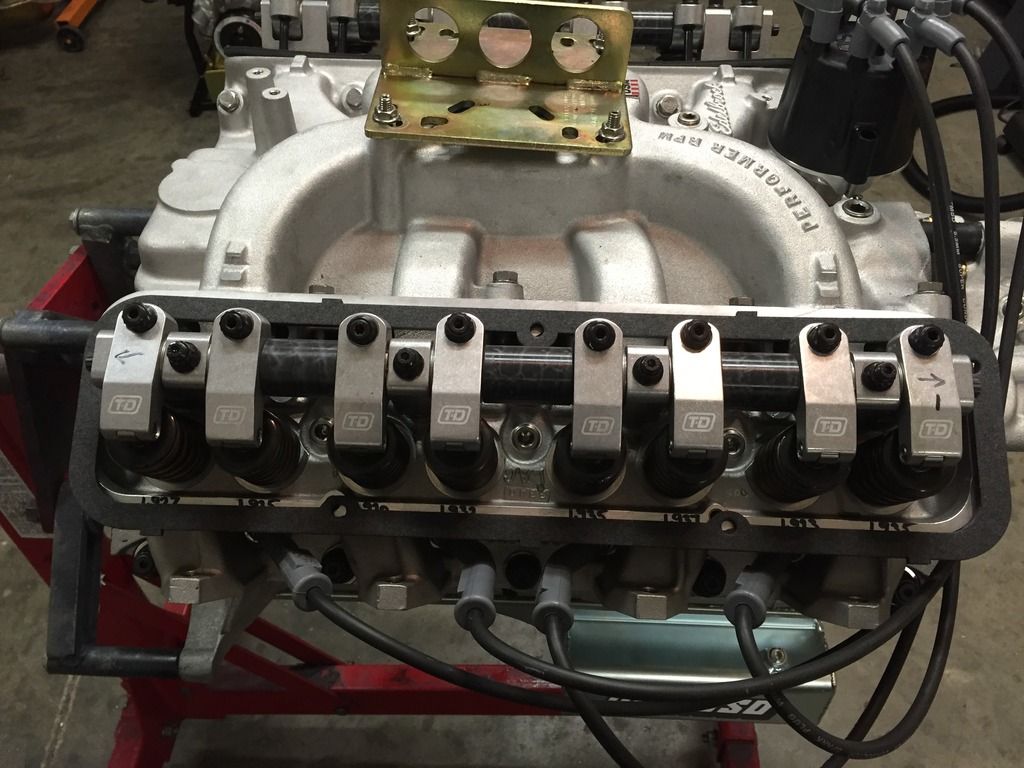

Rockers are on and the valves ran.

Front end stuff bolted on...

Ran out of valve cover studs and forgot that I hadn't ordered breathers.....but here's what she'll look like.

|

04-23-2016, 06:01 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

I thought I was going to be sneaky and dyno Chris' engine yesterday, then surprise him with some pictures and a video last night.

We got her dyno'd yesterday; it made 588 hp @ 5700 and 620 lb-ft of torque. Sweet little engine, no external leaks....

I had walked outside to watch a pull from the outside and notice a few wisps of steam from the driver's side, so I went back in the dyno room and pulled the driver's side valve cover. Milkshake.

Got it home last night, pulled the intake and head off and one of the sleeves had dropped .011".

Now, one of the things we do to prep the aluminum blocks is to set the sleeves, which includes putting them in an oven, while clamping a head gasket and torque plate down to each deck. So, I'm not sure why that one dropped more, but the fact of it is that the engine will have to be pulled down to the bare block.

Good thing is that Chris' car will be in limbo until June, so we have some time.

|

04-23-2016, 06:23 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,283

|

|

Not Ranked

Not Ranked

Just curious, was there glycol in the cooling system? If so, what effect, if any, does gycol have on bearing babbit. This would include short and long term.

The reason I ask is for several months I had a small intrusion of glycol into my oiling system on my Pond 482. It was not enough to make the oil milky, but enough to get some condensed froth in the valve covers. Fast forward 3 years and my oil pressure is the same as when the engine was new.

__________________

Too many toys?? never!

|

04-23-2016, 06:24 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

Dynos don't use antifreeze. |

04-23-2016, 06:25 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,283

|

|

Not Ranked

Not Ranked

Can you answer the second part of the question anyway?

__________________

Too many toys?? never!

|

04-23-2016, 06:29 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

Sorry, was trying to do 16 things at once....LOL

On long term, I think it would be bad for the bearings. Obviously, sometimes we get condensation under the valve covers from outside temperature changes, but a steady stream of water/ antifreeze/gasoline can etch the bearings and not allow the oil to fully support the load. |

04-23-2016, 06:36 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,283

|

|

Not Ranked

Not Ranked

Thanks...

