Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

01-14-2008, 08:34 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Exeter,

CA

Cobra Make, Engine: KMP 498

Posts: 495

|

|

Not Ranked

Not Ranked

Did I screw Up? With my cam.

Did I screw Up? With my cam.

Here I am getting ready to stuff the engine, Yes I am mind screwing my cam.

Opinions please.

427So with: Ported Low riser heads, 9.5 CR, Kirkham, TKO, 3.42 rear end, stoke forged crank, arias pistons, MSD Dig-6 Ignation with a converted to EI old dual point dis. Just a very nice 427SO.

Cam:

• Comp No. FB 294B-8 , Part Number 33-648-5

• Valve Adj. IN-.028 / EX-.030

• Gross Lift: IN .600 / EX .626

• Duration @ .050 IN 256 EX 266

• Lob Separation 108

• Lobe Lift IN .3410 / EX .3560

• Using Full roller chain w/ variable timing keys

• Needle bearing thrust bearing at front of cam.

• Fuel pump eccentric was installed.

I am not looking for a "headache" to drive.

|

-

Advertising

01-14-2008, 09:06 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,287

|

|

Not Ranked

Not Ranked

With a cam thrust bearing I'm assuming you're running a solid roller??

__________________

Too many toys?? never!

|

01-14-2008, 09:08 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Location: Queen Creek,

AZ

Cobra Make, Engine: Midstates, Vette suspension, Baer 6P brakes, 540 cid Chevy, Haltech Fuel Injection

Posts: 906

|

|

Not Ranked

Not Ranked

You did not indicate your compression ratio, so some of the necessary info is missing. But since you left the CR out, I am guessing it is not 12:1...

My opinion: This is pretty long duration for this small motor (Over 525 ci will effectively "shorten" duration), especially without high CR and with the small separation at 108. I usually associate 108 separation and over 260 deg duration with high rpm engines. I think it will be a headache to drive and will not have good street manners.

If you want good street manners with low CR for running pump gas, I would keep duration to 240 deg max and make the separation angle 112 or 114. Do whatever lift you want as long as the springs are OK.

Only my opinion.

__________________

E. Wood

ItBites

10.69 @ 129.83mph - on pump gas and street tires

|

01-14-2008, 09:35 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,016

|

|

Not Ranked

Not Ranked

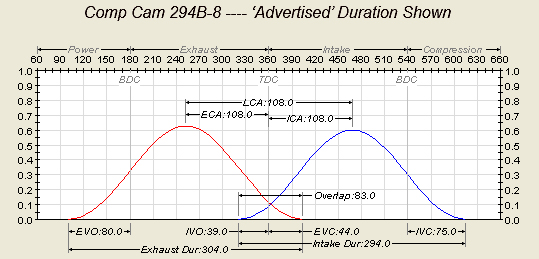

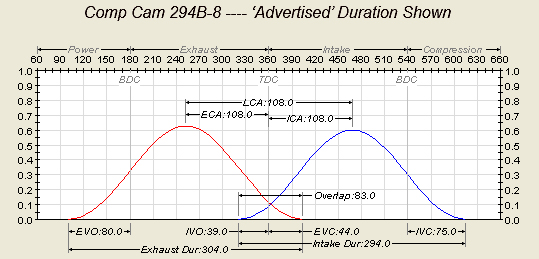

For that cam I'm showing advertised (not .050, not really seat to seat) as being 294/304 and your lift as .600/.626 with an LSA of 108. You have a significant amount of overlap, a pretty tough idle, and you're not going to come on strong until higher RPMs. Knowing more of the details on your motor would help a lot. Here's a rough graph of it if you were to install it straight up (which I'm sure you're not) with an estimation on the ramp rates. BTW, Comp touts this as a "Drag Race" cam -- I would not have chosen this for a predominantly street-driven FE Cobra.

