Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2024

November 2024

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

1 |

2 |

| 3 |

4 |

5 |

6 |

7 |

8 |

9 |

| 10 |

11 |

12 |

13 |

14 |

15 |

16 |

| 17 |

18 |

19 |

20 |

21 |

22 |

23 |

| 24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

CC Advertisers

CC Advertisers

|

|

1Likes 1Likes

09-05-2007, 12:03 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Notice how this one DOESN'T!!! The tie rod has moved 0.025" with our fingers. Just think how much it moves when you are really leaning on your machine. This car will NEVER align like this.

We also found the bushings were completely worn out that the rack slides on. From the looks of it, the rack was probably put together from various parts and pieces--and not too well at that. Cosmetically it looks perfect. Mechanically it would put you in the ditch.

Finally, notice how the threads are cut REALLY short on the end of the rack. Next comes a story that only would work on an original Cobra. Times were sure different then. Original Cobras ran an adapter on the end of the steering racks to lengthen the rack so it would reach to the wide track of a Cobra. (Well, wider than an MGB).

Original Street 427 cars had Sunburst wheels on them that were narrower than the normal Halibrand wheels. The steering arms ran into the Halibrand rims; so, they had to bend the steering arms inboard to clear the wider Halibrand rims when they swapped out the Sunbursts.

BUT, they still weren't long enough. They ALMOST made it, but not quite. (2 threads isn't enough to be safe with).

So, they ended up cutting the steering rack inner tie rods back 0.9 inches/side and then still having to put an adapter on to make up the distance.

Reminds me of High School shop class.

Anyway, here is the wiggly rack. Notice it has moved just over 0.025 inches.

Last edited by David Kirkham; 09-05-2007 at 12:48 PM..

|

-

Advertising

09-05-2007, 12:36 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

Hey David any idea what you like for a caster number on the rear hubs?

|

09-05-2007, 01:20 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Jan 2002

Location: Provo,

UT

Cobra Make, Engine: Daytona Coupe

Posts: 1,359

|

|

Not Ranked

Not Ranked

Caster on the rear hubs is used to adjust out bump steer...

|

09-05-2007, 01:27 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

David,

I have seen some stainless steel parts, especially as you go up the hardness scale, become notch sensitive and quite brittle. Then if you don't grind the part and carefully remove all stress risers it suddenly snaps like a tooth pick, after some use. I ran into this with a gear pump that used a tool steel up in the rockwell 50 C range (forget the number). Am I comparing apples to oranges?

|

09-05-2007, 03:32 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

olddog,

Brittleness is HIGHLY dependent on alloy selection. All stainless is NOT the same, just as all steel is not the same. Razor blades are made from 1080 and you can snap them with your fingers (be careful!). Most shims are made from 1010 and you can bend them in 1/2--several times, even.

What alloy did you use on the gear pump? I would bet had it been made from 17-4 and nitrided for wear resistance the gear would have outlive both you and I combined. One of the BIG reasons to use precipitation hardening steels is because they aren't subjected to the violent quench of the heat treating process. The quench sets up tremendous internal stresses and many times causes cracking. Your heat treater has to be GOOD and know what they are doing. Choosing heat treaters is much like choosing a wife...better get it right the first time or it's going to cost you a lot of $$$.

David

|

09-05-2007, 05:22 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now some commentary on the rear suspension.

This is a picture of the rear upper control arm and the trailing link. You can see the rear upper control arm has a cross tube welded on it (between the ends that attach to the frame). This is NOT original. The original street cars did not have this tube. The original S/C cars had a plate that was welded between the tubes (if I remember right). We welded tubes in the rear upper control arms of our early cars as well, but we welded them much closer to the pivot point of the control arm so they were more stable.

The trailing link is very interesting as well. There is only one rod end (heim joint as the English say) on the trailing link and the trailing link can only be put into the rear lower control arm ONE WAY!!! That means you have to rotate the original trailing links 360 degrees to adjust the toe! This is VERY BAD as you have very little fine adjustment of the rear toe. On our cars, we put a left hand threaded rod end in one end and a right hand threaded rod end in the other end for infinite adjustment. That way we could dial the toe in perfectly.

|

09-05-2007, 05:29 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

I don't have a macro lens on my camera and I need one!

