Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

05-31-2006, 12:20 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

HSSS427, the alternatives to a water base temp sensor are complex at best. Exhaust gas temperature perhaps? Head temperature sensor?

From a practical stand point, there really is no easy solution. A low or normal reading on the temp gauge when in fact there is NO water in the system has been a problem over the years for LOTS of people. Including VERY good mechanic type people, on the race track and average Joes.

It's a tough one because it can happen SO fast (like a burst radiator hose) and you may not even be aware of it. Depending on the location of the T-Stat and it's FAILURE to open you can have the same problem, motor temp off the chart while temp gauge reads 'normal', SO you keep driving! If your lucky you might get a clue, but generally the 'clue' is a loss of power, pinging, rough idle and things just don't 'feel right' in general. Meanwhile, your motor is becoming a freakin' BBQ.

|

-

Advertising

05-31-2006, 04:57 AM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: Dacula,

GA

Cobra Make, Engine: Porsche 928 S4

Posts: 408

|

|

Not Ranked

Not Ranked

I agree with John Owen about the pulleys. They're mis-aligned and something needs to be spaced. I personally don't believe that the engine was running dry all along and that it caused the water pump pump to contribute towards belts flying off, I would guess that that you overheated only after the belt came off. Anyway, to align the belt, place a straightedge on the crank pulley and note the distance from the edge of the pulley to the belt, keep the straighedge on the crank pulley and swing it around to the accesory pulleys. I suspect you'll see something obvious. Also look for the alternator being square, the crank and water pump will be square but sometimes the alternator winds up in funny positions. Check it by placing the straightedge on the alternator pulley to verify the distance to the crank pulley, if it's different when you hold the straightedge on the alternator versus the crank you can assume that the alternator is crooked.

|

05-31-2006, 05:09 AM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Crystal Lake,

IL

Cobra Make, Engine: Everett-Morrison, 434 cid

Posts: 977

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by HSSS427

Just another thought / question......

If the water gauge won't catch this situation, and the oil temp in the pan didn't catch it, what's the best way to really have an accurate measure of your engine's temp so you know when the internal situation is getting out of hand? Is there some other kind of sensor or better location for current sensors?

Thanks! |

Because of harsh track conditions it's not uncommon for a dirtcar to lose coolant and "melt-down" without the temp gage catching the problem. We run a water pressure switch to a light on the dash. In the event that you lose coolant and the temp sender can not read actual temp, you will be warned of the pressure loss. Longacre has the kit.

Scott

Last edited by scottj; 05-31-2006 at 05:13 AM..

|

05-31-2006, 12:23 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

Scottj - saw the Longacre kit - $23 bucks for insurance seems like a good deal. However, it wasn't clear on where you mount the sensor. Where do you put it so that it would pick up this type of failure? I assume that if it's on the manifold near the temp sensor, it would light up when the thermostat wasn't open since that would drop the pressure.

Thanks!

|

05-31-2006, 04:02 PM

|

|

CC Member

|

|

|

Join Date: Jul 2001

Location: Senoia,

Ga.

Cobra Make, Engine: 427SO with big twin autolite inlines on custom intake, jag rear, top loader, wembeldon white, guardsmen blue stripes

Posts: 3,155

|

|

Not Ranked

Not Ranked

Oh you 'can' tell when somethings wrong, smell for one, I knew when my valve

covers were leaking when I smelled oil on the headers and, water mixed with antifreeze smells like nothing else. the open cockpit brings it all in.......

__________________

Perry

Remember!, there's a huge difference between a 'parts' changer, and a mechanic.

|

05-31-2006, 07:20 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

OK, having learned my lesson about not asking the dumb questions......

Here are some:

1. For the life of me I can't see any difference between the 2 heads - is there a left and a right head and is it important that they go back in the same locations?

2. Had a lot of burned oil / carbon on the cylinder heads and chambers. I'm assuming this is a by product of the problem, and I cleaned it off with laquer thinner. Is this a potential indicator of something else that I should evaluate?

