Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

01-08-2005, 06:11 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Rocker covers...

Rocker covers...

Those are Blue Thunder cast aluminum parts. Nice parts, but if you buy them...ask for extra fasteners; if you ever lose one you'll play hell finding another.

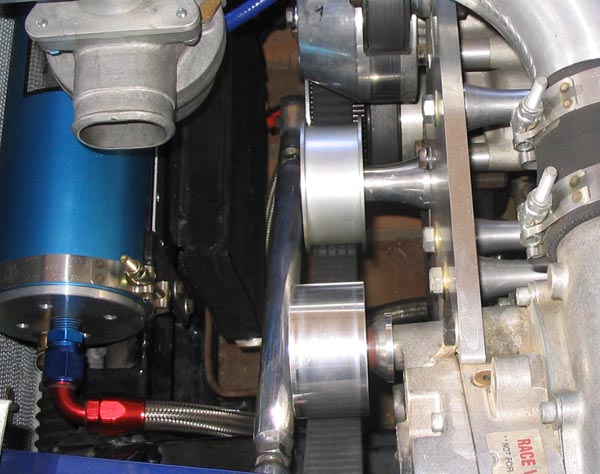

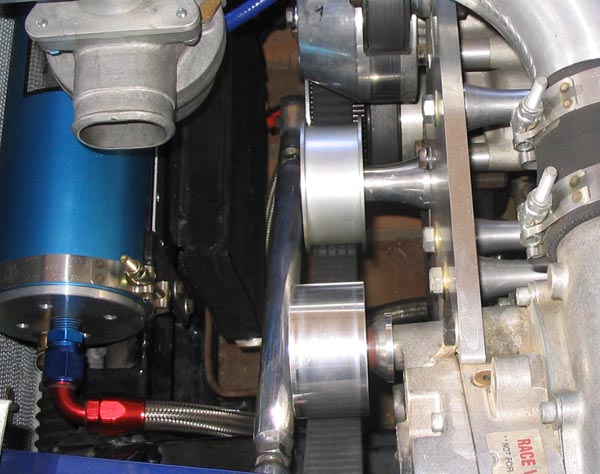

The blower drive was optimized pretty well for a cobra. If I did it all again, I'd design it for a 4" idler so I could use low-cost off-the-shelf idler parts. Designing it for a 3" idler created all kinds of hell; including having to use expensive class 7 bearings and a custom idler. The electric water pump was necessary, but they are very reliable these days; it shouldn't be an issue. I'm using a remote-mount meziere. In addition to chopping belt length, It also improves flow not having to feed the air through a sharp bend at the blower inlet. Mine feeds from a nose-mounted scoop.

|

-

Advertising

01-09-2005, 06:46 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: Brisbane, Australia,

Q

Cobra Make, Engine: Contemporary CCX3117 427FE

Posts: 4,381

|

|

Not Ranked

Not Ranked

How about an intercooler / aftercooler ?

__________________

Craig

|

01-10-2005, 04:41 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Byron If you drop the fuel pressure down to 25psi you will get the coils in the injectors and the quad drivers in your ECM to work harder and get hotter. The coils in the injectors use the fuel to help keep them cool. By slowing the rate of flow through them you are heating the gas more. I tryed this with my set and hurt the driver in the ECU, the ampage to turn them on and off gets higher. Same thing with the fuel pumps in the gas tanks. I have 2 255 walbro in my tank with 2, 1/2" line going to a 5/8 at the regulator. the gas gets hot after 20 minutes of racing. My gas gets to 110F after a race. I have a return system which doesn't help either. When the next motor gets done it will be returnless. Rick Lake

|

01-10-2005, 05:23 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Not with these injectors...

Not with these injectors...

At 100% duty cycle, the theory is that the injector coil will overheat to the point where the impedence changes and causes a catastrophic failure. I've heard this theory many times, but have ever seen an actual demonstrated case. The root cause is always something else once I investigate.

I've wired one of these ford alternative fuel injectors to a 12V, 10A capable bench supply and left it on indefinitely (this is not what a peak&hold driver does, this is flat-out abuse). The current flow and impedance never changes...and the coil never gets hot enough to melt anything. In fact, it gets to 140deg F after about an HOUR, and is quite boring to watch. Nothing interesting happens. No current changes, no impedance changes, no problem.

In my application I'd be lucky to see 70% duty cycle 10 seconds at a time...and I'll be using a true peak&hold system that only delivers less than 1/2A of current, so melt-down is impossible.

