Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

27Likes 27Likes

12-17-2014, 12:01 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: sac., ca,

ca

Cobra Make, Engine: owned Kirkham for 11 years

Posts: 1,032

|

|

Not Ranked

Not Ranked

Resto,

The Kirkhams use oxyacetylene torch for welding, so it might be easier to find someone local to do the job.

Maurice

|

-

Advertising

12-17-2014, 07:38 PM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: BRADENTON,

FL

Cobra Make, Engine: KIRKHAM 427 S/C, SHELBY 427 ALUM. STROKER

Posts: 1,396

|

|

Not Ranked

Not Ranked

Maurice: nope, sorry, that won't work. The bodies in Poland are gas welded, but not with acetylene. Some other gas that I don't remember at the moment. Last I saw from Provo was oxy/helium, plus other tricks like blue lenses & hammer welding. No welding rod exsisted for the polish alloy, so they used thin strips of the parent material. This all works for the people with the experience, but for everday repairs in this country, just TIG it.

Shurely there are alum welders in Birmingham !!!!????

__________________

"When Injustice becomes Law,

Rebellion becomes Duty." T. Jefferson

|

12-17-2014, 09:11 PM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

My fab guy is one of the finest tig welders around. However, he says the aluminum is so thin on the hood skin that if he welds the many divots around the hood scoop that it will warp the hood and it will require extensive hammering to straighten it.

Last edited by RestoCreations; 12-17-2014 at 09:13 PM..

|

12-17-2014, 09:15 PM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

I still don't have a vin for this car. I was sent the wrong tag recently which looked like it was stamped by a 12 year old.

|

12-18-2014, 06:35 AM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: BRADENTON,

FL

Cobra Make, Engine: KIRKHAM 427 S/C, SHELBY 427 ALUM. STROKER

Posts: 1,396

|

|

Not Ranked

Not Ranked

Was the hood messed up when you first received it ? Can you post a pic of the area in question?

__________________

"When Injustice becomes Law,

Rebellion becomes Duty." T. Jefferson

|

12-18-2014, 07:42 AM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

There is at least one picture a few pages back. The hood has some large divots around the scoop where the welds were not finished properly. I've been informed that when most people order a filed body, they intent to paint them, so that is why it was left that way....

It's like this on both sides of the scoop and the underside.

[IMG]  [/IMG]

Last edited by RestoCreations; 12-18-2014 at 07:47 AM..

