Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

04-01-2011, 07:45 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Stuttgart,

GE

Cobra Make, Engine: ERA #539/427 Holman Moody #7HM20 from 1967

Posts: 92

|

|

Not Ranked

Not Ranked

Linkage adjustment on QFT/Holley two fours

Linkage adjustment on QFT/Holley two fours

Question: what is a good start on adjusting /tuning the slotted opening of the second carb primaries coming into play. They are the Survival Motorsports/ QFT vintage carbs.

First quarter, Midway or last quarter of the slot?

What is a good start??

427, 282S, RPM heads, 10.3:1, Street driving but do not need it leaning out at partial throttle 90-100 mph with 3:54 at about 3,000 rpms.

I guess I am answering my own question as I type, leading to the fuel/air mix FAST tool and welding bungs in the side pipes to really get the answer without holing pistons.

|

04-01-2011, 08:01 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,284

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Learjockey1

Question: what is a good start on adjusting /tuning the slotted opening of the second carb primaries coming into play. They are the Survival Motorsports/ QFT vintage carbs.

First quarter, Midway or last quarter of the slot?

What is a good start??

427, 282S, RPM heads, 10.3:1, Street driving but do not need it leaning out at partial throttle 90-100 mph with 3:54 at about 3,000 rpms.

I guess I am answering my own question as I type, leading to the fuel/air mix FAST tool and welding bungs in the side pipes to really get the answer without holing pistons.

|

I've got the fisrt set of those made on my 482..

They should be pretty much setup from Quick Fuel... Open your idle screws up about 3/4 turn.

Are you running the Blue Blunder version of the OEM progressive linkage?

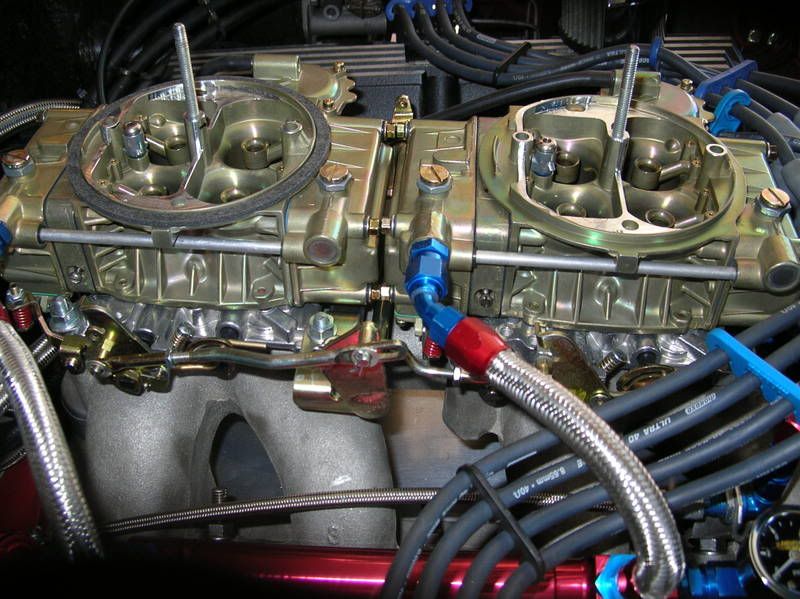

Here's a pic of my progressive linkage..

__________________

Too many toys?? never!

|

04-01-2011, 08:10 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Stuttgart,

GE

Cobra Make, Engine: ERA #539/427 Holman Moody #7HM20 from 1967

Posts: 92

|

|

Not Ranked

Not Ranked

Bought the linkage from Barry. To his credit I have sent a mail but he is pretty busy guy so just thought I would ask the forum as I got short break at work.

Setting the slotted progressive linkage on the right side, I am adjusting the slot which brings in the primaries of the back carb.

|

04-01-2011, 08:18 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Powder Springs,

GA

Cobra Make, Engine: ERA FIA 2008/351W/TOP-LOADER

Posts: 526

|

|

Not Ranked

Not Ranked

I used the same photo's as a reference. The carbs are outstanding!! The real adjustments are all over. These carbs have adjustments for everything! Not just the idle and but underneath the carb too. I'm sorry as I don't remember all the adjustments as a friend was helping. He spent about two hrs and after wards the car is just killer! Regards, Matt

|

04-01-2011, 08:19 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Stuttgart,

GE

Cobra Make, Engine: ERA #539/427 Holman Moody #7HM20 from 1967

Posts: 92

|

|

Not Ranked

Not Ranked

Did not get the photos

|

04-01-2011, 08:34 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,284

|

|

Not Ranked

Not Ranked

The best way to adjust ,IMO, is to set the linkage where the back carb if fully open when the front carb is too. That's the end product you want, at WOT both carbs are open 100% simultaneously. I think it works out to the front carb being open about 50% brfore the rear set starts to pick up. The rear carb opens about twice as fast as the front.

Make sure you adjust both front and rear idle jets, not just the front. Also make sure your accellerator pumps are adjusted properly, the actuator lever just touching the AP's diaphram.

I had to use the lightest spring (I believe the white one) on both secondary diaphrams, also ensure both secondary diaphrams are tied together, vacuum wise.

With no adjustments mine knocked down a 12.6 AFR on the chassis dyno, PERFECT!

The "design" was originally worked out by me with Quick Fuel for my Pond 482 setup. I bought the setup through Barry. Afterwards I forwarded the carb "design" to Barry since it worked out so well and he had interest.

__________________

Too many toys?? never!

Last edited by undy; 04-01-2011 at 08:41 AM..

|

04-01-2011, 08:43 AM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Stuttgart,

GE

Cobra Make, Engine: ERA #539/427 Holman Moody #7HM20 from 1967

Posts: 92

|

|

Not Ranked

Not Ranked

With both right side adjustable rods I can get just about get any slot percentage and still both fully open at he same time. I just needed a good start at the 50% of total slot.

I am looking forward to seeing how they run with an 427 cu in application. I think they flow about 750 cfm each

Undy, how are yours holding up with the E10 fuel ?

Thanks Undy and Matt

|

04-01-2011, 08:53 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,284

|

|

Not Ranked

Not Ranked

No problems to date with E10/15.

They're actually a tad too much carb but the adjustability allows you to still get spot-on. It was towards the end of the dyno pull before the rear set of secondaries came full open and that was with the lightest spring. I seriously doubt in street applications that you'll see the rear set of secondaries open all the way.

__________________

Too many toys?? never!

|

04-01-2011, 01:53 PM

|

|

CC Member

|

|

|

Join Date: Nov 2009

Location: Stuttgart,

GE

Cobra Make, Engine: ERA #539/427 Holman Moody #7HM20 from 1967

Posts: 92

|

|

Not Ranked

Not Ranked

Undy it looks like you pulled your upper fuel vent extentions out. Any problems??

The top of my oval air filter top comes awful close and with my last set of carbs, it was sitting on the air horns. My filter base is flat aluminum plate with holes cut out for the adjusting screws and other carb upper protrusions and then I used cut off spoons bottoms to cover the holes etc.

The choke horns were milled off these. When the carbs were built I asked that the vent tubes be cut minimim height but it seems they are the stock height. Does anyone know what is a good minimin height and issues involved with shorter ones??

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:26 AM.

Links monetized by VigLink

|