I've also done this same test with GM injectors after being told that they would fail. They don't. What fails is PCMs that don't perform true peak&hold, or running a peak&hold type low impedance injector on a PCM that is designed for high impedance injectors. I've seen both cases, and in both cases bad things happen...to the drivers in the PCM. I've never seen a "fried" injector due to current-induced thermal failure.

My pressure change from 40psi to 20psi changes the flow rate through the injector from 160lb/hr to 110lb/hr. That's still 1/3rd of a gallon of fuel per minute at 100% duty. There's no way an injector flowing a gallon of atmospheric temperature fuel every 3 minutes at 100% duty is going to get anywhere near critical temperature in under a minutes time. And, as I said...I would be lucky to see better than 70% duty and the duration will be more like 10 seconds. It's not an issue.

If you saw a failure doing this, I'd be curious to know which pcm and which injector you were using. The injector drive strategy is probably not correct. Peak current must be applied for far too long to build current like that. In a proper peak&hold strategy, on an SEFI injection system, the longest possible "hold time" is around 20mS on a 6000rpm engine. And, the "hold time" represents better than 99% of the entire injector pulse duration. During hold, the driver should supply about 1/2A of current. If the injector is say 5ohm, and you're flowing 1/2A, the coil is consuming 2.5watts of power. There's simply not enough power there to build enough heat to destroy the windings before the heat disspates through the surface area of the injector; whether or not fuel is flowing.

It might also help to know that I've done this before using Siemens Dekka 83's in at least 6 customer cars. It's a well known way to increase fuel pump flow if you are running a large injector on a car that doesn't need the full flow capacity of the injector. Simply drop the delivery pressure and the pump can deliver more volume.

In addition, the same applies to the "oh no your injectors are at 100% duty that will destroy them" myth. 100% duty is fine; it doesn't hurt an injector. It does mean your injectors are too small and you'll probably need to do something about it...but as for the injectors; they're fine at 100% duty. No damage done. I've tuned silver-state-classic cars that ran 170+mph for 80+ miles foot-to-floor with 100% duty railed injectors. Fuel was augmented with a fuel pressure control system with wideband feedback to maintain 11.5:1. Worked fine. No dead injectors. It's amazing how much misinformation is out there.

|

01-10-2005, 05:34 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Fuel heating...

Fuel heating...

To reduce fuel heating, use a PWM pump controller on your fuel pump with a 0-5V control input connected to your PCM. Map your PCM to output a control voltage that increases pump delivery in proportion to air mass, RPM, throttle angle, or whatever other inputs you need. Throttling the pump down will help fuel heating tremendously, as will running lower base fuel pressure.

I use a PWM controller designed for 12V wheel chairs. It uses a 0-5 control input. I have my own hardware that controls the pump based on the output of a mass-air meter that is measuring airflow into the engine.

Also, you will need a quality linear regulator that will not change the pressure differential as the flow changes. Some regulators are poor; and the pressure willd drift dramatically as you cycle the pump through it's flow range. Magnaflow regulators are excellent; they are stable through all flow ranges. I use weldon 2015, 2025, and 2031 pumps.

Lastly, if you still are unhappy about the heat, install a small power steering cooler or transmission cooler on the return line to drop the fuel temp to atmospheric. This is unnecessary in most applications when using a pwm controller.

Returnless systems are OK, but you'll have hotter fuel entering the combustion chamber on average than the system described above, and will also have a lot of trouble running any sort of positive displacement pumps like Weldons, gerotor pumps, etc. You'll end up water-hammering the pump to death, and the PID loop control algoritm they use to do returnless systems doesn't work well with those kinds of pumps. You'll have to run big turbine type fuel pumps...not Walbro's. If you need help selecting some high-flow turbine style pumps, I know of some Ford OEM parts that work well.

|

01-10-2005, 05:55 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Intercooler/Aftercooler

Intercooler/Aftercooler

I thought about implementing an intercooler; and decided not to.

Vortech's V7-YS generates about 160deg F intake air on a 70deg day at 15psi. I have tons of data logs to support this from customers running my datalogger product, SnEEC-IV.

160deg F intake air worst case, and 10-12psi of boost, and a 7.8:1 compression engine, should easily yield my desired result (1000fwhp) without the need for any additional power-adder devices like intercoolers. Additionally, I should not have a need for colder intake air to avoid detonation with the low compression engine.

