Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

4Likes 4Likes

11-07-2007, 07:43 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2006

Location: Jacksonville,

FL

Cobra Make, Engine: Hi-Tech

Posts: 475

|

|

Not Ranked

Not Ranked

Solid Roller vs. Hyd. Roller - Pros/Cons?

Solid Roller vs. Hyd. Roller - Pros/Cons?

I am not going to stick a 331 in my Hi-Tech after all. After collecting all parts needed for a complete motor (including webers) - I am going with an FE.

Why? Because I saw a cobra in my neighborhood a few weeks ago, he opened the hood and there it was in all it's glory...a 302.

So now the plan is a Pond Alum.

1st question: I know many have high praise for solid and hydr lifters but I want to get some clarity on the solid roller vs. hydraulic roller issue. I have some solid roller lifters and would like use them and save some $.

How will that impact my engine build? Will it require different/hard to find parts? I'm looking at the T&D rocker setup. What about MSD distributor, does the solid roller cam need the special gear like the 302 rollers need?

Thanks,

JB

|

-

Advertising

11-07-2007, 08:14 AM

|

|

CC Member

|

|

|

Join Date: Nov 2000

Location: Tucson,

Az

Cobra Make, Engine: Superformance 427 Side-Oiler

Posts: 2,156

|

|

Not Ranked

Not Ranked

Save yourself $ & aggravation-go with a solid flat-tappet.

__________________

The rest of the world can have their opinion about the United States just as soon as WE give it to them.

|

11-07-2007, 08:23 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Cobrabill

Save yourself $ & aggravation-go with a solid flat-tappet.

|

CB is right, go with a solid flat tappet in an FE. The only hurdle is the break-in and there are plenty of threads on CC and www.fordfe.com that will step you through that (even then it's not always 100% successful). Once broken in, if you can get past 1000 miles on it then the cam will, in all likelihood, outlast you (assuming you keep it happy with a high quality oil with proper levels of Zn & P, such as Brad Penn). A solid flat tappet cam just has a wonderful sound to it in a Cobra. It's meant to be there; it's almost musical. If you're going to the trouble and expense of an FE you really should put it in. If you don't, you'll always wish you had. |

11-07-2007, 09:21 AM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,444

|

|

Not Ranked

Not Ranked

Non roller lifters and cams have been failing at an alarming rate over the last couple of years. Some say it's the oil, some say it's the low quality lifters. Some say it's improper break in. I think it's a combination of the first two. The solid lifters may be a higher quality than hydraulics. You don't hear of so many failures. But so few people are using them, it's hard to make the comparison. But since you already own them, it's not really an issue.

Lately I'v been thinking of adding a solid roller to my engine. IMO, if you're going to step up to a solid lifter, it doesn't make sense to use a non-roller. As you build the engine, there are a few things to consider.

First, of course, is always the cam gear. This goes with almost any camshaft you install. Just make sure you talk to both the cam maker and the distributer maker to ensure you're using the right parts. That can get tricky, because sometimes the tech line is wrong and the company won't admit it. But do your research there.

Second, most solid cams are fairly radical. Even those that are referred to as a "Street Solid Roller" have pretty long duration. Might be more than you're after in drivability.

These big cams have a fairly late intake valve closing point. That can really drop the effective cylinder pressures. To comensate, you'll need to have a static compression >10. If you live at altitude, it would have to be >11'ish.

You have to set valve lash at regular intervals. In theory, once it's set properly it's set for life. As long as the rocker arms are torqued and locked, it should never move. In reality, as parts wear you'll need to re-adjust. But that's not very often, maybe once a year.

