Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

|

View Poll Results: Various stacked EFI company's (mainly for a FE)

|

|

Very Cool Parts

|

|

2 |

11.11% |

|

MOMAR

|

|

0 |

0% |

|

TWM

|

|

12 |

66.67% |

|

Dynatek Racing

|

|

2 |

11.11% |

|

Other

|

|

2 |

11.11% |

01-19-2008, 12:10 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Kevin,

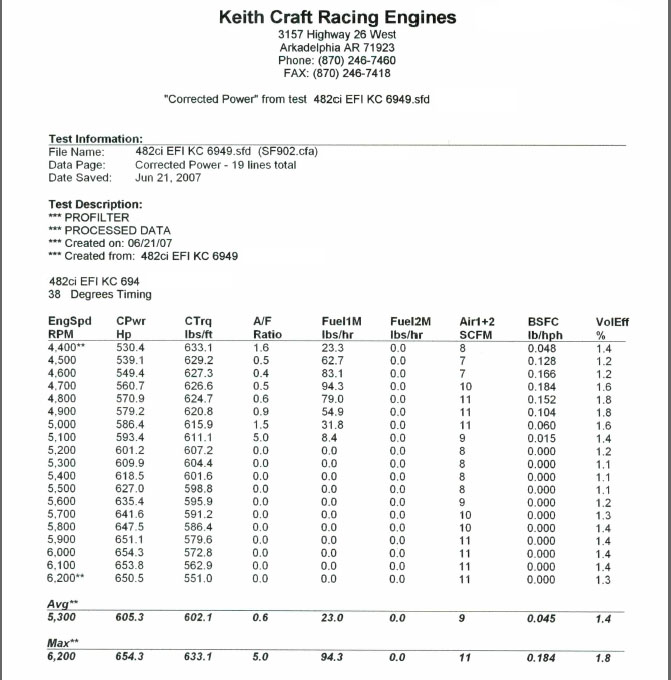

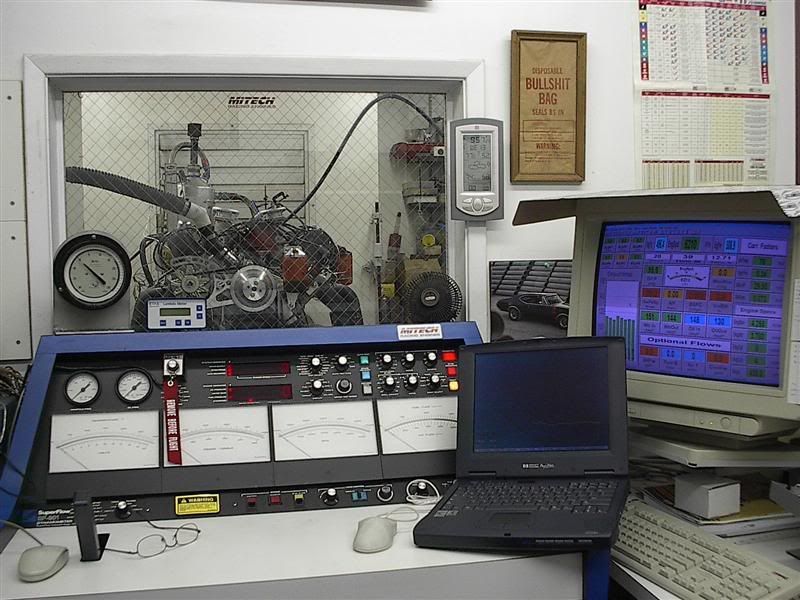

I don't remeber the exact cost of the distributor but its not that different from an electronnic MSD billet distributor. BTW, attached are the dyno output numbers for the engine. There is a complete parts list and specs for it in my gallery if you're interested.

- Fred

|

01-19-2008, 12:14 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Thanks, Fred, I'm taking notes for the future. I love the system. Outstanding. How much maintenance is involved after installation and tuning?

|

01-19-2008, 01:11 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

I would expect very little mtce. after the initial tune in the car is completed. I have a Blown and Inject Vette running the same type of setup and the only mtce I have done to it in the last 3 years is to change oil and spark plugs. These systems adapt to conditions, wear on the engine, etc. pretty well and there is nothing that will wear out in the life of a "hobby car" like this.