|

12-18-2014, 07:44 AM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

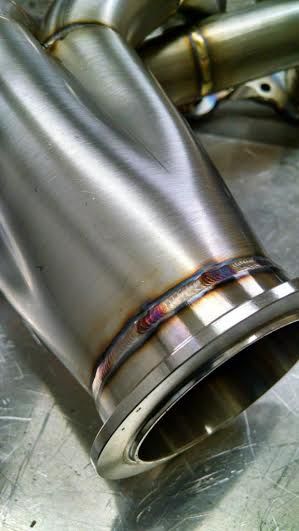

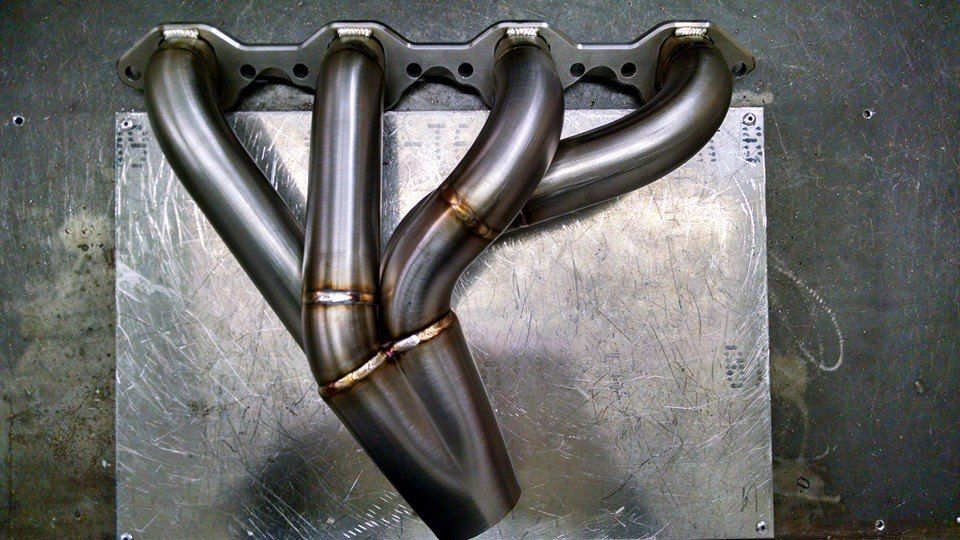

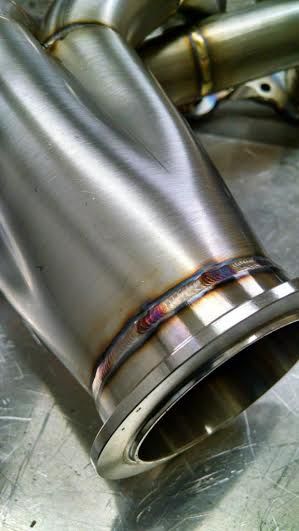

Progress on the driver's side header

[IMG]  [/IMG]

[IMG]  [/IMG] |

12-18-2014, 09:18 AM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: BRADENTON,

FL

Cobra Make, Engine: KIRKHAM 427 S/C, SHELBY 427 ALUM. STROKER

Posts: 1,396

|

|

Not Ranked

Not Ranked

Resto: Did you talk to David or someone else about the hood ? It seems so unlike Kirkham to send out 2nd rate work ! I know it's a hassle sometimes to make things right, but Kirkhams are (IMHO) supposed to be the best, and they previously had always gone the extra mile to accomadate the customer. I would call and tt David hiself, and ask if all FIA hoods had these flaws. No? then mine must be substandard and should be replaced or repaired at their expense !!! (you probably would be stuck with freight)

I have other suggestions also.

Ted

__________________

"When Injustice becomes Law,

Rebellion becomes Duty." T. Jefferson

|

12-18-2014, 09:25 AM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

Yes, i spoke with David and he sent me a free coolant tank for the trouble with the hood. I just have to find someone who is willing to weld on the hood and a few other areas on the body and then hammer them out afterwards if necessary. There aren't a lot of shops experienced with aluminum around my area, but I have been informed of one in Atlanta, which isn't too far away.

|

12-18-2014, 09:46 AM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: BRADENTON,

FL

Cobra Make, Engine: KIRKHAM 427 S/C, SHELBY 427 ALUM. STROKER

Posts: 1,396

|

|

Not Ranked

Not Ranked

OK, an adjustment of approx $500 retail to make the problem go away. (for them, but not for you) Yeah, trying to find someone proficient in alum sheetmetal work is tough! I had to replace most of my front clip using 5 factory pieces and found a few, but thousands of miles away. Ended up fitting them myself, and having a local british race car guy tig it all together. It was not smooth enough to leave bare, so I painted it.

I don't know about the FIA hood, but all 427 panels are .060, not what I would call thin.

One thing you might try is a local metal sculpture artist. Some work with aluminum and weld or "braze" it together. Many years ago in an aircraft maint shop I worked in, a sales guy sold us some "aluminum brazing rod and flux" it works with oxy/acy torch at lower temps, and I was "brazing cracked .032 and up sheetmetal with no warpage. I still have the flux ! I think an alum sculptor may be using someting similar to this.

