Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

09-08-2016, 10:19 AM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: shellvalley 428 ford

Posts: 397

|

|

Not Ranked

Not Ranked

You might try and get that cylinder as close to top dead center as you can.

|

-

Advertising

09-08-2016, 10:20 AM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Keller,

TX

Cobra Make, Engine: Lonestar Classics LS427. Self-built 408W, AFR 195 heads, Performer RPM Intake, Quick Fuel 750, 407rwhp, 479rwtq

Posts: 549

|

|

Not Ranked

Not Ranked

Edit: Byron beat me to it.

Make sure you have that cylinder at TDC when you remove the springs. You will use less rope. If you have compressed air, you can pressurize the cylinder instead of using rope, but still make sure you are at TDC. If a valve slides down into the cylinder, you get to take off the head to get it out. Once you have the spring off, use a rubber band or a zip tie around the valve stem while you work on the other one. Just remember to remove all rope, zip ties, or other things before you restart it!  |

09-08-2016, 10:51 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA427

Thanks everyone. I think this gives me the right plan...

|

You get bonus points for replacing the valve spring and rod without removing the rocker shaft.  |

09-08-2016, 12:08 PM

|

|

CC Member

|

|

|

Join Date: Aug 2011

Cobra Make, Engine: ERA 427S/C w/ 1968 428 Cobra Jet Holley 750

Posts: 44

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

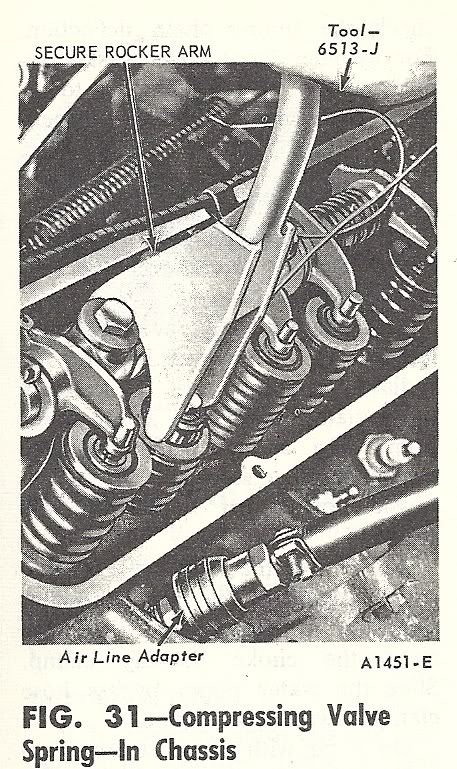

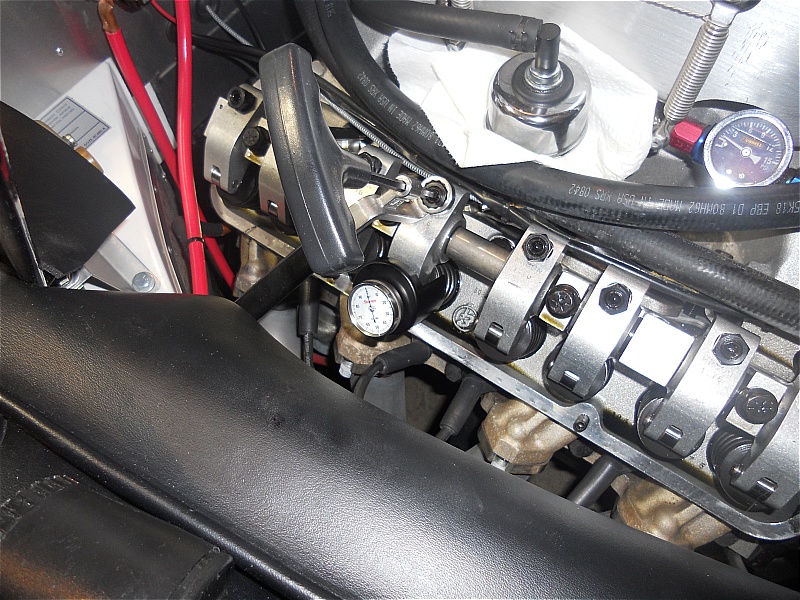

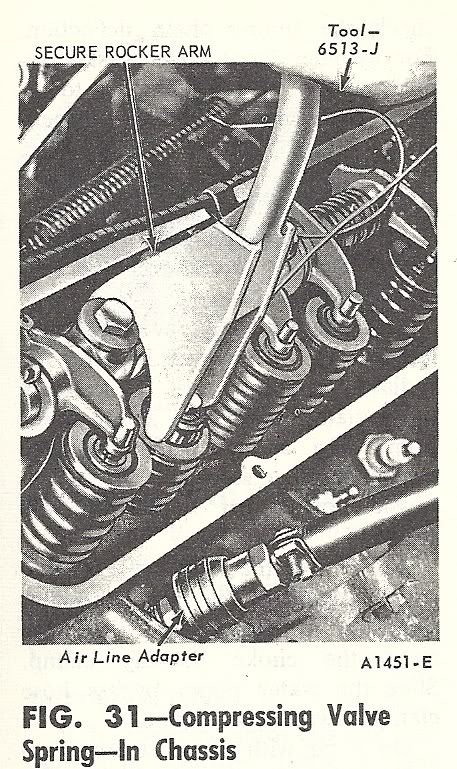

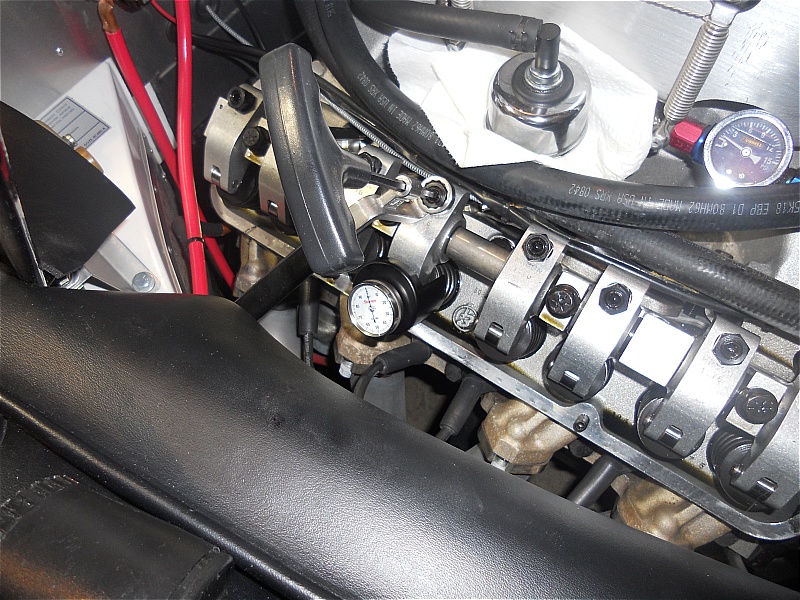

But since you've got stock rockers, this would do the trick quite nicely:

|

