Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

07-31-2008, 05:57 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Posts: 1,330

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by FatBoy

You have your hubs and spinners on the wrong side of your car, please accept the combined wisdom and experience of countless authorities on the subject. I'm sure you won't find a single credible manufacturer that designs them to be the way you have them.

Paul

|

Let's not get all huffy here. I've accepted the fact that they need to be changed. Just trying to better understand what I'm seeing. I guess I'm a bit surprised that, considering the importance of following conventional wisdom, that instructions weren't included.

Quote:

Originally Posted by FatBoy

There could be a number of reasons why you appear to have more slack in your wire, but rest assured, it isn't because your spinners have tightened.

Paul

|

Name two. |

-

Advertising

07-31-2008, 06:35 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Posts: 1,330

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by A-Snake

Ok, let's start with your comment "I have a loop in the safety wire that I monitor before each drive." I took that to mean you had a loop in the wire around midway and if the loop straightened out the knock-off had moved. The wire in the picture is shown more or less straight showing the knock-off has rotated counter-clockwise which would be "loosen" on right hand threads. What am I missing?

Now that I look at your safety wire a few more questions come to mind. The wire looks rusted. Are you not using stainless steel wire? How is the wire wrapped around the segment of the wheel? Did you drill a hole in the wheel as I don't see the wire going around a segment of the wheel.

http://www.whizwheels.com/Tips/safetywiring.html |

Maybe its the perspective. Here's what it should look like (with stainless wire). Yes I drilled the wheel and wrapped it around the webbing. The loop is still there in my first pic. You're just looking at it from the side.

Last edited by TButtrick; 07-31-2008 at 07:42 AM..

Reason: more descriptive

|

07-31-2008, 08:53 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

TButtrick

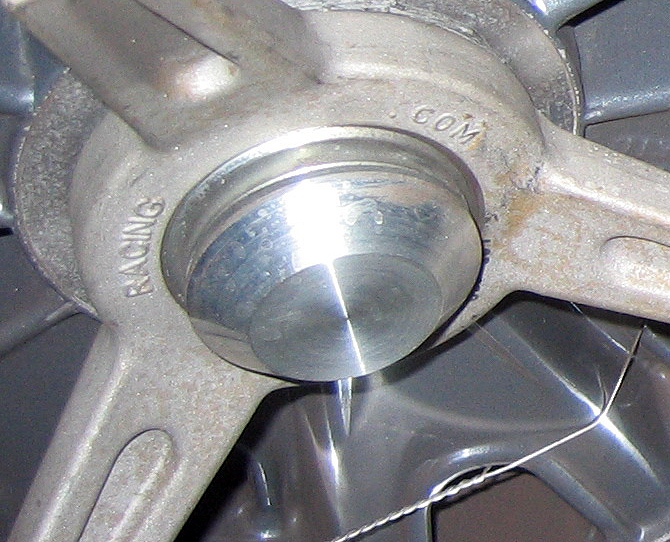

More of a concern once you do get the hubs & wheels installed in the correct

( accepted ) position, is the lack of thread grip you appear to have on the spinners.

On my Vintage hubs & wheels I have all of the starter portion of the hub plus several threads exposed once the spinners are installed.

Unless yours are designed differently ( I would like to see a photo of the hub, less wheel & spinner ) I am under the impression you do not have enough threads holding the spinners in place.

Craig

|

07-31-2008, 08:58 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Posts: 1,330

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by cdnus

TButtrick

More of a concern once you do get the hubs & wheels installed in the correct

( accepted ) position, is the lack of thread grip you appear to have on the spinners.

On my Vintage hubs & wheels I have all of the starter portion of the hub plus several threads exposed once the spinners are installed.

Unless yours are designed differently ( I would like to see a photo of the hub, less wheel & spinner ) I am under the impression you do not have enough threads holding the spinners in place.

