Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2025

February 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

|

|

CC Advertisers

CC Advertisers

|

|

04-04-2007, 12:25 AM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

Fuel Return Line...How do you do it?

Fuel Return Line...How do you do it?

Ok, I want to run a fuel return line to my tank, but obviously I have to limit the amount of fuel that returns to maintain fuel pressure. So how do you do this? Do you run the standard 3/8 hose or whatever back to the tank, or a thinner line, or a restricted 3/8 or???? This is probably brain dead simple, but...well...I'm apparently brain dead!

Thanks for the help. |

-

Advertising

04-04-2007, 12:30 AM

|

|

CC Member

|

|

|

Join Date: Aug 2003

Location: San Diego,

CA

Cobra Make, Engine: BDR #455, KC427W, TWM-FI

Posts: 727

|

|

Not Ranked

Not Ranked

Same diameter hose but YOUneed to have a pressure regulator after the point wherE you want the pressure to drop (and start its return to the tank). Here is a FI pick of a setup:

http://www.twminduction.com/EFI/EFI-FR.html |

04-04-2007, 12:53 AM

|

|

CC Member

|

|

|

Join Date: Apr 2005

Location: Tucson,

AZ

Cobra Make, Engine:

Posts: 5,391

|

|

Not Ranked

Not Ranked

Yeah, the way to do it is from a regulator. The one from Holley (for carb cars) has two outlets and one inlet. Just route the second line back to the tank. That's the way I did it on my old Camaro.

Larry

|

04-04-2007, 08:10 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

Brent

Since you have a Kirkham...... you will have to drop the fuel tank and weld another bung in the fuel tank so you can return the fuel back to the tank and not interfere with the venting of the tank......

Some will say use the vent and put a tee in the vent line..... not really a good idea.....

If you want to track the car....then you will need a collector for the returned fuel to enter into....... which is where the pickup is ...so the fuel is circulated....and no it does not get heated....

Use a regulator as suggested to regulate the fuel pressure at the carb ....and use a fuel line that is equal to or larger then the pressure side....

Morris

__________________

Morris

|

04-04-2007, 08:32 AM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Austin, TX, US,

TX

Cobra Make, Engine: Exact427

Posts: 70

|

|

Not Ranked

Not Ranked

Return line sizing

Return line sizing

There is a huge amount of information on the Internet... and the more you read the more confusing it becomes. What follows is a summary.

Many of those presenting "factual" information are SELLING high performane pumps or regulators... its to their advantage to be conservative... recall the muscle cars of the 60's ran 3/8" lines with the HP engines, no return lines, no engine compartment regulator... just a mechanical pump. Of course most street cars will NEVER see continuous usage at max fuel draw, just bursts of action... so guess it also depends on usage, street terror or NASCAR.

To prove this data is REALLY CONSERVATIVE, look at a Ford 190 liter/hr (50 GPH) in tank fuel pump. Built with 3/8" output and 1/4" return line, this violates the recommended sizes below...

Seems the feed line size is related to the HP (*Mallory site has original data):

Up to 500HP 3/8 -6AN

Pump size GPH is either .23 x HP for a dead head or .17 x HP with a return.

500HP x .23 = 115 GPH fuel pump dead head

500HP x .17 = 85 GPH pump with regulator

Return line is dependent on Pump size as worse case is idle and you need to be able to easily bleed off enough fuel to allow the regulator to work. At WOT there is little fuel returned to the tank, thus the return size is unimportant.

Up to 90 GPH 3/8 -6AN

I'd guess the one size smaller return line is used on production cars mostly to distinguish it from the fuel line, i.e. idiot proof!

Seems your 3/8" fuel line would have a 3/8" return line (seems normal to use one size smaller if the pump isn't oversized, guess the assumption is some percentage of the flow is used even at idle and thus the return doesn't present a restriction). I see no reason to ever make it larger, though it wouldn't hurt anything.

One important item is to ease the feed to the pump, if you look at the system flow numbers running the next larger size (in this case -8An or 1/2") line from the tank to the pump is an excellent idea. Then use the 3/8" or -6AN for the longer main line and a 3/8" (or 5/16") line for the return.

