Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

09-05-2004, 11:56 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

427 FE dumps roller lifter and eats camshaft

427 FE dumps roller lifter and eats camshaft

There was that recent thread on "Roller Lifters for the Street", I think I got jinxed reading it!

I lost a roller lifter this weekend and it ate the cam and broke the rocker arm shaft. Damage is localized and not to bad, got lucky!

SO,,,,,,

I been doing some reading on roller lifters. Looks like "heat" is the damaging factor. The engine oil seems to play a big role in carrying away the heat buildup at the roller. Street use generally means less oil to that critical area, thus over heating the roller, leading to failure. The high spring pressures are what causes the heat build up apparently. 150 pounds or less seems to be OK for street use. 200 plus is far more common for a roller cam.

Who was it that mentioned changing valve springs every 5,000 and the roller lifters every 10,000 miles? For some of us 5 or 10,000 miles might be a LONG time. But I drive MY Cobra "alot". I've put a few thousand on it in a few months! Might take others guys years to accumulate 5000 miles.

The car has about 12,000 miles and there is nothing in the "paper work" with the car to indicate any additional major engine work since it was built. SO,,, a 10K estimate for replacing roller lifters could be accurate!

Worthy to note I DON'T have an oil cooler on this car. The oil temp is typically 200-220. I wonder if an oil cooler would have made the difference?

Now carefully considering my options as to WHAT kind of cam and lifters to re-install in the engine! I really like the BIG horse power and may stick with rollers anyway!

Last edited by Excaliber; 09-06-2004 at 01:17 AM..

|

-

Advertising

09-06-2004, 01:05 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

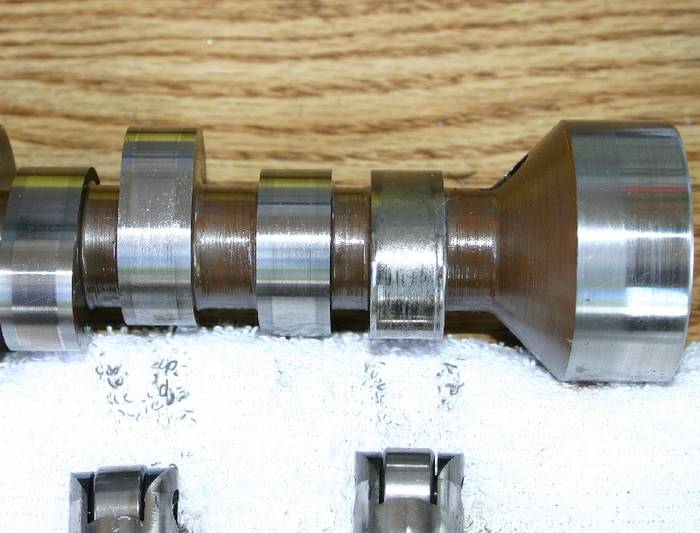

Pic of lifter

Pic of lifter

.  |

09-06-2004, 03:17 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Castalia,

Oh

Cobra Make, Engine: EM cobra, 450 inch sbc running a best ET of 9.14..so far..ALL MOTOR...approx 800 horse.............ERA with 482 FE..All Aluminum Engine

Posts: 1,395

|

|

Not Ranked

Not Ranked

That's what my lifters looked like for 2 yrs in a row, after using CompCams POS that they called lifters. Then try to talk to the company about them....told me the lifters would last 800 miles and 2000 miles was excellent. After doing my homework the best lifters I could find were Crower. They have a pressurized oiling system to the roller. Took them out about a month ago after a couple thousand miles, to check them, and they look like new.

Lack of oil is what kills the roller lifter, if you're using oil restrictors in the galley take them out. Low rpms also helps kill the lifter, because it isn't getting the oil thrown off the crank on them.

__________________

Jack

XSSIVE .....

|

09-06-2004, 06:01 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,597

|

|

Not Ranked

Not Ranked

Ernie,

NASCAR gets 800+ horsepower out of their small blocks and they have to use flat tappet lifters. You should easily be able to top that with your Big Block even going to flat tappet lifters. Mine with the mild build and lowering the cam to make it driveable dynoed out at 440 H.P.at 6300. That is more than I really needed or was wanting but so far I like it ok. We are going in different directions as I am tired of high powered temperamental motors that blow up. But as stated in an earlier thread, Big Block = Bigger Bang when it blows. Sorry to hear about your bad luck. Keep us posted on what you decide. Maybe lower compression and twin turbos.

