Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

April 2025

April 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

1 |

2 |

3 |

4 |

5 |

| 6 |

7 |

8 |

9 |

10 |

11 |

12 |

| 13 |

14 |

15 |

16 |

17 |

18 |

19 |

| 20 |

21 |

22 |

23 |

24 |

25 |

26 |

| 27 |

28 |

29 |

30 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

06-16-2008, 02:35 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Don,

Thanks for the tip! I'll post more pics soon.

David

|

06-16-2008, 02:37 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Gents,

And now for the push to have this baby driving by Thursday (our track day)!

David

|

06-16-2008, 02:53 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

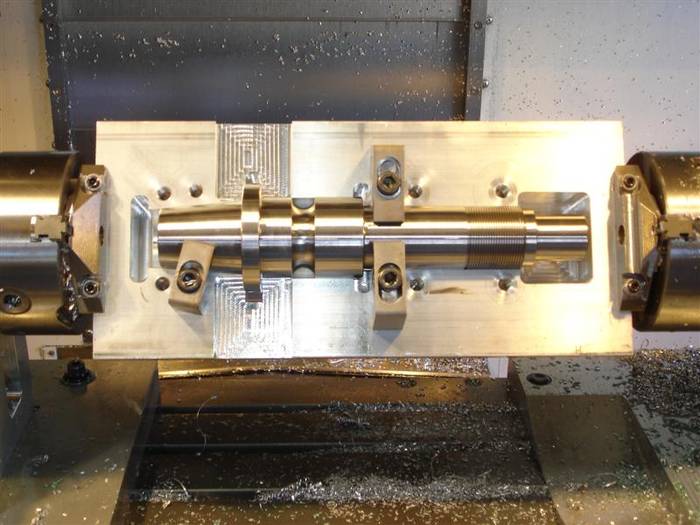

We were thrown a HUGE curve ball this past week. We have a CNC tube bender and we needed some 3/4 tooling to make the body tubes for our ride. The supplier kept putting us off and putting us off and putting us off... Finally, I told Sandwich to tell the guy either it showed up this week or we were going to make it ourselves. He laughed and said it was too complicated for us to make and that it would take us way longer than the 5 extra weeks he was quoting us...

Telling me I can't do something is a "no-no" around here. Waiting on this car is NOT an option.

Truthfully, the part is pretty hard as the tolerances are very tight. To complicate matters further, 17-4 SHRINKS in heat treat, so you have to make the part over sized on the bearing surfaces and then "guess (educated guess from our long experience with 17-4). Sandwich was busy so it fell to me to baby sit the part. It took 3 passes to hit the tolerance. As you can imagine, it makes you sweat when you are moving the lathe wear offsets by 0.0005" at a time to make sure you hit it just right.

The bending tool posed a particular problem as the radius we needed is actually smaller than the axle shaft the bending dies normally sit on. Solution? Cut the die groove right into the axle!

Everyone told us we couldn't do it (I hate it when people say that; I even told my guys in Poland I was going to fire the next worker who told me "niemozliwe" (not possible).

So, here is is the tool, 3 DAYS later. Engineered, lathed, milled, ready for heat treat.

|

06-16-2008, 02:57 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

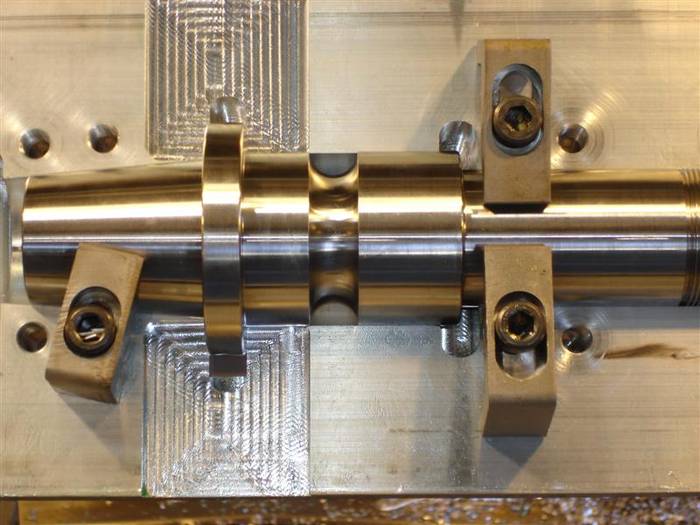

The part was a real pain as we had to mill in a flat spot to keep the incoming tube straight as it is being bent. The flat spot is critically positioned tangent to the radius of the groove. If you miss, you put ugly "bite" marks in the tube and we don't like ugly!

So, Sandwich milled an exact female of the tool to hold it exactly in place. That way, there is NO way X Y Z or A can move.

|

06-16-2008, 02:58 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is the part with the milled out area and the insert installed--perfect fit--no tool marks from this baby!

