Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

07-19-2007, 07:55 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you need to take the input shaft bearing off of the old (long) input shaft. We are going to be reusing this bearing so don't get gorilla with it!

Here we have a special "bearing splitter" tool with a very sharp edge to get under the bearing so we can press it off. This is a very handy tool. If you don't have one, it is time to CELEBRATE!!! (Because you are about to add to your tool collection!)

You don't have to make the bolts on the bearing splitter very tight. Finger tight is fine. Just make sure the edges of the splitter are under the edge of the bearing. Make sure you are not pressing on the cage of the bearing. If you press on the cage, you will bend it and your bearing will burn up!

AT THIS POINT YOU NEED TO MAKE SURE YOU HAVE PULLED THE NEEDLE BEARINGS OUT OF THE INPUT SHAFT!!! OTHERWISE, THEY WILL FALL OUT WHILE YOU ARE PRESSING ON THE SHAFT AND YOU WILL GET TO PLAY HIDE-AND-SEEK...AGAIN!

Last edited by David Kirkham; 08-03-2007 at 10:50 PM..

|

-

Advertising

07-19-2007, 07:58 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

We have never found the bearing press to be very hard. So, make sure you have your hand under the input shaft as you are pressing the bearing off. If you don't catch the input shaft, the input shaft will drop on your toe and you will scream--or WORSE, the input shaft will land on the concrete floor and you will not be able to sell it on eBay! (Toes heal...usually.)

In this photo, Sandwich has already caught the input shaft and is now taking the entire assembly out of the press.

|

07-19-2007, 08:03 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you need to do a little cleaning of the new input shaft. It comes to you covered in a waxy grease conservative that has generously picked up all sorts of hitch-hikers on its way to you. You will need to clean them off. As in many areas of life, picking up hitch-hikers is not good idea.

Make sure you clean out the area where the needle bearings go.

Last edited by David Kirkham; 07-20-2007 at 06:11 PM..

|

07-19-2007, 08:10 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you need to press the old bearing onto the new (short) shaft. You need to use a tube to press the bearing on. A note here: You need to press on the internal RACE of the bearing and NOT on the rollers or the cage. If you press on the rollers or the cage something will be damaged--most likely, your WALLET!

Last edited by David Kirkham; 07-20-2007 at 06:11 PM..

|

07-19-2007, 08:11 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now take some CLEAN grease (notice how our grease can in the above pictures is ALWAYS in a plastic bag so no boogers can make their way into our tranny to make funny noises later) and put it into the race where the needle bearings go on your new (short) input shaft. We put grease in there to hold the needle bearings in place while we are putting the new shaft back in. Don't be shy with the grease! You DON'T want them falling out when you are putting the shaft back in!

Last edited by David Kirkham; 07-20-2007 at 06:10 PM..

|

07-20-2007, 07:49 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

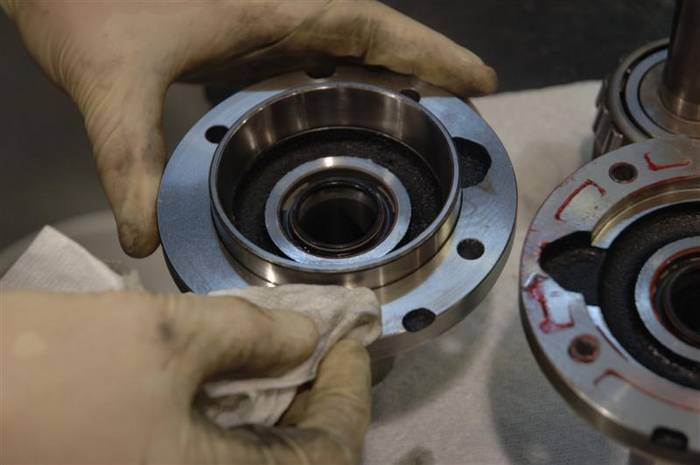

Now you have to CLEAN EVERYTHING!!!