- Fred |

01-19-2008, 04:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: GTA, Ont,

Posts: 302

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by FUNFER2

I agree !

How much was the distributor ?

That's the way to go but, it's even more $$$

|

Summit is/was selling Accel dual sync distributor for FE for less than $300 couple of years ago. Part # Accel 77200 for small cap housing.

Ken |

01-19-2008, 05:29 PM

|

|

CC Member

|

|

|

Join Date: Oct 2002

Location: Eagle,

Ne.

Cobra Make, Engine: 1966 Lone Star 427SC.

Posts: 4,310

|

|

Not Ranked

Not Ranked

Fred- truly a dream engine. You cobra looks very nice also. Looking at your photo's, is it not completed yet ? Nice color too.

__________________

Regards,

Kevin

|

01-19-2008, 08:21 PM

|

|

CC Member

|

|

|

Join Date: Aug 2005

Cobra Make, Engine:

Posts: 19

|

|

Not Ranked

Not Ranked

Didn't you build Carroll Shelbys 1300 HP motor with TWM Induction and twin turbos?

Quote:

Originally Posted by dynoroom

Here are a couple I've done using TWM throttle bodies. We're also a dealer for severial electronic systems. FAST, Accel DFI, AEM, & Motec to name a few.

I would say yes, around 8 to 10K. You need the intake manifold, throttle bodies, injectors, fuel system, ECU, sensors, harness, then dyno time and tunning.

But it sure look good.

|

Last edited by rick50; 01-19-2008 at 08:26 PM..

|

01-20-2008, 10:57 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Kevin,

Your are correct, my cobra is not yet complete. The car is about to go back to ERA to complete assembly and then will come to me as a roller. We decided to polish all of the visible aluminum panels on the car so ERA left them off so that we would not get paint overspray on the polished parts.

- Fred

|

01-20-2008, 11:08 AM

|

|

CC Member

|

|

|

Join Date: Oct 2002

Location: Eagle,

Ne.

Cobra Make, Engine: 1966 Lone Star 427SC.

Posts: 4,310

|

|

Not Ranked

Not Ranked

Fred- please email me when you have time.

Kevin

__________________

Regards,

Kevin

|

02-08-2008, 06:14 AM

|

|

CC Member

|

|

|

Join Date: Oct 2007

Cobra Make, Engine:

Posts: 24

|

|

Not Ranked

Not Ranked

Sir; I really like the looks and fit of your Air cleaner Assy, May I ask as to who makes it?, Thank you...Mike

|

02-08-2008, 07:34 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Tucson,

AZ

Cobra Make, Engine: ERA 427" 351W

Posts: 562

|

|

Not Ranked

Not Ranked

The TWM cost is not $10k, look on my site. www.thormotorsports1.com The install is relatively easy if you are somewhat adept at wrench handling. The entire setup install time should be under 16 hours. Most Kirkhams come with a plugged return bung in the fuel tank which simplifies things a little. I can turn you on to someone in your area that can do fine tuning on a chassis dyno. The performance and ease of tuning over webers is well worth it in the long run.

__________________

Al W.

|

02-08-2008, 09:39 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Al, as soon as the money tree in the backyard sprouts some new growth, I'll be knocking on your door. Thank you.

|

07-17-2008, 03:52 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by fkemmerer

Keith Craft is a pretty good source for an EFI setup if you are doing an engine from scratch. I would recommend the TWM setup with a FAST computer. You might also look at FAST's new electronnic traction control option. I'm going to try this on my ERA. Also, FAST has just started offering a dual-sync distributor for the FE engines. This allows individual cyclinder correction of fuel and timing to get the best possible tune. Attached are a few pics of the engine the Keith Craft did for me. More pics of the engine and the rest of the project can be found in my gallery.