A professionally modified Kirkham tank I owned had the original bung bumped up a size with a 1/2" pickup tube and a second large bung installed for the return line.

Last edited by Roger Bolick; 04-16-2007 at 10:57 AM..

|

04-04-2007, 08:40 AM

|

|

CC Member

|

|

|

Join Date: Sep 2001

Location: Danville,

CA

Cobra Make, Engine: CSX 6079 482CI CSX cross ram

Posts: 1,354

|

|

Not Ranked

Not Ranked

Cant you just tee on the suction side of your mech pump? Instead of going all the way back to the tank?

|

04-04-2007, 08:53 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: San Diego,

CA

Cobra Make, Engine:

Posts: 2,979

|

|

Not Ranked

Not Ranked

Brent many people have just tapped into the filler hose with a fitting for the return line so they wouldn't have to weld a new bung in the tank.

__________________

Remember, It's never too early to start beefing up your obituary.

|

04-04-2007, 09:58 AM

|

|

Administrator

|

|

|

Join Date: Jan 1999

Location: Duvall,

Wa

Cobra Make, Engine: KMP286, Shelby 482, Webers, 593HP

Posts: 4,162

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by xlr8or

Brent many people have just tapped into the filler hose with a fitting for the return line so they wouldn't have to weld a new bung in the tank.

|

Oh, what a great idea! I was having visions of welding on a kaboom tank....errrr..gas tank.

The other idea that seems logical is suction side of the hose between the pump and tank.

Morris, I was thinking about the T at the vent you mentioned. Thanks for the recommendation for not doing that. |

04-04-2007, 10:18 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Virginia Beach, Va & Port Charlotte, Fl.,

Posts: 2,287

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Brent Mills

Ok, I want to run a fuel return line to my tank, but obviously I have to limit the amount of fuel that returns to maintain fuel pressure. So how do you do this? Do you run the standard 3/8 hose or whatever back to the tank, or a thinner line, or a restricted 3/8 or???? This is probably brain dead simple, but...well...I'm apparently brain dead!

Thanks for the help. |

Hey Brent,

Here's the template I used, as I just changed my system to a return system. Jegs has a sweet return regulator (their own brand) that works like a champ. Size your return line the same size as the supply.. I used all 8AN (1/2").

http://www.holley.com/data/Products/...199R7914-3.pdf

Dave

__________________

Too many toys?? never!

|

04-04-2007, 10:28 AM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Austin, TX, US,

TX

Cobra Make, Engine: Exact427

Posts: 70

|

|

Not Ranked

Not Ranked

kaboom

kaboom

Have you dropped the tank yet?

The fuel pickup is welded into a cover plate on the front of the tank. Its removable and is the best place for the return fitting. No "kaboom", you just unscrew it and take it to a welding place. Pickup line is attached. Just add a second one. Folks have done this to activate the "reserve" feature (2nd pickup 1/2" shorter). You're NOT welding on the tank. (assume you're talking the 42 gallon tank, unsure how the others are arranged)

This way the two lines can run together, you're returning the fuel to the low point and you're not splashing fuel down the filler piece and depending on a rubber hose to get it back into the tank!

See KMP259 technical photos for details.

If you're into originality, the comp cars had two cloth braided lines running forward... just reverse the flow on the 2nd line...

Last edited by Roger Bolick; 04-04-2007 at 10:36 AM..

|

04-05-2007, 02:49 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: Las Vegas,

NV

Cobra Make, Engine: Classic Roadster; 351W

Posts: 743

|

|

Not Ranked

Not Ranked

You want to run a big as possible return line (at least as big as the feed line anyway). The regulator will take car of the pressure. But, if the return line is too small, it will result in a back pressure. Lets say the back pressure is 3 psi. So you set the regulator for another 4 psi for a total of 7. This is fine for crusing. However, when you step into it and start using all the fuel, the 3 psi restriction goes away because you are now using all the fuel - no fuel left to be return. When this happens, the regulator drops to 4psi - what you actually set it at. Obviously this will create a problem of not enough fuel pressure at WOT. Clear as mud? I think the Barry Grant website has some really good tech on the subject

|

04-05-2007, 08:30 PM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: TACOMA,

