Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

5Likes 5Likes

06-06-2022, 02:32 PM

|

|

CC Member

|

|

|

Join Date: Apr 2015

Location: Prescott,

AZ

Cobra Make, Engine: Classic Roadsters

Posts: 209

|

|

Not Ranked

Not Ranked

Gas tank becoming pressurized???

Gas tank becoming pressurized???

I've been experiencing something different and am curious to understand what might be causing it. The gas tank in my Cobra is becoming pressurized when I drive the car. It seems to run fine but I do need to loosen the gas cap very slowly to let the pressure escape or it can burp raw gas out the cap.

The car has a 5.0L Ford with the early 90's style Ford EFI, so it's a return style system. It has the LeMans style gas cap mounted in the passenger side fender top and I use a OEM screw-in gas cap under the flip cap. There's a couple of things that might be contributing but it's not clear to me they are. The car was stored away for about 3 years and not driven. Prior to putting the car in storage, I regularly drove the car and there were no indications that the fuel tank was being pressurized. I also recently moved from CA to AZ, so prior the car was getting CA formulation fuel, and now it's getting AZ gas. I guess the other change is fuel formulations may have changed over the last few years and especially with the current fuel situation.

The first symptom of the issue is that gas was bubbling up out of the LeMans cap while I was driving the car to the extent that it would run down the fender. It would start bubbling out after about 15 minutes of driving. The gas would bubble out until the cap was loosened and there would be a big whoosh of air (and gas) until the pressure in the tank dissipated. It would be good for the next 20 minutes or so of driving and then start bubbling gas out again. On closer inspection, the gas cap O-ring was not sealing and thus the gas could be pushed by it. I modified the cap so it could screw down further, completely seal and this stopped the gas bubbling out.

My next stop at the gas station told me I had effectively sealed the system. When I loosened the screw-in cap, a bunch of pressurized air was released along with some liquid fuel. I have learned to loosen the cap very slowly in order to slowly bleed off the air to avoid having liquid fuel burp out. So the situation seems under control but it still worries me some.

Has anyone else experienced something like this? I'm guessing this is "normal" for an EFI car where the fuel is being constantly recirculated and likely being warmed during this process. But I thought it worth while putting the question out there in case there's an underlying issue that I should address.

__________________

Thanks,

Joel Heinke (early 90's CRL Cobra)

|

06-06-2022, 03:59 PM

|

|

CC Member

|

|

|

Join Date: Dec 2015

Posts: 1,442

|

|

Not Ranked

Not Ranked

Typically the fuel caps are vented and it sounds like your is not.

Another issue if the tank vent line (that usually runs from the top corner of the tank to the side of the fill line) has a low spot (right after it leaves the tank, typically look will like a J vs the required L shape) it will cause the fuel to start backing up the fill pipe as temperature increases. If can be exasperated even more if the return fuel line dumps into the fill line as well.

|

06-07-2022, 11:45 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

Gasoline uses what is called light ends to enhance octane rating. The light ends in gasoline boil (vaporize) below 98˚F. On a warm day these light ends are easily boiled off in the gas tank. The problem is aggravated with the use of a return style fuel system that has the fuel system pressure regulator located in close proximity to engine compartment heat.

Return style systems will vaporize the light ends in the pressure regulator and return them to the fuel tank as a vapor along with the now low octane base stock the fuel was originally made from. That vapor that is now in the tank is the whoosh you experience when you open the tank. This is a double whammy, as Al Capp's Mammy Yokum liked to say.

The first whammy is the vaporization issue. The second is, like a soda that has been stored too long and lost its 'fizz', the lost fizz can not be put back in the soda. Neither can the light ends be put back into the gasoline base stock! When you open the soda can, the soda is flat and just like the soda so is the gas in your tank. What used to be 93 (or hihger) octane is now down to or near to base stock octane ratings of 88 or 89 octane, sometimes even lower.