- Fred

|

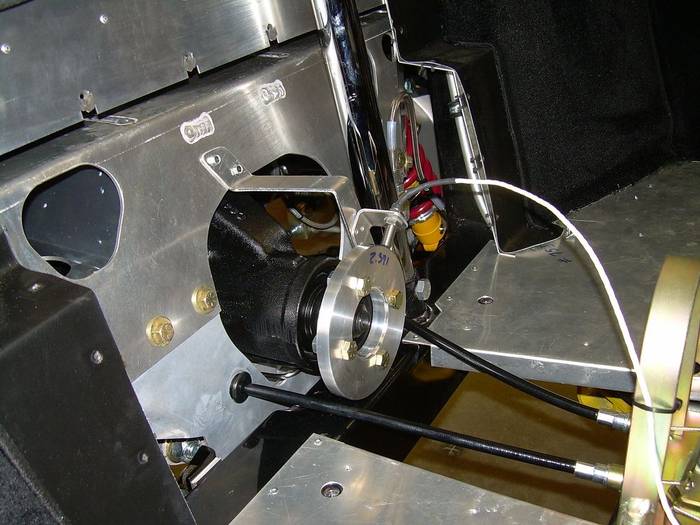

I've gotten some interest from several folks on this forum on the Electronnic traction Control setup that I'm installing on my ERA Cobra so I thought I'd post an update. The ETC system is based on the latest version of the FAST XFI ECU. The system uses a driveshaft speed sensor (picturedbelow) to allow the EFI computer to detect when the rear wheels begin to speed. When this happens, the ECU retards the ignition timing which reduces the motor's torque output and controls the spin.

The driveshaft sensor is a custom made part. ERA, a local machinst, and I collaborated to modifity a standard FAST driveshaft sensor to create the custom setup for my ERA cobra. I'm anxious to see how this setup will perform.

|

07-17-2008, 04:05 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Tucson,

AZ

Cobra Make, Engine: ERA 427" 351W

Posts: 562

|

|

Not Ranked

Not Ranked

Still have the TWM group puchase special going on till August 15th.

www.thormotorsports1.com

thormotorsports1@msn.com

__________________

Al W.

|

07-17-2008, 07:01 PM

|

|

CC Member

|

|

|

Join Date: Jul 2004

Cobra Make, Engine: 347 Stroker Morrison Injection. Registered.

Posts: 1,440

|

|

Not Ranked

Not Ranked

I used Morrison Injection. Love it!

Regards.

__________________

Mando

|

07-18-2008, 06:04 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Lynn MA. USA,

Posts: 64

|

|

Not Ranked

Not Ranked

fkemmerer. What type ao alternator is on the motor and how many amps. It looks like a nice setup.

COBRAMAN 484

|

07-18-2008, 09:43 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by COBRAMAN 484

fkemmerer. What type ao alternator is on the motor and how many amps. It looks like a nice setup.

COBRAMAN 484

|

Its a 100A unit from Powermaster. I'd consider a 100A alternator about the minimum for a car with an EFI setup. It works on a Cobra because these is not much else in terms of electronnics or lighting that will use alot of power. Big items are the EFI Computer, Ignition Box, Fuel Pump, Electric Fans, and then the lighting system on the car.

- Fred |

07-18-2008, 10:12 AM

|

|

CC Member

|

|

|

Join Date: Feb 2007

Location: Colorado Springs,

CO

Cobra Make, Engine: Backdraft, supercharged Coyote

Posts: 2,452

|

|

Not Ranked

Not Ranked

I use a stock replacement 65A unit on my Cobra. Cheap at Autozone and carries a lifetime warrenty. Never have a problem with it not keeping up. I do drive with the lights on pretty often, makes it easier to be seen. But I don't have any kind of sound equipment.

|

07-19-2008, 07:27 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Lynn MA. USA,

Posts: 64

|

|

Not Ranked

Not Ranked

I tried a 100amp powermaster but it wouldn't fit, it was about .125 inches to long. I picked up a 100 amp chrome motorola. It works fine the only problem I have is even with the smallist pully I could find, at night with the lights on when the engine is at idle (1000rpm) my wideband meter won't show the air fuel readings. It defaults to 14.7 when the voltage is below 12volts. I use a tempo regulator and have it set at 14.5 volts but i don't think I want to set it any higher.

|

07-19-2008, 07:41 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by COBRAMAN 484

I tried a 100amp powermaster but it wouldn't fit, it was about .125 inches to long. I picked up a 100 amp chrome motorola. It works fine the only problem I have is even with the smallist pully I could find, at night with the lights on when the engine is at idle (1000rpm) my wideband meter won't show the air fuel readings. It defaults to 14.7 when the voltage is below 12volts. I use a tempo regulator and have it set at 14.5 volts but i don't think I want to set it any higher.

|

Sounds like a good solution. You can install the 100A powermaster by using a 2 groove pulley set and a spacer on the alternator mount. This is what I did with my motor. To improve the appearance, I had a local machinist remove the back unused groove on the water pump pulley. If you look closely at the damper pulley in the picture below, you can see the second groove.

