Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

1Likes 1Likes

03-08-2008, 11:37 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2007

Location: Friant,

ca

Cobra Make, Engine:

Posts: 106

|

|

Not Ranked

Not Ranked

you will still always win the " grab the $ off the dash " game...especially with the 4 spd

brobehr

|

-

Advertising

03-08-2008, 11:39 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

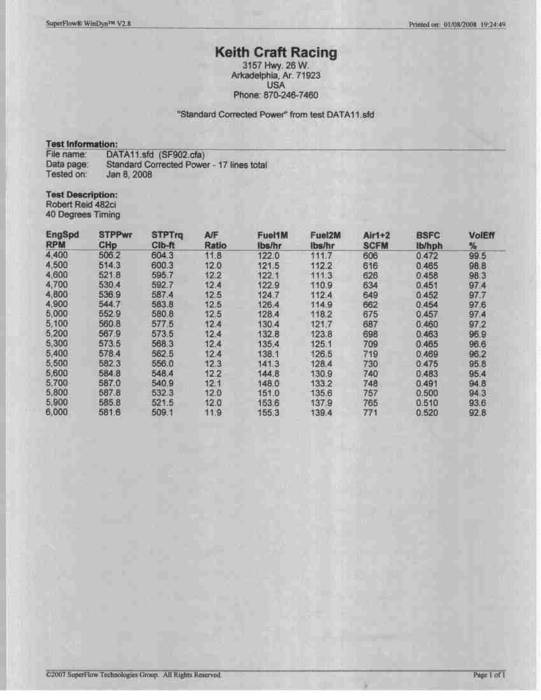

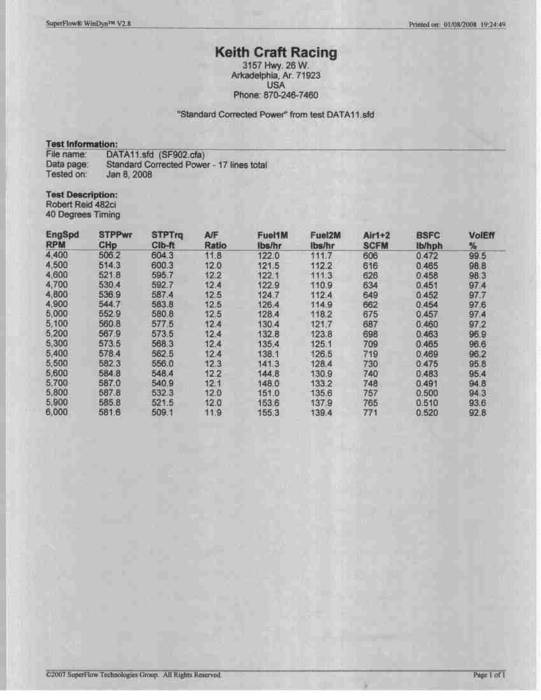

Nice, but (and I asked this on another recent KC thread and never got a response), what exactly does "standard corrected power" mean, and what sort of exhaust is hooked up, any mufflers, etc., what sort of accessories are hooked up, water pump, etc., and what other corrections are dialed in to the dyno when it's run?

|

03-08-2008, 12:01 PM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Millbrook,

NY

Cobra Make, Engine: ERA 758 KC Pond 482

Posts: 391

|

|

Not Ranked

Not Ranked

Patrick-

Not 100% sure, but I believe the standard corrected power is to compensate for different elevations above sea level (air density basically). For the dyno run the water pump and alternator are on, exhaust headers to an un muffled exhaust system. Keith could give a more detailed answer I'm sure.

|

03-08-2008, 12:54 PM

|

|

CC Member

|

|

|

Join Date: Jul 2006

Location: Ankeny,

Ia

Cobra Make, Engine: Hi tech 427 SC

Posts: 126

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xracerbob

Here is my motor dyno info:

|

Thats sweet! I wish they showed more of the RPM range. |

03-08-2008, 01:05 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Max power is at 5800 rpm, what else is their to see? Hydraulic roller cam, rpm is limited. Interesting the max VE is 4400 rpm.

When I rebuilt my motor Gessford estimated I would give up about 150 horse with my new specs. The motor dynoed at 667 before, never dynoed after, but assuming I DID give up a 150 horse, I don't even notice it! Where you can 'feel' the difference is the shift point, down from 7000 to about 6200 rpm. 1/4 mile ET went up from 11.90 to 11.99 and mph dropped from 121 to 118. "Numbers" you can't feel on the street but have to measure at the track don't really matter in the real world. Gas mileage, torque and streetability dramatically improved. You can only put so much power to the ground, after that, it really doesn't matter how much you got.