You need to be sure and use the proper matching parts: Pushrods, springs, retainers, etc. The springs have considerably more pressure than a hydraulic part. You'll need a more robust rocker arm and pushrod. You should really consider titanium retainers and keepers. It makes a differance at 7,500 rpm's. I prefer to get them all from the same company, like Comp Cams.

|

11-07-2007, 09:59 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,588

|

|

Not Ranked

Not Ranked

Oye Vey, go roller cam all the way. Soild rollers cam be revved beyond 6,000-6,200 RPM and hydraulic rollers need to stay at or below that RPM level. Depending on how many miles you put on your car every year and the RPM level you desire will determine which roller to use.

|

11-07-2007, 10:12 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,283

|

|

Not Ranked

Not Ranked

Solid rollers are no good for the street, perio. The lifters will fail (needle bearings) with any significant "street" useage. Hydraulic rollers are the way to go, near solid roller performance at "streetable" RPMs. The best thing too, the cam lobes don't go away prematurely as with hydraulic/solid flat tappets. Even with a good break-in there's been many reports of later on cam failures. Today's oils, in general, aren't designed for flat tappet cams. I still don't have a warm fuzzy that the additives are a cure-all either.

__________________

Too many toys?? never!

|

11-07-2007, 10:25 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Modern 'rollers', be they hydraulic or solid can be made to rev high and live! Hydraulic rollers can push the 7000 rpm range these days. Solid roller lifters, in certain blocks not all, can be force fed oil pressure to make them 'live long'. Lack of oiling on a street driven (lower rpm for much of the time) has been the killer of solid roller bearings. With the new pressure oil feed, thats no longer an issue. High tech hydraulic rollers can see some lofty rpms these days.

BUTT, there is a significant cost to either approach, this is NOT a cheap solution. Even standard roller hydraulic lifters cost considerably more than a flat tappet combination. Valve springs, rockers and push rods will still need to be matched for the cam/lift/geometry no matter which one you choose.

When I was rebuilding my motor I considered all the various factors and went with flat tappet at a max rpm of around 6400. Number one, I didn't want to rev the engine much higher than that for longevity reasons. The higher you rev, the shorter the life of the motor, period! Number two I wanted to control costs, which can VERY quickly spiral out of control when your building a motor. You find yourself in a trap like. Well, it's 'only' a few bucks more to do this or that. Those 'few bucks more' add up to a substantial number when the smoke has cleared! Spend your money wisely. I chose to spend big bucks on the pistons, for instance. Cost/benefit analysis, in my case, showed that was where the money needed to go.

A flat tappet cam would do a fine job for my projected horse power and combination street driving and some track use. The price difference sealed the deal. I get all the performance I want at a nice price. Flat tappets can cost more if your having the motor built for you because of the extra work involved initially 'breaking in the cam'. That extra cost MAY make it advisable to go with a roller because the cost of the parts may be offset by the cost of the labor to properly setup a flat tappet. I built my motor myself, labor was not an issue. I work for 37 cents an hour...

Labor costs and risk management are the PRIMARY reason professional engine builders recommend a hydraulic cam. Thats the PRIMARY reason. It is then justified by pointing out the 'performance' enhancements, high rev potential, blah blah blah. But don't forget the PRIMARY reason, it's easier for them to build, warranty and the parts profit level is better!

Proper breakin and careful oil selection will gaurentee a long life for a flat tappet cam, as long as the engine itself holds together.

Last edited by Excaliber; 11-07-2007 at 10:35 AM..

|

11-07-2007, 10:45 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Excaliber

Labor costs and risk management are the PRIMARY reason professional engine builders recommend a hydraulic cam. Thats the PRIMARY reason. It is then justified by pointing out the 'performance' enhancements, high rev potential, blah blah blah. But don't forget the PRIMARY reason, it's easier for them to build, warranty and the parts profit level is better!.

|

Excalibur is right on the money -- breaking in a solid lifter cam takes extra work and is a little risky. Breaking in a roller is easy. On the street though you're not going to notice any performance difference between a solid roller and a solid flat. So, if you elect to go with the solid roller be careful about restricting the lifter galleys as you do with a solid flat tappet. Low FE oil pressures and street idling can limit the life of the solid roller. I believe the problem of a few years ago with the cheap foreign lifters has now passed us by, but perhaps Barry R. could chime in on that. Other than the break-in issue, there is no real benefit on a street machine to going with a solid roller over a solid flat and, with the solid roller, you still have the specter of limited life. Makes it all simple, huh?  |

11-07-2007, 10:50 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2006

Location: Jacksonville,

FL

Cobra Make, Engine: Hi-Tech

Posts: 475

|

|

Not Ranked

Not Ranked

Solid Rollers

Solid Rollers

Great info guys! Thank you.