The only thing an intercooler or aftercooler would do for me is make more power; quite a bit more; and if I do that things will break. My engine runs a forged steel 429 production crank. It will do (and has done) 1000fwhp in applications far more strenuous than mine (like jet boat racing, monster truck racing, etc.). However, they are known to fail at about 1300hp; so I'm not going beyond 1000. Also, my engine is built on a production 1971 429 block with a 1/3rd fill, and a 4-bolt billet main conversion. As strong as this is, it's still a production block, and it has its limits. I can point to several 1000+hp combinations with far more stroke than mine that lived; and several at 1300+hp that did NOT live, so I draw the line at 1000.

But, if I fail to reach my goal and it's within the range that an intercooler might provide...it's an option. I didn't use better parts for a variety of reasons; the largest of which was cost. No point putting thousands of dollars into parts to make an engine run in a power category that it will never see. This engine is built strong enough to see my occasional "1000" number on a dyno, and plenty strong to live out it's life in the sub-700 range that I might have a chance at connecting...at least on the big end.

Byron

|

01-15-2005, 08:04 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: Brisbane, Australia,

Q

Cobra Make, Engine: Contemporary CCX3117 427FE

Posts: 4,381

|

|

Not Ranked

Not Ranked

I didn't fit an intercooler to make more power (I'm still running in the 11s A/F ratio and 18 degrees at max boost - so all very conservative), but I wanted the added safety margin of having cooler air.

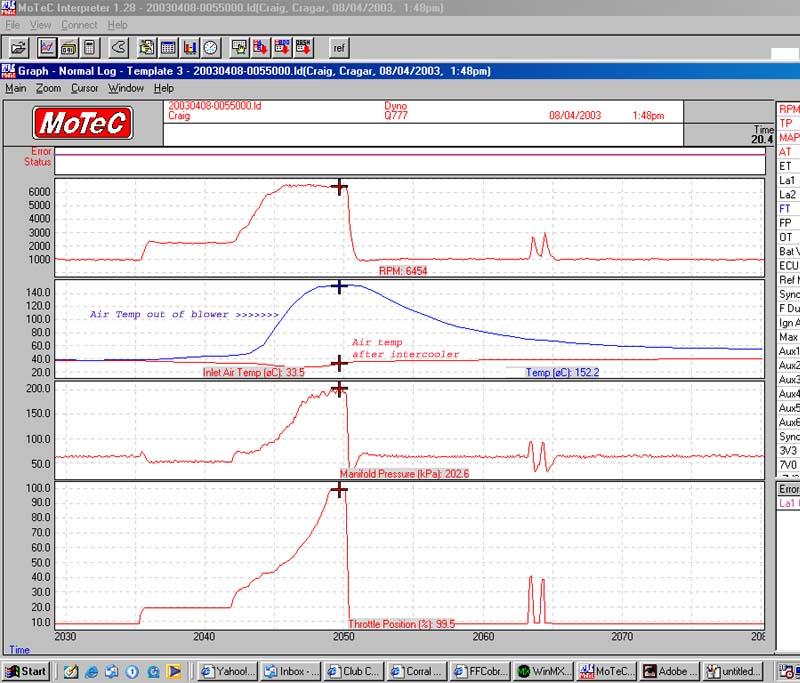

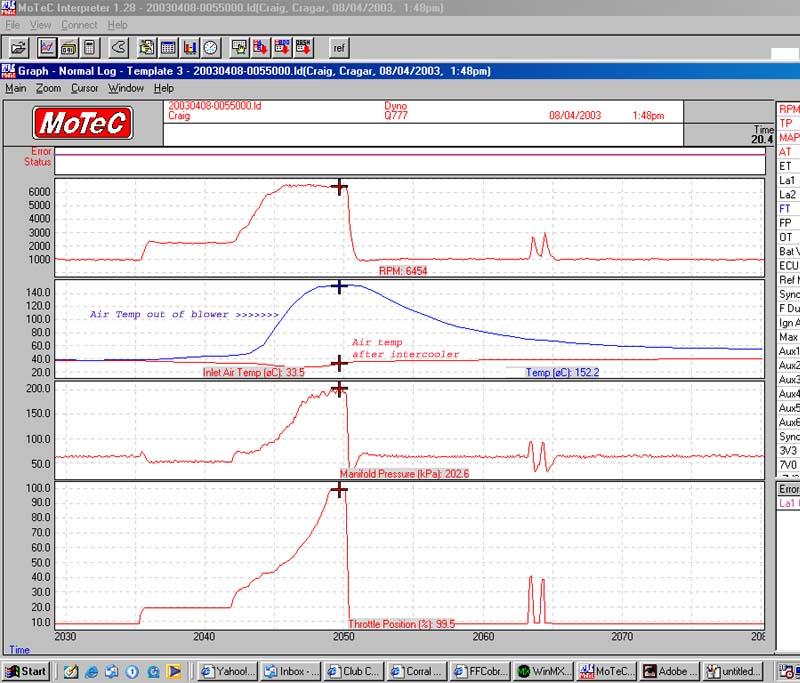

I have to disagree with your datalogging results with regard to the intake temps. Have a look at the datalogging from my dyno session. By pure luck, this datalog shows a YS Vortech at 15psi