FWIW, when I bought the shortblock from Keith he didn't include proprietary head studs with the purchase. Knowing nothing about the "special" deep skirt head stud requirement I used ASRP head bolts. One of the head bolts pulled the threads from the block, unloading the head over a water port causing a small degree of seepage. I kept focusing my attention on a "potential" porous Dove tunnel wedge intake and finally found the true culprit. What a fiasco it was...

__________________

Too many toys?? never!

|

04-23-2016, 08:32 AM

|

|

CC Member

|

|

|

Join Date: Aug 2010

Location: San Antonio Valley Ca,

ca

Cobra Make, Engine:

Posts: 1,275

|

|

Neutral

Neutral

How tough are those sleeves to replace? Who stands good for it?

|

04-23-2016, 08:49 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

Not going to replace the sleeve, just deck the block.

Stands good for it? That's funny....

Nobody ever stands good for anything except the engine builder.

|

04-23-2016, 09:23 AM

|

|

CC Member

|

|

|

Join Date: Aug 2010

Location: San Antonio Valley Ca,

ca

Cobra Make, Engine:

Posts: 1,275

|

|

Not Ranked

Not Ranked

OK, if you deck the block that changes your piston to deck clearance. Are you going to do both sides and then trim the pistons a bit? What was the piston to deck clearance to start with?

We all know from bad experience that some manufacturers and machine shops won't stand good even when it's blatantly their fault.

It's not just the engine builder who takes it on the nose. It filters all the way up and down the chain.

|

04-23-2016, 09:59 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

Deck both sides, adjust with head gasket thickness.

|

04-24-2016, 08:37 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

I have read that on highly forced induction engines, they groove a circle, I think on the block deck, but I doubt it would matter if it went on the head, just outside the bore. Then they lay a wire in the circle. The head gasket then partially crushes the wire, but end up with a higher pressure point, making a better seal.

I'm sure there is a detail in material, and thickness of the wire, and the shape of the groove. I have had some experience with gear pumps where the aluminum gaskets on the end plates crush and that affects the side clearance on the gear set. In fact, I wanted to change this design to a wire in a grove, but the bean counters wouldn't spend the money to save a known cost. No risk in staying with the status quot. They could predict the cost. But I digressed....

I'm curious why some type of crush material, such as the groove and wire is not put on top of the sleeves, in a sleeved engine. It allows some forgiveness. I may be somewhat remembering a diesel tractor designed this way, but I cannot trust my memory.

Anyway it was a thought.

|

04-24-2016, 09:11 AM

|

|

CC Member

|

|

|

Join Date: Sep 2013

Location: Memphis,

TN

Cobra Make, Engine: SPF#1867 , KC427

Posts: 429

|

|

Not Ranked

Not Ranked

Sounds like an awesome street engine. Kudos to the new owner and for the builder divulging the incident and standing behind his work.

|

04-24-2016, 09:45 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,415

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by olddog

I have read that on highly forced induction engines, they groove a circle, I think on the block deck, but I doubt it would matter if it went on the head, just outside the bore. Then they lay a wire in the circle. The head gasket then partially crushes the wire, but end up with a higher pressure point, making a better seal.

I'm sure there is a detail in material, and thickness of the wire, and the shape of the groove. I have had some experience with gear pumps where the aluminum gaskets on the end plates crush and that affects the side clearance on the gear set. In fact, I wanted to change this design to a wire in a grove, but the bean counters wouldn't spend the money to save a known cost. No risk in staying with the status quot. They could predict the cost. But I digressed....

I'm curious why some type of crush material, such as the groove and wire is not put on top of the sleeves, in a sleeved engine. It allows some forgiveness. I may be somewhat remembering a diesel tractor designed this way, but I cannot trust my memory.

Anyway it was a thought.

|

The head gasket fire ring should make up for any discrepancy in deck/sleeve height. However, it just couldn't make up the difference here. |

04-24-2016, 02:07 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gore. New Zealand.,

SI

Cobra Make, Engine: DIY Coupe, F/T ,MkIV.

Posts: 808

|

|

Not Ranked

Not Ranked

Rather than using a head gasket and head to set sleeves I use a large solid steel bar thru the main bearing tunnels with an old diesel truck rod which has a 1" dia fine thread rod welded on its small end and a circle plate to fit sleeve od/id to pull down on each sleeve individually, this avoids stressing the block in head bolt area. Built this way back in 70/80 era when I was looking after some tour jet boat stuff that where possible always got driven home regardless of what was damaged in the engine, hence the need for sleeves to restore bore damage... tourists don't like swimming in alpine rivers!!

__________________

Jac Mac

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:26 PM.

|

8Likes

8Likes

Linear Mode

Linear Mode