Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

April 2025

April 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

1 |

2 |

3 |

4 |

5 |

| 6 |

7 |

8 |

9 |

10 |

11 |

12 |

| 13 |

14 |

15 |

16 |

17 |

18 |

19 |

| 20 |

21 |

22 |

23 |

24 |

25 |

26 |

| 27 |

28 |

29 |

30 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

06-21-2008, 04:20 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

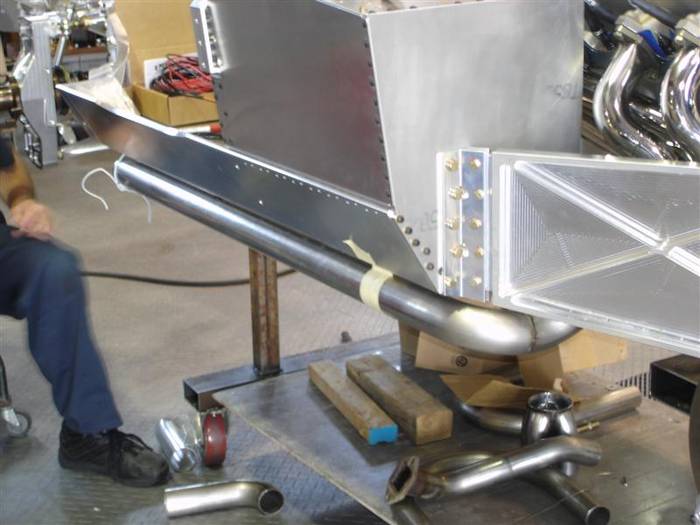

This is a shot of the prototype gas tank (just to make sure everything fits). The tank for the car will be polished to a mirror finish. The tank is stainless (about anything we make that is not aluminum we make out of stainless--just say no to rust).

|

-

Advertising

06-21-2008, 04:22 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is a picture of the steering intermediate shaft support. The angle on the steering column shafts is so high, we had to use a Borgeson double jointed u-joint. When you use those floppy monsters, you MUST use another support in the system to keep everything rigid. It just barely clears the #5 head tube.

|

06-21-2008, 04:24 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

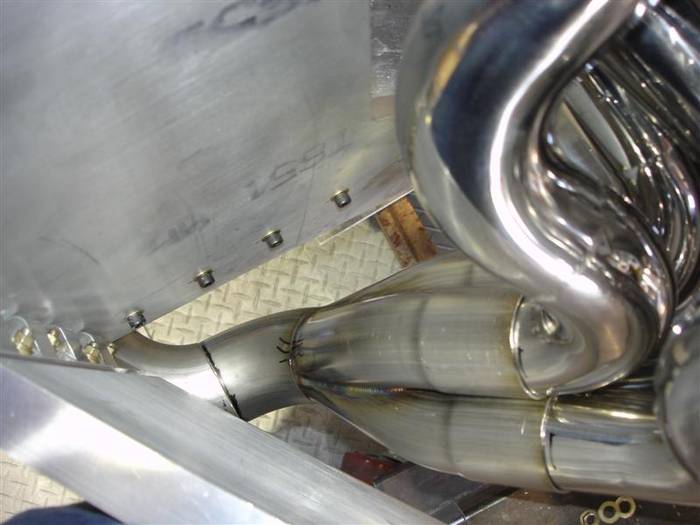

Speaking of head tubes and exhaust...the customer wanted the exhaust to run out the back...complete custom job here.

|

06-21-2008, 04:26 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

We used 2 inch radius bends on the entire system (except the collectors). We had to keep everything as tight as possible.

|

06-21-2008, 04:27 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a shot of the exhaust going under the car. As you can see, it is tucked right up next to the frame to clear the ground.

