Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

06-05-2008, 06:38 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a pic of the front upright with the steering arm attached. Notice the upper AND lower rod ends are both held in double shear.

|

-

Advertising

06-05-2008, 06:40 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is a pic of the front lower control arm. Notice the push rod mounting location is as far outboard as possible. That is to reduce the bending moment on the front lower control arm as much as possible. You can see we milled the brake line holders directly into these control arms as well.

|

06-05-2008, 06:42 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Again, on the front lower control arm in the above picture you can see we milled the crotch of the control arm in one motion so the cutter wouldn't stop and make an ugly mark 1/2 way through the arm. We were very concerned about the tool paths on the parts and that they looked good.

|

06-05-2008, 06:44 PM

|

|

CC Member

|

|

|

Join Date: Dec 2002

Cobra Make, Engine: KMP

Posts: 790

|

|

Not Ranked

Not Ranked

Wow!! Simply amazing!!

b/t/w, did you say 15" wheels?

__________________

Lew

I'm no expert.

|

06-05-2008, 06:52 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Si senor...but only if you don't raise your rates to me! So, am I converting you to the Dark Side (billet)?

David

|

06-05-2008, 07:02 PM

|

|

CC Member

|

|

|

Join Date: Dec 2002

Cobra Make, Engine: KMP

Posts: 790

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by David Kirkham

Si senor...but only if you don't raise your rates to me! So, am I converting you to the Dark Side (billet)?

David

|

..... magnesium bilet (the true Dark Side).

__________________

Lew

I'm no expert.

|

06-05-2008, 07:04 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

06-06-2008, 09:18 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a shot of a dual use bracket. This bracket holds the gas tank straps on the bottom and the 3/4 body tubes on the top.

|

06-06-2008, 09:21 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is a pic of the rear differential upper mounts. We are using the same differential we use in our own cars, original Cobras, and Shelbys.

Last edited by David Kirkham; 06-06-2008 at 09:23 AM..

|

06-06-2008, 09:23 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

06-06-2008, 09:38 AM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Baton Rouge, Louisiana,

La.

Cobra Make, Engine: Waiting to Order a BDR, engine to be a SA C408. TKO to hook it up.

Posts: 1,259

|

|

Not Ranked

Not Ranked

sigh ........

__________________

Pull a gear .... drop the hammer .... and enjoy the Drive !!

|

06-06-2008, 10:26 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is a shot of the support brace that connects the front suspension to the foot boxes--completing the load paths from front to rear. The side pipes normally go through this area, but since the customer wanted under-car exhaust this left a very nice place to tie the frame all together.

Last edited by David Kirkham; 06-06-2008 at 10:32 AM..

|

06-06-2008, 10:34 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

06-06-2008, 10:36 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This shot shows the 1/2 inch gap that will be filled in with the front of the foot box.

|

06-06-2008, 10:38 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

06-06-2008, 10:40 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

06-06-2008, 10:45 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

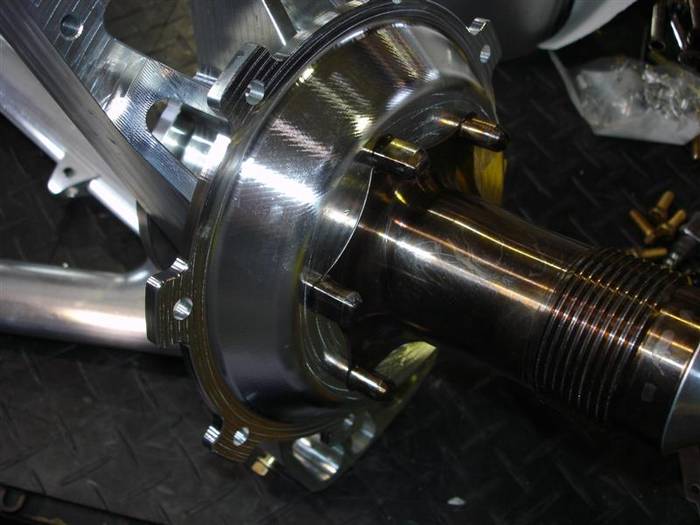

This is one of my favorite pics! We milled the outside flange of the hub so it could be used to drive the rotor hat. We did that for many reasons. I was out one day looking at Sandwich's Ducati and noticed the rotor was completely floating on the hat. The reason you float the rotor on the hat is to prevent the dreaded brake shutter. You see, most rotor hats are sandwiched between the rotor hub and the wheel. So, if there is ANY tolerance (unevenness) on the machining of the wheel (always) or the hub (we try very hard to keep that minimal) then the tolerance will show up as a vibration in the brakes. Over the years, people (customers) have gotten less and less tolerant of the brake vibrating.

By driving the rotor hat on the outside of the hub, we completely decoupled the rotor hat from the hub and wheel. Now the rotor spins freely and is able to move left, right, up and down without vibrating the caliper pistons. This was one of my brighter ideas. At least, I think so. We'll see how it works in real life soon

|

06-06-2008, 10:47 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This shot shows you better what I mean by driving the rotor hat on the outside of the hub flange.

|

06-06-2008, 10:50 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

We made the rotor hat (the aluminum part) 0.005 inches thinner than the flange on the hub. That way, when the wheel is clamped on to the hub, the hat still has 0.005 inches of play. The brake hat can now heat up and expand away from the hub without warping the rotor. Another really cool benefit is there is a tremendous break in the thermal paths from the rotor to the hub--so you don't overheat your hub bearings under hard braking.

|

06-06-2008, 10:53 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

A couple of more comments on the hubs. There is a little step milled into the the back of the hub flange on 3 of the 6 sides so the rotor hat can't fall off the back side of the hub. Also, notice the drive pins are milled directly into the hub. This is the lightest hub we have ever made (and the most expensive one too!)

The hub is made from billet 17-4 PH. The precipitation hardening gives it that cool bronze look.

David

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 11:27 PM.

|

|

2Likes

2Likes

Linear Mode

Linear Mode