Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

1Likes 1Likes

06-02-2013, 07:51 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2006

Location: McKinney,

TX

Cobra Make, Engine: ERA GT #2077, 331 SBF, Webers, Gurney Eagle heads

Posts: 1,275

|

|

Not Ranked

Not Ranked

Tom, I used the Kirkham FAQ for all my BH/FW/Clutch parts. See:

KMS FAQ

The Mcleod 563210 has billet alum body, with steel friction surface (rebuildable) and steel 184 tooth starter ring:

McLeod Racing - Aluminum Flywheels

Your pinion engagement of 2/3 to 3/4 ought to be enough if you are using the correct starter for the 184 tooth FW. I use the Tilton 54-20013 Severe Duty Super Starter. I can't say how many teeth it has, as it is not possible to see the pinion with it in the car. Do not use the supplied shim between the face plate of the starter and the starter body. If you don't use this Tilton, then make sure you use a starter for the FE and not the FT or 429/460 motor. They have different FW sizes and tooth counts.

Sam |

06-03-2013, 03:22 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Block saving plate??

Block saving plate??

Krammer did you cut out the part of the motor plate where the starter goes? Make sure that the surface where the starter goes is flat. This will give you about 80% coverage of teeth to teeth on flywheel and starter. THis is what I have been running for the last couple of years and no wear problem any more.

As for the car cranking, was the distributor removed from the motor at any time?? It is possible you are 1 tooth off and having this problem. The timing light trick will work if the motor is spinning over fast enough. Cut the fuel system off and remove spark plugs. Unhook all the injectors and have timing light hooked to #1 wire. THis will let you crank over the motor at a quicker speed. Check your timing. If it comes up OK we have a software problem and need to check the base timing chart. You might at this point fine an FI guy and dyno shop and have the car checked out. ON some FI systems you have retard or advance the timing on cranbking to help the motor to start easier. IF you are snapping flywheel bolts and teeth on the flywheel we need to check the crankshaft end play. There may be a machine problem and causing the crank to no stay centered in the block and has worn out one side of the thrust bearing or the other. end play should be about .005" to .015" max. Anything more than this, pull the oil pan and do a vision check and look for metal in the pan.

This may help get trans out of car easier, jack up back of motor to clear trans mount and easy twist to remove it. If you have the room a engine crane will handle the weight. Sorry have no easy way to install it. I do it the bull way, by hand. This is also my regular job of tranny R&R. Rick L. Lets stay with the clutch setup you have right now and see if we have another problem first. If you have the flywheel off again, cut a couple of threads of the end to make sure there is no contact with block.

Last edited by RICK LAKE; 06-03-2013 at 03:25 AM..

Reason: brain fart, my bad

|

06-03-2013, 05:28 AM

|

|

Member of the north

|

|

|

Join Date: May 2003

Cobra Make, Engine: A Cobra

Posts: 11,207

|

|

Not Ranked

Not Ranked

I burned up the first powermaster and went back to FORD. Not sure if this helps, but the power master did not align well with the teeth of the flywheel.

Hope this helps.

__________________

I'm a writer, feed the artist and buy a book.

|

06-03-2013, 08:25 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

Rick - Although I did not put the motor/trans together in the system the first time, I am now checking everything I can think of to get this right. There is a plate between the motor and the trans and it appears to be flat (by using a simple straight edge). I can't say if the distributor was ever removed but I guess its possible. The first time the motor ever ran it was run with a normal intake with carburetor....then after that it was switched out for TWM intake. Perhaps the distributor was moved at that time but I don't know. My next step will be to check end play and run out as well as the bell housing alignment with a dial indicator.

Sam - do you have a engine plate with the LW bellhousing as well?

|

06-04-2013, 06:49 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2003

Location: West Linn,

OR

Cobra Make, Engine: ERA #684, 428 FE, TKO600

Posts: 1,378

|

|

Not Ranked

Not Ranked

FWIW when you reinstall the transmission. Get a couple of long bolts the same size as the mounting bolts that hold the transmission to the block. Hand thread them into the upper two mounting holes in the back of the block, figure out how much depth you'll need with the transmission attached to allow them to stick out about 1/2 to 3/4 of an inch and cut them off at that length. Slot the cut off end with a Dremel tool or a grinder with a cut off wheel. Make the cuts wide enough so you can get a large screw driver into them.