Ron  |

09-06-2004, 06:27 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Excall Looking at the pictures, I see broken shaft at the mount hole. The problem may have started there. The lifter bounced onthe cam giving the roller flat spots and cause the lifter to destroy itself. What does the push rod look like?? You didnot say how big the cam is? Depending on the ramps and lift of the cam a don't agree with the 5000 and 10,000 mile rule. Car have hydro roller in them and go 100,000 miles without a problem. Was your block lifter bores sleeved?What pressure are your springs at and what is the chip in your msd rpm limit? How many times did you bang the rpm limiter? The cam I am looking at is the crane 349521 with hydro lifters seat pressure's 130and 350 at 1.30 compression of the spring. Rpm 2500 to 6000 rpm chip 6250 in the msd. 40 psi at idle and 80- 90 psi in racing mode. I am not a good engine builder yet but learning every day and geting better. I side note, some lifters or bores have a .010 groove in them to spray oil on the roller and cam face, did your's? I am not picking on you, just looking for answers also.   Rick Lake

|

09-06-2004, 06:27 AM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Cobra Make, Engine:

Posts: 1,514

|

|

Not Ranked

Not Ranked

Ernie - Sorry that happened to you!

Ron - Yes, Nascar gets power but only for 500 miles and that's a long race which many don't finish and they have to turn 9,000 rpm's to get it anyway - not quite like our BB's - IMOTI. |

09-06-2004, 06:34 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,597

|

|

Not Ranked

Not Ranked

Cracker,

My post never came out quite like I intended it to. What I meant to point out is that you can get big power with flat tappets, IE my 1966 427 Tunnel Port that put out just over 650 HP with flat tappets and a lower profile cam. Also I just ran 11:5 compression. With a higher cam and more compression I could have had it over 700 and it would have been even less friendly to drive. I was almost relieved when that thing left the car. I think part of it is still in the forests surrounding this area. It made it's peak power around 7,000 if I remember correctly.

Ron  |

09-06-2004, 07:45 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2003

Location: West Linn,

OR

Cobra Make, Engine: ERA #684, 428 FE, TKO600

Posts: 1,378

|

|

Not Ranked

Not Ranked

Ernie:

I wouldn't worry about oil temps in the 200 to 210 range. That's about where it should be to outgas condensation and some comtaminants that accumulate in the oil.

Running an oil cooler quite often results in oil temps being too low which is why people use an oil cooler thermostat in their applications.

DonC |

09-06-2004, 11:04 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

DonC, good point about the oil temp, I'm still trying to "analyze" the failure.

I'm with you Ron61, I've about had it with tempermental high strung motors. But this one sure was fun, dam that horse power IS addictive! Flat tappets this time around.

Excellent observations Rick and good questions. I to wonder if the broken shaft came first! The push rod is toast, I shut it down immediatly after I heard the "bang", the damage looks very contained at this point.

I did not see a groove in the STOCK lifter bore. 427 side oiler can't run hydraulic so solid is the only option without serious machine work. I don't plan on "pulling the engine" at this point, simply "clean up" and replace cam and lifters. POSSIBLY pull the heads and replace the pistons with dished to lower the compression (currently 12.5 to 1).

No specs on the cam but it IS way radical. I recently had the heads off and down to the machine shop for "cleaning up". Check spring height, replace valve seals, check stem clearance, etc. The TRIPLE springs are SO stiff the machinist could NOT use his normal air powered spring removal tools. He had to fabricate a hand tool to compress the springs!

I usually shift at 6000, but occasionally take it to 6500, which is where it was when it "blew". Rev limit set at 6750, I HAVE bounced off the limit a few times!

I JUST installed a couple of rebuilt Holleys and the motor had never run so "sweet", man it was pulling like a frieght train and smooth as silk, well,,,, right up until the last moment anyway! I could "loose" a 100 horse and not miss it, at 667 horse all ready it did have "enough".

|

09-06-2004, 11:16 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,597

|

|

Not Ranked

Not Ranked

Hey Ernie,

Remember the old saying, "They always run the best just before they blow."

Ron  |

09-06-2004, 11:19 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Exactly why I mentioned it Ron!!!! Aint it the truth!!!!

By the way, as Pat the Gashole pointed out, the tappet (roller rockers too) clearance was .040 when I got the car. Hard to say HOW it was driven, IF it was ever maintained or WHEN the valves got an adjustment before I bought the car. One of the first things I did was set the clearance at .030 (I don't have "specs" on the cam). I now believe (as Pat suggested) mid 20's would have been better.

It seems these rollers are "sensitive" to being bounced around!

|

09-06-2004, 11:31 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,597

|

|

Not Ranked

Not Ranked

Ernie,

The settings for my roller rockers on the big block are .027/.028.