The easiest fix for the problem is to move the fuel pressure regulator as far from the engine bay heat as possible. The harder fix is to convert to a returnless system. Detroit has embraced returnless systems for a lot of additional reasons but the boiling off of the light ends and subsequent negative impact on emissions testing / compliance is certainly at the front of the parade.

The warmer the climate the more pronounced the problem becomes, because the fuel tank is also heated by the ambient air — which in AZ can get fairly toasty. The easiest fix is relocating the fuel pressure regulator and parking in the shade (or you garage) when you're not driving it.

The reason that the returnless systems fare better is there is no pressure regulator returning unused fuel to the tank. In fact the fuel still boils and still separates the light ends from the base stock in a returnless system but, and this is a biggie, there is no place for the light ends to go — except into the cylinder which is the destination they were originally intended for.

When the intake valve opens and the injector fires, the vaporized light ends and the gasoline which is itself now being vaporized, in preparation for ignition, mix as vapors and burn in the engine as they were originally intended to do.

FWIW my brand new BMW has the same whoosh performance when opening the gas cap if I am at my AZ home in the summer months. During the winter months — no whoosh. The fuel system is a returnless system so just going returnless is not a panacea. Keeping the fuel pressure regulator and fuel tank cool are the easiest, least expensive and at least at this time, best fixes.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 06-07-2022 at 06:50 PM..

Reason: Spelling & Grammar

|

06-07-2022, 02:17 PM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Edmond,

Ok

Cobra Make, Engine: Classic Roadsters

Posts: 628

|

|

Not Ranked

Not Ranked

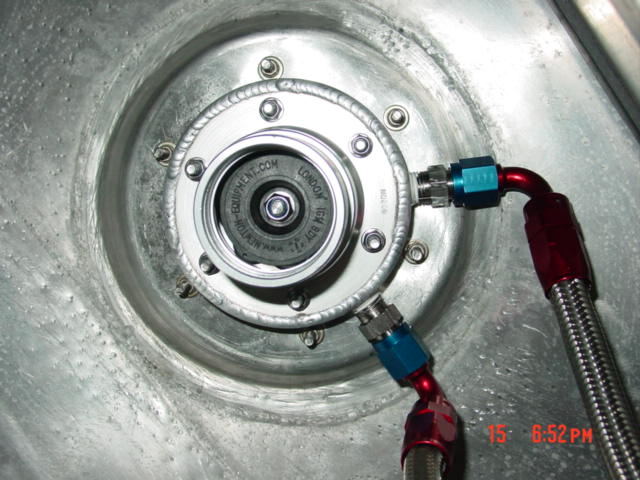

This is a Classic Roadsters tank and filler neck. TankCraft Corporation Darien, Wisconsin. 5 hole sender unit 9Ē deep, 0-90 ohms. The LeMans cap has a fuel drainback line too. Plugged maybe? Fuel, emissions and return line fitting are in the sender unit. If you donít have one good time to add it.

Edit: return line fitting is added to sender unit

__________________

Chaney Shores Studio

Last edited by sunman; 06-20-2022 at 02:56 PM..

|

06-07-2022, 03:09 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Joel

I'll try and explain how it should be done....

Here we start with the Fuel Cell with vents on both sides

Then we weld in the Aero Fuel cap inside of the Quick Fuel on the fender

Now we drill holes in the outside cap for vents on both side of the fuel cell

Now we go to the outside cap and drill two holes above the Aero Fuel cap so the fuel fumes can vent to the outside ambient pressure.

Then we mount Check valves to the vent lines coming up from the fuel cell vents on the corners of the fuel cell.

Now you can see the Check valves attached above the Aero Cap to vent to the atmosphere and from both sides of the cell for high speed corners in either direction.

Also please note the ground wires going from the cap to the chassis of the car so you have no issues with static electricity to ignite any fuel vapors.

Sorry for the long post

Morris

__________________

Morris

|

06-09-2022, 07:54 AM

|

|

CC Member

|

|

|

Join Date: Apr 2015

Location: Prescott,

AZ

Cobra Make, Engine: Classic Roadsters

Posts: 209

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by spdbrake

Typically the fuel caps are vented and it sounds like your is not.

