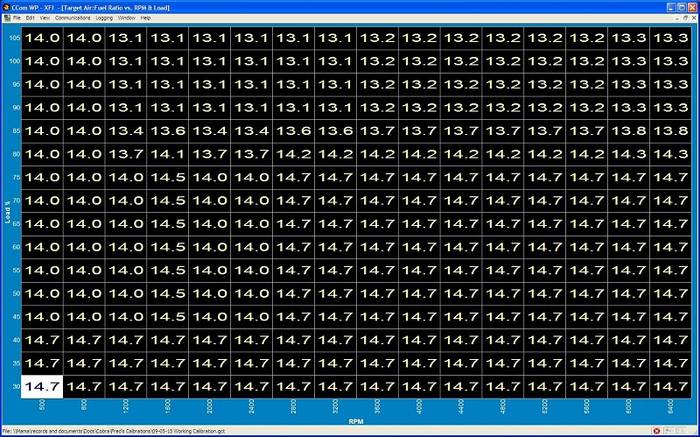

kobrabytes Len The general numbers are 12.7-12.9 to make the most torque. 13.1-13.4 make the most HP Idle or light cruising you want in the 13.7-14.1. The problem is that EVERY MOTOR likes different things when running. There are a bunch of guys on the forum running now 482 motors. They all have KCR stage III heads and same cams, compression, carbs and intakes, basicly similar motors. These motors all have different sweet spots for maken the most Torque and HP. It may vary by 25 rpms or 300 rpms. Another thing is Location, location, location. 300 ft above sea level against 700 ft. Could have same specs and be 10-15 HP differents and 8-10 ft of torque. How clean the air is, this is a biggie.

I don't know where you live but there is a big different between my town and 10 miles away in E-town. In the evenings the air is heavy and the cars run faster. The best thiing for you is to try and find a good dyno shop and have them setup your motor for the best specs. I have my car setup for 90 degree days and 80% humitity. I run it a little soft because I am not looking for every last HP out of my motor. Timing is another big thing with how much and when it comes in. Some motors like 40+ degrees, others like 34-36 total. Same motor with the same specs. Spark plugs and the gaps of them. .002" can make a differents in power of the motor. Heat ranges also make a differents, some motors like colder plugs, some like hotter than the standard range of our motor. I run 1 range cooler. I am not trying to confuse you but all these things change the way each motor runs. I am a wrench for over 30+ years, to me a motor is a living, breathing thing, and talks too. The hard part is understanding what it wants.

The best info I can give you to 2 things. First off Buy a good LM- meter to read both banks of the motor with a datalogger. If you want to try and do your own tuning, make sure you have a backup file to return to where you started if the motor gets upset. You will also down the road, depending on where you live have 3-5 programs for different times of the year if you drive 3 out of 4 seasons. You can go crazy with the tuning issues with FI. If money was not a issue, there is an 8 O2 sensor recorder for each cylinder and EGT with the same ability to record the motor working. If you have a system that can controll spark and fuel to each cylinder, you can really fine tune a motor for max power. Each motor has weak and strong cylinders, this is cause by, ports not being the same size, location of the cylinder, firing order, flow ratings being little different, the intake manifold not being ported to match all cfm equally. Some manifolds are 10-30 cfm off from each other. This is why I recommend Joe Craines services for intakes. He will match the flow to within 5-8 cfm on most manifolds. I have seen the beautiful work he does. Motors also run better. Some pick up 3-5 HP others pick up 15-18 hp. these are REAL numbers, not bench racing specials. Matching ports in and out of the heads, intake and exhaust manifold is a magic that the pro know and do. The other thing is a Bigger port is NOT a better port for power. It's about matching parts.

I hope this explains a little about what you are trying to do and why somethings either work or don't work. It is not to hard to get your motor in the ball park and setup with the A/F, but to have it razor sharp takes alot more work.

Side note to this, I was working on my tuneup of the 482 motor, the O2 sensor was not reading the correct A/F numbers, I burnt the paint by the side pipes off the body in 30 seconds.

I also run a soft setup with timing and A/F readings. Rick Lake

I don't know where you live but there is a big different between my town and 10 miles away in E-town. In the evenings the air is heavy and the cars run faster. The best thiing for you is to try and find a good dyno shop and have them setup your motor for the best specs. I have my car setup for 90 degree days and 80% humitity. I run it a little soft because I am not looking for every last HP out of my motor. Timing is another big thing with how much and when it comes in. Some motors like 40+ degrees, others like 34-36 total. Same motor with the same specs. Spark plugs and the gaps of them. .002" can make a differents in power of the motor. Heat ranges also make a differents, some motors like colder plugs, some like hotter than the standard range of our motor. I run 1 range cooler. I am not trying to confuse you but all these things change the way each motor runs. I am a wrench for over 30+ years, to me a motor is a living, breathing thing, and talks too. The hard part is understanding what it wants.

I don't know where you live but there is a big different between my town and 10 miles away in E-town. In the evenings the air is heavy and the cars run faster. The best thiing for you is to try and find a good dyno shop and have them setup your motor for the best specs. I have my car setup for 90 degree days and 80% humitity. I run it a little soft because I am not looking for every last HP out of my motor. Timing is another big thing with how much and when it comes in. Some motors like 40+ degrees, others like 34-36 total. Same motor with the same specs. Spark plugs and the gaps of them. .002" can make a differents in power of the motor. Heat ranges also make a differents, some motors like colder plugs, some like hotter than the standard range of our motor. I run 1 range cooler. I am not trying to confuse you but all these things change the way each motor runs. I am a wrench for over 30+ years, to me a motor is a living, breathing thing, and talks too. The hard part is understanding what it wants. Side note to this, I was working on my tuneup of the 482 motor, the O2 sensor was not reading the correct A/F numbers, I burnt the paint by the side pipes off the body in 30 seconds.

Side note to this, I was working on my tuneup of the 482 motor, the O2 sensor was not reading the correct A/F numbers, I burnt the paint by the side pipes off the body in 30 seconds.

I also run a soft setup with timing and A/F readings. Rick Lake

I also run a soft setup with timing and A/F readings. Rick Lake

Linear Mode

Linear Mode