That .040 sounds like a lot of gap and if the car wasn't so noisy already you would surely have heard it. Even before Ilowered my cams profile the setting was still the same. And I had a 312 duration, .630 lift cam with 96 degree overlap. The new cam is much milder than that but sure pulls a lot better at lower RPM and is a lot nicer to drive with. I think it just has a .535 lift and 292 duration with about 84 degrees overlap.

Ron

|

09-06-2004, 03:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Ernie I ran solids 20 years ago and spent every week end in the valve covers with adjustments. I went back to hydro, smaller cam, matched runners on the intake, heads, and header. Made a little less power but no problems. Motor is in the backyard in my 72CJ5. Solid rollers are ment for short racing 1/4 mile in my feeling. This is why hydro rollers came out. Most enduro motors run about 600-650" lift. Triple valve springs are not needed. If you want to run them then you need a rev kit that keeps the lifter wheel in contact with the cam surface, other wise a bouncing problem. even a .015" will damage the surface of the cam lobe and the roller wheel. You can still run your setup, just change a couple of things, Lighter springs, watch your rpm banging off the limiter. Check the valve lash every 500 miles. Having the oil temp and the right wieght in the motor is important but not what cause this problem. My bet is $20 on the shaft broke first. The rocker was twisting and ate the roller on the bottom of the lifter by bouncing on the cam and the push rod finally bent or snapped. I have to look at the oiling system on a SO motor, there most be some oil to lube the lifters in the bores or a splash effect. I will get back to you on this. You didn't say what gears you have in this monster? Build more tork, drop the ratio 10% and the car will be just as fast without the maintance problems. I have a 360hp motor 460 tork 9.2 compression, 501-533 cam from crane, idle is 700 rpm with a glass of water on it and not spill. runs 12.5 in the 1/4 with 3.31 gears, I can smoke the pilots in second gear at will, the tires are 2 years old and kept in the dark on a rack when not racing. Do you have Alum heads?? 12.5 is not bad if you watch the timing and good fuel. I have to do some research and get back to you. Rick Lake

|

09-06-2004, 05:06 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

A litte emory cloth to polish it up.......

A litte emory cloth to polish it up.......

Pat the Gashole said because the cam lobe shows such minimal damage I could just polish it up, buy one new roller and put the engine back together.

Just poking fun at Pat, it's a JOKE.

See, the cam lobe aint "that bad".

3.31 rear gear 26.5" tire and heres the kicker, CLOSE ratio top loader which means that FIRST gear in the trans is WAY higher ratio than the WIDE ratio trans. 1st gear is good to 65 mph. I STILL run the 1/4 in the high 11's. I have considered going to a lower rear gear..........

NOW, about the block. The side oiler block of mine IS the ribbed block, (ribbed for more pleasure or higher rpm or something) meaning it's 66 or later and IS drilled for hydraulic lifters. Now I'm seriously considering a roller hydro cam.

Last edited by Excaliber; 09-07-2004 at 07:14 PM..

|

09-06-2004, 05:30 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: Annapolis,

MD

Cobra Make, Engine: Unique, 427SO, it runs

Posts: 2,636

|

|

Not Ranked

Not Ranked

Ernie, if it's ribbed and there are no numbers on the passenger side of the block (indicating which vehicle it was intalled in), it's probably a service block circa late 60's early 70's. I've also been told they tended to be stronger, and I have one cast in 71.

I'm running solids, with an Elgin Pro-Stock that calls for .025 int. and exh. lash. I have checked them and had others more knowledgeable check them every 1000, and I swear they don't change more than a hair, so I'm a little confused by some of the guidance above. But it is a mild street cam for a street motor....everything's nice and symmetrical

__________________

Clay

Last edited by clayfoushee; 09-06-2004 at 06:45 PM..

|

09-06-2004, 05:59 PM

|

|

CC Member

|

|

|

Join Date: Jan 2003

Location: Atlanta,

GA

Cobra Make, Engine: CAV GT40 with 331 KC

Posts: 2,187

|

|

Not Ranked

Not Ranked

Geez,

At least let everyone know you're joking, Ernie.

