Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

9Likes 9Likes

09-30-2016, 06:43 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Last edited by blykins; 09-30-2016 at 06:46 AM..

|

-

Advertising

10-01-2016, 09:15 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

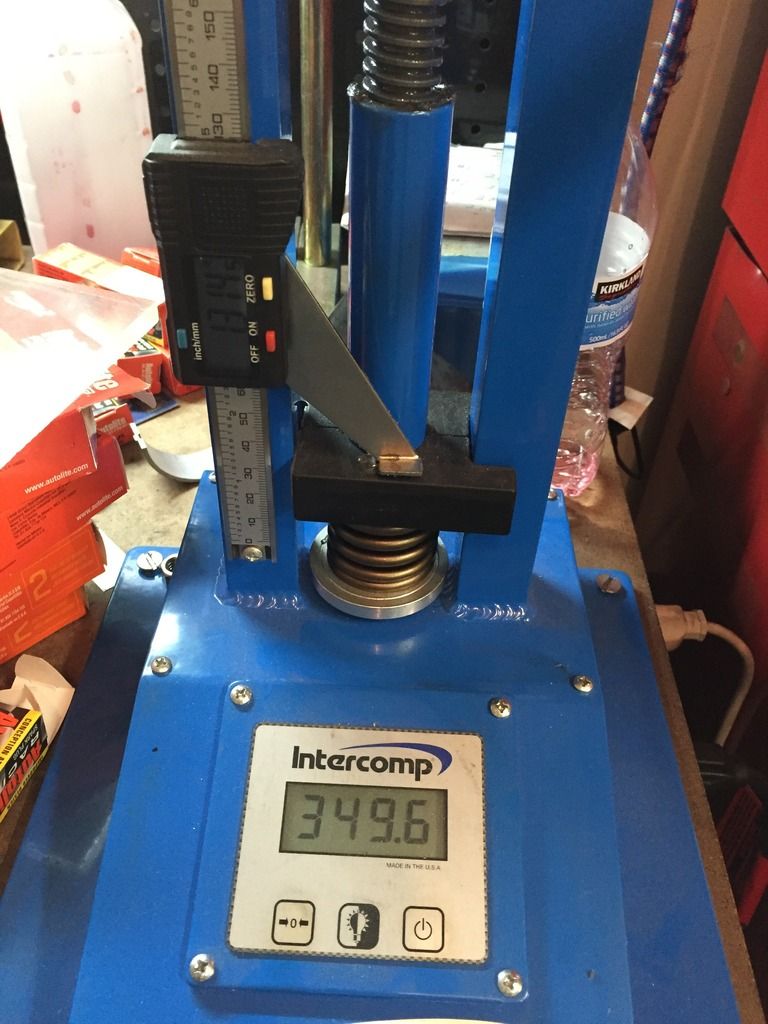

Strange, I never actually used clay to check valve clearance, and I new it was the best way. I have measure the valve stem movement with the valve spring off. In my defense, that was back in my puppy days.

I was surprised how close the intake valve comes to the notch in the piston. Especially surprising to me after seeing the exhaust is a mile away, in comparison. I never gave clearance radially from the valve to the piston cut any thought. Measuring the valve stem travel, only measures one dimension. The edge of the valve may only have 0.002" clearance from the cut in the piston, and that method of measure wouldn't tell you that. That would get ugly when things heated up.

I learned something today. I'll never miss this step again.

Thanks

|

10-01-2016, 09:21 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

On the intake, I have been surprised how many people talk like they believe aluminum equals better flow. Aluminum is a nice soft easy metal to work with, but the material has nothing to do with flow. Cast Iron can flow just as much; it is just harder to machine and work with.

|

10-01-2016, 10:03 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

If the clearance starts getting close, then it's best to use a degree wheel and dial indicator to check clearance as the clay can move around and stick a little. Typically the intake valve will be closest at around 10° ATDC. The exhaust valve will be closest around 10° BTDC.

As you mention though, the clay will show the radical clearance and has saved my butt a few times. Have had to adjust the reliefs on some custom pistons before.

I don't think I have heard anyone say that the material makes the flow different, but typically, your aftermarket heads are all aluminum, and they are the ones that will most likely yield aftermarket performance...

