Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

06-21-2008, 08:25 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2006

Location: McKinney,

TX

Cobra Make, Engine: SPF #867 gone....

Posts: 1,272

|

|

Not Ranked

Not Ranked

So how does one test for "chassis flex" and those sorts of rigidity issues. I mean, I've read the descriptions of the parts being in "double shear" and the like, is that anticipated to achieve a more rigid chassis? Besides the obvious WOW factor, which really is off-the-charts, is this anticipated to have greater performance characteristics other than lighter weight?

Your rookie in frame dynamics,

__________________

MadMiles442  She said, "The only thing I'll ask of you, you gotta promise not to stop when I say when..."

She said, "The only thing I'll ask of you, you gotta promise not to stop when I say when..."

|

-

Advertising

06-21-2008, 08:27 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

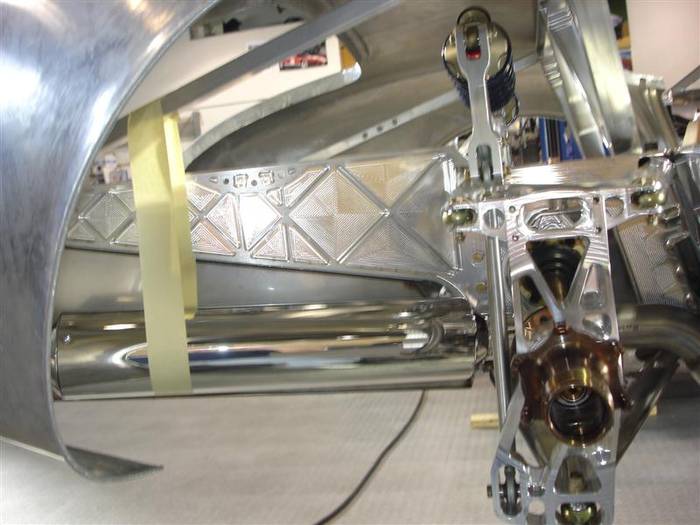

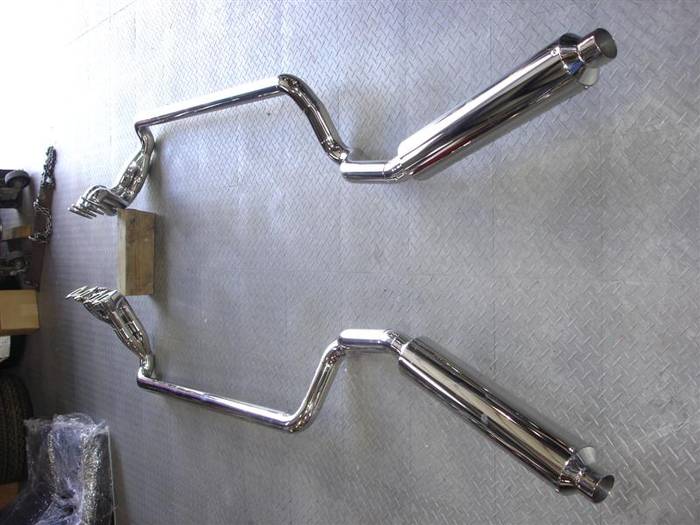

Here is a pic of the muffler snaking out the back. Notice how we ran the exhaust OVER the rear lower control arm. The suspension is right now at full droop so we ran the exhaust within 1/4 inch of the 1/2 shaft axle for maximum clearance.

|

06-21-2008, 08:29 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is another picture of the snake around. Notice all the bends to make the exhaust go where you want it to go. There are 5 different tubes all welded together in this section.

|

06-21-2008, 08:40 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Madmiles442

So how does one test for "chassis flex" and those sorts of rigidity issues. I mean, I've read the descriptions of the parts being in "double shear" and the like, is that anticipated to achieve a more rigid chassis? Besides the obvious WOW factor, which really is off-the-charts, is this anticipated to have greater performance characteristics other than lighter weight?

Your rookie in frame dynamics,

|

One way to "test" for chassis flex is to do FEA (Finite Element Analysis). That works really well--for the first shot. The next way to test it is to simply tie the chassis down to something really rigid and bend the chassis with a long lever. We are thinking how to do that right now. You always need to prove your designs and thoughts.

Of course, another way to test the chassis (which we will do shortly) is to simply drive the chassis. An experienced driver will know immediately how stiff (relatively) the chassis is. Stiff chassis react faster.

