Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

11-02-2007, 04:15 AM

|

|

CC Member

|

|

|

Join Date: Mar 2007

Location: seekonk,

ma

Cobra Make, Engine: factory five mkIII roadster 445 fe quick fuel 750 q series,irs

Posts: 468

|

|

Not Ranked

Not Ranked

piston ring question?

piston ring question?

does the term drop in actually mean you can just drop in the rings with out fitting them? referring to mahle rings part# 4080ms on the box it says standard tension drop in. how do these differ from the file fit version?.

|

-

Advertising

11-02-2007, 05:46 AM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: FFR 390 toploader IRS

Posts: 258

|

|

Not Ranked

Not Ranked

call KC where you got them.

__________________

FFR MarkIII,FE,toploader,IRS,3.27,Vintage pin's SOLD!

68 F100 Custom Cab 418 cube FE/auto

99 SuperDuty Tuner/chipped/4" Banks TOTALED!!

02 Super Duty 7.3L

|

11-02-2007, 05:58 AM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Broken Arrow. OK ( South Tulsa), USA,

OK

Cobra Make, Engine: 66 COBRA FE 427 /4SP. (HCS Coupe w/ 408 Stroker and TKO 600 -sold)

Posts: 5,595

|

|

Not Ranked

Not Ranked

I have never seen a ring that didn't require some fitting due to the variations in bore and hone. That's the easy part of the build.

Clois

__________________

Sunshine, Asphalt and no stop signs...Perfect

"Let's roll"

"Be part of Something Good

......Leave Something Good Behind!"

from CD "Long Road Out of Eden"

|

11-02-2007, 07:11 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Hickory,

NC

Cobra Make, Engine: ERA 427SC w/427so, ERA GT #2002

Posts: 1,106

|

|

Not Ranked

Not Ranked

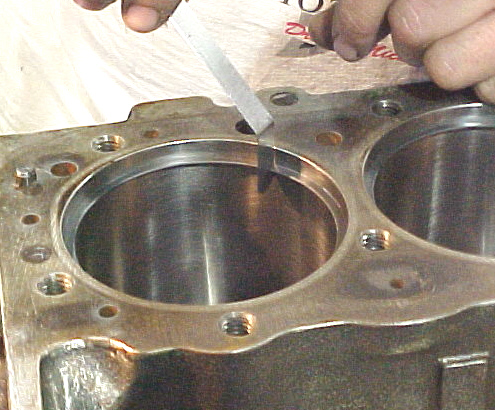

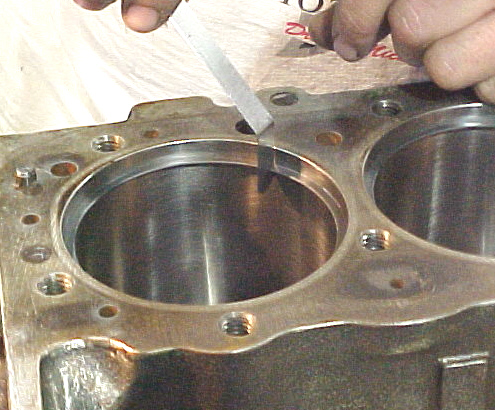

File-fit means exactly that, rings are manufactured with minimal end gap which requires filing to obtain the desired end gap. On the other hand pre-gapped rings don't require fitting, however you should check end-gap by installing each ring in its bore. Square it up about an inch down the bore and check gap with your feeler gauges. This is critical as I've seen boxes labeled for a particular bore size that contained rings sized for another.

How much end gap a ring should have depends on its material, bore size and application--street or racing and normally aspirated, turbocharged/supercharged or nitrous. Also, the type of fuel used has to be considered, i.e., gasoline, alcohol or whatever. Cooler operating alcohol doesn't require as much end gap. For normal street operation with gasoline and ductile top rings, 0.004 in. per inch of bore size will work. Increase this to 0.005 in. per inch of bore size for racing applications. Second ring-end gap should be about 0.0055 in. per inch of bore size. Oil-ring rails can be all the same at 0.015 in. per inch of bore size.

For a 4.00-in. bore, ring gaps should be 0.018--0.020 in. top; 0.022--0.024 in. second and 0.016--0.020 in. oil rail for road racing. With turbocharging/supercharging gap rings to 0.024--0.028 in. top; 0.024--0.026 in, second and 0.016--0.020 in. oil. For nitrous applications, gap the rings 0.028--0.030 in. top; 0.028--0.030 in. second and 0.016--0.020 in. oil.

Keep in mind that when gapping rings, a larger end gap is much safer that not enough. If the ring ends were to butt because of insufficient gap, serious ring and bore damage could result. Testing with very large gaps has shown that the increse in blowby is virtually imperceptible. On the other hand, there are those who swear by Total Seal's gapless and Childs & Albert's Zero Gap rings used in the second grooves.