Craig

|

This is how they arrived from Vintage Wheels. All the threads on the spinner and hub are engaged. Making the hub longer will not make a difference. |

07-31-2008, 09:25 AM

|

|

CC Member

|

|

|

Join Date: Dec 2004

Location: toronto,

ont

Cobra Make, Engine: 408w 500 h.p. 550 ft.lbs

Posts: 562

|

|

Not Ranked

Not Ranked

Looking at your photos one can see clearly there is at least a portion of unthreaded area of the hub inside the spinner. On mine that is quite wide ( I will have to go out to the shop & measure to be exact ) if yours is the same you do not have enough thread holding the spinner on.

Craig

Went out & measured---3/4" protruding out of spinner.

1/2" unthreaded starter nipple--approx 2 threds=1/4" Total--3/4"

So if yours are manufactured the same, you do not have proper thread engagememt

Craig

Last edited by cdnus; 07-31-2008 at 09:47 AM..

Reason: verifying fittment of spinners.

|

07-31-2008, 10:02 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,005

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by cdnus

Looking at your photos one can see clearly there is at least a portion of unthreaded area of the hub inside the spinner...

Craig

|

I think Craig might be right. Here's a shot of mine for a comparison.

|

07-31-2008, 11:04 AM

|

|

Backdraft Racing Dealer

|

|

|

Join Date: Dec 2004

Location: North Haven,

CT

Cobra Make, Engine: Backdraft Racing

Posts: 5,121

|

|

Not Ranked

Not Ranked

Todd,

Do your wheels have recesses in the back for the lugs that hold the adapter on? If so you need to make sure the recesses are lined up with the lugs to allow the wheels to fully seat against the hub... this in essence makes "the snout longer" and you get the proper (read more) thread engagement.

If you need all this redone, stop in sometime. We do this on every car now.

|

07-31-2008, 11:12 AM

|

|

CC Member

|

|

|

Join Date: Dec 2002

Location: Apopka,

FL

Cobra Make, Engine: Building 289 Lemans / FFR mkIV chassis w/ Bruce Chervenak

Posts: 700

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Cashburn

Todd,

Do your wheels have recesses in the back for the lugs that hold the adapter on? If so you need to make sure the recesses are lined up with the lugs to allow the wheels to fully seat against the hub... this in essence makes "the snout longer" and you get the proper (read more) thread engagement.

If you need all this redone, stop in sometime. We do this on every car now.

|

I had to clearance my "pin holes" on the wheel so it would seat all the way down. If that's the difference in Todd's snout measurement  I'd think some major wobble action would be happening. |

07-31-2008, 12:14 PM

|

|

Super Moderator

|

|

|

Join Date: May 2001

Location: Fresno,

CA

Cobra Make, Engine: KMP 184/482ci Shelby

Posts: 14,445

|

|

Not Ranked

Not Ranked

Folks...some good stuff here, but we are getting just a bit away from the subject of this thread, which is on an Mfg's forum. Kirkhams soitenly don't use adaptors.

No smartass responses please...just respect the fact that this is an mfg's forum.

__________________

Jamo

|

07-31-2008, 12:43 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Posts: 1,330

|

|

Not Ranked

Not Ranked

Jamo's right. I'll start a new thread called "spinners". I'm sure it will the first of its kind  |

07-31-2008, 03:54 PM

|

|

CC Member

|

|

|

Join Date: Sep 2006

Location: Tampa,

fl

Cobra Make, Engine: Kirkham #473 427 every option, Keithcraft aluminum FE 482 ci. Mass Flo FI. Tremec TKO 600.

Posts: 260

|

|

Not Ranked

Not Ranked

Jamo, copyright infringement?

Jamo, copyright infringement?

Quote:

Originally Posted by Jamo

Folks...some good stuff here, but we are getting just a bit away from the subject of this thread, which is on an Mfg's forum. Kirkhams soitenly don't use adaptors.

