Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

5Likes 5Likes

09-21-2006, 08:03 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Ft. Worth,

Tx

Cobra Make, Engine:

Posts: 257

|

|

Not Ranked

Not Ranked

Hsss,

I bet when you get your engine back you will notice the crank does set back farther than the mounting holes for the bell on the back of the block. Trust me you will be fine, if you want it to be in the same location than have the long shaft re-installed and use the adaptor plate instead. jimig@standardtransmission.com

Jimi G.

Last edited by Jimi G; 09-21-2006 at 08:07 AM..

|

-

Advertising

09-21-2006, 09:10 AM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

Jimi - thanks. Sent you an email.

Problem is I don't want to use the short input shaft as I'll have to change the cross member mount and modify the shifter opening in the transmission tunnel.

Thanks!

|

09-21-2006, 09:15 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Input shafts and Crank flanges are different with each manufacture...

The polished end of the input shaft is approximately 1.00" long..... and on a FE it goes into the crank about .375"inch .....so we made the bronze oilite bushing to fit into the crank and have a outside flange to give more support to the input shaft to run on.....

The flange on the pilot bushing is about .400"inch so we are working with only .775"inch on the polished input shaft.....

Here's some photo's to show....

Bushings are much better then roller bearings.....because they can handle slight variations between the crank and input shaft.....

And if you are only going to be inside the roller bearing .375"inch.... just not enough for us...

Morris

__________________

Morris

|

09-23-2006, 01:33 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

So Morris, where do ya get one of them thar fancy bushins'? That seems like a good idea, but I've just been buying the standard bushing from NAPA.

I've basically resigned myself to the short input shaft setup with no space plate, but am having a hard time figuring out what to so with the rear cross brace mount. It was welded in for a 3550, Ford bell, and 5/8" spacer plate. Some have said slot the holes on the cross brace, but if I measure correctly the mount holes actually need to be too far forward and would actually be half on the brace, and half off.

Couple of thoughts that come to mind are:

1. Cut off the brace and re-weld it in the correct position - but, don't have a cutting torch, have a MIG welder I bought on a whim, but have never welded anything in my life

2. Can I somehow pull the engine back toward the tranny 1/4" or so by widening the motor mount slots a bit. Then move the brace holes as far forward as possible and try to make the combination of the two be enough for a fit

3. Figure out some kind of fixture that can adapt between the cross brace holes and tranny mount and the bolt holes on the tranny rear housing. I have something like this from Forte's ie a slotted aluminum plate, but it doesn't appear that it will work for the amount of distance I need to adjust - one setup is too small, and the other is too big and for it to be correct I'd end up with bolt heads overlapping each other.