Another issue if the tank vent line (that usually runs from the top corner of the tank to the side of the fill line) has a low spot (right after it leaves the tank, typically look will like a J vs the required L shape) it will cause the fuel to start backing up the fill pipe as temperature increases. If can be exasperated even more if the return fuel line dumps into the fill line as well.

|

The screw-in fuel cap I'm using is vented, but it has a one way valve that lets air pass in but not out of the fuel tank. I'm sure this one way vent is for pollution control as otherwise the fuel vapors would be constantly vented to the atmosphere.

I did check the vent line on the gas tank to ensure it was clear when I first noticed this fuel tank pressurization issue. It is. I do have the EFI return line T'd into the vent line. This is probably not ideal but CRL didn't design this tank for EFI so it doesn't have a dedicated port for the fuel return. I can say that using the vent port for fuel return hasn't seemed to be an issue for the 20+ years that it's been used this way.

__________________

Thanks,

Joel Heinke (early 90's CRL Cobra)

|

06-09-2022, 08:06 AM

|

|

CC Member

|

|

|

Join Date: Apr 2015

Location: Prescott,

AZ

Cobra Make, Engine: Classic Roadsters

Posts: 209

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by sunman

This is a Classic Roadsters tank and filler neck. The LeMans cap has a fuel drainback line too. Plugged maybe? Fuel and return line are in the sender unit. If you donít have one good time to add it.

|

Yes, this is the style of CRL fuel tank that's in the car and the same style of vented fill that the LeMans cap is mounted on. I believe it's the location of the fuel fill pipe in the vertical middle of the tank that causes fuel to rise up to the fill cap when the tank becomes pressurized. That is unless the tank is less than half full. When I was checking to ensure the vent line was clear, I could make fuel rise up in the fill pipe simply by blowing on the vent hose with my mouth.

Overall, I think the location of the fill pipe in the tank is a poor design but I'm not inclined to change it at this point unless there's a real pressing issue that can be resolved by doing so.

__________________

Thanks,

Joel Heinke (early 90's CRL Cobra)

|

06-09-2022, 09:10 AM

|

|

CC Member

|

|

|

Join Date: Apr 2015

Location: Prescott,

AZ

Cobra Make, Engine: Classic Roadsters

Posts: 209

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by eschaider

Gasoline uses what is called light ends to enhance octane rating. The light ends in gasoline boil (vaporize) below 98˚F. On a warm day these light ends are easily boiled off in the gas tank. The problem is aggravated with the use of a return style fuel system that has the fuel system pressure regulator located in close proximity to engine compartment heat.

Return style systems will vaporize the light ends in the pressure regulator and return them to the fuel tank as a vapor along with the now low octane base stock the fuel was originally made from. That vapor that is now in the tank is the whoosh you experience when you open the tank. This is a double whammy, as Al Capp's Mammy Yokum liked to say.

The first whammy is the vaporization issue. The second is, like a soda that has been stored too long and lost its 'fizz', the lost fizz can not be put back in the soda. Neither can the light ends be put back into the gasoline base stock! When you open the soda can, the soda is flat and just like the soda so is the gas in your tank. What used to be 93 (or hihger) octane is now down to or near to base stock octane ratings of 88 or 89 octane, sometimes even lower.

The easiest fix for the problem is to move the fuel pressure regulator as far from the engine bay heat as possible. The harder fix is to convert to a returnless system. Detroit has embraced returnless systems for a lot of additional reasons but the boiling off of the light ends and subsequent negative impact on emissions testing / compliance is certainly at the front of the parade.

The warmer the climate the more pronounced the problem becomes, because the fuel tank is also heated by the ambient air ó which in AZ can get fairly toasty. The easiest fix is relocating the fuel pressure regulator and parking in the shade (or you garage) when you're not driving it.