__________________

Tom

"If you can make black marks on a straight from the time you turn out of a corner until the braking point of the next turn, then you have enough HORSEPOWER." Mark Donohue

|

11-02-2007, 07:27 AM

|

|

CC Member

|

|

|

Join Date: Mar 2007

Location: seekonk,

ma

Cobra Make, Engine: factory five mkIII roadster 445 fe quick fuel 750 q series,irs

Posts: 468

|

|

Not Ranked

Not Ranked

when i built my 342 i had to file fit the rings, i was also using keith black pistons so it was a little different . but i was curious about the term drop in ?mahle also makes a file fit version. so what does the term drop in mean?

|

11-02-2007, 07:44 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Hickory,

NC

Cobra Make, Engine: ERA 427SC w/427so, ERA GT #2002

Posts: 1,106

|

|

Not Ranked

Not Ranked

I neglected to mention Drop In. If you refer to Mahle ring charts, you'll see rings are listed as file fit or drop in. Drop in simply means you should be able to install the rings without the need to fit them. Regardless, always check end gap to be sure.

__________________

Tom

"If you can make black marks on a straight from the time you turn out of a corner until the braking point of the next turn, then you have enough HORSEPOWER." Mark Donohue

|

11-02-2007, 08:33 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

Drop-In rings means they come already gapped for the application.........DO NOT ever trust this, ALWAYS check the rings in the bore they will go into........

99% of the time, they will be spot on, it's that other 1% of the time when they were mis-labeled or accidently put into the wrong box that will destroy your high dollar motor......

I've used both and had good results, file fit are kinda a pain and time consuming to get right, but when they are right, they are right...........

David

__________________

DAVID GAGNARD

|

11-02-2007, 12:15 PM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Location: West Bloomfield,

MI

Cobra Make, Engine:

Posts: 717

|

|

Not Ranked

Not Ranked

Drop in means just that - they drop in with an overly large gap for most applications - usually about .010 on the safe side

__________________

Survival Motorsports

"I can do that....."

Engine Masters Challenge Entries

91 octane - single 4bbl - mufflers

2008 - 429 cid FE HR - 675HP

2007 - 429 cid FE MR - 659HP

2006 - 434 cid FE MR - 678HP

2005 - 505 cid FE MR - 752HP

|

11-03-2007, 06:38 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Nothing is drop in

Nothing is drop in

wrench 87 Nothing is drop in. Anyone would be foolish not to check all the parts going into anything, this includes, engine parts,trans parts, clutch assemblies, rearend parts, trims pieces, and brake components. Back spacing on wheels is another problem because the tires are not on the rims and after assembly, you have a rubbing problem. I got a stroker kit from Barry R. Rods,crank, pistons, rings and bearings. Basicly the kit is a drop in except for the piston rings and filing the end gaps to my specs. I got 2 sets of rod and main bearings and got the numbers a wanted for a shelby block (clearances). The bearing that came with the kit where 3/4 groove bearings, ones that came out where total grooves. Called Barry and was told no problem. Put togeather and motor ran great. Everything still needs to be checked before anything is installed in your car or on it. This will save alot of money and down time in the long run. Rick L.

|

11-03-2007, 07:36 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Hickory,

NC

Cobra Make, Engine: ERA 427SC w/427so, ERA GT #2002

Posts: 1,106

|

|

Not Ranked

Not Ranked

Just do this, then file if needed.

__________________

Tom

"If you can make black marks on a straight from the time you turn out of a corner until the braking point of the next turn, then you have enough HORSEPOWER." Mark Donohue

Last edited by speed220mph; 11-03-2007 at 07:41 AM..

|

11-03-2007, 07:39 AM

|

|

CC Member

|

|

|

Join Date: Mar 2007

Location: seekonk,

ma

Cobra Make, Engine: factory five mkIII roadster 445 fe quick fuel 750 q series,irs

Posts: 468

|

|

Not Ranked

Not Ranked

wow all this advise but no one answered my question, i never heard the term (drop in ) before now i know but is the drop in ring and the file fit ring made with the same material? only one is cut to a different tolerence? or are they totally different . and why would they supply you with the drop in rather than the file fit?. just curious

|

11-03-2007, 07:45 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Hickory,

NC

Cobra Make, Engine: ERA 427SC w/427so, ERA GT #2002

Posts: 1,106

|

|

Not Ranked

Not Ranked

wrench87: Last time . . . so you can get the exact end gap for the exact bore size you're installing the ring in. Production engine shops don't use file-fit rings . . . race engine shops do for the reason just stated. Material doesn't have anything to do with it. Drop in simply means the rings are pre-gapped for the specified bore size.

__________________

Tom

"If you can make black marks on a straight from the time you turn out of a corner until the braking point of the next turn, then you have enough HORSEPOWER." Mark Donohue

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:39 PM.

|

Linear Mode

Linear Mode