Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

March 2025

March 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

07-06-2008, 10:14 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Side view. As the collet is drawn back into the tube, the taper is what is what clamps down on the tube.

|

-

Advertising

07-06-2008, 10:16 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

But a collet won't clamp unless you cut it apart...so all my nice work goes to the band saw.

In order for the collet to collapse, you have to cut your nice part you just made into pieces! But, as it is round, there is no way to hold it to cut it in the saw. So, I welded it to a square tube to hold it firmly in the saw for cutting. I welded it on the outer edge, where weld distortion won't affect the precision work of the inner OD and tapered surfaces.

|

07-06-2008, 10:18 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

The collet is actually 4 pieces. So, I had to tack weld it back together after I cut it in 1/2 and then rotate it 90 degrees to cut it again. I made a little tubular fixture to hold everything together while I cut it. The space that the saw blade removes allows for the collet to collapse onto the tube and clamp it tightly.

|

07-06-2008, 10:19 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is all my nice work in 4 pieces.

|

07-06-2008, 10:21 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is all my nice work deburred and post heat treat! Now it is hard and ready for use.

I really like the bronze color the stainless takes after heat treat.

We will start bending tubes this week!

Hopefully all our engineering worked!

|

07-06-2008, 10:24 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: San Diego,

CA

Cobra Make, Engine:

Posts: 2,979

|

|

Not Ranked

Not Ranked

By the time you are done you will have more money in tooling than the car itself.

Can't wait to see the final results and performance numbers.

__________________

Remember, It's never too early to start beefing up your obituary.

|

07-06-2008, 11:05 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by xlr8or

By the time you are done you will have more money in tooling than the car itself.

Can't wait to see the final results and performance numbers. |

We took a different approach on this car. We had to. With all the holes that had to line up, we had to do everything in CAD. Sometimes you just have to do what you have to do.

I can't wait to see the performance either. Just from preliminary tests, it feels much stiffer.

David

|

07-07-2008, 09:08 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

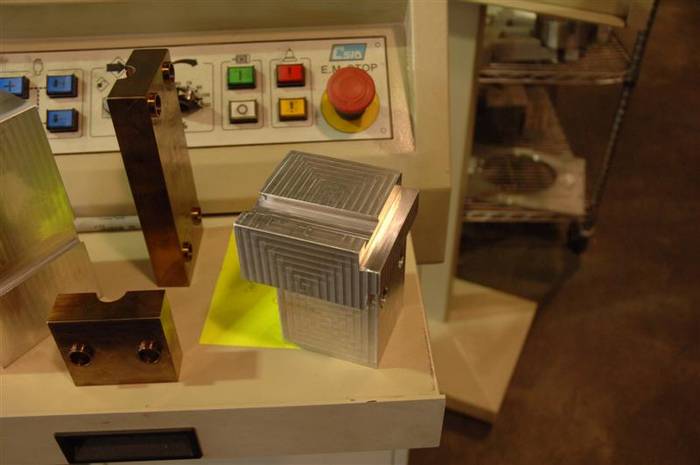

This is a picture of the pressure die assist die we had to make (the big one on the left). The smaller one is the clamp die. The dies for the big CNC tube bender machine we have are really big and so these dies are really heavy if made from steel--not to mention all of that die material is very expensive and hard to machine. Because there is so little pressure when bending a 3/4 tube, we don't need all of that expensive steel in there. The weight makes everything harder to work with as well.

Last edited by David Kirkham; 07-07-2008 at 09:14 AM..

|

07-07-2008, 09:58 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

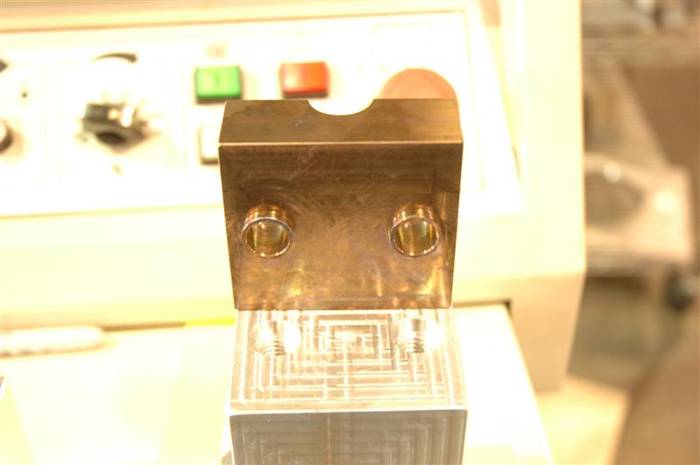

Here you can see how we "pin and dowel" the tools together so they are perfectly aligned. We machine the "dowel" right into the steel part because the raised boss of the dowel is very delicate and can be damaged easily. In this tooling stainless, it is extremely durable.

|

07-07-2008, 10:40 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is a close up of the back side of the clamp die. Even though the picture sucks, there is a hole bored into the aluminum block to accept and locate the steel clamp block.

|

07-07-2008, 12:19 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

These are the backing blocks for the dies. There is no reason to make them from hardened steel as there is little pressure on them when you are only bending 3/4 tubing. Besides, they are heavy and hard to deal with when they are made out of solid steel. If I were going to bend a million tubes, I'd make them out of hard steel.

Incidentally, this is what they call "hard" and "soft" tooling. Soft tooling is easier to make and costs less, but doesn't last as long. "Hard" and "soft" is an industry standard term.

|

07-07-2008, 12:54 PM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

Tubing bender envy.

Tubing bender envy.

You'll notice the 17mm socket welded to the threaded rod, for no slip action. And the duct tape on the threads of the gas pipe handle, for maximum protection of the operator.

|

07-07-2008, 01:03 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Hoofa,

I sure wish I would have had thought of that years ago in Poland! It sure would have helped. Sometimes the simplest ideas are the best.

Here is a picture of Joe. He is in charge of keeping the place going while I am buried on this car.

|

07-07-2008, 01:14 PM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

Joe is pretty cute, but lets stick to cars n tools. I see my tube is out, What does Joe think of it?

|

07-07-2008, 01:26 PM

|

|

CC Member

|

|

|

Join Date: May 2007

Location: Stoke on Trent (Potteries),

UK

Cobra Make, Engine: DB427SC. 289FIA. COUPE. Round tube, Aluminium body, 427FE

Posts: 93

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by David Kirkham

Here is a picture of Joe.

|

He sounds much taller on the telefone.   |

07-07-2008, 01:31 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

We fiddle with the tube all the time. Notice it is right out there to keep an eye on it. When we finish with this car we will get back to other fun things.

David

|

07-07-2008, 01:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here we are lining up the variable radius rollers. All these tools have to be held in square in place in all 3 dimensions...it can get quite tedious. If they are not lined up, the bending machine is so powerful it will simply crush the tube at worst, and leave a nasty line in it at best. Nasty lines are horrible stress raisers.

Notice the collet I made last week in place and doing its job of holding the tube in place. It also orients the tube if we need it to.

|

07-07-2008, 01:56 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Lining things up and making sure everything is just right.

|

07-07-2008, 02:07 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a close up of the collet I made last week. Now you can see better what it does. It holds the tube in place, indexes the tube, pushes the tube into the die, and pushes the tube through the 3 roll bender to make variable arcs--all depending upon what you want to do.

|

07-07-2008, 02:27 PM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

That's cool, Looks like the big wheel is powered too? How much more work after Solidworks till finished piece? I had to make a giant DNA Helix a few years ago, I wish I knew such a machine existed. How about some video???

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:42 PM.

|

|

2Likes

2Likes

Linear Mode

Linear Mode