The reason that the returnless systems fare better is there is no pressure regulator returning unused fuel to the tank. In fact the fuel still boils and still separates the light ends from the base stock in a returnless system but, and this is a biggie, there is no place for the light ends to go ó except into the cylinder which is the destination they were originally intended for.

When the intake valve opens and the injector fires, the vaporized light ends and the gasoline which is itself now being vaporized, in preparation for ignition, mix as vapors and burn in the engine as they were originally intended to do.

FWIW my brand new BMW has the same whoosh performance when opening the gas cap if I am at my AZ home in the summer months. During the winter months ó no whoosh. The fuel system is a returnless system so just going returnless is not a panacea. Keeping the fuel pressure regulator and fuel tank cool are the easiest, least expensive and at least at this time, best fixes.

|

Ed: thanks for your insightful and detailed explanation. It makes the most sense to me for the symptoms I'm seeing.

The EFI pressure regulator is an integral part of the injector fuel rails on this EFI system. The fuel rail was provided in the EEC-IV EFI kit I bought from Ford Motorsports back in the middle 90's. The pressure regulator has a vacuum line running to it. As I recall from when I was first installing this EFI, it uses the vacuum signal to adjust fuel pressure in the rail/injectors in an effort to predict fuel squirt volume at the injector tip in varying vacuum conditions. I think the objective for the Ford EFI engineers/designers is to have higher fuel pressure at low vacuum and lower fuel pressure in high vacuum conditions such that a predictable amount of fuel will leave the injector tip even when the engine vacuum changes. If the pressure regulator were moved from it's present position, then I'm guessing the ECM programming would need to also change as it was optimized during dyno runs on the current setup.

If my theorizing above is correct (or even close to correct), then even moving the pressure regulator from it's current location could become very involved very fast. Engine vacuum levels are constantly changing (especially in the hard driving I put my Cobra through) so re-locating the pressure regulator could delay vacuum signals to it and thus delay fuel pressure changes and so on. I'm guessing these things can be worked around with ECM tuning but at that point it's a very involved project for an EFI system of this vintage.

I guess the good news side of this is that I live in the cooler part of Arizona. The summer temperatures here in Prescott, AZ are very similar to Livermore, CA (my former location) which is similar to Gilroy, CA temperatures. Assuming the underlying cause for fuel tank pressurization is related to ambient temperatures, then I'm not sure if the location change is the only factor at play. Could elevation play into this somehow. My former stomping grounds was less than 1,000 feet elevation and my new location is 5,130 feet in elevation. That's quite a change and a good testament to a strength of EFI in automatically adjusting to elevation changes as with zero tuning changes the engine still runs great.

Any additional insight and information you (or others can provide) is much appreciated! I'm sort of in a quandary, I don't like the thought of gas potentially puking on the paint job or a pressurized gas tank, but I also don't want to open a can of worms for a car that has been a very dependable play toy and I'd like to keep it that way.

__________________

Thanks,

Joel Heinke (early 90's CRL Cobra)

|

06-09-2022, 09:38 AM

|

|

CC Member

|

|

|

Join Date: Apr 2015

Location: Prescott,

AZ

Cobra Make, Engine: Classic Roadsters

Posts: 209

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Morris

Joel

I'll try and explain how it should be done....

Here we start with the Fuel Cell with vents on both sides

Then we weld in the Aero Fuel cap inside of the Quick Fuel on the fender

Now we drill holes in the outside cap for vents on both side of the fuel cell

Now we go to the outside cap and drill two holes above the Aero Fuel cap so the fuel fumes can vent to the outside ambient pressure.

Then we mount Check valves to the vent lines coming up from the fuel cell vents on the corners of the fuel cell.

Now you can see the Check valves attached above the Aero Cap to vent to the atmosphere and from both sides of the cell for high speed corners in either direction.

Also please note the ground wires going from the cap to the chassis of the car so you have no issues with static electricity to ignite any fuel vapors.

Sorry for the long post

Morris |

Morris: thanks for the detailed explanation and all the pictures!