3. Anything else I should take the time to do while I've got the heads and intake off the engine? Was thinking of confirming TDC mark on my harmonic balancer. Should I do anything to the chambers on the heads?

4. Should I put any prelube or oil in the cylinders before closing it up? I plan on using a drill and attachment to prime the system with the oil pump, so would this be redundant?

Other questions I forgot to ask?

Thanks!

Scott |

05-31-2006, 11:48 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

I had the opportunity to look closely at one very well known 427 race car CSX3035 that has a pressure gauge integrated into the cooling system. The idea being that if the indicated pressure pressure begins to dip or varies from the norm (for that application) there is some sort of leak or gasket issue. Makes sense...........something to think about.

I just reread your initial post of this problem. I hate to say it but if you lost the bulk of your water (taking 3 gallons to refill) and the heads being the first to go dry since they are the highest point, there is a real good chance they could be damaged since the bulk of the heat is created in their local. Sorry to see this happen to anyone. If you have the heads off you might have some one look at them.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

Last edited by Rick Parker; 05-31-2006 at 11:57 PM..

|

06-01-2006, 08:13 AM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

What should I look for?

What should I look for?

Heads are off and I've cleaned them up. What kind of damage am I looking for? Warping? or other things as well? I can say there's nothing obvious to the eyeball.

|

06-01-2006, 08:40 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Lay a straight edge end to end and corner to corner....take a feeler gauge and see if there are any gaps.

Also, I know it sounds like a lot of work....but I'd change the valve seals while you're down this far.

|

06-01-2006, 09:38 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

Worst case would be loss of Heat Treat. You can check by doing Rockwell test on the castings, it is non destructive and verifies the hardness of the material. IF they got REAL hot they CAN lose their integrity and dimensions begin to change. Valve seats and guides can get loose due to dimensional changes & loss of press fit between components. This is the thing to be concerned about.

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

06-01-2006, 07:28 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

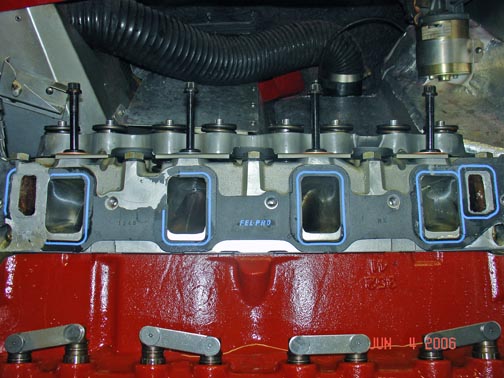

Got the heads back on and torques down to 100 ft lbs - pretty good workout after going through 3 steps on each of 20 bolts

I did the feeler gauge test with a carpenters square and it appeared to be flat - couldn't get a .008 feeler gauge under it, which was the smallest gauge I had. The "book" said .003 was the tolerance so got my fingers crossed on that.

I'm opting out of the rockwell test and valve seals - the things have just been rebuilt 250 miles ago by Keith Craft and it wasn't exposed for that long to the heat. So, I'm going to roll the dice and take my chances.

Now off to wrestle the intake and intake gasket! and then on to figuring out the pulley alignment.

Thanks! |

06-04-2006, 05:40 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

Bad news.....

Bad news.....

|

06-04-2006, 05:59 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

You didn't notice if any of the cylinders were cracked did you?

Is it possible that an intake gasket moved when you put the intake on?

|

06-04-2006, 06:33 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

I didn't notice anything in the cylinders. I guess it is possible that the gasket moved. For the volume of water that just flowed into the cylinder i guess that would be the most logical cause - at least I hope that's it.

|

06-04-2006, 06:43 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

You either have coolant coming in from the water jacket...or it's coming from the intake.....

Pop the head off and check her out.

|

06-04-2006, 06:59 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Doubtful head gasket moved, it sits on dowels. Intake maybe, OR, head gasket mounted upside down or incorrectly.