Last edited by patrickt; 11-07-2016 at 01:25 PM..

|

01-14-2008, 09:51 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Exeter,

CA

Cobra Make, Engine: KMP 498

Posts: 495

|

|

Not Ranked

Not Ranked

Solid with shell lifters and 9.5 CR.

|

01-14-2008, 09:56 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

You do say stroked, but what size? I would tend to agree. Considering the compression ratio, small heads and the size of the engine, I think the duration and LSA are too big. Even for a 482,, it's big.

|

01-14-2008, 10:10 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,016

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by RodKnock

Even for a 482,, it's big.

|

I have a stroked and bored FE -- 447 CID. His cam is much larger than mine. I run the original "K" cam, with seat to seat duration of 324 degrees, 114LSA, and I have it installed 6 degrees advanced. At .050 my specs are 245/.525 while his are 256 and 266 duration with much greater lift. Granted, my compression ratio is higher (10.6 to 1), but I don't believe he is going to be happy with how his engine behaves at 3000RPM and under. He might not even like how it sounds since it will sound rougher than mine (which you can hear by clicking the link in my signature below). |

01-14-2008, 10:14 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Location: Queen Creek,

AZ

Cobra Make, Engine: Midstates, Vette suspension, Baer 6P brakes, 540 cid Chevy, Haltech Fuel Injection

Posts: 906

|

|

Not Ranked

Not Ranked

Even at 498 ci with only 9.5CR, you're asking for headaches with that cam. My 540ci, with 10.5CR uses 246/252@.050 with 111 separation and installed 2deg advanced from straight-up has OK idle and manners, but is still not a "street-friendly" engine and needs the EFI I run to have crisp response at low rpms.

__________________

E. Wood

ItBites

10.69 @ 129.83mph - on pump gas and street tires

|

01-14-2008, 02:04 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Exeter,

CA

Cobra Make, Engine: KMP 498

Posts: 495

|

|

Not Ranked

Not Ranked

No, stroke. You guys are making me feel real good about this.

|

01-14-2008, 02:20 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,016

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by big-boss

You guys are making me feel real good about this.

|

Well, you haven't put the stick in it yet right? Go milder and just eat the cost of the new cam. Or, you can just ignore us.  Seriously, having played with cams for decades I will tell you the only sure-fire way of knowing that a cam will do what you want it to do is having put the same cam in the same build once before and having been pleased with it (but I still say you're not going to like that cam). What made you pick it in the first place? |

01-14-2008, 02:41 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2002

Location: God's country,

ME

Cobra Make, Engine: Original ERA 427sc, Powered by Gessford

Posts: 2,678

|

|

Not Ranked

Not Ranked

Big-Boss-

Sorry to have to tell you this, but I have to agree with everyone. I had a 428 that had Comp Cams' 292H cam in it- the specs on that cam are: duration @ 50 was 244/244 with .561 lift on intake and exhaust. Like you, I do all of my driving on the street and back country roads. That cam had horrible throttle response in the lower rpm, idled lile a pro stocker, vacuum at idle was about 4.5", and the engine didn't really begin to smooth out until 2800-3000 rpm. I disliked the cam so much, and found it so unpleasant for the type of driving that I do, that I wound up pulling the motor to change the cam. (Of course, when I had the motor out I decided to upgrade to a stroker, but that is a different story  .)

Anyway, for the new motor (472 cubes), I picked a mild custom ground hyd roller cam from Crane- duration at .50 is 228/234 and lift is under .600 with 112 lsa (I actually was going to install this cam in the 428 before I decided to go with the stroker). This cam is night and day compared to the old. The engine has a little lope to it at idle, but idles nicley at 800 rpm with about 12.5" of vacuum. And it runs smoothly and pulls hard from about 2000 rpm and has so much power in the rpm range that I normally drive (2500-4500) in it is an absolute pleasure to drive this car now.

If you haven't installed the motor yet, I would seriously consider taking Patrick's advice and eating the cost of the cam and swapping it to something smaller. You will be much happier.

__________________

Replica is not a dirty word.

"If you can't be a good example, then you'll just have to be a horrible warning."

|

01-14-2008, 03:42 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: San Diego,

CA

Cobra Make, Engine:

Posts: 2,979

|

|

Not Ranked

Not Ranked

Just upgrade to a stack fuel injection unit and the computer will smooth it out for you.

__________________

Remember, It's never too early to start beefing up your obituary.

|

01-15-2008, 12:31 AM

|

|

CC Member

|

|

|

Join Date: Nov 2001

Location: Prineville,

OR

Cobra Make, Engine: Contemporary / FE

Posts: 130

|

|

Not Ranked

Not Ranked

Big Boss

Making a cam shaft selection is complicated. May I offer some points of view.

1. Unless your combination of engine components and your driving style is exactly same as someone's other engine and driving style using their cam is useless to you.