Over 300deg F is seriously hot air to feed an engine !

__________________

Craig

|

01-16-2005, 04:59 AM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Interesting data...

Interesting data...

Thanks for the plots. To really appreciate what's going on here, I would like to know a little more about your bypass valve arrangement.

What size bypass valve are you running? Does it bypass air from before the intercooler to atmosphere? Or, does it recirculate?

What this plot looks like to me is a bypass/recirculation system that is operating at part throttle and building heat in the head unit as it recirculated hot bypass air. I noticed that your TPS is at part throttle for most of this test log, even though the engine is turning as much as 6000rpm. It would build a tremendous amount of heat if the bypass air is recirculated and / or the bypass valve isn't large enough to drop the head pressure. I have seen that problem before. Many of the Vortech kits come with small bypass valves and recirculate bypass air back into the inlet. In road-race applications where you spend a great deal of time at part-throttle, the heat buildup in the head unit is extreme. In cases like this, I wouldn't be at all suprised to see these kinds of temperatures.

If you have a giant bypass valve dumping to atmosphere when at part-throttle, this data is indeed shocking and inconsistent with all the data I've ever seen. I have logs from a few Renegade drag cars that spike close to 200deg F on a drag pass spinning Novi 2000's and V7-YSi's at 110% of spec, but I've never seen one get to 280 like yours. Does it show these kinds of temperatures even during a WOT only test?

Also, the temperature of the air exiting your intercooler seems too good to be true. You're reading 40deg C or below no matter if the engine is at idle, 2000, or 6000RPM...and no matter if the air exiting the supercharger is 40deg C or 140deg C? I'm used to seeing intercooler plots that drop the intake air temperature by some percentage relative to ambient...tracking the inlet temperature to some degree. Yours sits relatively flat at 40C or below. Is this intercooler enormous or special in some way or is it a normal air-to-air type cooler? How did you manage to make it work so well? The only intercoolers I've seen that resulted in a plot like that were the giant air/water "ice box" type coolers used in drag applications; and they typically would create temperatures lower than 40deg C.

Please let me know, I'm indeed curious.

Byron

|

01-16-2005, 12:58 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Air temps

Air temps

I was working on my tuning laptop today, and found some data to show you. This plot shows RPM and ACT (air charge temp) for a drag pass on a 9 second 347" small block mustang running a cogged V7-YS making 20psi @ 7500.

The reason for the two groups of data is that the lower grouping is low gear, and the second grouping is high gear. I just plotted all "WOT" data...this is how it turned out.

I specifically went looking for data with temperatures hotter than 180deg F and was suprised to find this extreme case...I do have data hotter than I thought. At 6000rpm on the initial spin-up, the temperatures hit about 180deg F at 16psi at 6000rpm. As the rpm and boost climbs further, it rises to 220deg F. In high gear, he's hitting 250deg F and goes through the traps at about 7000rpm.

This is all WOT data, and a 20psi cog configuration. His initial temperatures from 1100 to 5000RPM are all under 150deg F. From 5K to 6K, the temp starts taking off. My guess is that your temperatures are somewhat higher because of the part-throttle high-rpm you encountered during your logs. Considering this is 7500rpm and 20psi, and 250deg F...it does still seem odd that you're hitting 280+deg F at 6000 with 15psi though. I would expect your data to look more like the 6000rpm area of this plot, which is 100deg F cooler than your data.