|

06-21-2008, 04:29 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

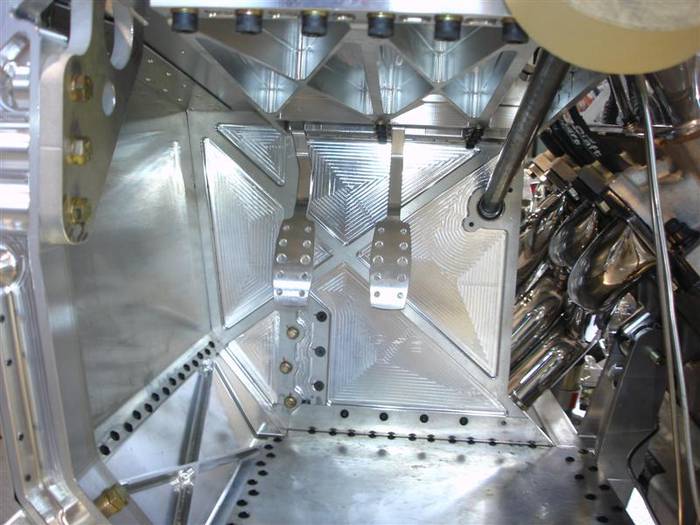

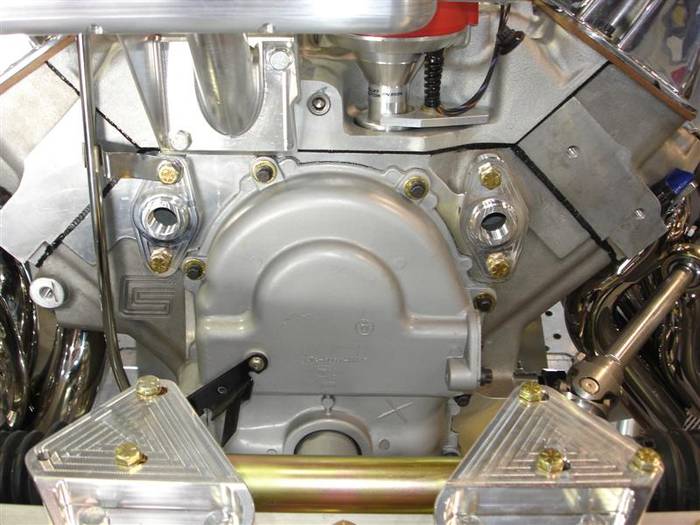

Here is a shot from the driver's foot box. As you can see, we moved the engine back almost 6 inches!

|

06-21-2008, 04:31 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

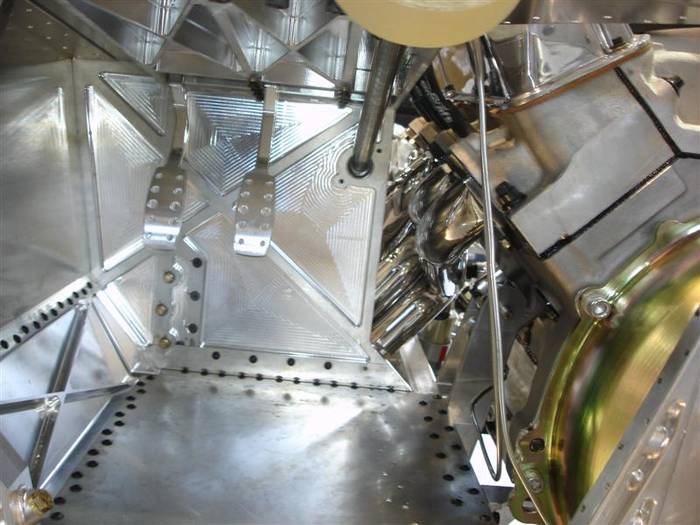

This is another shot from the driver's foot box. Everything was done on CAD to make everything fit. We digitized the body, the engine, the transmission, and the differential! We would have never got anything to fit without the CAD files in Solidworks.

In this shot, you can see the front and rear brake hard line snaking down the inside of the driver's foot box. In an original 427 Cobra, there are 6 brake hard lines. The control arms are so long on this car, we only have 2 hard lines--one front and one rear. They then "tee" to the flex lines and out to the calipers.

|

06-21-2008, 04:35 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

We tried 3 different collector lengths until we found the perfect length/look combination.

Last edited by David Kirkham; 06-21-2008 at 04:37 PM..

|

06-21-2008, 04:37 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is another shot so you can see how tight we kept the exhaust to the car. I hate it when the exhaust drags on the ground.

|

06-21-2008, 04:38 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here you can see we had to use a lot of bends to get everything to line up.

A lot of people have emailed me wondering how to make head tubes. Well, this is how you do it. First you bend up some tubes on your CNC tube bender  or just buy them. Take the bends and start cutting and fitting until you have an exhaust system. The black marks on the tubes are from a magic marker we use to orient the bends right. We then cut the tubes on a band saw and then use masking tape (believe it or not) to tape the bends together. Masking tape works really well to hold the tube in place. Just peel it back and tack weld the tube in place when you have it in the right position.