I have access to one of the best head porters around though....  |

10-01-2016, 08:07 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by olddog

Strange, I never actually used clay to check valve clearance, and I new it was the best way. I have measure the valve stem movement with the valve spring off. In my defense, that was back in my puppy days.

I was surprised how close the intake valve comes to the notch in the piston. Especially surprising to me after seeing the exhaust is a mile away, in comparison. I never gave clearance radially from the valve to the piston cut any thought. Measuring the valve stem travel, only measures one dimension. The edge of the valve may only have 0.002" clearance from the cut in the piston, and that method of measure wouldn't tell you that. That would get ugly when things heated up.

I learned something today. I'll never miss this step again.

Thanks

|

Yes, it certainly is the best way.

I have had one engine where the valves were increased to almost total bore diameter, 52% and 43% and the block needed to be notched for clearance for the exhaust valve.

Same for making custom valve reliefs in the piston.

Observe how blykins has about the same radially as it does vertically.

|

10-02-2016, 08:00 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

I don't think I have heard anyone say that the material makes the flow different, but typically, your aftermarket heads are all aluminum, and they are the ones that will most likely yield aftermarket performance...

|

No, me either, but I have had people dismiss cast iron as low performance junk and act like aluminum equal performance. It's the porting not the material it is made from. There are some aluminum heads sold that are not significantly different from the factory cast iron. |

10-02-2016, 08:03 AM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 922

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

As promised....

Everything has went together pretty much without fuss, with the exception of the oil pump pickup. I used a Canton oil pan with Alan's build and the pickup that is recommended for the pan showed 9/16" of pickup clearance when I mocked it up and measured. Luckily, I had a Moroso pickup on the shelf that showed a more desirable 5/16" when I tried it. So, it has a Canton pan with a Moroso pickup.  I also had to dimple the oil pan around the rear rail so that it would sit on the block without contacting the rear main cap bolts. |

This build is really nice, I'm jealous.

Back to the Canton oil pan. Are you running the RR pan or the standard T pan? Wind-age tray? This winter I am hoping to finally switching out my regular pan for the RR pan with the dipstick on the right (Passenger) side.

Also not aware of any dimpling that needs to be done. I installed a Canton pan on my last 428 with no issue. Is the 427 different?

Along with my oil pan switch, I will be removing anything with a gasket because I am leaking oil from everywhere. A real ugly mess! Everything has been sitting on a shelf for three years now...LOL. Just not enough time!

Dave

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

|

10-02-2016, 08:10 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Gaz64

Observe how blykins has about the same radially as it does vertically.

|

Yes that is what caught my eye. A picture is worth a thousand words.

Then when you think of all the head and piston manufactures (especially twisted wedge and Cleveland types SB), the valve reliefs and heads are not always going to match.

Just one of those light bulb moments for me. I'm not afraid to admit I learned something or didn't truly understand it in the first place.

Even though I was aware the other dimension (radial) existed, I always thought one dimensional in valve clearance. I was fully aware of valve shrouding by the cylinder wall, and that some applications people notched the top of the cylinder wall. It just never clicked that the radial clearance needs to be checked until I saw that picture.

Last edited by olddog; 10-02-2016 at 08:21 AM..

|

10-02-2016, 01:18 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

David, Canton has two front tee sumped pans. They both look exactly alike, but one has all the trap doors and one doesn't. This one doesn't.

If you are using aftermarket rear main cap fasteners, chances are something will have to be done to whatever pan you're using. Even ARP bolts stick high enough up that they will hit the pan rail. Some guys mill the bolts down, I find it easier to just dimple the pan rail from the inside. Also, a factory 427 block has a small pipe plug near the block rail. The pan rail hit it.

I don't use windage trays for street engines. No need in it. You won't see any horsepower gains on the dyno and it serves as yet another gasket that could cause sealing problems. In this case, it would have made the pickup clearance even worse...

|

10-03-2016, 07:13 PM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 922

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

David, Canton has two front tee sumped pans. They both look exactly alike, but one has all the trap doors and one doesn't. This one doesn't.

If you are using aftermarket rear main cap fasteners, chances are something will have to be done to whatever pan you're using. Even ARP bolts stick high enough up that they will hit the pan rail. Some guys mill the bolts down, I find it easier to just dimple the pan rail from the inside. Also, a factory 427 block has a small pipe plug near the block rail. The pan rail hit it.