I do get what you're saying and it totally makes sense to me for a carbureted application. I guess the question back to you is if this venting system is applicable for an EFI application? Ed's explanation for the separation of fuel vapors at the fuel pressure regulator with the non-liquid part getting returned to the tank via the fuel return line seems to make a lot of sense to me. If the tank venting efficiently let those vapors out to the atmosphere, then what?? Is it better off for having a non-pressurized gas tank and a potentially greater contribution to air pollution? Does the pressurized fuel tank help minimize additional vaporization? Is there a fuel additive that would help promote less vaporization?

I guess I'm better at asking questions at this point than answering them. I hate that but I'm willing to be educated on this topic because I do have other homebuilt cars that can benefit from getting a more optimal answer. On my replica Ferrari 250 GTO the fuel tank venting is almost exactly as you've described. It's also an EFI car so maybe the way I setup the current fuel tank venting on it is non-optimal?? I don't know but I haven't been able to move that car to my new location yet so I only have the Cobra to try things out on right now.

__________________

Thanks,

Joel Heinke (early 90's CRL Cobra)

|

06-09-2022, 10:42 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Edmond,

Ok

Cobra Make, Engine: Classic Roadsters

Posts: 628

|

|

Not Ranked

Not Ranked

The fuel return line should be below fuel level. Adds air to gas if it’s above. Just a thought, car manufacturers return to bottom of tank. Use or add another sender mounted fuel supply line for return or just add AN fitting with line to bottom. I’d get off the filler neck backsplash line.

__________________

Chaney Shores Studio

Last edited by sunman; 06-09-2022 at 01:58 PM..

|

06-09-2022, 11:50 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by C5GTO

Ed: thanks for your insightful and detailed explanation. It makes the most sense to me for the symptoms I'm seeing.

The EFI pressure regulator is an integral part of the injector fuel rails on this EFI system. The fuel rail was provided in the EEC-IV EFI kit I bought from Ford Motorsports back in the middle 90's. The pressure regulator has a vacuum line running to it. As I recall from when I was first installing this EFI, it uses the vacuum signal to adjust fuel pressure in the rail/injectors in an effort to predict fuel squirt volume at the injector tip in varying vacuum conditions. I think the objective for the Ford EFI engineers/designers is to have higher fuel pressure at low vacuum and lower fuel pressure in high vacuum conditions such that a predictable amount of fuel will leave the injector tip even when the engine vacuum changes. If the pressure regulator were moved from it's present position, then I'm guessing the ECM programming would need to also change as it was optimized during dyno runs on the current setup.

|

Joel,

You've been doing homework, haven't you?

The pressure regulator on the fuel rail is used essentially, as you suggest, with a few differences. Ford has a preferred fuel system pressure which they operate all their EFI systems at and rate all their injector flow rates at. That pressure is 39.15 psi, or in BAR terms (if you think that way), it is 2.7 BAR. This metric is essential in determining the pulse width the ECU wants to command the injector to operate at.

At idle, the engine will run with its max intake manifold vacuum. It will not be an absolute vacuum but a partial vacuum. Essentially what we are doing is choking off the engine's air supply. Today Ford uses fairly fancy Mass Air Flow (MAF) based systems to precisely measure airflow for emissions compliance reasons. Back in the day, when they designed your EFI system, they were 'evolving' to what they use today.

Your system also measures and approximates intake air mass by using Boyles Law (remember High School Chemistry?). To do this, they need to know the Intake Air Temperature (IAT) in the manifold and the air pressure or vacuum in the intake manifold. To get these numbers, they use a relatively straightforward air temp sensor and a Manifold Air Pressure (MAP) sensor — essentially an electronic barometer.

With that information, they can do a reasonably accurate calculation of the air mass in the cylinder at any given time. The calibration engineers have target Air Fuel Ratios (AFRs) they are shooting for to meet both emissions and driveability targets. They want to operate the injectors in a delivery model that will not command a pulse width so small the injector can not respond, nor so large the injector bangs up against a 100% duty cycle where the injector coil is on all the time. That magic pressure Ford has hung their hat on is 39.15 psi.