No doubt if I had some slicks my 1/4 mile ET would improve a bunch, both before and after the rebuild. Traction limited is the key element for most Cobras.

One thing has always bothered me about the new motor ET time slip. It ran 11.99 WITH the side pipes on and the new motor. I ran 11.90 WITHOUT the side pipes and the old monster motor. I've always wondered if it was more about the side pipes and less about the new motor that reflects the slower ET. Now that the 1/4 mile drag strip is closed, I may never know.

Last edited by Excaliber; 03-08-2008 at 01:18 PM..

|

03-08-2008, 01:05 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xracerbob

Patrick-

Not 100% sure, but I believe the standard corrected power is to compensate for different elevations above sea level (air density basically). For the dyno run the water pump and alternator are on, exhaust headers to an un muffled exhaust system. Keith could give a more detailed answer I'm sure.

|

Your numbers are strong regardless; it's really just a curiosity thing. You can play a lot of games with dynos, but for the most part it doesn't really matter -- most of us can't begin to tap the HP we have in our cars. What you might want to do though is put your car on a chassis dyno and measure the numbers at the rear wheels. You will be shocked at what your mufflers (side pipes) and drivetrain sap out of the numbers you have now. |

03-08-2008, 01:08 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Ernie, don't be dogging hydraulic rollers  ....they're capable of 6800-7000 rpm with the right lifters, springs, and retainers. |

03-08-2008, 03:22 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

I haven't seen any reports of that high an rpm range with a hydraulic yet. Keith mentioned he is working on some he expects to run 6200 or so. Thats about as high as I've heard of. At any rate, my solid flat tappet is mostly done at 6200 anyway, which is high enough for me! It gets pretty expensive pushing that rpm limit much higher than 6500 (crank, rods, pistons, valves, heads, etc.).

|

03-08-2008, 03:24 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Ah, 6200 is easy.

KC had a Cobra at one of the Cobra shows in London that had a hydraulic roller. If I remember, I think he said it would pull to 6800 or maybe a little higher. |

03-08-2008, 04:18 PM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Location: West Bloomfield,

MI

Cobra Make, Engine:

Posts: 717

|

|

Not Ranked

Not Ranked

I've only seen really high RPM out of hydraulic rollers in cars that were required to run them by the class rules. They "cheat" them into acting solid by nearly bottoming out the innards with the adjusters. They always seem to poop out on me around 6200 when run normally. But thats where they belong anyhow...

That dyno sheet looks like it had a safe and honest pull on it. I am pretty confident that you could wring more bragging numbers out of it with a leaner mixture - 12.0 coupled with BSFC around .5 shows it pretty safely rich. A bigger carb would also help with the glory part of the pull. I recently tried a 445 incher that made 455 on a 750 and 485 with an 850 - no other changes. Now - put that big carb and lean mixture on your motor and you'll have higher peaks but weaker throttle response, and a higher risk as far as fuel toreance.

Sounds like a nice engine to me....

__________________

Survival Motorsports

"I can do that....."

Engine Masters Challenge Entries

91 octane - single 4bbl - mufflers

2008 - 429 cid FE HR - 675HP

2007 - 429 cid FE MR - 659HP

2006 - 434 cid FE MR - 678HP

2005 - 505 cid FE MR - 752HP

|

03-08-2008, 04:35 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Barry, IIRC, this engine used "lightened" lifters with beehive springs, titanium retainers, and titanium locks.

|

03-08-2008, 05:14 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

The Z06 Corvette runs hydraulic rollers and runs up to 7,100 RPM. I'm sure the new ZR-1 will top that and you might as well include Porsches and such. However, these cars do not run FE's.

|

03-08-2008, 05:24 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Pushing 7,200 rpm with beehives