As for performance, the car was built to perform. It is not a trailer queen. Our customer will drive the wheels off the car. Sometimes I think the guys who make really beautiful show cars have it easy. No one ever drives Chip Foose's cars. (Don't think I am dissing Chip here, his work is fantastic). The challenge we were faced with is our customer expects a Ridler type car that handles extremely well. We are up against fierce competition...he owns a Bugatti Veyron, McLaren F1, Ferrari Superamerica, Audi A8 and I am sure I am forgetting some. I told him I was going to make him the best possible car based on a Cobra body dimensions that could be made. This is what we came up with. Now, that has to be tempered with artistic license. We wanted a high performance car that was beautiful as well. There are compromises inherent in anything. We simply tried to minimize them as much as possible. In the end, I think of it more as art than I do a race car. But I always have in the back of my mind he intends to drive it.

David

|

06-21-2008, 08:42 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here we are putting on the rear clip to check for muffler and rear exit exhaust tip clearances.

|

06-21-2008, 08:51 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

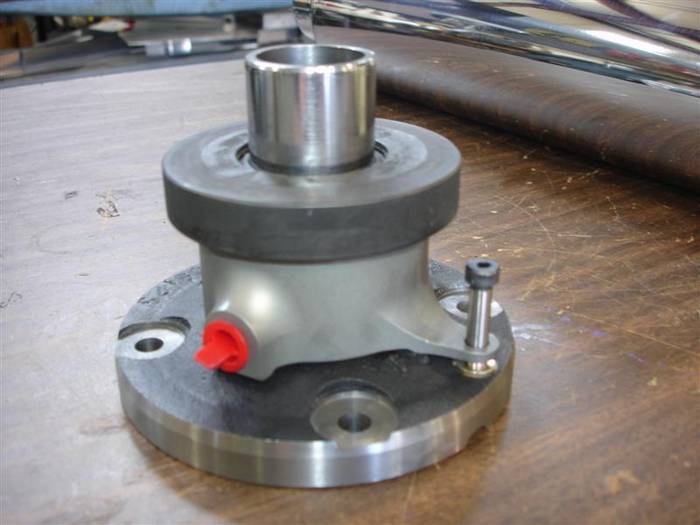

The throw out bearing in the car presented a very special problem to us. As we moved the engine back about 6 inches, there is simply no room for a standard throw out bearing lever arm. We had to use a hydraulic unit on this car.

Now, many of you know I feel like the McLeod hydraulic throw out bearing has been banned from our shop as unworthy. So, we had to look for another unit. I figured I'd try a Tilton 61-601 hydraulic throw out bearing. Now, it says you HAVE to buy a base unit to use with that set up...baloney. We just make our own stuff around here

Anyway, you can't use the Tilton base as they don't have one that will work with an FE. So, we had to do a little modifying...(another reason the test drive is slightly delayed.)

|

06-21-2008, 09:07 PM

|

|

CC Member

|

|

|

Join Date: Sep 2002

Location: Phoenix,

AZ

Cobra Make, Engine: FFR: 302 w/aluminum heads, Edlebrock injection. Street car trim, no scoop, side pipes or rollbar.

Posts: 1,869

|

|

Not Ranked

Not Ranked

As for "crapsmanship," we have all committed our fair share of boo boos. As I look back on some of the things in life I have done I wonder what the hey was I thinking. I assure you that you don't have the corner on that market!

Hey now all my stuff works, it just don't look as nice as your's!

Yeah I understand needing the round tube to go around corners, I used round as well from the collectors to the straight sections, I was just thinking of it for the section under the car but it sounds as if you have plenty of clearance.

Some great stuff here that's for sure. This is a great thread.

__________________

"Cobra-Cobra-bo-bobra, banana-fanna-fo-fobra, fe-fi-mo-mobra...Cobra!"

|

06-21-2008, 09:36 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is the Tilton 61-601 hydraulic throw out unit. See the inside of the bore with the threads? That is so you can use the base Tilton sells separately that screws in. The thread allows you to adjust the bearing height to the proper distance. Well, the Tilton unit, even without the base, is too long to use. So, we had to do a little modifying. The first thing I did was take a piece of aluminum and make a ring that we could press into the back of the unit. The ring is to reduce the size of the bore so it will fit over the input shaft collar of the Tremec tranny. Of course, the unit is too small to fit over the collar, so we had to lathe 0.033" off the collar shaft. Then I pressed the little aluminum ring (0.001 interference fit) into the back of the hydraulic unit. Then everything lined up perfectly...but it was still too long.