Sorry for the blur, but the car is going together and I take the photos as I can while trying to run the business!

This is another weak link in the original 427 Street Cobra. If you look closely (and I know that is hard to do in the lousy picture) you can see the threads at the end of this Rose joint (the English rod end supplier) were relieved. Well, that was nice. BUT, they relived them with a SHARP 90 degree cutter and that was dumb.

I am sure if we were to Magnaflux this part we would find a nice crack right at the root of the threads. This rod end is only 5/8 in diameter. The original 427 Comp cars had the same 5/8 rod end--until they broke. So, all of the original 427 Comp and S/C cars were upgraded to a 3/4 rod end. That should tell you something! We change ALL 427 Street car rear upper control arms to the 3/4 rod end. A broken rod end will definitely break the bank on one of these cars! I wouldn't run a 5/8 rod end on the rear upper control arm unless you like gambling on double autopsies--one performed by me on your car and one performed by someone you probably don't know--on YOU!

Last edited by David Kirkham; 09-05-2007 at 05:46 PM..

|

09-05-2007, 07:50 PM

|

|

CC Member

|

|

|

Join Date: Mar 2006

Cobra Make, Engine:

Posts: 79

|

|

Not Ranked

Not Ranked

Original Cobra photos

Original Cobra photos

Thank You for the posts of pictures and tec tips.

Could you post pictures of car, dash and trunk!

I am sure all have enjoyed your posts.

Fast_4

|

09-06-2007, 07:59 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

fast_4,

Coming up! May take a bit as I am headed off this morning to a supplier for a few hours.

David

|

09-06-2007, 08:02 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

What the heck,

While I am here, I might as well post a few more pictures.

Now, for the most miserable job on a Cobra. (Well, there are more miserable jobs--like having to SELL your Cobra because of a divorce...)

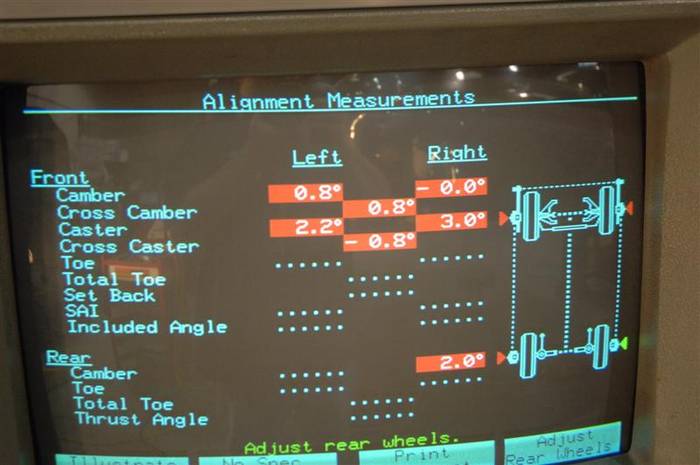

ALIGNMENT ON AN ORIGINAL 427 STREET COBRA!

The only thing worse is alignment on an original 289 Cobra!  (One day I will post that).

Notice we use a 4 wheel alignment system. That is because it is nice to have all 4 wheels going in the same direction! We asked the Hunter rep for the alignment specs for a Cobra!

Last edited by David Kirkham; 09-06-2007 at 08:05 AM..

|

09-06-2007, 08:10 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a close up of the screen. LOTS of things you HAVE to pay attention to. When you change one thing, other things change! It is like riding on a merry go round. One of the particularly maddening things is tightening up the rod ends when you have everything "perfect." Just tightening up the rod ends changes the angles!!! So, you have to keep trying until it is PERFECT! When these cars are perfectly aligned...magic happens.

|

09-06-2007, 08:16 AM

|

|

CC Member

|

|

|

Join Date: Oct 2004

Cobra Make, Engine: CSX2321

Posts: 1,368

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by David Kirkham

This is the famous Cam Gears steering rack. They are next to impossible to find...and we are about to replace this one!

|

David,

What if the rack in question only needed a rebuild, what would be the process? |

09-06-2007, 08:24 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is our set up. Wires EVERYWHERE!!!