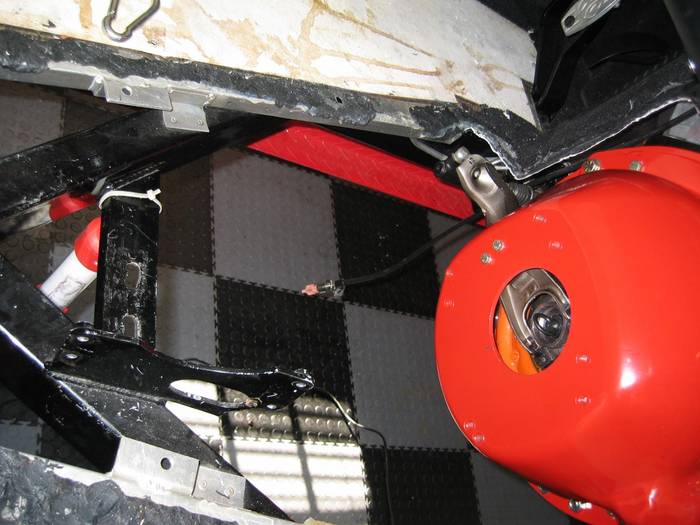

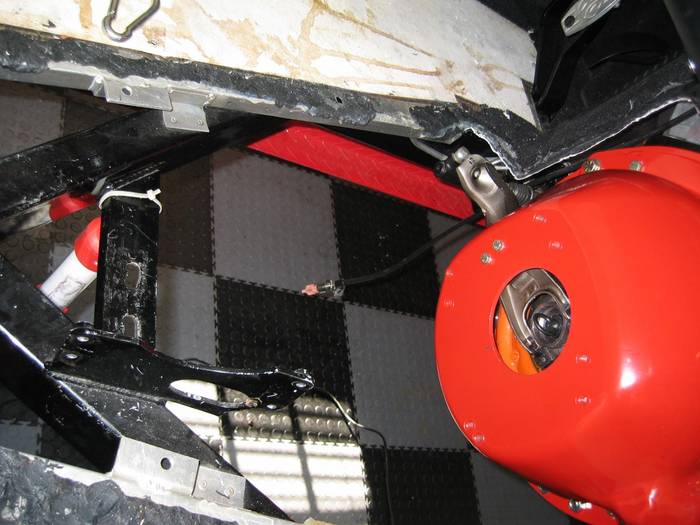

Appreciate any ideas. Here's some pics of the mount situation

Thanks!

|

09-23-2006, 07:31 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

HSSS

Here's some shots of us facing off the flange of the bushing.....

Oilite bushings are the best and most forgiving..... and we make our own....

Also in one of the shots you can see the flange of the bushing behind the double plate clutch....

__________________

Morris

|

09-23-2006, 07:35 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Here's the facing off of the bushing....

And how we mounted the TKO 600.....All chassis are different.....

You will have to figure it out once the tranny is installed...

You won't notice it ..... but we are using a 1350 Spicer u-joint....on both ends of the drive shaft..... much better because they are so much stronger.....

Morris

__________________

Morris

|

09-23-2006, 10:05 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Location: Alpharetta,

GA

Cobra Make, Engine: ERA #414 427 s/o w. Shelby Aluminum heads, Edelbrock Performer RPM Intake, Mighty Demon 750, Tremec TKO 600

Posts: 714

|

|

Not Ranked

Not Ranked

Morris, you have too many toys!

Morris, you have too many toys!

I'm just a lonely guy in his garage with a simple ERA....no machine tools, not nice custom built round tube frame. The extended bushing makes a lot of sense. Would you sell me one?

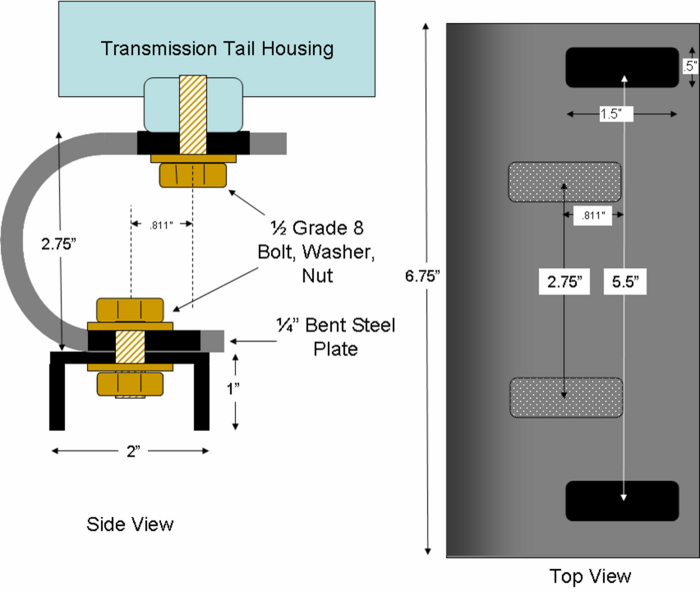

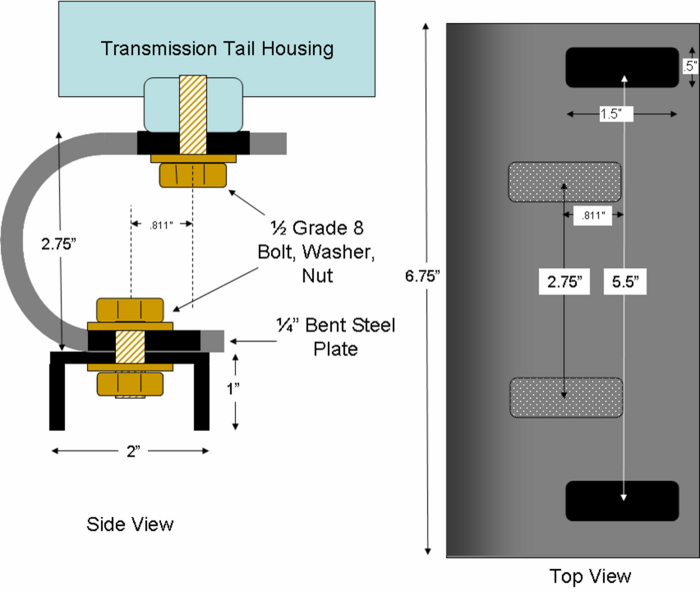

I think I may have figured out what I need for the mount. Find a channel, or have one made, with one bolt on the top and one on the bottom like the pic below