WA

Cobra Make, Engine: Everett Morrision FE 427 so 2-4s

Posts: 2,025

|

|

Not Ranked

Not Ranked

I used a Barry Grant diaphram adjustable fuel log. It returns any exsess fuel after meeting need for desired presure . I had a bung welded into the bottom of my tank. If acsess to the top would have been better I would have made a tube that extended almost to the bottom of the tank to keep the return submerged and reduce airation.

__________________

Mike H

|

04-05-2007, 10:15 PM

|

|

CC Member

|

|

|

Join Date: Nov 2000

Location: Tucson,

Az

Cobra Make, Engine: Superformance 427 Side-Oiler

Posts: 2,156

|

|

Not Ranked

Not Ranked

Back the bus up.................

Back the bus up.................

Quote:

|

Originally Posted by Roger Bolick

There is a huge amount of information on the Internet... and the more you read the more confusing it becomes. What follows is a summary.

Many of those presenting "factual" information are SELLING high performane pumps or regulators... its to their advantage to be conservative... recall the muscle cars of the 60's ran 3/8" lines with the HP engines, no return lines, no engine compartment regulator... just a mechanical pump. Of course most street cars will NEVER see continuous usage at max fuel draw, just bursts of action... so guess it also depends on usage, street terror or NASCAR.

To prove this data is REALLY CONSERVATIVE, look at a Ford 190 liter/hr (50 GPH) in tank fuel pump. Built with 3/8" output and 1/4" return line, this violates the recommended sizes below...

Seems the feed line size is related to the HP (*Mallory site has original data):

Up to 500HP 3/8 -6AN

Pump size GPH is either .23 x HP for a dead head or .17 x HP with a return.

500HP x .23 = 115 GPH fuel pump dead head

500HP x .17 = 85 GPH pump with regulator

Return line is dependent on Pump size as worse case is idle and you need to be able to easily bleed off enough fuel to allow the regulator to work. At WOT there is little fuel returned to the tank, thus the return size is unimportant.

Up to 90 GPH 3/8 -6AN

I'd guess the one size smaller return line is used on production cars mostly to distinguish it from the fuel line, i.e. idiot proof!

Seems your 3/8" fuel line would have a 3/8" return line.

A professionally modified Kirkham tank I owned had the original bung bumped up a size with a 1/2" pickup tube and a second large bung installed for the return line.

|

I was FORCED to step up to 8AN to feed my 189 CI inline six as i was starting to run out of fuel above 6K RPM.

So much for the 500 HP only needs a 3/8 line data.

The only reason you would need a 3/8ths return line with a 3/8ths feed line is if you are planning on returning the same amount of fuel TO the tank as you are sending FROM the tank.4AN is plenty.And you can do it WITHOUT a reg.All you have to do is tap 4AN fitting off the fuel log and insert a Holley jet.You now have a metered return line.

The comparison to 60/70 muscle cars is really apple to oranges as they weren't race cars and the 3/8 line only had to fill the tiny bowls on Q-jets & Carters.And almost none saw over 6Krpm on a regular basis.

With regards to idiot proofing,that sounds reasonable,however the reality is,that the factory sized the line according to needs.

__________________

The rest of the world can have their opinion about the United States just as soon as WE give it to them.

