Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

31 |

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

05-21-2010, 05:29 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: Huntington, CT,

CT

Cobra Make, Engine: engineer

Posts: 22

|

|

Not Ranked

Not Ranked

Scratch Build

Scratch Build

Mark,

Ah, the picture clears that up.

I'm not aware of any shrinking dies that would access that shape.

I think the plan you and your son came up with is ideal. Forming one flange will make it much easier to clamp the part in a form block.

No gutters on my project yet.

|

09-26-2011, 08:32 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

Hi All. I haven't posted any thing on my build in a while. I have been working on it slowly. I am getting ready to go to Metal Meet in October and take the buck and make some panels. I have been busy filling in some areas of the buck with polyurethane foam, one layer of fiberglass cloth, skim coat of kittyhair and finishing it off with good old bondo. This lets me see if the lines are what they need to be. I have been making minor changes to make the lines on the buck flow more smoothly. When I finish getting this part smoothed up and primed, I will be able to make flexibls shaped patterns and finally be able to start shaping some aluminum panels for body skins.

Still needs filler and priming

Last edited by MAStuart; 09-27-2011 at 09:47 PM..

Reason: post pics

|

09-26-2011, 10:25 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

Excellent work. I am anxious to follow your progress.

Jim

|

09-27-2011, 06:46 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Manchester,

MO

Cobra Make, Engine: Hurricane - FE

Posts: 627

|

|

Not Ranked

Not Ranked

Progress

Progress

Mike

Good to see your progress. Looks like things have begun to come together since I was up to your shop.

thanks for the hospitality

Paul Proefrock

|

09-27-2011, 08:17 PM

|

|

CC Member

|

|

|

Join Date: Apr 2005

Location: Tucson,

AZ

Cobra Make, Engine:

Posts: 5,391

|

|

Not Ranked

Not Ranked

Really impressive Mark!

Larry

__________________

Alba gu brąth

|

09-27-2011, 10:44 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

Aera partly fill with pink foam board and a piece of aluminum to block off the rest of the aera

This much 2 part urathane foam

After mixing and pouring into cavity

After foam expands and form stripped

After all aeras filled

Tools used to ruff foam in

Pic after epoxy and glass cloth also aluminum panel sitting in place

Shot of rocker I made in place

Looking inside buck at rocker ......nice fit

More later |

09-27-2011, 11:25 PM

|

|

CC Member

|

|

|

Join Date: Mar 2008

Cobra Make, Engine:

Posts: 85

|

|

Not Ranked

Not Ranked

Hi, Looks nice work. Could you say what kind of alloy you use?

|

09-28-2011, 05:42 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

.060 3003 H14 aluminum

|

09-28-2011, 06:59 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Manchester,

MO

Cobra Make, Engine: Hurricane - FE

Posts: 627

|

|

Not Ranked

Not Ranked

Metal Meet

Metal Meet

Mike

Sent you a PM about Metal Meet

Paul

|

09-29-2011, 12:05 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2008

Location: Jacksonville,

FL

Cobra Make, Engine: VSE alum. frame, FFR carbonfiber body (under construction)

Posts: 293

|

|

Not Ranked

Not Ranked

Very inspiring!

Is there any problem with the urethane expanding with enough force to warp the jig?

Keep up the good work and keep the pictures coming!

John

|

09-29-2011, 06:50 AM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

The foam I used is what they called 2 1/2 pound density. 2 1/2 pounds per cubic foot.

As long as it is not completely enclosed I dont think it will be a problem. Mark

|

11-29-2011, 08:56 PM

|

|

CC Member

|

|

|

Join Date: May 2003

Location: Bugtussell,

AR

Cobra Make, Engine: FFR 4859GT Spyder GT 414W EFI

Posts: 257

|

|

Not Ranked

Not Ranked

Howdy Mark,

Pretty neat!

Any updates on your build?

Paul

__________________

"A veteran - whether active duty, retired, national guard, or reserve - is someone who, at one point in his or her life, wrote a blank check made payable to The 'United States of America', for an amount of 'up to and including my life.'" (Author unknown)

|

12-29-2011, 01:00 PM

|

|

CC Member

|

|

|

Join Date: Feb 2003

Location: Plymouth,

MA

Cobra Make, Engine: MidStates, 351C, 4spd, 9"

Posts: 400

|

|

Not Ranked

Not Ranked

Hi Mark,

Sorry to post out of sequence, but is there any chance you could fab the channel by using a tipping wheel on a beadroller?

Love the scratchwork! Very excited it's a coupe. Keep rollin'

Mike.

__________________

"It's not about getting from point A to point B. It is the point"

-J. James

M. Krause

1.508.944.3368

|

01-26-2012, 12:58 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

Sorry about not posting in a while.