Last edited by HSSS427; 09-24-2006 at 06:04 PM..

|

09-24-2006, 07:37 AM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by HSSS427

This has been bugging me for a while, so figured a picture is worth a thousand words. Below is a diagram I made trying to determine what clearance I had between the input shaft on my Tremec TKO 600 and the crank on my 427 so. I learned the hard way that an input shaft that is too long = torn up thrust bearings, pain and agony.

I now have a short shaft installed, and understood that I would not require a spacer between the tranny and Lakewood scattershield when I used this. However, when I originally installed it, I couldn't get the input shaft to seat far enough down in the pilot bearing to get the tranny butted up against the scattershield. Based on past experience I also didn't want to force it together for fear of bottoming out in the crank.

So, installed it with the 5/8" spacer and all appeared fine. Have the engine out for other reasons, but am now concerned that I'm not getting enough engagement of the input shaft into the pilot bearing.

So, assuming I have my dimensions correct, it appears there's no way to use the longer input shaft as it's longer than the total distance from tranny face to block face. I also can't use the short input shaft without the spacer as it is longer than the depth of the scattershield plus block plate, thus appearing to invalidate the idea of using a short input shaft without a spacer.

So now the thing I don't know if how far away from the block face is the bottom of the hole in the end of the crank, and how far from the block face is the surface of the crank flange. If I have this, I can tell how much engagement of the input shaft I'm getting.

I am not and engineer, but play one when I'm in the garage. Appreciate comments, observations and corrections to my diagram to help clear this up.

|

When I had a long input snout, I just measured the distance that a large input shaft tip is from the front of the tranny, and then while the longer input snout was sticking out of my tranny, I measured and marked the distance on the longer snout. I then taped around the snout a little closer to the tranny, sealing the front of the tranny . I got an air die grinder with a cut-off wheel, and cut a little of the snout off, and then dressed the front edges, tapering them, with an angle grinder. Took off the tape, no shavings in the front of the tranny. No disassembling of the tranny, no spacer plate. Done. Has seemed to work fine.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

Last edited by Anthony; 09-24-2006 at 07:56 AM..

|

08-30-2010, 09:24 PM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Location: Kalamazoo,

mi

Cobra Make, Engine:

Posts: 234

|

|

Not Ranked

Not Ranked

Spacers

Spacers

If anyone needs a 1/4" spacer for the tKO-600 and quicktime Ford FE bell housing, I have two available that i didn't use.

One is just shy of 1/4" thick.

Free if you need it. Just pay the shipping please.

Send me a PM if you need one.

Dan

|

08-31-2010, 09:44 AM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Cobra Make, Engine:

Posts: 75

|

|

Not Ranked

Not Ranked

Output Shaft vs Spacer

Output Shaft vs Spacer

I machined a 3/8ths spacer because I had a twofold problem. Not only was the shaft to long but the splines wouldn't accommodate my 11" dual friction clutch. The first clutch would bottom out on the splines (input shaft) before the tko 600 would mate up to the Quicktime bell housing. Even though I have a 557 cu in 385 series. I have a Ram FE aluminum fly wheel and an 11 in. dual friction clutch.

If you go to the 429/460 form I have some pictures.

|

11-13-2015, 07:42 PM

|

|

Registered User

|

|

|

Join Date: Oct 2015

Cobra Make, Engine:

Posts: 2

|

|

Not Ranked

Not Ranked

Hi guys,

I know this feed is approaching 10 years old, but I came across it while trying to find the TKO dimensions with a short input shaft. I'm sure you guys have long ago worked out your original problem, just thought I would throw some new measurements out there. I was just trying to determine where the tip of my standard length TKO 600 (TCET5008)(long shaft) would end up. I had the standard bronze pilot and decided to go with the roller type pilot bearing. I went with a Quicktime bell and the measurement of my bellhousing and blockplate added up to 7.3 inches exactly, so I should be good to go, wish me well as this is my first conversion. I'll update as I go along. Nice diagrams by the way.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:44 AM.

|

5Likes

5Likes

Linear Mode

Linear Mode