Pat

|

09-06-2004, 06:14 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

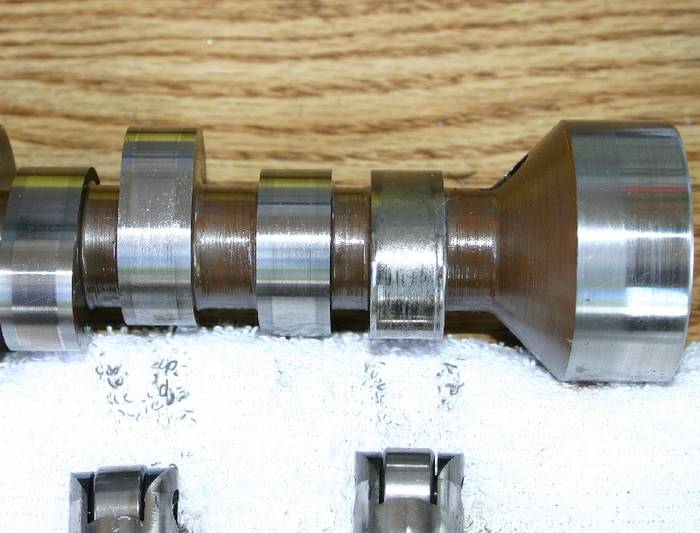

If you think I'm serious about Pats advice....

If you think I'm serious about Pats advice....

I have a bridge you might be interested in!

Looks like a custom grind cam, "hand writing" on the end of the cam says:

Crane R-258/3383-2 12

3 4-1-90

The other end is "stamped":

349356

7J2A |

09-06-2004, 06:38 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Olympia/Lacey,

WA

Cobra Make, Engine: West Coast. 514 / 6 speed Richmond overdrive

Posts: 1,981

|

|

Not Ranked

Not Ranked

Here's what my machine shop expert told me as we adjusted my valves the first time...

Here's what my machine shop expert told me as we adjusted my valves the first time...

"You'll need to adjust them every 500 to 700 miles or so until it has a few thousand miles on it, as they seat in and settle". Then if the next few times you check them maybe every 1,000 miles and there's no sign of change, then you can extend the check interval quite a bit."

It's about getting them right at first (We did this at 350 miles and we also re-torqued the heads and the intake, all of which had loosened! I'll check them maybe next spring at the 1000 mile mark and then at 1700 or 1800 miles and that will tell a lot.

__________________

James Madison, father of the Constitution, said, "If Tyranny and Oppression come to this land, it will be in the guise of fighting a foreign enemy." He also said, "No nation could preserve its freedom in the midst of continual warfare..."

~~~~~~~~~~~~~~~~~~~~~~~~

http://www.standdown.net/index.htm

|

09-06-2004, 06:43 PM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Here's the specs from crane:

Part Number: 348461 Grind Number: R-258/3383-2-12

Engine Identification:

Start Yr. End Yr. Make Cyl Description

1963 1976 FORD-MERCURY 8 ROUGH IDLE, PERFORMANCE USAGE, GOOD MID & UPPER RPM H.P.

Engine Size Configuration

352-428 C.I. V

Valve Setting: Intake .028 Exhaust .030 HOT

Lift: Intake @Cam 3383 @Valve 595 All Lifts are based

on zero lash and theoretical rocker arm ratios.

Exhaust @ Cam 353 @Valve 621

Rocker Arm Ratio 1.76

Cam Timing: TAPPET @.020

Lift: Opens Closes ADV Duration

Intake 41 BTDC 75 ABDC 296 °

Exhaust 90 BBDC 36 ATDC 306 °

Spring Requirements: Triple Dual Outer Inner

Part Number 99874

Loads Closed 200 LBS @ 1.938 or 1 15/16

Open 535 LBS @ 1.361

Recommended RPM range with matching components

Minimum RPM 4000

Maximum RPM 7000

Valve Float 7400

Cam Timing: TAPPET @.050

Lift: Opens Closes Max Lift Duration

Intake 22 BTDC 56 ABDC 107 258 °

Exhaust 71 BBDC 17 ATDC 117 268 °

Remarks:

Crane Cams continuously improves and upgrades its cam designs. In some cases this may mean that two Crane Cams with the same part number may actually be different grinds. You must check the GRIND NUMBER stamped on the front of the camshaft and check it against the Grind Number near the top of the Spec Card. For more information on the finest available camshafts, valve train components, and automotive ignition products, visit your local Crane dealer or call the Crane Cams tech line at (386) 258-6174 or FAX (386) 258-6167

Kind of big on duration, but not very big on lift ( I-.595, E-.621), minus lash of .030, brings to I-.567, E-.591"

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

|

09-06-2004, 06:50 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Thanks Anthony, I tried and failed to find that info!

High riser heads, ports SO big you could drive a truck through them!

"Rough" idle, yeah, they got that right! I think 6500 rpm is about all it was good for. Shifting at 6000 produced same ET as shifting at 6500. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:48 PM.

|

Rick Lake

Rick Lake

Linear Mode

Linear Mode