Sorry about not posting in a while.

Paul, Mike,

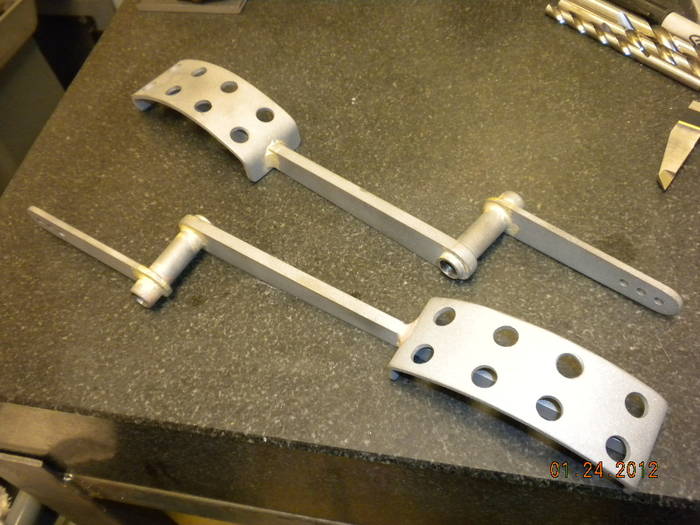

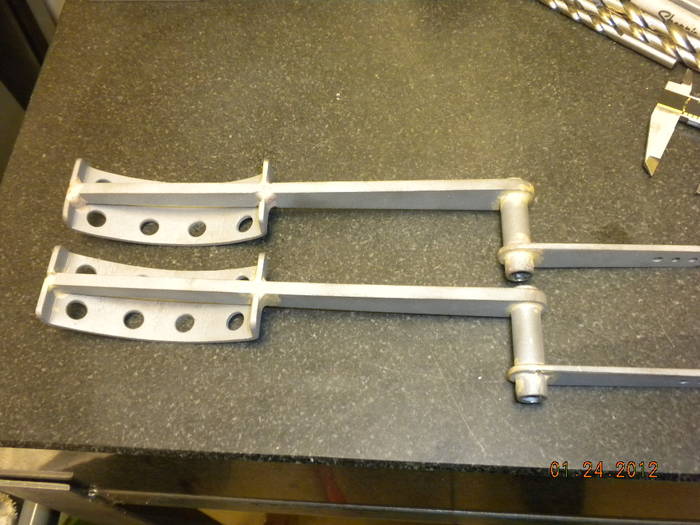

Thanks for your interest in my project. I have been slowly getting some work done on it. Not very good about posting about it. I have lots of pictures of progress and will be posting some information soon on how I made the gutters and other parts. Meanwhile here are a couple of shots of a pair of gas pedals that I made this last weekend, for the coupes.

Last edited by MAStuart; 01-26-2012 at 01:03 PM..

Reason: change pic size

|

01-28-2012, 05:53 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

They look nice. Period details like brazing them together are very cool.

|

01-29-2012, 09:09 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

Gas pedal

Gas pedal

Thanks Nick. At one time I thought I saw a ad for a used original 427 rear lower control arm and some of it appeared to be brazed. Was there parts that were brazed on original cars? Thruth be told my welding lately sucks. It takes the fun out of building nice parts. When the part looks good only to put a big crappy looking weld on a part like this. I thought brazing was the way to go. Mark

|

01-29-2012, 09:48 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2008

Location: Jacksonville,

FL

Cobra Make, Engine: VSE alum. frame, FFR carbonfiber body (under construction)

Posts: 293

|

|

Not Ranked

Not Ranked

Keep building up the weld......then grind it down nice and smooth! Works for me (as long as you're getting good penetration).

|

01-29-2012, 10:21 PM

|

|

CC Member

|

|

|

Join Date: Mar 2009

Location: Mendota,

IL

Cobra Make, Engine:

Posts: 697

|

|

Not Ranked

Not Ranked

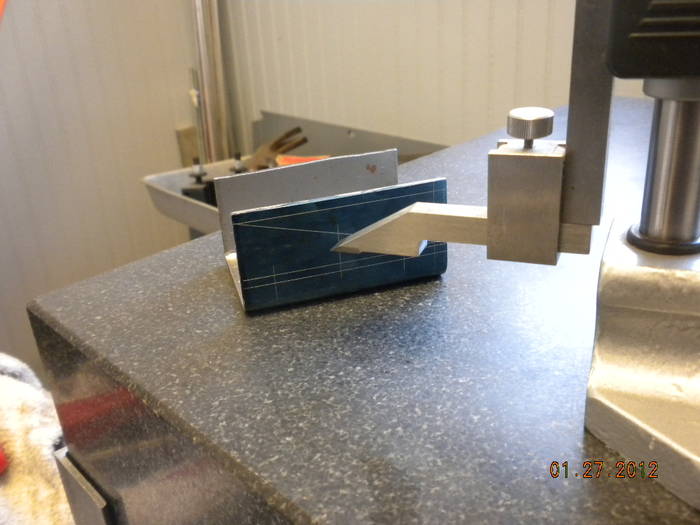

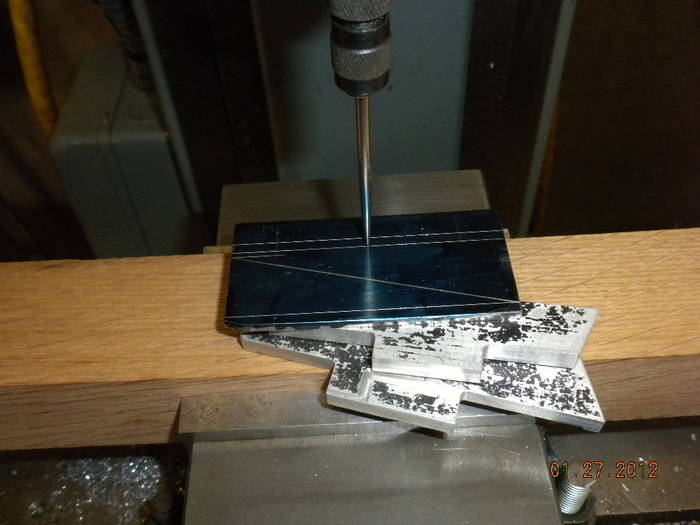

Gas pedal mounting bracket

Gas pedal mounting bracket

Today I built some mounting brackets for the gas pedal. These are bolted to the side of the pedal box.

The proccess I used to build them was. First I cut a blank to the width It needs to be but I left it longer than needed. Next I took a piece of scrap of the same thickness and scribed lines where the bends should be and bent in the order that the real bracket will be bent. I then measured the piece, in this case the lines were scribed at 2 inches, the actual measurement of the part was 1.900. Now I know I need to add .100 to my measurement. Now I scribe my lines at 2.100 on my part and bend, using this method you can usually have a part that measures within a few thousands of what you want it to be. By the way, I am bending this in a Di Acro 24in box and pan brake rated at 16 gauge. Bending 11gauge is called abusing it.

Next, I put layout bluing on the part and used a digital height gauge and layed out where the holes are to be drilled and the part needs to be trimmed.

Next I clamped it in the mill and use a wiggle indicator to dial in where the holes need to be drilled.

Part is center drilled and then drilled to size and then repeated for the other holes.

For the rest of the process I didn't take any pictures. The part was cut on all cut lines with a delta 4x6 band saw. A little file work to clean up sharp edges and you end up with a nice part. Using the same process make and bend the throttle stop bracket and weld it to the other part, throw in the bead blaster and clean it up. It is then ready for paint. I will post some more when I get a chance. Mark

|

01-30-2012, 03:15 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Sep 2000

Location: Holderness, NH, US of A,

NH

Cobra Make, Engine: CSX 4772 old iron FE

Posts: 5,499

|

|

Not Ranked

Not Ranked

I saw those control arms. They may have been made in England, from original parts by the original guy in the original factory but they were originally welded together not brazed on suspension. There is a pretty good formula for calculating stock gain on bends based on angle, thickness, bend radii etc. Try using a material thickness for a 90 and see how close that is. The way we explain machinery abuse is it can bend 4 ft of 16 ga so it can bend 2 ft of 11 ga, same thing only different ha ha yeah right ;-)

Good work and progress.

|

01-31-2012, 01:02 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Allen,

TX

Cobra Make, Engine: Werk77 289FIA

Posts: 1,295

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by mickmate

The way we explain machinery abuse is it can bend 4 ft of 16 ga so it can bend 2 ft of 11 ga, same thing only different ha ha yeah right ;-)

Good work and progress.

|

The difference is, you need 1.9 t/ft (16Ga) or 9.2 t/ft (11Ga) - with a 0.875 V.

The 50% does not quite cut it hehe

__________________

Scratch build 289 FIA see the Scratch builder forum on CC - sold

DRB GT40 MK1 red #49- sold

FF5 Mk4 #7733 302/T5/IRS - dark blue - sold

FF5 MK4 #7812 427/TKO/IRS - Guardsman Blue - sold

FF5 MK4 #8414 501/TKO600/48IDA Ollie the Dragon #91 - sold

FF5 Daytona Coupe 347/TKO/IRS Homage CSX2299 Viking Blue - sold

SPF 2063

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:02 PM.

Links monetized by VigLink

|