No smartass responses please...just respect the fact that this is an mfg's forum.

|

Didn't WC Fields copyright "soitenly" or was it Larry Mo or Curly? |

07-31-2008, 03:54 PM

|

|

Super Moderator

|

|

|

Join Date: May 2001

Location: Fresno,

CA

Cobra Make, Engine: KMP 184/482ci Shelby

Posts: 14,445

|

|

Not Ranked

Not Ranked

TB, thank you sir.

Murph...the original Curly.

__________________

Jamo

|

07-31-2008, 04:17 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Gents,

I do not mean to rain on anyone's parade or seem brash or abrupt when I say the following as I mean no offense to anyone. No one knows everything and we all learn together (at least I hope so). Hopefully I can shed some light on the subject.

I have seen more tequila on this thread than I have in many a thread combined. If any more appears, some politician will figure out how to put a vice tax on it.

When Jamo commented on "centrifugal force" wanting to unscrew the knock offs I decided he must have had an EMPTY bottle of tequila beside him before posting.

In reality, the direction of the threads is absolutely inconsequential as to whether or not your nuts nut come off!.

It makes NO difference which direction the threads run--right or left on EITHER side of the car.

Wing nuts come off for one reason and one reason only...they are not installed with enough clamping load on the wheel. Now, that said the level of "tightness or clamping load" required certainly varies with myriad reasons that would take me 20 pages to explain. Suffice it to say, an incredible amount of torque is required to develop the proper clamping load if you have sloppy holes in your wheels, your drive pins are under-sized or loose, or the taper on your wing nut-to-wheel interface is wrong as the point contact between the wheel and the nut will yield and then your nuts will be loose. (This is NOT an exhaustive list of all the innumerable things that can go wrong, by the way). On the other hand, NO torque (or clamp) is needed to keep a wing nut on if the wing nut is welded to the hub because it galled (a sad situation I have seen more than once--usually with stainless knock offs--but thankfully not one I have seen for years.)

To some of you, this may seem shocking. "WHAT, the direction of the threads doesn't matter!?", you say! "You must have an entire CASE of empty tequila beside you--along with some "happy weed" to boot to post such a thing! EVERYONE knows I have right hand and left hand nuts for a reason! There MUST be a reason--or, why would they DO it?"

Before you bust out the pitch forks (or more tequila), let me explain. The wheel is not held on by the DIRECTION of the threads per se--but by the clamping load applied BY the threads. The direction the threads run is completely immaterial to the clamping load the threads apply. (Just ask any poor soul who has had some unmentionable body part in a thumb screw if he (or she) asked the senor inquisitioner dude which way the devise was threaded before he "converted" to Christianity.) I am sure you would all agree with me on that. In fact, if you were to press a sleeve onto the hub with NO threads, it would do an equally satisfactory job of retaining the wheel (with the proper clamping press fit, of course). We only use threads for the convenience of being able to take the wheels on and off--hopefully only when we want to--or, for "convincing" people they really should convert.

To give you an idea of how much clamping force threads can (and do) generate, I post the following picture. Notice those huge I beams are BENT

As you can see, we are pressing on the threads (in an attempt to elastically fail the threads in a destructive test) with around 22 tons. Our press ran out of press before our nuts ran out of clamp. The threads were fine after our test as 22 tons was sufficient to convince me of such.

I post the following link so you can see how much standard threads clamp. The diameter of a Cobra hub is about 2.3 inch by the way.

http://www.coxhardware.com/usefulinf.../7_btorque.htm

Now, if you don't belive me (and you shouldn't without going through a careful thought experiment of your own) then think of a harmonic balancer. The harmonic balance is held on with NO threads! It is only held on with the clamping load of the harmonic balancer bolt.

As for the knock off and the wheel rotating at different speeds...I think more tequila has been involved (and quite possibly an enormous amount of happy weed--California medical variety only, of course. If the nut is properly tightened, then it is absolutely IMPOSSIBLE for the wheel and the nut to move at different angular velocities. If you think about it, the furthest out atom on the aluminum of the the rim is moving at a higher circumferential velocity to the very next atom closer to the center of the rim--but there is NO relative movement between them as their ANGULAR VELOCITIES are identical. There couldn't be a difference in "w" (w=omega=angular velocity) as the rim is not tightening or loosening itself together or apart. If the nut is loose, then of course, all bets are off. The wheel can be moving at 2000 rpms and the nut at 0--where in you will very soon be in for a change of underwear.