We place sliding turn plates (the red plates) on ALL 4 WHEELS. VERY IMPORTANT!!!

As the wheels travel up and down, they travel on an arc. So, when the wheels are in full droop the track of the vehicle is actually SMALLER than when it is at ride height. As the car settles down from the lift, the wheels SPREAD out and so you have to have plates that SLIDE to take up the movement. If you don't have the sliding plates, the tires will simply stick to the ground and the car will not settle to ride height. It is VERY BAD to align the car when it is not at ride height!

Also, notice we have scales (the dark grey boxes) under each of the 4 corners of the vehicle. We will get into why we do that a little later.

|

09-06-2007, 08:44 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

A-Snake,

Good question!

The inner tie rod was worn quite badly on the socket joint where it attaches to the rack. We could "rebuild" it, but it would be VERY expensive as we would have to make new inner tie rods. "Rebuilding usually includes "replacing" a LOT of parts! We would have to make new inner tie rod races as well. Because they are in effect bearings we would have to make them out of a hardenable material and get the Rockwell at least into the very high 50's. Ideally, they would be made out of 17-4 H1150 and then nitrided but then the tie rods would be about $1000 each! Fine for the space shuttle, but not too good a choice for us mere mortals.

You could probably get away with making them in 17-4 H900 and then just running them. The would not rust that way and would PROBABLY last forever. But, they would only be in the low to mid 40's Rockwell C which is NOT enough for a bearing. They would wear out before the automotive standard of 50,000-100,000 miles. But with as many miles as THIS car is likely to see they would probably be fine.

Now you are starting to see the problems we face with these cars! It is all a game of compromises. If you use a nice steel that you can harden--it will rust. If you use a nice stainless that will not rust, you can't get it hard enough to turn into a bearing surface without horribly expensive processes--like nitriding. It is enough to keep me up at night practicing Chopin! Now you know why I play the piano so much. I have to clear my mind so I don't think about how to prevent rust and prevent Cobras from going on unintended off road excursions all day long!

That is the long answer and I feel like Harry Reid--long winded and waxing eloquent about nothing--and not anywhere near answering the question.

Short answer...

Yes, we could rebuild it, but it would probably cost several thousand dollars because the parts are no longer available and they would have to be custom made. In addition, the rebuild would take a month to make all the parts. So, we just replaced the rack until we have time (and enough racks) to rebuild them all at once and make it cost effective.

Last edited by David Kirkham; 09-06-2007 at 08:48 AM..

|

09-06-2007, 09:45 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Oct 2004

Location: Granite Bay,

Ca

Cobra Make, Engine: SPF GT40P-2265/393W, KMP318 (PROJECT!!!!!)/CSX478

Posts: 1,158

|

|

Not Ranked

Not Ranked

I like the Harry Reid reference.

__________________

Ron R

"Dishwasher? I thought that was for cleaning parts!?"

|

09-06-2007, 05:43 PM

|

|

CC Member

|

|

|

Join Date: Mar 2007

Location: Toledo,

OH

Cobra Make, Engine:

Posts: 253

|

|

Not Ranked

Not Ranked

Fantatic

Fantatic

Absolutely fantastic parts, info, photos, insight, knowledge, and tech info.

One mistake, street 427's DID NOT have hub caps. Rear caps only came into existance in the past 20 years, because of esthetics. Look at all of the old factory photos, of street cars, NO caps.

|

09-07-2007, 05:47 PM

|

|

CC Member

|

|

|

Join Date: Aug 2006

Location: Santa Matilde, above Marroquin de Abajo,

GTO

Cobra Make, Engine: SPF Coupe #2117, blown 4.6

Posts: 24

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by CSX3183

Absolutely fantastic parts, info, photos, insight, knowledge, and tech info.

|

Ditto.

signed,

He who seldom posts... |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:22 AM.

|

|

1Likes

1Likes

(One day I will post that).

(One day I will post that). Linear Mode

Linear Mode