where can I get that tool? I would love to use one like this where I don't need to pull the rockers and shaft...

I can't find any online like this. |

09-08-2016, 12:10 PM

|

|

CC Member

|

|

|

Join Date: Aug 2011

Cobra Make, Engine: ERA 427S/C w/ 1968 428 Cobra Jet Holley 750

Posts: 44

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Texasdoc

Edit: Byron beat me to it.

Make sure you have that cylinder at TDC when you remove the springs. You will use less rope. If you have compressed air, you can pressurize the cylinder instead of using rope, but still make sure you are at TDC. If a valve slides down into the cylinder, you get to take off the head to get it out. Once you have the spring off, use a rubber band or a zip tie around the valve stem while you work on the other one. Just remember to remove all rope, zip ties, or other things before you restart it!  |

Yes - important safety tip - thanks! |

09-08-2016, 12:13 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA427

where can I get that tool? I would love to use one like this where I don't need to pull the rockers and shaft...

I can't find any online like this.

|

I knew you would ask that question.  I have absolutely no idea where, or even if, you could find that now, but you could almost fabricate one yourself from that picture. If I had stock rockers, I would spend the time to see if I couldn't do just that, but I have big fat Erson rollers on mine.

Last edited by patrickt; 11-04-2016 at 10:03 AM..

|

09-08-2016, 12:36 PM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: shellvalley 428 ford

Posts: 397

|

|

Not Ranked

Not Ranked

Texasdoc, you typed too many words or you would have had me, LOL

|

09-08-2016, 12:46 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

The more I think abou it...