I'm hoping that with half the boost pressure, I'll see a lot less temperature. I don't think it's unreasonable to think that if 20psi@7500 = 220-250deg air, 10psi@6500 yields < 160. I guess I won't know until I run it. Here's hoping.

|

01-16-2005, 02:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

ByronRace Have you or anyone messed with a chiller using an AC system. GM or Ford was testing an cooler setup using an evaporator core used after the blower. The compressor would use 25hp but the return would be a 50-70hp advantage. The wieght would add 40lbs. Finding R12 over 134R would also be better. I see nobody is using water injection, How come? If nothing else the EGT would be 100F lower than without. Rick Lake

|

01-16-2005, 08:41 PM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

AC based intercooling

AC based intercooling

I read a bunch about the AC powered water/air chiller system Ford has been working on for the Lightning, and I've also seen a few home brew versions of this implemented. However, every implementation I've ever seen is designed to chill a water reservoir while driving around at part throttle, then utilize this chilled coolant at WOT for added power. I think this would work fine for my application, but I'd go air-air first for simplicity reasons.

I've installed water injection on several vehicles. In my opinion, water injection (once tuned) works well as an anti-detonation measure, but hasn't (at least in my experimentation) done much for intake air temperatures and power. I have never measured EGT, but I bet you're right. My favorite kit is the Aquamist system. Power gain due to the water alone has been quite small (10hp on a 300hp engine), but the additional knock headroom is on the order of 2-4deg additional advance before detonation on most small block Fords. This is a big deal if you're trying to run 91 octane pump gas and iron heads with 10-12lbs of boost. So, from that perspective...the gains are significant. What I don't like about it is having to keep an eye on level, worrying about it not working for some reason, having to use deionized water as to not clog the pump and nozzles, etc. It's not a "set it and forget it" relationship. I thought about designing my own system, just have never gotten around to it.

Byron

|

01-17-2005, 01:49 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: Brisbane, Australia,

Q

Cobra Make, Engine: Contemporary CCX3117 427FE

Posts: 4,381

|

|

Not Ranked

Not Ranked

Re: Interesting data...

Re: Interesting data...

Quote:

Originally posted by ByronRACE

If you have a giant bypass valve dumping to atmosphere when at part-throttle, this data is indeed shocking and inconsistent with all the data I've ever seen.

Also, the temperature of the air exiting your intercooler seems too good to be true. You're reading 40deg C or below no matter if the engine is at idle, 2000, or 6000RPM...and no matter if the air exiting the supercharger is 40deg C or 140deg C?

|

Hi Byron,

I have a Mondo bypass that dumps to atmosphere. The dyno run was just part of a general caning we gave the motor to make sure that it could handle various load levels, rpm levels, engine temps, air temps, etc. If anything on the motor was going to break, I wanted it to happen on the dyno. We had the usual dyno fan blowing over the intercooler/motor initially, then we turned the fan off and let the intercooler heatsoak for a few minutes, we then cycled the rpm/load all over the place and the temp after intercooler never got over 60C ! Anyone that's seen the motor after I've gone for a drive can see that the pipe leading into the intercooler is too hot to touch, but the pipe leading away from it is only as warm as the radiating heat in the engine bay. It's weird, but you'd swear it had it's own little dry ice box in there.... The intercooler core is 24"x12"x4.5", bar and plate, Garrett brand. It's as heavy as heck, and I suspect that the amount of aluminum that goes into making them allows them to absorb the initial hit of heat. I have numerous logs to show that my air temp inot the manifold actually drops a handful of degrees when I first hit the throttle. I'm never at WOT more than a few seconds at a time, so I never really tax the system as much as when we dynoed it. When I get my laptop back, I'll post the quarter mile runs I did. I can't remember what the air temps did then.

Thanks for the log from the Stang. Do you know what impeller speed that car was running through the traps. I have a 74/28 cog setup, and I'm at 400 cubes. I've seen a lot of smaller cube motors running much higher recorded boost levels at the same impeller speed. Your monster motor won't be showing much boost, but the airflow will certainly still be there for you!

|

01-17-2005, 09:36 AM

|

|

CC Member

|

|

|

Join Date: Feb 2002

Location: Gilroy,

CA

Cobra Make, Engine: West Coast Cobra w/ Centrifugally Blown Big Block, Pickles, Onions, on a Sesame Seed Bun.

Posts: 493

|

|

Not Ranked

Not Ranked

Wow, great intercooler!

Wow, great intercooler!

That's an amazing intercooler, especially considering this was on a dyno where airflow through the core is limited.

If I remember correctly, the car I produced logs from was running a 74/28 cog as well.

I'll be running 80/40 initially and have a 30 tooth driven pulley as well...which I should probably leave in the box; but we'll see how it goes.

I managed to fit the new idler this weekend and now I'm working on coolant lines and misc plumbing. Closer every day...

Byron

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:39 PM.

|

Linear Mode

Linear Mode