- Fred |

07-20-2008, 12:48 PM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

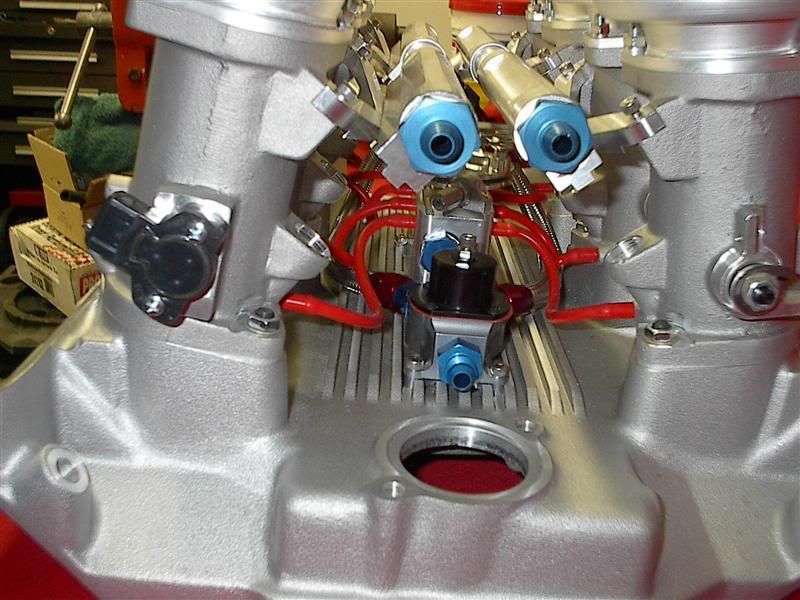

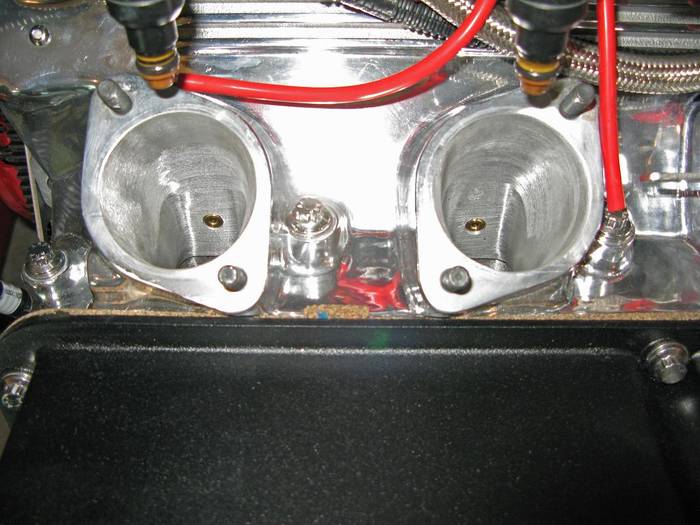

I am preparing to install my engine in my cobra an I needed to remove the IAC assembly to re-orient it and to polish the chamber cover. I thought I'd post a few pictures for the IAC air block and plumbing under my TWM intake. As you can see, there is a distribution block just below where the rear intake breather would go on the TWM intake for my FE. A line runs from this block to each intake runner on the the TWM manifold.

Here's a picture of the inside of the intake ports - you can see the fittings where the IAC plumbing connects to the ports.

The following shows the IAC and cover reinstalled on the TWM intake. A 90 degree fitting and a custom made aluminum cover allow the IAC motor to mount neatly on the the back of the TWM intake.

With this setup, my FAST XFI computer can regulate the idle speed of the motor my allowing a controlled amount of air into the cyclinders at idle.

Last edited by fkemmerer; 07-31-2008 at 07:39 AM..

Reason: Add additional pcis.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:59 AM.

Links monetized by VigLink

|