Another thing to remember is you can brake approximately as fast as you can accelerate in a Cobra (even though we would all like to think otherwise). So, wouldn't braking have just the same detrimental effect on the tightening or loosening of the wing nut as accelerating according to the above "tequila arguments?" So, do we make the threads "self tightening" for braking or for accelerating; or, do we just never use the brakes...  (The choice of some of the guys I have been on the track with  ). Remember, an F1 car can decelerate at some 4 g's and they certainly can't accelerate at 4 g's so for the Jamo empty bottle argument F1 should make make the threads REVERSE of what they are on our cars...  Alas, they don't. Some of the sharp guys on this thread may now say, "HEY! don't F1 guys use right and left hand threads!!!! HA!!!! You are BUSTED!!!"

Yes, they do...but why? Well, I have had LONG conversations with Metalore (the maker of almost all F1 and Indy car wheel nuts and hubs) and with the late Carroll Smith...

You know why they do it???

We all finally decided (in my deepest bass voice with a violin under my chin)...

"TRADITION, TRADITION!"

Yes, tradition. You see, that is the way they have always done it; so, that is the way they keep doing it. You see, pit crews don't change regularly and the guy on the right side of the car is trained to put on left-hand threaded nuts and the guy on the left side likes to use his right hand on his nuts. There never was a time for the team to change them--or a reason as right-hand-threads are the same weight as left-hand-threads.

Now, before this post gets too long and some of you run out of tequila, I should mention that temperature and many, many other things contribute to your nuts loosening up. I imagine the above guy has a sloppy wheel on his drive pins--something I have seen WAY too often. If there becomes relative movement because of a LACK of clamp, then who knows what can happen. Bottom line, make sure your nuts are tight! And if you are a Kirkham owner with the push button hubs, drill your hubs and SAFETY WIRE YOUR KNOCK OFFS UNTIL WE CAN FIGURE OUT WHAT IS GOING ON! Remember, if you don't tighten your nuts properly, you just might loose more nuts than you intend to!

Besides, safety wire looks cool.

As Issac Newton said, "The ONLY reason I see further is because we stand on the shoulders of giants."

David

ps. Murphy, your nuts left today!

Last edited by David Kirkham; 07-31-2008 at 06:47 PM..