Here is the cam (solid roller cam) I'm looking at. How does it look?

Duration Is 259* intake and 269* exhaust at .050. The total lift is .640

undy, Crane said their solid rollers don't have a problem like you mentioned. Do you have any experience with the Crane solid rollers?

Excaliber, do you know if the Pond block allow for the increased oil pressure needed for the solid rollers?

Will the stock Edelbrock FE alum heads work with the solid rollers or will I need to upgrade springs?

bobcowan, I know what you mean about getting accurate info for dist. gears. I got 20 different opinions from MSD and Comp Cams for my sbf roller cam...depending on the day.

Are there other distributors other than MSD that offer plug and play with the MSD 6AL? I ask because my wiring is already installed. |

11-07-2007, 11:17 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,283

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by hi-tech cobra

Great info guys! Thank you.

Here is the cam (solid roller cam) I'm looking at. How does it look?

Duration Is 259* intake and 269* exhaust at .050. The total lift is .640

undy, Crane said their solid rollers don't have a problem like you mentioned. Do you have any experience with the Crane solid rollers?

Excaliber, do you know if the Pond block allow for the increased oil pressure needed for the solid rollers?

Will the stock Edelbrock FE alum heads work with the solid rollers or will I need to upgrade springs?

bobcowan, I know what you mean about getting accurate info for dist. gears. I got 20 different opinions from MSD and Comp Cams for my sbf roller cam...depending on the day.

Are there other distributors other than MSD that offer plug and play with the MSD 6AL? I ask because my wiring is already installed. |

The cam is not very radical, for a solid roller. Peak power probably will be around 7K, +/-.

You need to talk to Barry R (survival motorsport) or Keith Craft on what's required, if anything, to modify the Pond block to work with a solid roller. I am still not understanding why you're hung on a solid roller.

Buy the Ebok heads bare and build them to your cam/engine's specs. The assembled ones come with 2.09 intakes (too small for a 427 up) and springs suited for a flat tappet up to .600 lift.

Check what your cam mfr recommends for the distributor gear. MSD makes a ditributer "roller" gear for my hydraulic roller application. Some roller cam mfrs are making their distributor drive gears (on the cam) a little more distributor gear friendly.

|

11-07-2007, 11:31 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by undy

I am still not understanding why you're hung on a solid roller.

|

I'm wondering the same thing. Are you going to track/race this car? Or will it be overwhelmingly a street car? Almost any cam that you put in a freshly built FE is going to get you well over 400HP. But if your car is going to be predominantly a street car you might want to pick a cam that has some manners around town (forgetting altogether whether it be solid/hydraulic/roller/flat). Regardless of what anyone says on this board, pretty much anything over around 450HP is wasted on the street and can actually detract from the overall enjoyment of a street Cobra. |

11-07-2007, 11:43 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2000

Location: St. Augustine,

FL

Cobra Make, Engine: E-M / Power Performance / 521 stroker / Holley HP EFI

Posts: 1,926

|

|

Not Ranked

Not Ranked

hitech,

I bought my hydraulic roller setup, springs, distributor gear and all from Crane. More than 20K street + race track miles later, no regrets! I use the MSD 6AL & distributor. MSD installed the Crane gear for me. Buying the distributor gear from the cam mfr at the same time as the cam eliminates any guesswork...

Dunno whether there's any significant reliability difference between the 385 & the FE, sorta doubt it. The FE should do fine with either lifter - note comment below.

Springs need to match the cam, rockers and lifters too. Don't guess, ask Crane!

If you can replace solid roller lifters every 3-5K miles as a regular maintenance item, go for it. Otherwise I'd suggest the hydraulics.

Tom

__________________

Wells's law of engine size: If it matters what gear you're in, the engine's too small!

|

11-07-2007, 11:58 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

The key thing required for an FE block is hydraulic lifter CAPABLE. The early blocks were not drilled for oil passages to the lifter, solids were the only option. Around 1968 or so they were drilled, in that case you could run either.