__________________

"When Injustice becomes Law,

Rebellion becomes Duty." T. Jefferson

|

12-18-2014, 11:55 AM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: BRADENTON,

FL

Cobra Make, Engine: KIRKHAM 427 S/C, SHELBY 427 ALUM. STROKER

Posts: 1,396

|

|

Not Ranked

Not Ranked

Here's my last suggestion (for now, anyway):

Fill the low spots with an aluminum epoxy filler. May not match perfectly, but I don't think it would be that noticeable with that acre of bare aluminum surrounding it !

Ted

__________________

"When Injustice becomes Law,

Rebellion becomes Duty." T. Jefferson

|

12-18-2014, 02:37 PM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

You must be referring to Evercoat metal to metal filler that is filled with aluminum dust. I would have never thought of that and it might work as a temporary solution.

|

12-18-2014, 03:30 PM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: BRADENTON,

FL

Cobra Make, Engine: KIRKHAM 427 S/C, SHELBY 427 ALUM. STROKER

Posts: 1,396

|

|

Not Ranked

Not Ranked

Yeah, that's the stuff. Couldn't remember where I saw it .

Worth a try.

__________________

"When Injustice becomes Law,

Rebellion becomes Duty." T. Jefferson

|

12-18-2014, 04:10 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,521

|

|

Not Ranked

Not Ranked

It's a little hard to tell from the picture but does the scope actually need more welding to the body, or are the divots around the scoop the main issue?

Pounding out small dents is not a major effort with a little care. It's pretty similar to fixing stainless steel trim on old cars. Mark the outline of the dent with a marker and with a blunt punch and light hammer, start on the outside perimeter of the dent and work in towards the center in a circular, spiral fashion. Use a light touch as you want to avoid a significant dimple in the other side as you will be filing that down. If the first pass doesn't get all areas up to level, make another pass around, starting a little further in from the edge. Then file the outer surface down level to remove the slight tool marks and contour to the adjacent surfaces. If a small area was knocked a little too far out, tap it back in with a body hammer and buck on the back side. File and finish up with various grades of sandpaper to get to the level of finish you are looking for.

If it really needs some more welding - sorry no help there.

|

12-18-2014, 06:04 PM

|

|

CC Member

|

|

|

Join Date: Mar 2008

Location: Lantana,

TX

Cobra Make, Engine: Just dreaming at this point

Posts: 201

|

|

Not Ranked

Not Ranked

Might be cheaper to fly Sandwich to Alabama for the weekend and have him fix everything

|

12-18-2014, 06:30 PM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

It's a little hard to tell from the picture but does the scope actually need more welding to the body, or are the divots around the scoop the main issue?

Pounding out small dents is not a major effort with a little care. It's pretty similar to fixing stainless steel trim on old cars. Mark the outline of the dent with a marker and with a blunt punch and light hammer, start on the outside perimeter of the dent and work in towards the center in a circular, spiral fashion. Use a light touch as you want to avoid a significant dimple in the other side as you will be filing that down. If the first pass doesn't get all areas up to level, make another pass around, starting a little further in from the edge. Then file the outer surface down level to remove the slight tool marks and contour to the adjacent surfaces. If a small area was knocked a little too far out, tap it back in with a body hammer and buck on the back side. File and finish up with various grades of sandpaper to get to the level of finish you are looking for.

If it really needs some more welding - sorry no help there.

|

Those are deep pits and it needs more welding. Same goes for some areas around the headlamps, fenders, and doors. thanks for the info though.

|

12-18-2014, 06:32 PM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by slider701

Might be cheaper to fly Sandwich to Alabama for the weekend and have him fix everything

|

If he works for food, drink, and car rides, that might not be a bad idea.  |

12-18-2014, 06:55 PM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

|

12-19-2014, 01:41 PM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

More header progress

Just a wee bit of a tight fit!

Weld on pyramid that makes a non-merge collector work like a merge collector.

Last edited by RestoCreations; 12-19-2014 at 01:44 PM..

|

12-24-2014, 10:39 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Those are some sweet pipes. Great craftsmanship!

David

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:09 PM.

|

|

27Likes

27Likes

Linear Mode

Linear Mode