When the transmission is ready to go back in hand thread the cut off bolts into the back of the block and use the cut off bolts as pilots for when you slide the transmission back onto the engine. They will help getting everything aligned and support the weight of the transmission until you get the lower bolts in and snugged up. Use a large screw driver to remove the "pilot" bolts one at a time and replace them with the regular transmission bolts.

Saw them using this method at ERA when they put my transmission in and it has worked for me when I had my transmission out.

It won't be easy to get it in but it can be done. Helps to have an extra set of hands for about 15 minutes to get the transmission lifted into place. Once in the rest is just a matter of getting everything tightened down.

DonC

|

06-04-2013, 07:47 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2006

Location: McKinney,

TX

Cobra Make, Engine: ERA GT #2077, 331 SBF, Webers, Gurney Eagle heads

Posts: 1,275

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Kramer

Sam - do you have a engine plate with the LW bellhousing as well?

|

Yes, although I have not trimmed out the portion that the starter sits on. That would put your pinion about .100" further in. If it is off by that much, then you could do that. Tilton recommended I have the starter face plate turned down by .060", so I had that done. But you should measure first.

Check the distance from the mounting surface of the block plate that the starter sits on to the near edge of the flywheel gear. You can do this with a 6" scale. I would bolt the BH on to get an accurate measurement. Compare that to the distance from the corresponding surface on the starter face to the outer edge of the pinion when it is pulled all the way out. The difference would be equal to the tooth engagement distance.

One concern I have is whether you have the correct starter pinion gear for your 184 tooth FW. If this is not an FE starter, it may have a different tooth pitch, and that would also bust teeth like you have been doing.

Sam

|

06-23-2013, 06:52 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

Lakewood Bellhousing

Lakewood Bellhousing

Quick Question:do lakewood bellhousing's come per-drilled for the starter?

The reason I ask is after talking to everyone including Rob at robbmc starters I am beginning to think that my starter(s) are not engaging properly radially...as in the teeth are not meshing fully. What do you think is this possible?

|

06-23-2013, 07:29 PM

|

|

CC Member

|

|

|

Join Date: Dec 2008

Location: Chester,

VA

Cobra Make, Engine: West Coast Dreams

Posts: 192

|

|

Not Ranked

Not Ranked

I was reading this and I could not help but wonder if the starter and the flywheel have the same tooth per inch ratio. Usually if the flywheel is the proper diameter and also the correct gearing there should be no problem. When you started your engine did you hear some grinding and crashing? I would think that you did, especially if you have up to 9 teeth missing... I would install it and inspect the starter engagement by pulsing the solenoid to throw the gear out to the flywheel. Do this at different points along the rotation of the crankshaft. If this is correct alignment, then is your flywheel out of round? If there are high spots it could mean that your flywheel choice does not fit. You may even find that it's on the crank, but it's not straight, or binding. This would cause the collision of the gears during cranking. You may be going down the wrong road just replacing item after item and you actually have something fundamentally wrong or binding in the flywheel/starter alignment. This would be the case no matter which starter you chose. Just some thoughts...

I found a USB borescope camera on Amazon for about $70. Yeah it was pricey, but it sure comes in handy for inspections on flywheel gear alignment and the like.

Regards,

Xack

|

06-24-2013, 07:30 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2006

Location: McKinney,

TX

Cobra Make, Engine: ERA GT #2077, 331 SBF, Webers, Gurney Eagle heads

Posts: 1,275

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Kramer

Quick Question:do lakewood bellhousing's come per-drilled for the starter?

The reason I ask is after talking to everyone including Rob at robbmc starters I am beginning to think that my starter(s) are not engaging properly radially...as in the teeth are not meshing fully. What do you think is this possible?

|

Yes, mine was drilled and threaded. As Rick Lake was saying, your bell housing itself could be seriously off center. I had this problem. To detect this, you need to have the trans and clutch out of the car and put a magnetic base dial indicator on the flywheel so you can measure the concentricity of the register bore of the bell housing with the flywheel/crank center line. Lakewood describes this procedure:

FAQs

This is more easily done with the motor out of the car. But it can be done in the car. Take the plugs out so you can rotate the crank with a wrench on the front of the engine while you measure the eccentricity of the BH.

