Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

09-24-2009, 01:55 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

No question, the advanced timing was the MAJOR issue with the failure of starters/flywheels over the years with my car. As such, the advice given to advance any one's base, total or curve of ignition should be taken very seriously. As well as the advice to run a vacuum advance unit. This is advanced level stuff, proceed with caution. Me? I'm not going to "back off" (the timing  ), I'm going to figure out how to make it work for me. Realizing I put my motor at risk by doing so! OK, I'm willing to pay the price in my search for perfection. Frustrating though it be at times... |

-

Advertising

09-24-2009, 02:13 PM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Cobra Make, Engine:

Posts: 416

|

|

Not Ranked

Not Ranked

Excaliber: One answer, although you'll always read it's not recommended, is to have your distributor start advancing at a lower rpm. Really, a dist should not start advancing until above idle, or say 1000 rpm.

Mine starts somewhere around 500 rpm (or possbly lower) and increases to 20 deg at idle (a little oveer 800 rpm for me). I think it's around 14 deg when not advanced, i.e. a static test would show 14 deg. That makes it great for cranking.

I have mine set for 38 max, but may change that to 36 for safety's sake. I also think I can get away with a little more intial. I do know that 28 is too much, but I may try 22 and then 24 intial.

|

09-24-2009, 02:18 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

WHOA!!! HEAD RUSH!!! THAT is a good point. I should set my base timing with existing springs and then change those springs to heavy ones to see if my timing has changed. Maybe the lighter springs are all ready allowing some advance at my 1000 rpm idle speed? I better check, just to eliminate a possible variable I might have over looked. What I thought was 20-22 base may actually be less than that.

See, THIS is what CC does best, a place to bounce ideas off each other.

|

09-24-2009, 04:06 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Dual pattern cams work. They work best with good breathing heads. Open the exhaust a little higher, a little longer with moderate overlap (108-110 LSA's).

__________________

Chas.

|

09-25-2009, 08:39 AM

|

|

CC Member

|

|

|

Join Date: Apr 2007

Cobra Make, Engine: # 757 ERA 427 SC , 482 Al. big block

Posts: 896

|

|

Not Ranked

Not Ranked

Elmariachi ... to answer your earlier question ... I`m running two heavy silver springs at Don`s suggestion . He said the lighter ones sometimes cause the timing to not come back fully to the base setting .... and also sometimes bring the advance in at idle ( not good ) .

Sorry for the delayed response ... I was out of town yesterday .

I believe someone mentioned dual pattern cams ( Excaliber ? ) . I used to run nothing but dual patterns on my race engines and still do on my 427 Galaxie . Reason was that Ford exhaust ports flowed much less than the intake and couldn`t really be opened up enough . Since most of us are now running E brock heads , that may not be a problem now . The only way to tell is to put the head AND the intake on a flow bench . I used to do that and then worked with my cam grinder ( Schneider ) who would come up with a grind for my particular application . I would give anyone exact cam specs if they asked , but it did them no good as it was optimized for my engine only .

Bob

|

09-25-2009, 09:09 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Bobcat

Since most of us are now running E brock heads , that may not be a problem now.

|

... or it still might. Here's the flow data: http://www.edelbrock.com/automotive_.../flow_data.pdf |

09-25-2009, 12:25 PM

|

|

CC Member

|

|

|

Join Date: Apr 2007

Cobra Make, Engine: # 757 ERA 427 SC , 482 Al. big block

Posts: 896

|

|

Not Ranked

Not Ranked

Partrick ... guess I should have been more specific .... my fault. I think that most of the guys running the E brock heads have had them modified by some sort of CNC program , i.e Keith Craft and others . This gets the exhaust up in the range it needs to be . The problem I had on the iron heads was that there wasn`t enough meat in the ports ( without major welding ) to get it where it needed to be , therefore the dual pattern cams .

You are 100 % correct on the stock heads from E brock . Maybe Keith or someone else can speak more intelligently on the modified flow figures than I can .