|

06-16-2008, 03:00 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

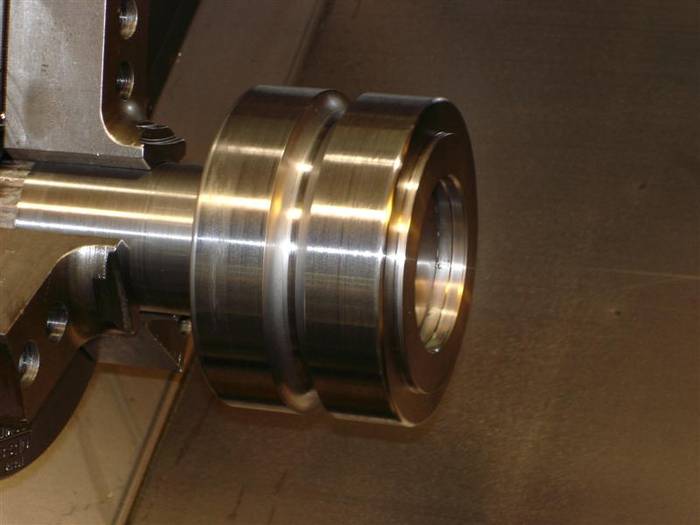

Here is the die that actually goes on top of the axle I just showed you. This die is for the "roll bending" or "push bending" of the 3/4 body tubes. Roll bending is really cool. If you have never seen it, you will not believe it. When we get it up and running, I will post a YouTube of it. We made this out of 4340 and man is it a pig to machine.

|

06-16-2008, 03:04 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is another shot of one of our lathes. It is a pretty big HL-30. We can spin around 30 inches on it I think--never had a reason to try something that big, however. We use big lathes because you have to have the power to hog on the nasty materials we use like 4340 and 17-4 stainless. It is a 30 horsepower lathe. For reference, home lathes are 1-5 hp. Most manual lathes in machine shops are 2-5 hp. Of course, there are lathes out there to turn battle ship barrels...who knows how many hp they have!

|

06-21-2008, 04:18 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Gents,

I will start posting this week's pictures now. We are still working in the car here (waiting for the Kirkham Homecoming crowd to come back). Post will be sporatic throughout the evening. Stay tuned for the fun

This is the throttle pedal. Notice the kink in it. It has to clear the steering column. The pedal matches the brake and clutch pedal.

|

06-21-2008, 04:20 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is a shot of the prototype gas tank (just to make sure everything fits). The tank for the car will be polished to a mirror finish. The tank is stainless (about anything we make that is not aluminum we make out of stainless--just say no to rust).

|

06-21-2008, 04:22 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is a picture of the steering intermediate shaft support. The angle on the steering column shafts is so high, we had to use a Borgeson double jointed u-joint. When you use those floppy monsters, you MUST use another support in the system to keep everything rigid. It just barely clears the #5 head tube.

|

06-21-2008, 04:24 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

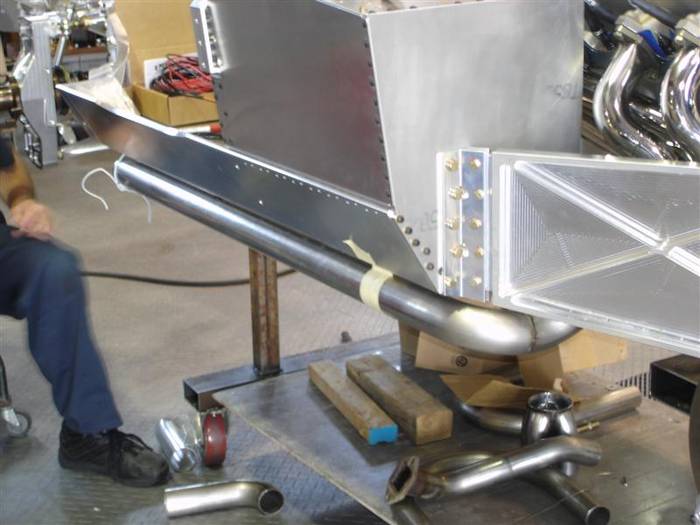

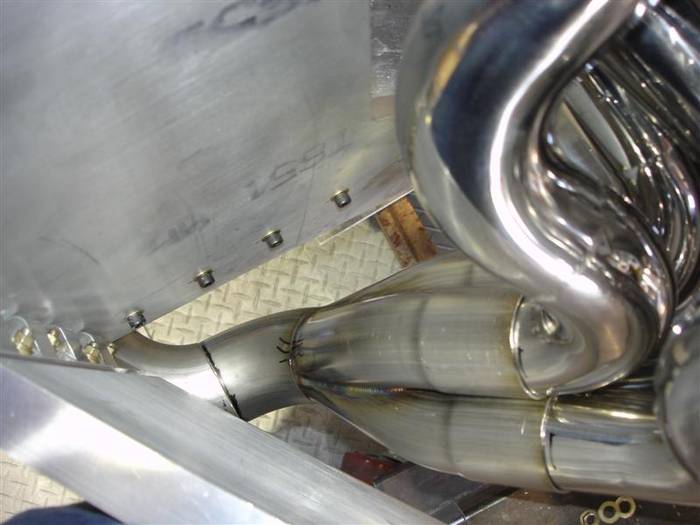

Speaking of head tubes and exhaust...the customer wanted the exhaust to run out the back...complete custom job here.

|

06-21-2008, 04:26 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

We used 2 inch radius bends on the entire system (except the collectors). We had to keep everything as tight as possible.

|

06-22-2008, 01:56 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

I was up late last night and so I just posted a lot of pictures without captions. I am going right now to caption the pictures so you may want to look back over the past page or two.

Thanks for looking and thanks for the comments and emails!

David

|

06-28-2008, 12:56 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Another week has come and gone. This, however, is a very special week...stay tuned.

Here are some pics of the parts as they came out of the mills.

|

06-28-2008, 12:58 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here you can see the sway bar pivot.

Last edited by David Kirkham; 06-28-2008 at 01:00 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 02:01 PM.

|

|

2Likes

2Likes

Hybrid Mode

Hybrid Mode