I'm pretty sure any modern after market block is also drilled to except either solid or hydraulic. You DO have to modify the oil gallery to the lifters depending on which way you go. Restrict oil if solid, increase oil if hydraulic, simply screw in the right size restrictor. A small but very important detail, which could easily be over looked by those not familiar with an FE block.

Stock E-brock head springs aren't matched to any specific cam profile, there only 'in the ball park'. You WILL want to buy a 'cam kit' (springs that DO match) and install the springs in whatever head your running.

I had a solid roller in my side oiler, it went belly up at about 8,000 miles. MAN was that a strong motor! Great on the track, nightmare on the street, no power below 3000 rpm. I estimat I gave up about 150 horse power on my rebuild, down from 667 to say 500 or so. Lowered compression, smaller carbs, smaller flat tappet cam, etc.

Now get this:

Loosing 150 horse resulted in loosing only a few hundredths of a second and a couple of miles per hour in the 1/4 mile! My gas mileage DOUBLED, streetability vastly improved and the car STILL runs in the 11's. BIG horse power doesn't mean squat if you can't 'hook it up'.

Last edited by Excaliber; 11-07-2007 at 12:08 PM..

|

11-07-2007, 12:35 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2002

Location: God's country,

ME

Cobra Make, Engine: Original ERA 427sc, Powered by Gessford

Posts: 2,678

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by patrickt

Excalibur is right on the money -- breaking in a solid lifter cam takes extra work and is a little risky. Breaking in a roller is easy. On the street though you're not going to notice any performance difference between a solid roller and a solid flat. So, if you elect to go with the solid roller be careful about restricting the lifter galleys as you do with a solid flat tappet. Low FE oil pressures and street idling can limit the life of the solid roller. I believe the problem of a few years ago with the cheap foreign lifters has now passed us by, but perhaps Barry R. could chime in on that. Other than the break-in issue, there is no real benefit on a street machine to going with a solid roller over a solid flat and, with the solid roller, you still have the specter of limited life. Makes it all simple, huh?  |

I don't know if I agree with that. Because of the cam lobe profiles of a roller cam are much more aggressive and open and close the valves faster (whether solid or hyd roller) than a flat tappet cam, you will get better performance from a roller than you will from a flat tappet cam with similar or even slightly greater duration. The aggressive lobe shape of the roller cam effectively opens and closes the valves faster (as compared to a flat tappet cam) which allows the valves to stay open longer, thereby creating more "area under the curve" which provides the cylinders more time to fill at any given duration as compared to a flat tappet cam with the same duration. Or put another way, you can run a smaller duration roller cam (which means better throttle response and better idle quality, i.e., more streetable) but still have as much if not more power than you could get out of a flat tappet cam of the same duration or even slightly larger duration.

IMO, hyd roller is the way to go for a street cruiser. You eliminate the break-in problems associated with flat tappets, don't have to worry about roller bearings in solid rollers, and because of the cam lobe profiles, can run a smaller cam with better street manners without sacrificing performance of a larger flat tappet. Needless to say, I am having one installed in my motor as we speak.

__________________

Replica is not a dirty word.

"If you can't be a good example, then you'll just have to be a horrible warning."

|

11-07-2007, 12:46 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Chaplin

I don't know if I agree with that. . .IMO, hyd roller is the way to go for a street cruiser. You eliminate the break-in problems associated with flat tappets, don't have to worry about roller bearings in solid rollers, and because of the cam lobe profiles, can run a smaller cam with better street manners without sacrificing performance of a larger flat tappet. Needless to say, I am having one installed in my motor as we speak.  |

All very valid points, and difficult to argue against. BUT, there is something to be said for the sound of a solid, flat tappet cam in an FE. I've never heard a hydraulic that came close to it. On the other hand, that sound doesn't mean much to a lot of people (and I've even on occasion had someone ask " Is your engine supposed to sound like that?")  |

11-07-2007, 12:51 PM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,444

|

|

Not Ranked

Not Ranked

Here's what I think I know from experiance and research:

There are 2 types of tappets/lifters: Hydrualic and solid. Both types can be had with either a flat bottom, or a roller bottom. Some people seem to mix up the terminology a bit, and that makes things confusing. You can't say a roller is better than a hydraulic.