Pushing 7,200 rpm with beehives

Excaliper My motor with the 482 kit will turn 6,500 rpm if I take out the limiter chip in the MSD. The motor doesn't fall on it's face with valve float either. I have been running these springs for 3 years. I went from a 501-533 hydro cam to a 587-607 hydro roller cam from crane. My motor pulls to 6,200 without any valve float or lifter pumpup. I set the lifter lash at .015". With high rpm the lifter doesn't hold the vale open. On LS2 motor they are turning 7,200-7,400 rpm with any float. At 7,600 rpm all hell breaks loose with lose of control of the valves. Gessford builds great motors. George and company like running solid lifter camshafts in there motors. This is a proven and durable motor if maintained correctly. Comp cams is coming out with stronger beehive springs. If someone ever makes a rev kit, the 8,000 rpm range will happen. IMO if you have not tryed beehive springs, don't knock them until you tryed them.  As far as your 2 motors running the 1/4 mile, running short pipes you have no back pressure and you loose HP in the upper rpm. The 2 motor is running with exhaust and the back pressure help the power bands. If you are looking for max power from your motor with exhaust sidepipes on you want to see about 1-3 psi of pressure at WOT. This will put you in the max power of both ranges, torque and HP. I am sure that George and Neil gave you a motor with 500+hp but I will bet you they got you another 40-60Ft of torque from less camshaft and matching the parts better.  Remember torque moves the car, HP keeps the speed up. As far as seeing how fast the car is, Find a 1/4 mile of road, 1,280 ft mark it off and run it one evening. It may not be perfect but close will do.  Watch out for the cops.

|

03-08-2008, 05:46 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Try them on your next EMC motor

Try them on your next EMC motor

Barry R Barry the guys that won last year where running beehives. You are a pro builder, why I can't I convince you to try these things???  I have been running them for 3 years with 2 different motors and camshafts. I do limit the rpm to 6,200 but they will go to 6,500 if I want to change the clip. I don't like revving a stroker to these limits because of the weight on the rotating assembly. Comp cams is coming out with new beehives soon with higher seat pressures. I don't understand the issues with pumped up lifters if you run a real small lash setup. I run .015" with my motor. This number is almost 0 when the motor is hot. (all Aluminium Shelby) This covers the expandsion rate. The valve are not stuck open from lifter pump up. The Ersons are working great. They are very heavy. I am looking at a couple of other rockers for the 498 motor. I already have T&D for the other motor. LS2 motors are going to 7,400 rpm with hydro lifters. The guys I know are not bottoming out the lifters. Your guys must be either limiting oil flow and pressure to the lifters or enlarging the lifter bled hole. The beehives become uncontrolled at 7,600 rpm. 7,400 is the safe number now. When I get back to work I am going to send you a set of beehives to try on one of your EMC motors. You can tell me how it turns out. An avergae of 44 grams of weight saved per valve has to be worth something and the extra 400-600 rpm to the same motor. I know they are not cheap with the springs, retainers, cups, and locks. I run the #26120 on the motor now with a max of .600" lift on the cam. I am looking at the 25595 for the other motor with a .750" max lift. The seat pressure is less. Running a 11/32 valve or a 5/16" valve stem would also help with the weight savings. I may send my heads back out and have 5/16" valves installed instead of the 11/32" and save some more weight. How's the baby, getting big?? have agood evening Rick L.

|

03-08-2008, 06:56 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,287

|

|

Not Ranked

Not Ranked

Don't discount the hydraulic roller. The Z06 guys are laying down over 600 rwhp SAE with hydraulic lifters, no nitrous or boost, just RPMs and motor.

|

03-08-2008, 07:19 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

My 347 pulls strong to 6500 with hydraulic rollers. Not sure what the springs are.

A 4.6 modular can turn 10,000 with hydraulic lifters. I know the overhead cam is apples to grapefruit, but there is a point to be made. To get to those rpms they use 0-5W oil to keep the lifters from pumping up. My experiance, back when I was a puppy, with a 383 Mopar (with hemi valve springs) was that it would turn 7000+ with 10-40W, but with 50W the valves would float around 6700. My point is that springs and valve train weight are very important, but so is the oil. I even suspect some of the very high oil pressure that I read of the FE engines could also negatively impact hydraulic lifter. |

03-08-2008, 07:59 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

The 4.6 engines don't use the normal type hydraulic lifters--they dn't move at all, just take up the slack at the end of the rocker that the cam runs directly on

|

03-08-2008, 08:06 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Jerry Clayton

The 4.6 engines don't use the normal type hydraulic lifters--they dn't move at all, just take up the slack at the end of the rocker that the cam runs directly on

|

Yes I know (why I said apples to grapfruit). But the point is with 5-30W the same lifters will not go much past 8000.

Granted I am going from memory here so the numbers are not exact.

Last edited by olddog; 03-08-2008 at 08:15 PM..

|

03-08-2008, 08:37 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

My point was no matter what kind of cam you run, when you push over 6500 rpm things get 'expensive'. You need a good bottom end, great heads, those bee hive springs I've been reading about look real good. The faster you go, the more it cost, and reliability becomes a factor to reckon with!