Here Sandwich is cleaning up all the extra oil that ran down the face of the collar. He is also cleaning the race to make sure no gremlins hitch a ride into the tranny. We use lacquer thinner to clean things. It stinks but it leaves no residue and cuts grease like nothing else.

|

07-20-2007, 07:52 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Clean the tranny face again! REMEMBER, NO LEAKS!!!

|

07-20-2007, 07:56 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now, put the new (shorter) input shaft back in the tranny. We don't tip it back up to do this (as we have grease holding our needle bearings in). You will have to wiggle the shaft until it goes in. The gears will need to line up. It is not hard at all to do. BUT DON'T FORCE ANYTHING...unless you want to give me a call to figure out what went wrong...  It should just slide right in.

|

07-20-2007, 07:59 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now back to the new collar you are about to install.

MAKE SURE YOU MEASURE THE DISTANCE FROM THE FACE OF THE COLLAR TO THE SHIMS AND THAT THE DISTANCES ARE THE SAME BETWEEN THE OLD COLLAR AND THE NEW COLLAR. THEN MAKE SURE YOU PUT THE SHIMS BACK IN!!!

The old (longer) collar is on the right in the picture.

Last edited by David Kirkham; 07-20-2007 at 04:34 PM..

|

07-20-2007, 08:03 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now, whip out the Permatex silicon sealer.

Last edited by David Kirkham; 07-20-2007 at 04:33 PM..

|

07-20-2007, 08:06 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Smear a little silicon ALL AROUND THE FACE of the collar and a LITTLE up on the bearing race.

This is definitely an area where more is NOT better. If you have silicon gushing out all over the place, we will classify you as a rank ametuer and turn you over to Jamo for a spanking.

Last edited by David Kirkham; 07-20-2007 at 05:27 PM..

|

07-20-2007, 08:11 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Everything works better with lube. Bearings hate to be dry! During the first few seconds of initial driving your bearing will be DRY if you don't lube it! Just don't let any drip down on the silicon or everything will be for naught. Notice in the picture that the seal is FLUSH with the machined inner face on the collar.

Last edited by David Kirkham; 07-20-2007 at 04:26 PM..

|

07-20-2007, 08:17 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now you MUST line up the hollowed out area in the collar with the hole in the top of the transmission.

|

07-20-2007, 08:31 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Then, put a drop or two of Loctite on the bolts and put them back in. If you don't use Loctite, two very bad things will happen--neither which will make you smile.

First, the bolt holes in the tranny case are through holes--as in all the way through to the oil. Hitting oil is cool in Texas, but sucks on a tranny. The oil will work its way around the threads of the bolt and leave a little puddle in your drive way to remind you that you didn't follow David's advise.

Or, WORSE, they will work out over time and start a very unexpected "Agitado" movement in your bell housing that will not be music to your ears.

Make sure you clean off any hanging boogers of the old Locktite that may still be on the bolts. You don't have to clean them perfectly as that is almost impossible. Loctite sticks to bolts harder than Congressman Murtha sticks to Pork.

Last edited by David Kirkham; 07-20-2007 at 06:18 PM..

|

07-20-2007, 08:45 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Bolt the collar back on! We torque them to 20 foot pounds. Done!

Last edited by David Kirkham; 07-20-2007 at 06:18 PM..

|

07-20-2007, 08:47 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

A little later today, I will show you how to install the new TOTALLY COOL shifter adapter we designed so you can put an original style shifter in your ride so you can have the proper look and not have a big glob sticking up in your shifter boot.

But for now, customers are waiting for their Chariot of Fire and I have to go and direct traffic.

David

|

07-27-2007, 04:43 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Place holder for the shifter

|

07-27-2007, 04:48 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

place holder for the shifter

|

07-27-2007, 04:50 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

place holder

|

07-27-2007, 04:53 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

another place holder for the shifter

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:54 PM.

|

|

2Likes

2Likes

It should just slide right in.

It should just slide right in.

Linear Mode

Linear Mode