|

07-31-2008, 04:19 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

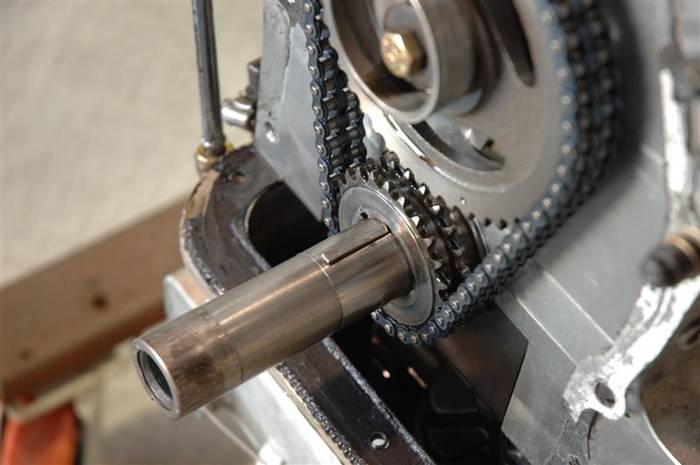

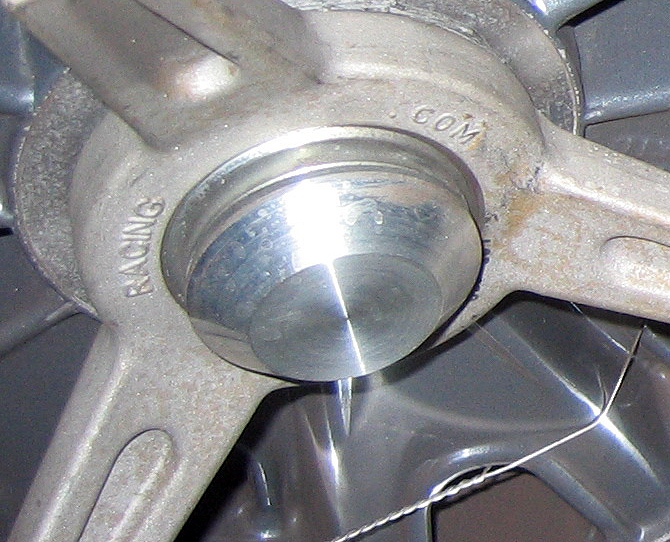

This is what happens when the harmonic balancer bolt is not tight. Notice the key is NOT in one of the 3 notches of the timing chain. This is an expensive lesson in right-hand vs. left-hand threads and why you should tighten ALL your threads so your nuts don't fall off.

Last edited by David Kirkham; 07-31-2008 at 06:54 PM..

|

07-31-2008, 04:21 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Another view of the sad day.

Last edited by David Kirkham; 07-31-2008 at 06:55 PM..

|

07-31-2008, 04:22 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Posts: 1,330

|

|

Not Ranked

Not Ranked

WOW! ...now where's my happy weed. Now, can you tell them its OK to drill the wheel for the safety wire?  |

07-31-2008, 04:24 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

And yet another view of why we tighten our nuts and bolts. I guess I should add here a harmonic balancer takes TREMENDOUS abuse...that is why it is there. The explosions of the pistons are constantly vibrating and torquing the balancer trying to shake it literally off the crank...yet, you don't see any threads here. CLAMP is why it is held in place.

Last edited by David Kirkham; 07-31-2008 at 06:56 PM..

|

07-31-2008, 04:25 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here you can see the key sheared from the beating (extreme far left side of the key way). Then the valves bent and the driver was left wondering why he had no more power on turn 4 a Miller Motorsports...

|

07-31-2008, 04:28 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by TButtrick

WOW! ...now where's my happy weed. Now, can you tell them its OK to drill the wheel for the safety wire?  |

You can drill the wheel (depending upon where you drill it) but we don't drill the wheel, we just wrap it around a spoke.

David

|

07-31-2008, 05:51 PM

|

|

Super Moderator

|

|

|

Join Date: May 2001

Location: Fresno,

CA

Cobra Make, Engine: KMP 184/482ci Shelby

Posts: 14,445

|

|

Not Ranked

Not Ranked

Well...you can't spell worth a damn either. "weather" instead of "whether" so bite me.

You might want to post this...this...theory...of yours on the "Spinners" thread Mr. Buttrick started on all Cobra Talk. Personally, I know from personal experience that given enough tequilla and a dance floor...centrifugal force does in fact work.

__________________

Jamo

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:58 AM.

|

|

I'd think some major wobble action would be happening.

I'd think some major wobble action would be happening.

(The choice of some of the guys I have been on the track with

(The choice of some of the guys I have been on the track with  ). Remember, an F1 car can decelerate at some 4 g's and they certainly can't accelerate at 4 g's so for the Jamo empty bottle argument F1 should make make the threads REVERSE of what they are on our cars...

). Remember, an F1 car can decelerate at some 4 g's and they certainly can't accelerate at 4 g's so for the Jamo empty bottle argument F1 should make make the threads REVERSE of what they are on our cars...  Alas, they don't. Some of the sharp guys on this thread may now say, "HEY! don't F1 guys use right and left hand threads!!!! HA!!!! You are BUSTED!!!"

Alas, they don't. Some of the sharp guys on this thread may now say, "HEY! don't F1 guys use right and left hand threads!!!! HA!!!! You are BUSTED!!!"

Linear Mode

Linear Mode