I built my motor on a budget and with longevity in mind. 6200-6400 is a reasonably safe range for a side oiler and a long life. 3 years ago, or so, a hydraulic roller cam in the 6200 rpm range would have cost a lot more than my flat tappet. Solid roller lifters have come a long way in the last 3 years as well. Longevity is up and the cost is coming down.

While my old motor would turn 7000 plus (solid roller), I gotta tell ya, it scared the heck out of me taking it that high. It was a rare trip to that lofty region. Like when I'd leave it in third gear and run 'out the back door' at the end of the strip. Whew, scary stuff.

500 plus horse under 6000 rpm, sounds like a GREAT motor to me!

Last edited by Excaliber; 03-08-2008 at 08:39 PM..

|

03-09-2008, 07:05 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,287

|

|

Not Ranked

Not Ranked

Another issue with these 4.25" stroke crank short blocks (482, 484 , 496 etc..) is their heavy rotating assemblies. The eagle rods uses (H-beam) is v-e-r-y heavy. This, along with valve train limitations, limits the usable RPMs of our stroked FEs. You guys, Ernie included, that have a stock stroke 427 will always have a more "rev-happy" engine. Those of us that are stoked on stroked are willing to give up statespherical rpm limits for mountains of low/mid range torque. This minimizes the need for any solid lifter on these large strokers, flat tappet or roller. Also, in a lot of cases with stroked FEs we will have run out of intake and carb by 7K rpms (dual plane intake w/ 750/850 carb and other "streetable" combinations). There's quite a few things that'll limit RPM other that cam design.

Dave

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 03:08 AM.

|

1Likes

1Likes

As far as your 2 motors running the 1/4 mile, running short pipes you have no back pressure and you loose HP in the upper rpm. The 2 motor is running with exhaust and the back pressure help the power bands. If you are looking for max power from your motor with exhaust sidepipes on you want to see about 1-3 psi of pressure at WOT. This will put you in the max power of both ranges, torque and HP. I am sure that George and Neil gave you a motor with 500+hp but I will bet you they got you another 40-60Ft of torque from less camshaft and matching the parts better.

As far as your 2 motors running the 1/4 mile, running short pipes you have no back pressure and you loose HP in the upper rpm. The 2 motor is running with exhaust and the back pressure help the power bands. If you are looking for max power from your motor with exhaust sidepipes on you want to see about 1-3 psi of pressure at WOT. This will put you in the max power of both ranges, torque and HP. I am sure that George and Neil gave you a motor with 500+hp but I will bet you they got you another 40-60Ft of torque from less camshaft and matching the parts better.  Remember torque moves the car, HP keeps the speed up. As far as seeing how fast the car is, Find a 1/4 mile of road, 1,280 ft mark it off and run it one evening. It may not be perfect but close will do.

Remember torque moves the car, HP keeps the speed up. As far as seeing how fast the car is, Find a 1/4 mile of road, 1,280 ft mark it off and run it one evening. It may not be perfect but close will do.  Watch out for the cops.

Watch out for the cops.

I have been running them for 3 years with 2 different motors and camshafts. I do limit the rpm to 6,200 but they will go to 6,500 if I want to change the clip. I don't like revving a stroker to these limits because of the weight on the rotating assembly. Comp cams is coming out with new beehives soon with higher seat pressures. I don't understand the issues with pumped up lifters if you run a real small lash setup. I run .015" with my motor. This number is almost 0 when the motor is hot. (all Aluminium Shelby) This covers the expandsion rate. The valve are not stuck open from lifter pump up. The Ersons are working great. They are very heavy. I am looking at a couple of other rockers for the 498 motor. I already have T&D for the other motor. LS2 motors are going to 7,400 rpm with hydro lifters. The guys I know are not bottoming out the lifters. Your guys must be either limiting

I have been running them for 3 years with 2 different motors and camshafts. I do limit the rpm to 6,200 but they will go to 6,500 if I want to change the clip. I don't like revving a stroker to these limits because of the weight on the rotating assembly. Comp cams is coming out with new beehives soon with higher seat pressures. I don't understand the issues with pumped up lifters if you run a real small lash setup. I run .015" with my motor. This number is almost 0 when the motor is hot. (all Aluminium Shelby) This covers the expandsion rate. The valve are not stuck open from lifter pump up. The Ersons are working great. They are very heavy. I am looking at a couple of other rockers for the 498 motor. I already have T&D for the other motor. LS2 motors are going to 7,400 rpm with hydro lifters. The guys I know are not bottoming out the lifters. Your guys must be either limiting  Linear Mode

Linear Mode