I don't use windage trays for street engines. No need in it. You won't see any horsepower gains on the dyno and it serves as yet another gasket that could cause sealing problems. In this case, it would have made the pickup clearance even worse...

|

Yes, I have both the pans. Very good point about the Windage tray and the extra gasket being a potential leak. maybe I will sell it and just install the RR pan with all the doors. I guess I should also find a way to measure the pickup to the bottom of the pan also.

I will also look for any interference.

Thanks for the great info Brent.

Dave

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

|

10-04-2016, 06:07 AM

|

|

CC Member

|

|

|

Join Date: Feb 2016

Location: North of London,

UK

Cobra Make, Engine: AC Cars Limited, 302 EFI

Posts: 204

|

|

Not Ranked

Not Ranked

I continue to be impressed with the level of expertise and care taken with these FE builds.

|

10-05-2016, 04:50 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Head gaskets are on and heads are on. Need to re-torque them and I'm waiting on the intake manifold to come back from being blasted....

|

10-07-2016, 03:21 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

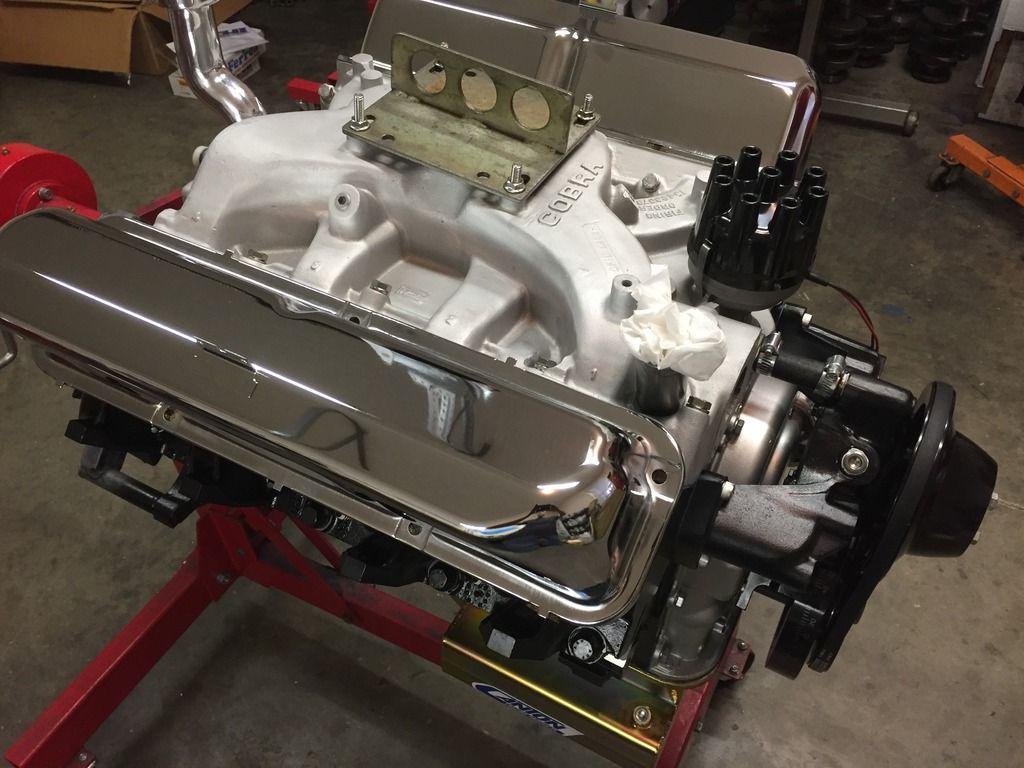

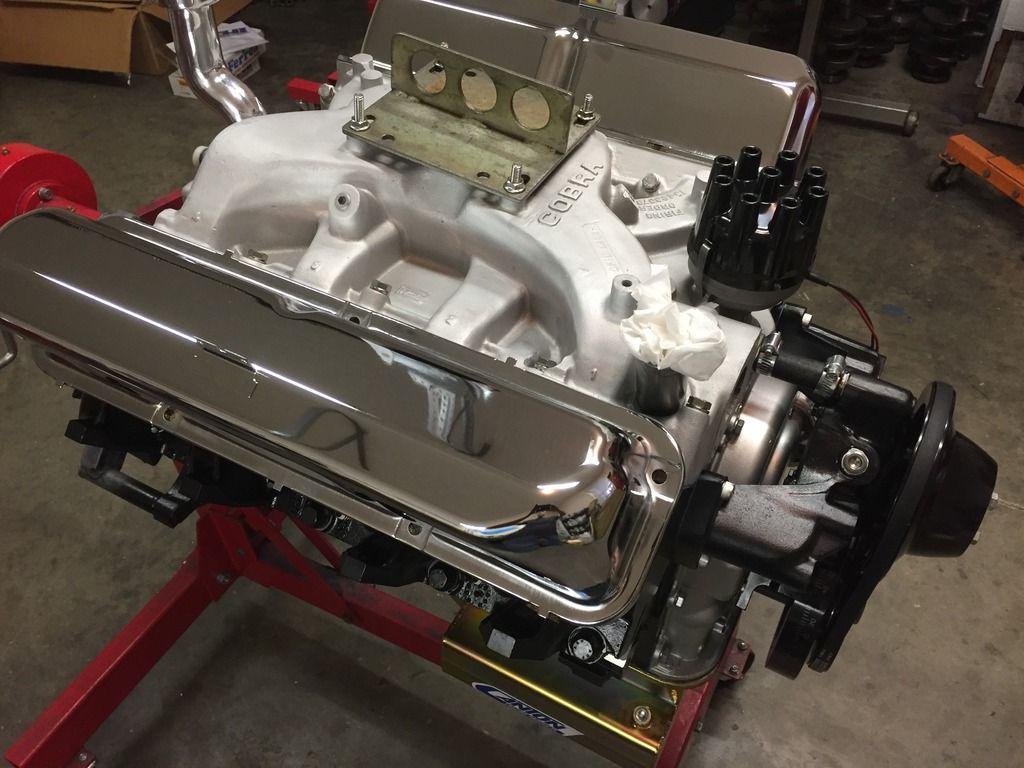

Almost ready to stick a fork in it....

Forgot that I didn't have a breather to fit onto the front oil fill tube and I need to run and get a few bolts for the intake manifold that are a little different length than normal.

Other than that, need to do a final oil pump prime (already spun it and checked for leaks this morning), put the plug wires on, and it will be ready.

Tentative dyno day is the 21st. Alan doesn't have his car yet and I'm gonna try and take two engines with me.

Old school cool....

|

10-08-2016, 05:17 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Come on Brent, valve covers sitting on already, no pics of valvetrain?

The one part I've been waiting to see.

Gary |