Last edited by David Kirkham; 06-22-2008 at 03:03 PM..

|

06-21-2008, 09:38 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

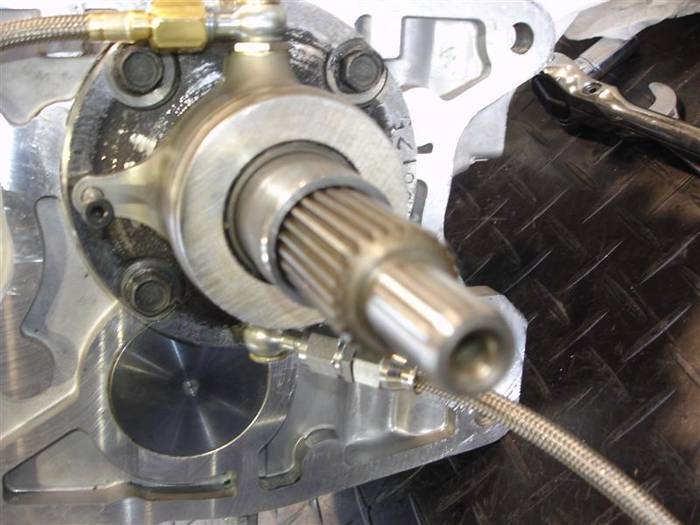

If you look closely at this picture, I had to lathe the collar back 0.100 inches to get the throw out bearing to sit back further. I also had to lathe the casting numbers off because they stuck up too far and were in the way. Then everything fit just right.

Last edited by David Kirkham; 06-22-2008 at 03:05 PM..

|

06-21-2008, 09:39 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here Jeremy is dialing in the Quicktime bell housing. We use the Quick times because they are really light.

Last edited by David Kirkham; 06-22-2008 at 03:06 PM..

|

06-21-2008, 09:41 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

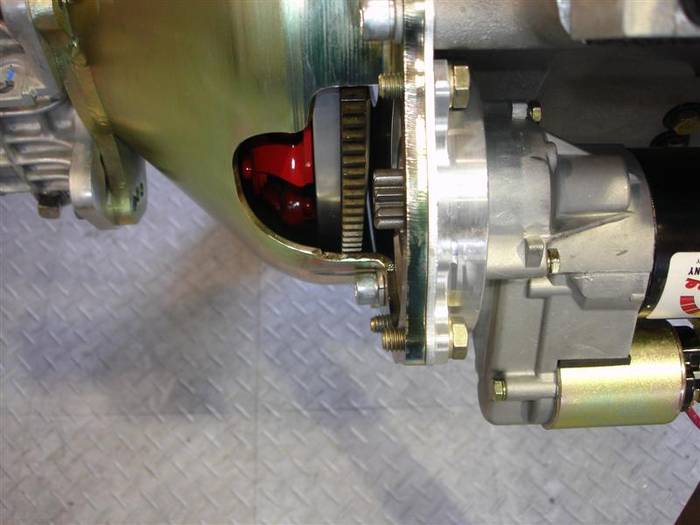

Here you have to make sure the distance is set right on your starter. Like EVERYTHING with Cobras and FE's NOTHING fits right out of the box. If you put the starter on right out of the box, the starter will be too far away and you will then grind the corners off of your flywheel ring gear because of poor engagement. We had to lathe 0.070 off the face of the starter to get the right clearance. Notice the bolts we put in are too long. They are the only ones we had at the moment and the shorter ones are on order for arrival on Monday.

Last edited by David Kirkham; 06-22-2008 at 03:08 PM..

|

06-21-2008, 09:42 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here the hydraulic throw out bearing lines are taped to the back of the bell housing so the engine can be put in.

Last edited by David Kirkham; 06-22-2008 at 03:09 PM..

|

06-21-2008, 09:44 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is the fuel pressure regulator. We use a Mallory bypassing fuel regulator. Notice we made a special little bracket that holds the Mallory unit and also serves as the throttle pedal return spring bracket. The big black plug on the back is the sending unit for our electronic fuel pressure gauge.