The 39.15 psi assumes the injector is firing into an air space at an ambient pressure of 29.92 inches of mercury. So what happens when the injector fires into a partial vacuum like the engine sees at various throttle positions and, in particular idle?

If the idle vacuum is 14 inches of mercury suddenly, the pressure across the injector nozzle looks ambient (29.92 in Hg) plus the vacuum in the intake manifold. The vacuum is literally sucking the fuel out of the fuel rails. The vacuum referenced pressure regulator adjusts its fuel rail pressure to maintain a constant 39.15 psi delta pressure across the injector nozzle to maintain a constant fuel pressure drop across the injector to maintain emissions compliance.

It turns out that this kind of control is needed not only for emissions compliance but, as luck would have it, engine control and vehicle driveability. To do this, Ford uses a manifold referenced fuel pressure regulator. The small rubber hose from the regulator to the manifold provides a manifold vacuum reference for the regulator so it can maintain a constant 39.15 psi delta pressure across the injector nozzle.

Lots of words, I know. The good news is that you can replace the OEM vacuum referenced fuel rail pressure regulator with an Aftermarket vacuum referenced equivalent and place it wherever you want. You should remove the OEM regulator from the system, or it may be a restriction. If removal is a plumbing problem, then you can gut the OEM regulator, so all it ends up being is a bulge in the fuel delivery lines.

So, where do you get these aftermarket regulators? Summit and Jegs are the easiest and most cost-effective. Don't forget you are not fueling a 1000 HP monster. You are probably in the 550, maybe 600 HP window. Most any of the aftermarket regulators on Jegs or Summit websites will work just fine for you — and co-incidentally better than the OEM unit.

When you install the aftermarket regulator, you set it with the vacuum line disconnected from the manifold and the manifold port line plugged. Start the engine and turn the adjusting screw on the regulator until a pressure gauge you have somewhere on your fuel rail reads 39.15 psi. BTW most fuel pressure gauges do not read that accurately, so you will adjust to a whisker over 39 psi. When you have, shut the motor off. Unplug the vacuum line and connect it to the vacuum barb on the pressure regulator — you're done!

With respect to fuel tank venting, it is an absolute necessity — but probably not for the reasons you think and possibly not the way you might suspect.

Again because of the federally mandated emission regulations, OEM fuel tanks are not allowed to vent unfiltered gasoline vapors into the atmosphere. Your system may use a charcoal filtering element to allow this outbound venting. Without an inbound vent, it will eventually become impossible to be draw gas from the fuel tank. The vacuum above the gas will easily overcome the drawing capability of any fuel pump you can use.

To fix this problem, the OEM venting model allows for atmospheric air to be drawn in, but unfiltered gas tank vapors must not be allowed to escape. The fix is accomplished typically with a valve that uses a spring-loaded check / shuttle or ball to be pulled down to allow air entry and pushed back up to prevent gasoline vapor escape to the atmosphere.

Because race cars are not subject to emission regulation, they do not have to worry about this. A racing application can vent the tank to the atmosphere to prevent the internal pressure build-up that creates the whooshing effect as you open the cap. If you are not subject to emissions testing, you can also.

Notwithstanding the fact you can, the whooshing is still signaling an overheating of the fuel, and all that nice $10+ per gallon 110 octane race gas is being reduced to the octane of whatever its base stock was. You're throwing good money away and potentially putting your engine at risk. Which brings us back to keeping the tank and gas inside cool, and not boiling off the light ends at the pressure regulator under the hood, returning them as gasses back to the fuel tank.

p.s. At the rate pump gas price is rising you may be able to buy $10/gallon pump gas shortly. Either way the vaporization of the light ends brings you back to base stock octane numbers. Thoughtful location of the pressure regulator and sensitivity to unnecessary heating of the gas tank contents will help in mitigating but not necessarily eliminating the problem.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

Last edited by eschaider; 06-10-2022 at 07:55 AM..