2. Do you know your heads flow numbers? Any cam selection without this is at best a poor guess. If you haven't flowed your heads consider getting them flowed. Flowing them will yield data to help you define the maximum lift your heads will flow well, flow verses port size and cross section which determines lobe profile, effective RPM range of head flow verses cam timing, and approximate cylinder filling capablility.

3. Have you accurately measured your true compression? Static compression is only a measuring tool to determine dynamic compression. The relationship between dynamic compression (intake valve closing point) is much more important than your static number. This, with cylinder filling capabilities, determines Cold Cranking Pressure. And that determines how much cam and /or compression you can run with pump gas. There are some other effective points but those points may clutter this discussion.

Let's consider your current cam and compare this to your engine based on the information you supplied.

1. 9.5:1 is very low for this size of cam. Your Dynamic compression is 6.87:1 and your cold crank is 165 lbs. This will yeild a lazy engine with poor throttle response, poor vacuum, and inconsistent idle characteristics. If you are going to run this cam you really need to reconsider your compression ratio. A minimum of 10.5:1 will yeild a still conservative number of 7.56:1 and 189 lbs of cold crank with this cam in your engine.

2. Given the size of your engine 498 CID. Low riser heads, even if ported to their best, will not flow enough to take advantage of that many cubic inches. So actually using a large duration cam, like you have, will allow more cylinder filling time and help these heads.

3. This cam is using some older design lobes for Comp. Intake is lobe # 6012 and the exhaust is # 6013. These are slow opening and closing lobes and should help promote reasonably good velocity through the runners/ports.

4. You cannot compare hydraulic profiles to solids so don't confuse the two.

5. Keep in mind that a solid cams duration and lift are impacted by the amount of lash. Net lift is obvious but the reduction in duration is harder to qualify without the cam being degreed in the engine but the rule of thumb is for every .001 of lash you need to subtract .5 degree of duration. So your intake lobe is really 242 degrees @ .050 and that is not too big for your engine and driving style. Exhaust duration has much less effect on the engines manners.

6. Cam LDA of 108 is on the tighter side but tighter lobe angles usually produce better cylinder scavenging and with the low riser heads having a poor combustion chamber design and very poor exhaust flow this should help.

7. This cam will make power to somewhere between 5800 to 6000 rpm then sign off very quickly. But that is a good street RPM. Power will come on around 2700. It will clean out around 2200 RPM. This is a big engine and it can use this cam.

8. Driving manners. It will idle rough. Stop and go driving will be a pain. But after all it is in a Cobra and that is what the cars are all about. IF not buy a new vette.

9. Tight lobe center cams work better with open plenum manifolds. So if you going to keep this cam then something like a Offy port-o-sonic and maybe a older Holley Street master would work. The Edelbrock Victor is too big for the heads. Dual plane manifolds could be used if you cut down the divider so the total carb. sees all the of cylinders.

10. Carb at least an 850 cfm but I would run a 1000 cfm holley HP.

11. Last comment though redundant. If you do not increase your compression, change cams. If you do decide to stay and 9.5:1 and this is accurate then respond to this thread and we can discuss this. But, changing cams will only be a band-aid to making this engine run to it's maximum efficiency. It needs more compression.

Concobra

|

01-15-2008, 07:57 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Exeter,

CA

Cobra Make, Engine: KMP 498

Posts: 495

|

|

Not Ranked

Not Ranked

Concobra, thanks. That is the best lessen on cam tech I have ever had. You have helped me start a new project.

I am going to run the cam (it does make my life alot easier since I am ready to stab verse taking it all apart again) I will acurately baseline everything and even take it ito the local dyno guy, then start screwing with it-I think it will be fun.

Thanks again.

|

01-15-2008, 09:58 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

big-boss, with those cast iron heads, I think 9.5:1 CR is about all you want here in CA. I know that the 91 octane in my neighborhgood is awful. Fortunately, there's a local Union 76 station that offers 100 octane unleaded from the pump and 110 leaded from barrels in the back room. Also, one of the disadvantages of a tighter LSA of 108 is that it will be more likely to ping/detonate. Just my humble opinion, but I would change the cam, especially if you want to be able to run the terrible CA gas.

|

01-15-2008, 10:51 AM

|

|

CC Member

|

|

|

Join Date: Nov 2001

Location: Prineville,

OR

Cobra Make, Engine: Contemporary / FE

Posts: 130

|

|

Not Ranked

Not Ranked

Hello Big Boss

Thank you for the kind words. Given your choice to stay with the large cam and low compression may I take the opporutnity to offer some suggestions to help compensate for this combination. Some things I will suggest may seem to oppose my initial suggestions but we are now dealing with conditions that are not optimized. Thats OK your eingine will still make good power.