But, if the BH is so far out radially that the FW and starter are not meshing, I don't know that you would even be able to get the trans input shaft into the pilot bushing. You would not be able to bolt up the trans. So if your trans was mating with the clutch plate and pilot bushing, BH alignment was probably close enough.

As I said in my last response, I am concerned about tooth pitch mismatch between starter pinion and FW.

Sam

|

06-24-2013, 11:05 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

Thanks Sammy - I could not agree with you more. My Dad and I were talking about it last night and came to the same conclusion. Once I have more time tomorrow night I am going to go through the alignment process step by step. After talking with another member here I do believe I can make the adjustments necessary (if the BH is aligned) with the engine plate. My first step I am going to take is to put the FW on as well as the engine plate, pull the plugs, and mount the starter up to the engine plate to see what is going on when I pull out the pinion gear on the starter.

|

06-24-2013, 12:13 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

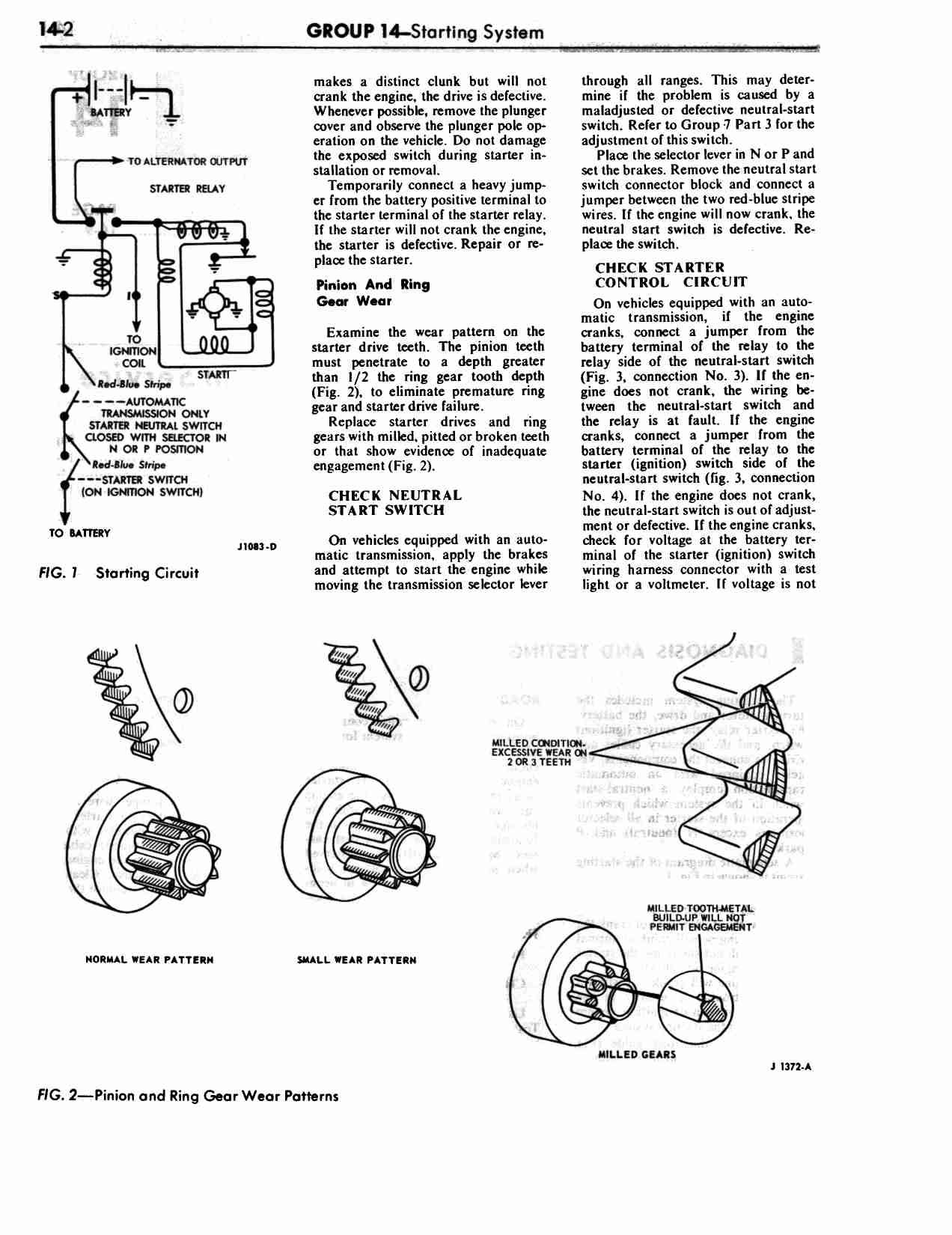

Kramer, if the parts are correct, aligned properly, and it goes the proper depth, then there's not much more to it. I thought I'd post the page from the original FE shop manual for you nonetheless.

Last edited by patrickt; 11-07-2016 at 12:28 PM..

|

06-24-2013, 09:06 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: HiTech Legends GT500

Posts: 1,359

|

|

Not Ranked

Not Ranked

Some rambling thoughts...

Why are you going to replace the flywheel? You can buy a new ring gear for about $30 at almost any auto parts store. All FE are 184 tooth ring gears. Tell the auto parts store it is for a 1968 390 Mustang. You do not have a pitch problem. You have to pay big money to get ring gears of a different pitch.

Can you post a picture of the old ring gear? With a picture I bet someone can identify the problem. Without a picture I bet your starter is not engaging into the ring gear deep enough. I have lost count of all the starters we have had to trim on the lathe. This is just not a Tilton problem.