The more I think abou it...

Yes, I would fabricate that tool, and I would make it out of wood, using my jig saw. Make a cardboard template that curls around the rocker shaft and "points" on to the retainer just like the picture. Then cut two of those out of 3/8" hardwood and fasten your pull handle between the two pieces so the points hit the retainer just like the picture. You could also substitute straps that go around the shaft for the fancy curled ends. That would be even easier. Come to think of it, you could probably use heavy duty zip ties around the shaft and a notched wooden pole that fits down over the retainer and it would work just fine for the few times you did it.  |

09-08-2016, 01:16 PM

|

|

CC Member

|

|

|

Join Date: Feb 2012

Location: Keller,

TX

Cobra Make, Engine: Lonestar Classics LS427. Self-built 408W, AFR 195 heads, Performer RPM Intake, Quick Fuel 750, 407rwhp, 479rwtq

Posts: 549

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by byron w

Texasdoc, you typed too many words or you would have had me, LOL

|

It is about quantity, not quality. |

09-08-2016, 01:52 PM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: shellvalley 428 ford

Posts: 397

|

|

Not Ranked

Not Ranked

I think your post had both!

|

09-08-2016, 04:16 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2004

Location: Huntington,

VT

Cobra Make, Engine: E-M 427 Top Oiler stroked to 482 by KC, Stage 2 heads, a Quikfuel and Voila, 640 hp

Posts: 502

|

|

Not Ranked

Not Ranked

So.....hours coming up with a template of this "tool" and the follow on prototype made out of fossilized whale bone which, in turn, is scanned into a 3D printer to render the final tool to depress the valve spring ??? All you have to do is take 2 minutes to remove 4 or 5 bolts holding down the rocker arm assembly and bingo......the whole damn thing is out of the way and you can start feeding the rope! You could also borrow a compressor and skip the rope all together (pun intended). Napa has a couple different types of spring compressors for little money too. One last suggestion, cover everything up before starting to remove the valve spring. Those little valve stem keepers have a habit of disappearing if you don't handle them with a magnet.

Tim

__________________

At first, nothing happened. Then after a few seconds, nothing continued to happen.

Douglas Adams - Hitchhiker's guide to the Galaxy

|

09-08-2016, 04:19 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by 55312

So.....hours coming up with a template of this "tool" and the follow on prototype made out of fossilized whale bone which, in turn, is scanned into a 3D printer to render the final tool to depress the valve spring ???

|

Yes. Because that is our nature.  |

09-20-2016, 09:26 AM

|

|

CC Member

|

|

|

Join Date: Aug 2011

Cobra Make, Engine: ERA 427S/C w/ 1968 428 Cobra Jet Holley 750

Posts: 44

|

|

Not Ranked

Not Ranked

Just to follow through here...

I was able to get my pinky finger into the spark plug hole enough to feel the bottom of the vavle and confirm that it was smooth all the way around. Also put a camera/scope in there to look for signs of damage to the piston. nothing.

So I packed the cylinder with rope to hold the valve up. I removed the old broken spring (broken in two places). I used the new spring compressor but soon realize that I could not get the new spring on without removing the rocker arm. So I took that off, put in the new spring, and then removed the rope. I then put the new pushrod in, and cranked the motor to confirm that the lifter was moving up and down (it was). Then i reinstalled the rocker arm, and cranked it again with the battery, while using a compression gauge. Everything checked out okay. So I reinstalled all the plug, hooked up the coil, crossed my fingers and let it fire up. It works! Thanks for all the advice. this is an amazing forum, and great to see that the members don't get into shaming other people who are not seasoned mechanics. I learned more than i intended to on this project and thankfully fixed it without having to remove the heads. And fixed it for $18 in parts, instead of having to pay $1,000s for someone to take it apart for me.

But I still may never know exactly what caused the spring to break and pushrod to bend. At minimum, I should probably fix my flaky tach (the needle jumps all around (stewart warner)

|

09-20-2016, 11:39 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,011

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA427

Just to follow through here...

|

Nice. I'm curious, when you pulled the broken spring out, did it turn out to be a single spring with a damper, or was it a dual spring (with or without damper)?  |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 04:57 AM.

|

Linear Mode

Linear Mode