Reason: Added Postscript

|

06-09-2022, 12:23 PM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Edmond,

Ok

Cobra Make, Engine: Classic Roadsters

Posts: 628

|

|

Not Ranked

Not Ranked

The fuel level sender Classic supplied (from the largest tank manufacturer in the world) has a fuel line and also an emissions connection that’s at top of tank level. It is hooked to an emissions system charcoal canister, if you want to.

The return needs to be a dedicated line to bottom of tank.

I’m running an 86 HO EFI with the harness redone by Dr K

__________________

Chaney Shores Studio

Last edited by sunman; 06-09-2022 at 12:42 PM..

|

06-09-2022, 02:43 PM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Joel

Do you have a photo of your Fuel Cell or Tank setup.....and a photo of the engine compartment of how the fuel gets to the fuel rail and returns to the tank...??

__________________

Morris

|

06-10-2022, 10:02 AM

|

|

CC Member

|

|

|

Join Date: Apr 2015

Location: Prescott,

AZ

Cobra Make, Engine: Classic Roadsters

Posts: 209

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Morris

Joel

Do you have a photo of your Fuel Cell or Tank setup.....and a photo of the engine compartment of how the fuel gets to the fuel rail and returns to the tank...??

|

I'm now fully convinced that something needs to be done about the fuel tank pressurization. I drove the car yesterday afternoon when the ambient temperature was around 95 degrees. I heard pressure being released around the gas cap and a small amount of fuel burped out on the rear fender.

The fuel tank is same as in post #4: Gas tank becoming pressurized???

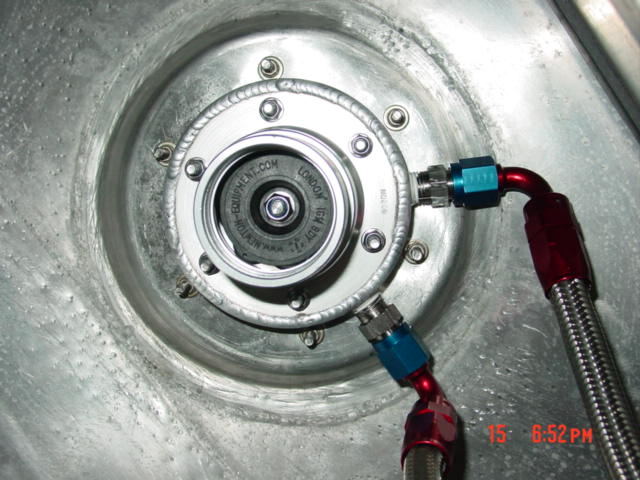

Here's pics of the engine compartment fuel stuff. Lower 90 degree fitting is the incoming fuel line. Upper fitting is the fuel return line. The hoses run down past the alternator, down to the frame rail and then connect to hard lines. At no time do the fuel lines get close to any of the "hot" parts like headers, etc. In fact the return line is run inside the frame rail until just in front of the rear axle.

The fuel pressure regulator is above the intake manifold on passenger side. Heat getting to it would mainly be heat radiated up from intake manifold. This should be offset somewhat from outside air coming through the hood scoop, that is when the car is in motion and ambient air temperatures aren't high.

__________________

Thanks,

Joel Heinke (early 90's CRL Cobra)

|

06-10-2022, 10:36 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Edmond,

Ok

Cobra Make, Engine: Classic Roadsters

Posts: 628

|

|

Not Ranked

Not Ranked

The emissions connection on the fuel tank sender is connected to the charcoal canister then to the purge solenoid then to throttle body vacuum port. To vent the tank. Check the line, is purge solenoid working?

You are pumping gas to the cap with return line also, thatís dangerous. Nobody does that.

Increase in elevation possibly makes problem worse.