Did your engine buck when you tried starting it? If not, your problem is probably not the initial advance timing. I suspect the Accel EFI system has a start retard function that you might not see at idle...

|

06-25-2013, 10:39 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

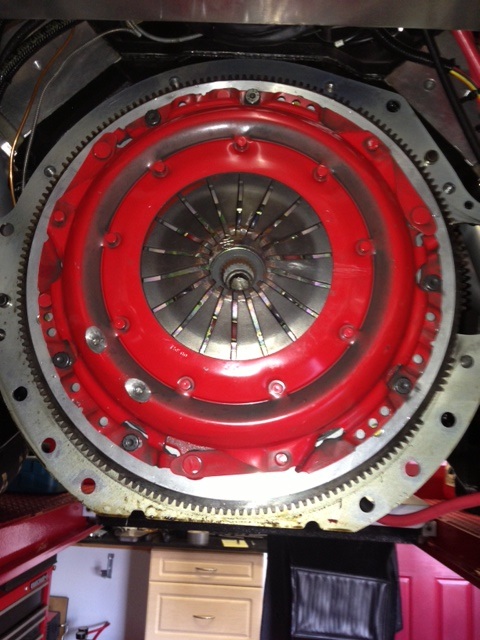

Tom - fyi, I did not replace the flywheel, just the teeth. McCleod did it for $75. I put some pics in my photo album I just put in there as well as picks from my number two (OEm) starter. I am still trying to figure out how to paste them in this message but here goes...

|

06-25-2013, 10:43 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

We call that a "West Virginia Flywheel" ... missing teeth.  Do you have upclose macro shots that show the wear pattern on the teeth and starter gear? |

06-25-2013, 10:47 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

|

06-25-2013, 10:49 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Yes, I found them in your photo album. It looks to me like the gears are only cathing the "tips" of one another. Just like the "small wear pattern" diagram in the manual.

|

06-25-2013, 10:51 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

ill get some starter pics

|

06-25-2013, 10:52 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

that is the OEM starter I used before the Robbmc model I have now.

|

06-25-2013, 10:55 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,017

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Kramer

that is the OEM starter I used before the Robbmc model I have now.

|

Does the wear pattern on the Robbmc starter look like the "normal" wear pattern in the manual page? |

06-25-2013, 12:42 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Cobra Make, Engine: ERA 739

Posts: 604

|

|

Not Ranked

Not Ranked

It looks better but similar....after talking with Rob and RobbMC starters he too, felt it appeared to him as if it was not properly engaging/meshing right.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 11:23 PM.

Links monetized by VigLink

|