Last edited by David Kirkham; 06-22-2008 at 03:11 PM..

|

06-21-2008, 09:45 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here you can see we ran into another little problem. The alternator bolts to the water pump...and as you can see from the above posts, we made a billet unit so we can't bolt the alternator to that!

So, we did a quicky left and right hand threaded shaft to adjust the alternator. This is just a temporary fix to get the motor running until we can think of something cooler to make. Also, notice the double pulley alternator on the motor...Checker send us the wrong part (should be a single pulley alternator). But, the double pulley unit works well for packaging considerations.

Last edited by David Kirkham; 06-22-2008 at 03:14 PM..

|

06-21-2008, 09:47 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

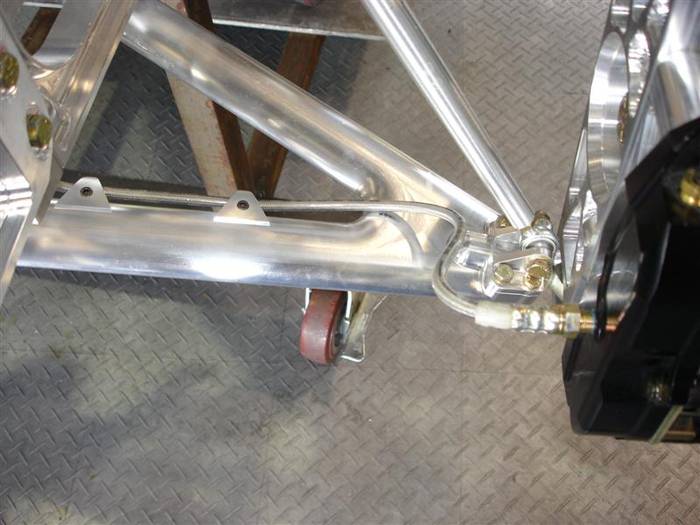

I hate brake lines that flop in the breeze. So we milled little brackets directly into the control arms to support the brake flex lines.

Last edited by David Kirkham; 06-22-2008 at 03:15 PM..

|

06-21-2008, 09:48 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is another view of how we held the brake lines.

Last edited by David Kirkham; 06-22-2008 at 03:15 PM..

|

06-21-2008, 09:50 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here is the exhaust all polished up and ready to bolt on. We got the engine back in and he exhaust hung last night. This week we WILL test drive

Last edited by David Kirkham; 06-22-2008 at 03:16 PM..

|

06-22-2008, 10:08 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Exeter,

CA

Cobra Make, Engine: KMP 498

Posts: 495

|

|

Not Ranked

Not Ranked

As a note here:

When I left the Kirkham shop at around 10AM Friday morning: The engine & trans were still in and together, just started header welding, tilton stuff was still in the box. David was telling "Sandwich" to take the front end back apart a cut more billet off. All the other staff were working on customers cars to get them on the road.

Get my point?

__________________

Sanded Aluminum Finish? Because I Can!

|

06-22-2008, 10:25 AM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Cobra Make, Engine:

Posts: 91

|

|

Not Ranked

Not Ranked

This has been truly inspirational for me, I almost hate to see it end. What's next? I can't wait!

I just got Solidworks, I already designed a billet hood latch with my logo in it. This Car, along with Solidworks, changed the way I look at everything. I've been doing the graphics for the Solidworks trade Show for about 4 years. I always read the stuff but it never sparked an interest until you guys showed me what could be done with it. Thanks again for sharing.

|

06-22-2008, 02:49 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by big-boss

As a note here:

When I left the Kirkham shop at around 10AM Friday morning: The engine & trans were still in and together, just started header welding, tilton stuff was still in the box. David was telling "Sandwich" to take the front end back apart a cut more billet off. All the other staff were working on customers cars to get them on the road.

Get my point?

|

Yes, it was a hectic day...well, it has been a hectic year with this car. After you left, we took the engine out, modified the hydraulic throw out bearing, welded the pipes, polished the pipes, dialed in the bell housing, and reinstalled everything. The only bummer was I wasn't able to go on the Homecoming run with you guys. But I am pretty focused on this car to get it done. As I am sure you can imagine, it takes a lot of focus to do something like this--and try to keep all your other customers happy at the same time.

Thanks for coming by! I hope you liked the car. Unfortunately, pictures don't do the car justice.

David

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:06 AM.

|

|

2Likes

2Likes

Linear Mode

Linear Mode