Last edited by David Kirkham; 06-21-2008 at 04:42 PM..

|

06-21-2008, 04:42 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

So, why didn't we get the car running...

Well, you keep running into little problems like this. This is a Jegs water pump part number 50950 that we were going to use. When we opened up the box, we noticed the fittings were Jegs "specials." (That means they don't fit ANYTHING metric or otherwise!) Also, we needed 2 outlets and not one so we needed a "Y" connection. Thomas suggested we just make our own water pump housing...no big deal. I turned it over to Sandwich and a few hours later...

Last edited by David Kirkham; 06-21-2008 at 04:47 PM..

|

06-21-2008, 04:48 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

06-21-2008, 04:49 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here you can see the rear intake that we made to fit a 2 inch hose (the normal size of the inlet on the water pump of a 427 Cobra). The outlets are JIC dash 12 with one outlet to both sides of the original water pump.

|

06-21-2008, 04:51 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Sorry for the blurry pics sometimes, but this shiny stuff is really hard to get the camera to focus on.

David

|

06-21-2008, 04:56 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is a pic of the billet adapters we made to adapt the electric pump to the block. They are o-ringed on the back so they don't LEAK!

|

06-21-2008, 06:57 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Phoenix,

AZ

Cobra Make, Engine: FFR: 302 w/aluminum heads, Edlebrock injection. Street car trim, no scoop, side pipes or rollbar.

Posts: 1,869

|

|

Not Ranked

Not Ranked

I hate when the exhaust drags the ground

David did you consider oval pipe? I used 3" pipe on my car that's been 'squished' to 2.25".

(Ugg, believe me it's painful to add my 'crapsmanship' to this thread.  )

__________________

"Cobra-Cobra-bo-bobra, banana-fanna-fo-fobra, fe-fi-mo-mobra...Cobra!"

|

06-21-2008, 07:17 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

[quote=Maricopa;854199] I hate when the exhaust drags the ground

David did you consider oval pipe? I used 3" pipe on my car that's been 'squished' to 2.25".

(Ugg, believe me it's painful to add my 'crapsmanship' to this thread.  )

Maricopa,

We did consider oval pipe but it would not work in our application. Our problem was not ground clearance under the car (rocker to ground). If we tucked the pipe up close, it cleared. Our problem was we had to cut, twist and orient the bends in very strange and tight areas. An oval tube does not allow you 360 degrees of rotation to work with.

As for "crapsmanship," we have all committed our fair share of boo boos. As I look back on some of the things in life I have done I wonder what the hey was I thinking. I assure you that you don't have the corner on that market!

David

|

06-21-2008, 07:21 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Maricopa,

Hopefully this pic will explain it better than I was able to. A pic is worth at least 1000 words. Here you can see some of the snakey bends we had to make.

|

06-21-2008, 07:23 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is how you make the snakes. We take the bends and cut them on a band saw. The critical thing to remember is to ALWAYS cut your bends toward the MIDDLE of the radius. That way you end up with a round hole and not an oval on one end and another oval (that doesn't match) on the other end.

|

06-21-2008, 07:25 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

What good is stainless if you don't polish it!

Here we are using our standard muffler that is ALL stainless. The outer shell is stainless; the inner tube is stainless; the packing is stainless. No rust or packing blow out here!

Above the mufflers, you can see various bends and cuts. It is one big jig saw puzzle.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:17 AM.

|

|

2Likes

2Likes

or just buy them. Take the bends and start cutting and fitting until you have an exhaust system. The black marks on the tubes are from a magic marker we use to orient the bends right. We then cut the tubes on a band saw and then use masking tape (believe it or not) to tape the bends together. Masking tape works really well to hold the tube in place. Just peel it back and tack weld the tube in place when you have it in the right position.

or just buy them. Take the bends and start cutting and fitting until you have an exhaust system. The black marks on the tubes are from a magic marker we use to orient the bends right. We then cut the tubes on a band saw and then use masking tape (believe it or not) to tape the bends together. Masking tape works really well to hold the tube in place. Just peel it back and tack weld the tube in place when you have it in the right position.

)

)

Linear Mode

Linear Mode