I also remember my cylinder head guy telling me there was a ratio between intake and exhaust flow that should be maintained .... the difference being that exhaust gases were being pushed out ( and pulled by the collector ) and to go beyond that ratio would hurt overall performance . No data to back that up , just what I was told ... but my heads always outperformed everyone else`s on the track ... flowing everything as a unit is the only way to go . My guy always went for velocity and equal flow first and then total flow second .

|

09-25-2009, 12:57 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

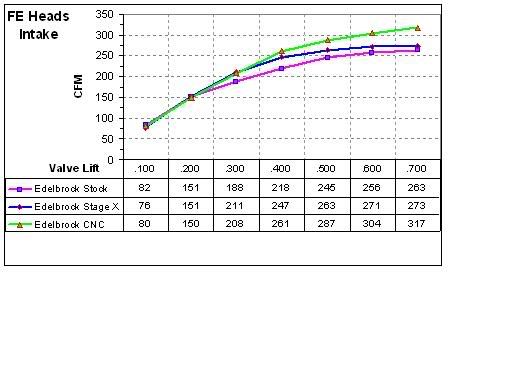

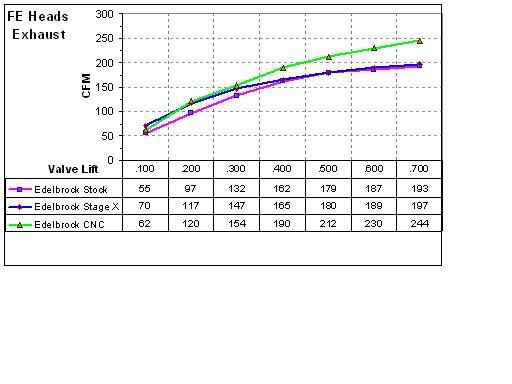

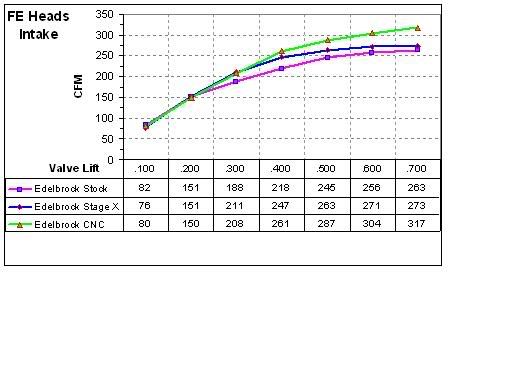

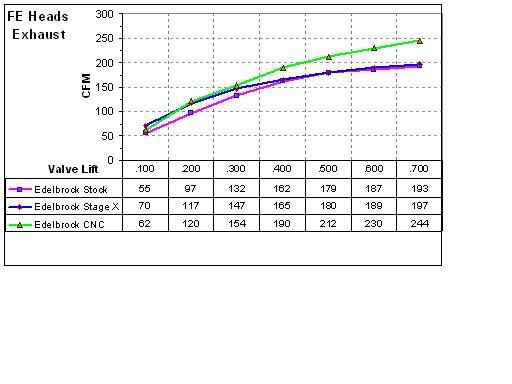

I'll go way out on a limb and say that most of us that have had our heads worked on probably land in the vicinity of the KC Stage 2 numbers. Now that's a really broad statement, so please no flames. Here's what Keith wrote about his Stage 2 numbers a few years ago:

Stage 2 Flow numbers

October 28 2003, 9:29 PM

We flow our heads at 28 inches of water which is pretty much the industry standard. The stage2 Edelbrock heads with a 2.19/1.75 valves flow as follows. Intake .400/280, .500/300, .600/318, .650/322 and the exhaust .400/198, .500/220, .600/235, .650/240. These numbers vary a few cfms each way. These are the numbers on what we call our stret strip stage 2 heads. We can change the valve angles and back-cuts on the valves and get as much as 335 on the intake at .700 and 250 at .700 on the exhaust. If someone needs real big flow number shtere is always our CNC heads that flow real big numbers. Thanks Keith

|

09-25-2009, 01:03 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

And this is Barry's Stage X info...

Is this easier?

April 17 2007, 4:23 PM

Just the Edelbrock heads. All flow data shown is SF1020 bench @ 28" - - same operator, same setup, no pipe on exhaust...good comparable numbers...

The stock Edelbrocks are just taken out of the box and flowed - no work at all. Certainly good enough for a mild stroker or a small displacement motor, but likely to run out of breath on a bigger cube or higher RPM combo.

The Stage X heads are completely untouched in the ports. The only changes are in the valves, valve job, and spring combination. The target customer is building a street oriented 427 or 428 stroker, adn does not want or need to spring for the fully ported package. This gives them a modest cost upgrade.

The CNC Edelbrocks are fully ported and have much larger cross sections - especially on the exhaust side. Definitely targeted toward big cube and higher RPM guys that are willing to sacrifice some low end response. And bigger coin too...