__________________

Chaney Shores Studio

Last edited by sunman; 06-10-2022 at 10:53 AM..

|

06-10-2022, 10:43 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by sunman

This is a Classic Roadsters tank and filler neck. The LeMans cap has a fuel drainback line too. Plugged maybe? Fuel and return line are in the sender unit. If you don’t have one good time to add it.

|

Show us a photo of the inside of the LeMans cap.....

Maybe all you have to do is put a check valve in your line and drill some holes in the sealing part of the open cap

The fuel tank has to vent to the Atmosphere

__________________

Morris

Last edited by Morris; 06-10-2022 at 10:49 AM..

|

06-10-2022, 10:50 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by sunman

This is a Classic Roadsters tank and filler neck. The LeMans cap has a fuel drainback line too. Plugged maybe? Fuel and return line are in the sender unit. If you donít have one good time to add it.

|

Show us a photo of the inside of the LeMans cap.....

Maybe all you have to do is put a check valve in your line and drill some holes in the sealing part of the open cap

__________________

Morris

|

06-10-2022, 11:22 AM

|

|

CC Member

|

|

|

Join Date: Jan 2009

Location: Las Vegas,

NV

Cobra Make, Engine: Shelby CSX4005LA, Roush 427IR

Posts: 5,610

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by sunman

The emissions connection on the fuel tank sender is connected to the charcoal canister then to the purge solenoid then to throttle body vacuum port. To vent the tank. Check the line, is purge solenoid working?

You are pumping gas to the cap with return line also, thatís dangerous. Nobody does that.

Increase in elevation possibly makes problem worse.

|

I don't know if this engine really has the full emissions, but if it does there is also usually a vacuum pump on or close to the charcoal canister. However, with an evap system the entire system should be running under NEGATIVE pressure. So if there is a vacuum line to the throttle body port check that line to see if it is making vacuum. Then work backwards.

__________________

Cheers,

Tony

CSX4005LA

|

06-10-2022, 11:25 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Edmond,

Ok

Cobra Make, Engine: Classic Roadsters

Posts: 628

|

|

Not Ranked

Not Ranked

The fuel tank does not vent to atmosphere. You have a check valve in the gas cap and a vacuum line to the tank.

The EGR pump injects fresh air into exhaust to trick emissions testing or help complete fuel burn whatever you want to believe, it’s a separate part of system.

__________________

Chaney Shores Studio

Last edited by sunman; 06-10-2022 at 12:05 PM..

|

06-10-2022, 11:36 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gilroy,

CA

Cobra Make, Engine: SPF 2291, Whipple Blown & Injected 4V ModMotor

Posts: 2,738

|

|

Not Ranked

Not Ranked

Joel,

Your underhood air temps are probably higher than you suspect. Use one of those cheap Harbor Freight laser thermometers to measure the heat of the fuel pressure regulator (FPR) after you have been driving for a while in that 95˚ heat. I think you might be surprised.

What Morris has said about the tank venting is true. It probably occurs through the charcoal canister. Make sure you venting valves and canister are working. Even when they are you will still build some pressure in the tank but it should not force fuel out the filler cap.

A couple of thoughts on charcoal canisters. A charcoal canister is a part of your carís evaporation control system. It is designed to prevent the release of volatile organic compounds that escape from your fuel system and engine. Charcoal pellets in the canister absorb the harmful fumes from the carís fuel system and store them. Later these fumes are burned by the engine while it is running.

A blocked or inoperative canister system will not vent the vapors to the engine for burning. The lack of venting will increase pressure in the fuel tank. While not a sure bet, the blockage can raise fuel tank pressure. Is it enough to force fuel out the filler cap ó I'm not sure, but a check of the system could either eliminate or identify it as one of the problems.

I know it sounds silly but do the laser temp test on your FPR after driving around in the AZ heat. You might just be surprised. While you are at it get on your back and also check the fuel tank. The fuel tank check will either eliminate it as a potential problem source or identify it as a potential problem source ó either way good to know information.

__________________

Help them do what they would have done if they had known what they could do.

Help them do what they would have done if they had known what they could do.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 04:59 AM.

Links monetized by VigLink

|