Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2025

January 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

12-11-2006, 08:46 PM

|

|

CC Member

|

|

|

Join Date: Jul 1999

Location: Ottawa Lake , Mi USA,

Posts: 96

|

|

Not Ranked

Not Ranked

AN fittings

AN fittings

Does anyone have any advice on using AN fittings with braided hose? I installed a sump kit in my tank and want to go with the AN and braided lines. How do you get the braiding into the back of the fitting without it all bunching up? Jemannie Chistmas!

Steve

|

-

Advertising

12-11-2006, 09:36 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Glendale,

AZ.

Cobra Make, Engine: Cobray-C3, The 60's body lines on todays chassis technology

Posts: 2,302

|

|

Not Ranked

Not Ranked

Steve ,

The secret to no hassle when putting hose ends together is how the hose is cut!!!

1. wrap hose with electrical tape along about 3 to 4 inch's very tightly in a spiral manor so cut comes out in center of taped area.

2. cut hose with a shear or large bolt cutter, if not possible or working with larger hose use a metal cut-off wheel in a 4 inch grinder and cut slowly so each wire is not pulled out of position.

3. after hose is cut inspect for loose or stray wires and trim with electronic type or flush cut dikes.

4. remove tape from hose and twist or thread nut over hose. Push last bit of hose into the nut with thumb nail if needed.

5 apply anti-seize to threads on hose fitting end and assemble and tighten.

6. use AN wrench's or apply tape to adjustable wrench face so it will not mark the fittings/nut

|

12-11-2006, 10:11 PM

|

|

CC Member

|

|

|

Join Date: Mar 2003

Location: PVE,

CA

Cobra Make, Engine: ERA 289 FIA #2027, 65' 289" PS wheels

Posts: 345

|

|

Not Ranked

Not Ranked

In cutting many hoses for my friends Backdraft with a heat exchanger...

We used a contractor type "chop saw" with a cutting "disc"..I am forgetting the correct name but its looks like a resin based abrasive disc.

This one was about 10" inches in diameter.

Best results from VERY TIGHT wrapping with duct tape...makes it easy to mark the cutting point...one of us held the hose in place and smoothly lowered the cutoff saw, and the other pulled very gently untill the last little bit, then popped the hose back.

Nice clean cuts.

We had die blocks to hold the hose as the threaded coupling was screwed on.

You can do it...but if you are close to an Earls's, Russels distributer and shop...can measure well...let them cut and install the fittings.

If you have to, do it one or two lengths at a time...you will get better at measuring and marking your cuts.

The short lengths are very unforgiving...it doesn't like to bend, the long cuts are not critical...

Pete

__________________

ERA 289 #2027

|

12-12-2006, 08:18 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

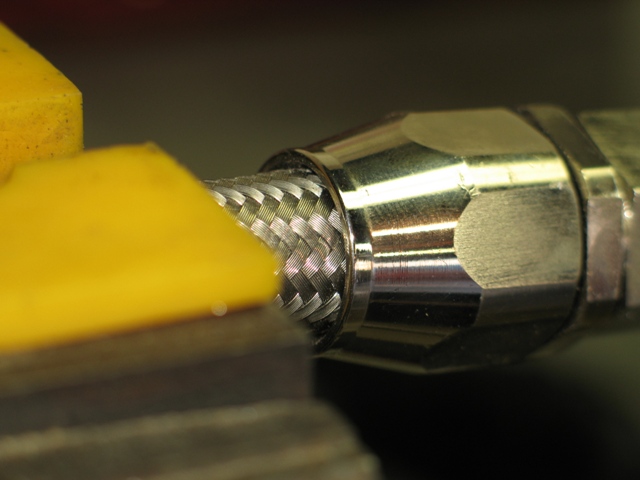

If you look closely at the Red part of the hose end....( the part that holds the hose on the fitting)......

You will see a small line on the corner of the hex of the Red hose end.....

That is the place to mark your hose to cut.....

__________________

Morris

|

12-12-2006, 08:23 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

You can see here ..... you mount the hose end to the hose...... then hose to the connector on one end.......and then put the hose in position where you want it to be......

Then install the Aeroquip hose end you are going to use ....and find the line mark on the hose end fitting ......that is where you mark your hose.....to cut.....

__________________

Morris

|

12-12-2006, 10:33 AM

|

|

CC Member

|

|

|

Join Date: Apr 2006

Location: Los Angeles,

ca

Cobra Make, Engine: Hurricane Motorsports, 427w

Posts: 439

|

|

Not Ranked

Not Ranked

Jeff's "6 Step Program" is right on. One thing I'd add is to insert the hose into the AN fitting quickly after removing the tape. The braid starts to curl and spread out some after the tape is removed. 4" grinder with cut-off wheel always worked well for me.