Barry Rabotnick

Survivalmotorsports.com

Barry Rabotnick

Survivalmotorsports.com |

09-25-2009, 01:07 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

|

09-25-2009, 01:11 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodKnock

|

Once it became apparent that Ernie had the wrong goddamm flywheel on there to begin with, and had for years, by default the thread opens up to new avenues that are at least tangentially related to the original issue at hand.  |

09-25-2009, 01:25 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

It's a thread drift, but ya got a point. Flow, cam profile all effect timing, which is the fundamental issue.

Perhaps on my NEXT engine I will be asking myself more about cylinder filling as it relates to compression ratio, cam profile, port velocity vs flow numbers, idle speed rpm and how all that relates to initial timing, carb selections and finally,,, the STARTER!  Not to mention counting the teeth on the dang flywheel.

And I'm going to be SO depressed if I discover a hydraulic roller is just the ticket.

Last edited by Excaliber; 09-25-2009 at 01:27 PM..

|

09-25-2009, 01:29 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

Perhaps on my NEXT engine I will be asking myself more about cylinder filling as it relates to compression ratio,cam profile, port velocity vs flow numbers, idle speed rpm and how all that relates to initial timing, carb selections and finally,,, the STARTER!  Not to mention counting the teeth on the dang flywheel. |

For now, just bolt the right flywheel back on there and don't forget to use a little LocTite so it doesn't fall off.  |

09-25-2009, 01:54 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Got confirmation the flywheel ring gear has shipped, as well as the new synchro's for the top loader (preventative maintenance, it shifts fine) and the speedo driven gear to get the speedometer more accurate. I don't know, Locktite on the flywheel bolts ya think? Didn't use it last time, maybe got lucky. Didn't use it on the clutch cover plate either, maybe got lucky. BOTH were tight as heck on the tear down. I'll re-use the clutch plate which shows minimal wear, all surfaces (cover/flywheel) look good. Throw out bearing only has about a 1000 miles on it, I just recently replaced it.

|

09-25-2009, 01:58 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

Locktite on the flywheel bolts ya think? Didn't use it last time, maybe got lucky. Didn't use it on the clutch cover plate either, maybe got lucky.

|

We've had a few threads on this recently. The considered opinion is to use it, without a doubt. There is some debate as between red and blue. |

09-25-2009, 02:22 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Blue for me! Even without it those bolts were a real bear to break loose. Man, with red it might be nigh onto impossible trying to do it IN the car. The extension pipe I used on the breaker bar gave me clearance issues.

|

09-25-2009, 02:24 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Once it became apparent that Ernie had the wrong goddamm flywheel on there to begin with, and had for years, by default the thread opens up to new avenues that are at least tangentially related to the original issue at hand.  |

I know, I know. Sheesh. I was only kidding around.  |

09-25-2009, 02:30 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

I have spoken to Barry in the past about this and for serious power he prefers to slightly modify Art Francis' Blue Thunder castings.

They're how it got him over 700 on pump gas.

My out of box CNC'd Shelbys are 320/230 @ .600 (which is where my cam works) and they clearly out perform my ported iron Med. Risers which had 2.250's and 1.75's.

Ring gears? We ALL got stinkin' ring gears!

__________________

Chas.

|

09-25-2009, 02:36 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

Blue for me! Even without it those bolts were a real bear to break loose. Man, with red it might be nigh onto impossible trying to do it IN the car. The extension pipe I used on the breaker bar gave me clearance issues.

|

Yikes Ernie,

Mine were Locktited in at 85 LbFt and my Ingersol spun them right out. Don't have clue why your gun wouldn't break 'em. Put back new ARP's same way using f'wheel tool and holder and it's t!ts.

__________________

Chas.

|

09-25-2009, 02:40 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

I have spoken to Barry in the past about this and for serious power he prefers to slightly modify Art Francis' Blue Thunder castings.

They're how it got him over 700 on pump gas.

My out of box CNC'd Shelbys are 320/230 @ .600 (which is where my cam works) and they clearly out perform my ported iron Med. Risers which had 2.250's and 1.75's.

Ring gears? We ALL got stinkin' ring gears!  |

Isn't the only issue with the BT heads, the raised exhaust ports and thus a revision to the headers and exhaust? |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:04 AM.

|

), I'm going to figure out how to make it work for me. Realizing I put my motor at risk by doing so! OK, I'm willing to pay the price in my search for perfection. Frustrating though it be at times...

), I'm going to figure out how to make it work for me. Realizing I put my motor at risk by doing so! OK, I'm willing to pay the price in my search for perfection. Frustrating though it be at times...

Linear Mode

Linear Mode