What needs to happen now is to to focus on creating high initial runner velocity to help pack as much air/fuel charge into the cylinder. There will be a top end power sacrifice to do this do but there are no free lunches in engine building.

1. Advance the cam to 6 degrees if you can. Watch your intake valve to piston clearance. You need at least .080". If you cannot get 6 keep as much advance as possible. This will create more vacuum and Cold Crank PSI. You will loose about 200 RPM at the top of the power curve.

2. Stay with a two plane manifold. This is not the best choice with the cam but the need to keep vacuum high is more important to help fill the cylinders. Don't cut down the center divider as suggested before. Again velocity is king. May I suggest the Edelbrock Performer RPM. This manifold has good plenum size balance and smaller gentle curved runners that promote good velocity. It will help attain a good flat torque curve. Port match with the exception of the bottoms of the intake runners to the bottom of the head ports. The low riser floor is too low for good short radius turn to the valve and keeping the air/fuel mix high in the port will help.

3. Carb would be a Holley 850 HP. May I suggest contacting Patrick James of Pro-systems. He builds my carbs and I have nothing but respect for his knowledge and expertise. His website is www.pro-system.com. Even if you already have your carb. send it to Patrick to have him calibrate it. It will save you time and money in the long run.

4. Timing will help. With this low a cylinder pressure you will be able to get away with high initial and full timing. Try 20 degrees of initial and curve to be fully in by 2000-2200 RPM. Don't be surprised if the engine likes 40-42 degrees of total. Remember that you have a lot of area to create a combustion cycle in. This will create vacuum and the more vacuum the higher cylinder filling. You may need to use a high torque starter but it is worth it to keep the timing way up.

5. Please consider the use of a multi-spark CDI ignition enhancer such as MSD. I have experienced these adding as much a 3" of vacuum on a back to back / with and without test.

Good luck and be safe

Concobra

|

01-15-2008, 11:03 AM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: shellvalley 428 ford

Posts: 399

|

|

Not Ranked

Not Ranked

Concobra / Big Boss,

I think an annular discharge carb would also aid in lower rpm ranges as well.

Any thoughts on this ? I am watching this closely as I am building a .060 over 390

with a 244/250 and 554 hydraulic cam with Stage 1 heads and 7.6 dcr.

Byron

|

01-15-2008, 11:36 AM

|

|

CC Member

|

|

|

Join Date: Nov 2001

Location: Prineville,

OR

Cobra Make, Engine: Contemporary / FE

Posts: 130

|

|

Not Ranked

Not Ranked

Hello Byron W

I agree with the thinking that the annular boosters would help. Though I have to submit that my experience with them is limited. By theory they should help. Especially with Big Boss' combination. I would yield to the expertise of Patrick James @ Pro-System on this though. On all my Ford related / naturally asperated engines he has installed double step down leg boosters.

Concobra

|

01-15-2008, 11:44 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Admittedly, I'm not an expert at anything, but doesn't advancing the cam 6 degress and using 40-42 total timing create a huge detonation problem on 91 octane gas and cast iron heads?

|

01-15-2008, 12:06 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Exeter,

CA

Cobra Make, Engine: KMP 498

Posts: 495

|

|

Not Ranked

Not Ranked

I haven't got the carb yet-I will be giving those guys a call. Already have the MSD Dig-6 box that has the 20degree retard for start up and I am using a high torque gear drive starter. Thanks again. As dumb luck will have I port matched the sidwinder manifold but did not match the bottom-I was too chicken.This will be a fun challenge.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:15 PM.

|

Seriously, having played with cams for decades I will tell you the only sure-fire way of knowing that a cam will do what you want it to do is having put the same cam in the same build once before and having been pleased with it (but I still say you're not going to like that cam). What made you pick it in the first place?

Seriously, having played with cams for decades I will tell you the only sure-fire way of knowing that a cam will do what you want it to do is having put the same cam in the same build once before and having been pleased with it (but I still say you're not going to like that cam). What made you pick it in the first place? .)

.) Linear Mode

Linear Mode