Assuming theres no major cracks in the cylinder bore of #2...

|

06-04-2006, 07:01 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2004

Location: St. Louis,

Mo.

Cobra Make, Engine: 427 S.O. Dual Quad / Cobra undecided

Posts: 1,380

|

|

Not Ranked

Not Ranked

HSSS,

Sorry to hear the bad news. I know you used fresh head gaskets which leads to the next assumption, a warped cylinder head or an undetected crack in a water jacket allowing coolant to invade the cylinder.

Unfortunately you almost certainly have coolant in the bottom end.

You may serioulsy want to consider pulling the heads and taking them to a machine shop/builder to check for warpage. Maybe they can be milled down. As for the block, a pressure test of the cooling channels or soni check may be in order.

Heat is the enemy. I feel for you, having done the rebuild only to find you have to do it again, been there done that. Had a cam jump a gear tooth on an 60' Healy and spent a long time trying figure what was wrong and ended up tearing down a meticulos build. It still turned out to be a great runner in the end.

Good luck.

|

06-04-2006, 09:21 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

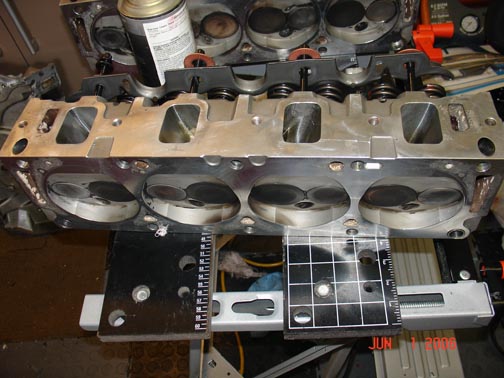

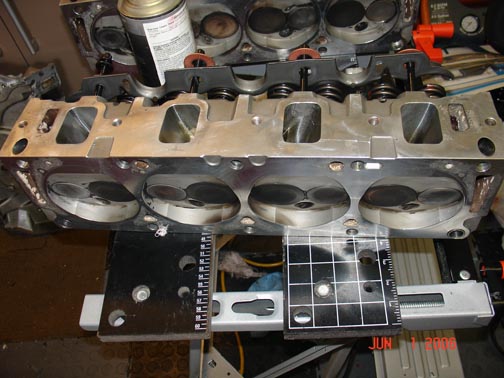

Tore it back down...here's the pics

Tore it back down...here's the pics

|

06-04-2006, 10:09 PM

|

|

CC Member

|

|

|

Join Date: Jan 2004

Cobra Make, Engine:

Posts: 32

|

|

Not Ranked

Not Ranked

Looking at the photo of the cylinder head combustion chambers, I can't see the imprint of the metal ring of the head gasket well between #2 and #3 cylinders. I would guess the head is a bit warped and the head gasket is not sealing well in that area. Also looks like you are using the low riser Printoseal intake gaskets instead of the medium riser gaskets for the Edelbrock heads.

|

06-04-2006, 10:34 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Well it's possible the imprint isn't there because the head is really clean in that area, I wouldn't conclude 'warped head' from that alone.

I would take the head to a machine shop and have THEM check for warpage. They will have a really long very straight 'edge' and can run a feeler gauge along it to check for clearance. You can do the same, assuming YOU have a really long really straight 'edge'.

At any rate the question now is: WHERE is that water coming from! Even a badly warped head should reasonably seal when 'cold' and 'new gasket' and prevent THAT much water from getting in so quickly. From that I would have to assume were looking for a virtual 'crater' of a gap\crack somewhere.

Even though the intake gaskets may not be totally 'correct' it appears the water transfer holes (head to block) had a good seal.

No doubt it will be obvious and simple once discovered, a kind of a "DOH" moment.

Last edited by Excaliber; 06-04-2006 at 10:40 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:45 AM.

|

Got it all back together, filled with

Got it all back together, filled with

Linear Mode

Linear Mode