Jeff, also like the idea of taping the wrench to protect the fittings! Much better than investing in those high dollar AN wrenchs.

Matt

|

12-12-2006, 10:39 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,285

|

|

Not Ranked

Not Ranked

I use a porta-band saw. I just wrap 2 or three layers of electrical tape over the area I want to cut and let the band saw do the rest. I clean up any wild strands on the bench grinder. Never a problem.

__________________

Too many toys?? never!

|

12-12-2006, 11:04 AM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Crystal Lake,

IL

Cobra Make, Engine: Everett-Morrison, 434 cid

Posts: 977

|

|

Not Ranked

Not Ranked

Although pricey, by far the easiest and cleanest way to cut hose is with a braided hose cutter. Because the hose cutter bends the braided cover inward there is no need for tape and the cover won't fray. Don't try bolt cutters as they do not have the shearing action necassary to make a clean cut.

The AN wrenches are intended for installation of the hoses. Using aluminum AN wrenches to assemble hose ends will cause the jaws to spread if you assemble a lot of hoses... better to use tape and steel wrenches.

Use the Aeroquip vise jaw inserts to hold the fitting during assembly.

With the proper tools assembling hoses is a snap.

Scott

Last edited by scottj; 12-12-2006 at 02:51 PM..

|

12-12-2006, 11:09 AM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Broken Arrow. OK ( South Tulsa), USA,

OK

Cobra Make, Engine: 66 COBRA FE 427 /4SP. (HCS Coupe w/ 408 Stroker and TKO 600 -sold)

Posts: 5,595

|

|

Not Ranked

Not Ranked

Morris,

As usual you provide pictures with good instructions. I use a cut off wheel as well but I like to use the white nylon stranded strapping tape. Another thing to add is that no matter what you use to cut your hose with be sure and clean the inside of your hose before your final connection. I like to use a coat hanger with a piece of cotton soaked in mineral spirits attached and then an air blow gun.

Clois

__________________

Sunshine, Asphalt and no stop signs...Perfect

"Let's roll"

"Be part of Something Good

......Leave Something Good Behind!"

from CD "Long Road Out of Eden"

|

12-12-2006, 12:29 PM

|

|

Banned

|

|

|

Join Date: Oct 2003

Location: Yorba Linda,

CA

Cobra Make, Engine: SPF w/392CI stroker

Posts: 3,293

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Clois Harlan

Another thing to add is that no matter what you use to cut your hose with be sure and clean the inside of your hose before your final connection. I like to use a coat hanger with a piece of cotton soaked in mineral spirits attached and then an air blow gun.

Clois

|

Good point. As careful as I am when doing this, I managed to miss a small piece of wire filament when I recently changed over to -8 fuel line. Got about one block from the house and the carb flooded over. The filament hung open the primary needle & seat. Better to have been stuck there then ingested into the engine.

Also, no one has mentioned name brands. I personally always insist on Aeroquip. You pay a little more but their quality is unsurpassed. I don't like to skimp on fuel and oil lines/fittings...too much to risk.

Great thread and awesome photos from Morris.

Regards,

-Dean |

12-12-2006, 12:47 PM

|

|

CC Member

|

|

|

Join Date: Mar 2000

Location: Fairfield, NJ, USA,

NJ

Cobra Make, Engine: A & C, 351W, Tremec 3550. Exiled Member: Club Cranky

Posts: 5,897

|

|

Not Ranked

Not Ranked

I used to use a dremel with cutoff wheels but upgraded to a mini sawzall, air powered. Great for fine cuts in fiberglass and metal too. 101 uses....

Roscoe

__________________

Roscoe

"Crisis occurs when women and cattle get excited!"....James Thurber

|

12-12-2006, 12:58 PM

|

|

CC Member

|

|

|

Join Date: Nov 2004

Location: Rehoboth Beach,

DE

Cobra Make, Engine: SPF #2459 460ci, TKO 600

Posts: 45

|

|

Not Ranked

Not Ranked

Check out www.koultools.com , got a set last year, no more bleeding fingertips. Doesn't matter how badly raged the end is, just goes right into the fitting.

__________________

Thom

|

12-12-2006, 02:27 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Aug 2001

Location: Rocky River, Ohio,

OH

Cobra Make, Engine: Everett-Morrison, 347 Tri-power Stroker

Posts: 678

|

|

Not Ranked

Not Ranked

Have to agree with Scott,

Pony up and buy a braided hose cutter; $39.95 at Summit Racing SUM-900040. Just don't use it for anything else, (like trimming bushes, trees, etc.)