The lobe profile of the cam MUST match the type of lifter being used.

New solid rollers are the bee knees. They work well, and last nearly as long as a hydraulic. They will certainly last longer than most people drive their Cobra's.

The only advantage to a solid lifter is stability at rpm's greater than 6,000 rpm's. Getting a hydraulic lifter to work well at 6,500 rpm is almost impossible. With the new stabilizer kit it can easily be done on a SBC. But not on any other engine.

If you don't road race the car, a solid lifter cam won't make you happy.

|

11-07-2007, 12:56 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Ahhh, the joy of valve adjustment! Becoming one with your motor, grasshopper. In the modern technology world we live in, the fine art of valve adjustment is a dieing art. Perhaps this weekend I will once again pull off the valve covers and 'feel' up my valves. After which I shall retire with a fine cigar and contemplate the wussification of Amercia...  |

11-07-2007, 01:00 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,000

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Excaliber

Ahhh, the joy of valve adjustment!  |

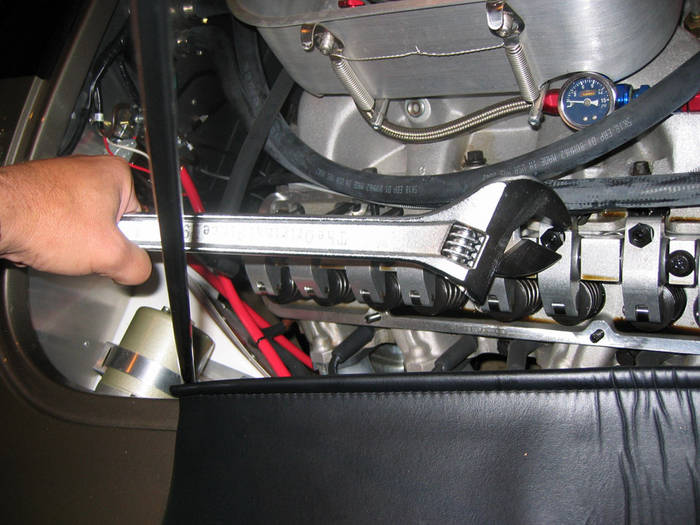

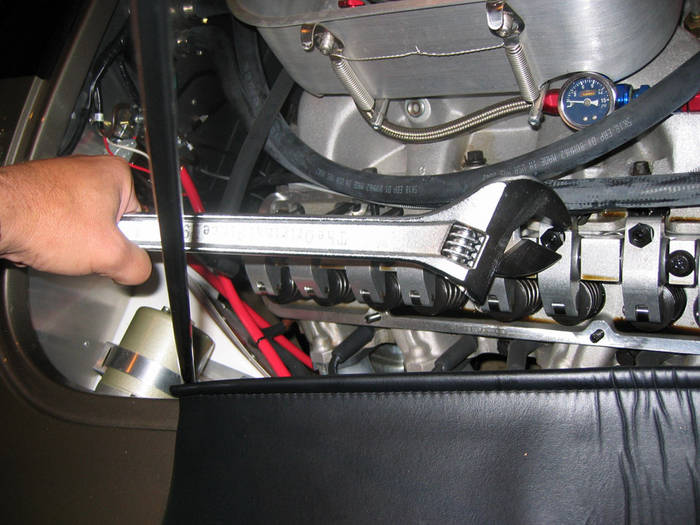

It requires a deft touch, and the proper tools.

|

11-07-2007, 01:02 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Now thats what I'm talking about, get a BIG wrench and have it at!

When it's time to install the inner springs after breakin of your flat tappet cam I recommend using a 'ball joint removal' pickle fork. Combined with the adjustable metric wrench, your in solid 'man country'!

Last edited by Excaliber; 11-07-2007 at 01:09 PM..

|

11-07-2007, 01:14 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Cobra Make, Engine: 31XX Car

Posts: 374

|

|

Not Ranked

Not Ranked

Roller lifter Oil Passage Tools

Roller lifter Oil Passage Tools

If anyone here is interested, I have some custom boring bits available to make the long lifter bore oil passages......

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:44 PM.

|

4Likes

4Likes

Linear Mode

Linear Mode