10-08-2016, 06:26 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Cometic head gaskets....

Morel lifters and Cometic intake gaskets....

|

10-09-2016, 04:25 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Nice, very nice, should go well,  |

10-09-2016, 05:53 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Gasdoc (Alan) hasn't been seen on the forum since June. ERA builds take awhile but most owners typically have some questions and observations along the way in the meantime. Hope all is well.

|

10-09-2016, 06:17 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,013

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

Gasdoc (Alan) hasn't been seen on the forum since June. ERA builds take awhile but most owners typically have some questions and observations along the way in the meantime. Hope all is well.

|

Well, I suppose he could have lost his CC username/password, but you'd think he'd pick up the phone and chat with Brent. I sense there is a problem.  |

10-09-2016, 08:10 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,527

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

|

Are those stock Ford rockers or an aftermarket look alike? Kind of surprised 427 adjustable rockers weren't used so lifter pre-load could be set. |

10-09-2016, 09:59 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Alan is ok, he's been emailing me.

The rockers are new factory replacements. The non-adjustables work just fine with careful pushrod length measuring. The lifter preload is built into the pushrod length. I have been doing a lot of builds with factory non-adjustable rockers. They are very light without the adjuster and nut hanging off the back and are beefy enough to handle hydraulic roller spring pressures.

The shafts are new as well and the stands are reconditioned. The end stands are necessary IMO, and come from Precision Oil Pumps.

Last edited by blykins; 10-09-2016 at 12:10 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 03:38 AM.

|

9Likes

9Likes

Linear Mode

Linear Mode