For me, it works much better than all the taping and cutting mentioned above. Plus, once one side is put together and installed, I can cut to length inside the engine compartment.

- Dan |

12-12-2006, 03:49 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2004

Location: St. Louis,

Mo.

Cobra Make, Engine: 427 S.O. Dual Quad / Cobra undecided

Posts: 1,380

|

|

Not Ranked

Not Ranked

I've got a method through trial and error that works pretty well for me, first I mount the hose in a soft jaws vice...

at which point I snug up a cable tie around it, not tight, just snug....

at this point I use a diamond cutoff wheel that is mounted on my Dremel and begin to cut the surrounding wrappping using the cable tie as a guide.

The cable tie keeps the braided wrappping tight against the outer hose while giving a nice flat even cut without any stray "fraying".

I then oil the braiding/hose and begin to slip the collar of the fitting on to the hose, the cable tie will slip back along the hose as the collar pushes against it keeping any strands from popping up...

once I have filled lthe collar end with hose I then screw the oiled down tube into the hose with taped jaws of a crescent wrench until it reaches the position Morris showed in his shots...

Once completed I blow the finished hose out with compressed air and then run a soft cleaning brush from my gun cleaning kit down through the entire setup, there are a bunch of good techniques in this thread, this is yet another way to do it.

Last edited by lineslinger; 12-12-2006 at 03:56 PM..

|

12-12-2006, 04:08 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Cinnaminson,

NJ

Cobra Make, Engine: Cobra Fibercraft Bodies 427 S/C, 351W disguised as a 427.

Posts: 391

|

|

Not Ranked

Not Ranked

Lineslinger, very cool idea. I intend to try that trick the next time I do a braided hose. I like to use the aluminum jaws in my vise to hold the hose in place. When I twist on the nut sometimes I have to use a tiny screwdriver to help coax a couple of braided steel strands into the nut but once they are all inside the nut everything goes quite smoothly. I use Russell Hose Assembly Lube. That stuff is SLIPPERY. Just be sure all rubber residue is cleaned out of the hose prior to assembly. One more thing, to the best of my knowledge, only Aeroquip fittings have the notch on the nut to use as a hose length guide. The Russell fittings do not have that notch.

__________________

Political correctness is a doctrine, fostered by a delusional, illogical minority, and rabidly promoted by an unscrupulous mainstream media, which holds forth the proposition that it is entirely possible to pick up a turd by the clean end."

|

12-12-2006, 04:41 PM

|

|

CC Member

|

|

|

Join Date: May 2003

Location: Hudson Valley NY,

NY

Cobra Make, Engine: Backdraft, 302, Tremec 3550. #038

Posts: 863

|

|

Not Ranked

Not Ranked

Surprisingly in my line of work which is gaseous type fittings and plumbing, a notched nut indicates left hand threaded. Just look at any propane barbecue fitting. I'll have to keep that one in mind.

__________________

Kids in the backseats cause accidents, accidents in the backseat causes kids ! Good reason to get a Cobra !!!

|

12-12-2006, 06:37 PM

|

|

CC Member

|

|

|

Join Date: Jul 1999

Location: Ottawa Lake , Mi USA,

Posts: 96

|

|

Not Ranked

Not Ranked

Wow, Thanks guys for all the help, WITH PICTURES! I should be able to get this now with the help on technigue. You guys are the greatest.

Steve

|

12-12-2006, 07:08 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Oct 1999

Location: Menomonie, Wisconsin,

Posts: 3,505

|

|

Not Ranked

Not Ranked

Great photos and advice. Could someone on the forum talk about what the designations mean -8, -6, etc?

Thanks

|

12-12-2006, 07:21 PM

|

|

CC Member

|

|

|

Join Date: Oct 2000

Location: Crystal Lake,

IL

Cobra Make, Engine: Everett-Morrison, 434 cid

Posts: 977

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Cal Metal

Great photos and advice. Could someone on the forum talk about what the designations mean -8, -6, etc?

Thanks

|

The dash number is the nominal hose inside diameter in sixteenths of an inch. The actual size is slightly smaller.

Scott |

12-12-2006, 09:05 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2001

Location: Evans,

CO

Cobra Make, Engine: NAF 289 FIA, 347 stroker with Weber 48's, building a '48 Anglia gasser, driving a '55 Chevy resto-rod

Posts: 3,119

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by scottj

The dash number is the nominal hose inside diameter in sixteenths of an inch. The actual size is slightly smaller.

Scott

|

As Scott said, also -AN fittings were developed initally for Military use thus designated -AN for Army/Navy.

__________________

"Breathe in... Breathe out... then move on with life. Lifes too short to sweat the small stuff"

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 11:46 PM.

|

Linear Mode

Linear Mode