Last edited by Cobrabill; 04-05-2007 at 10:17 PM..

|

04-05-2007, 10:59 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2003

Location: West Linn,

OR

Cobra Make, Engine: ERA #684, 428 FE, TKO600

Posts: 1,378

|

|

Not Ranked

Not Ranked

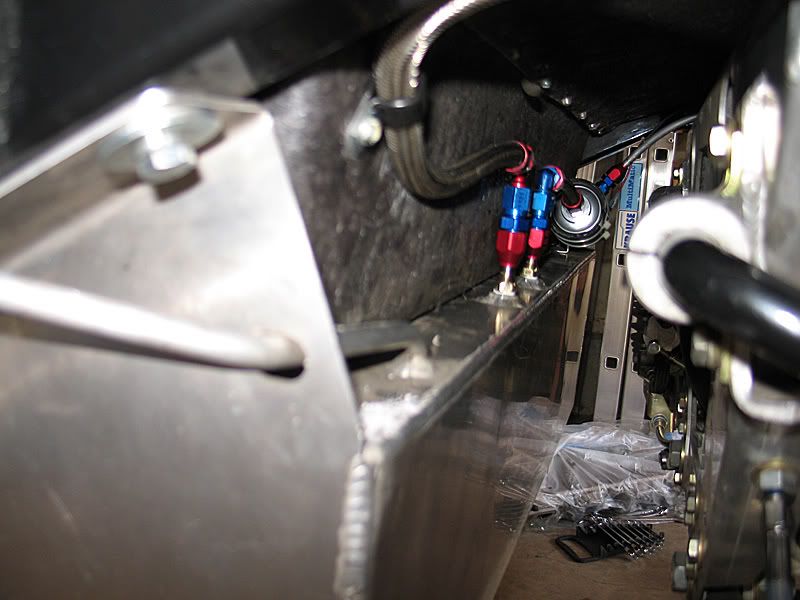

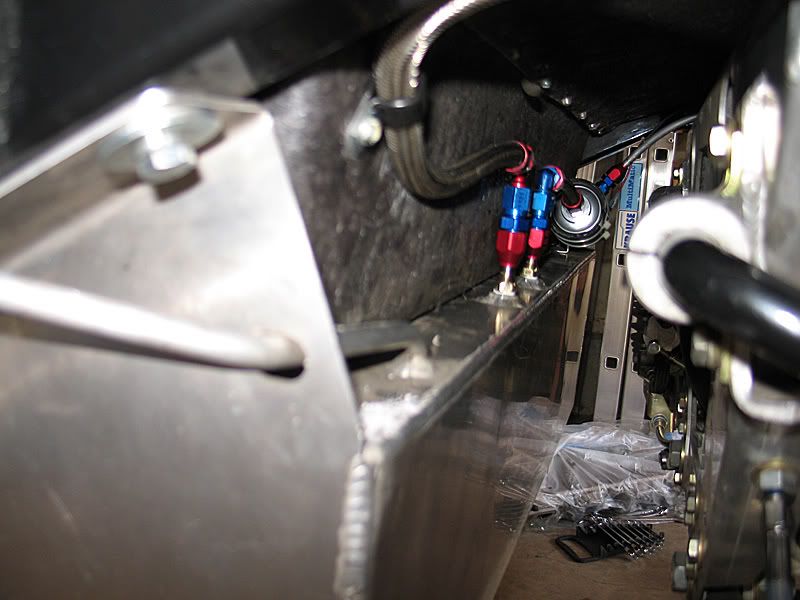

I got lucky installing the Masss-Flo EFI on the big block in my ERA since they not only already have a return line bung (plugged) on their tanks standard but they also have a connection for an electric fuel pump included in their wiring harness. All I had to do was to plumb in the pump, make up a new return tube for the existing bung and run the lines from the regulator back to the return tube. All in all a very clean installation.

Used -6 all the way through (feed and return) and it has performed without a problem.

These are the feed and return lines from the return line side of the tank. You can just make out the inline pre-filter on the feed line on the far side.

DonC |

04-06-2007, 05:16 AM

|

|

CC Member

|

|

|

Join Date: Jun 2003

Location: Palma de Mallorca, Spain,

ESP

Cobra Make, Engine: Contemporary with 482 KC/SO, TKO600,IRS Jag/AMP, 3.54 Salisbury PL,

Posts: 582

|

|

Not Ranked

Not Ranked

Brent,

I did use the second output of a Holley Fuel Pressure Regulator and fed a line to somewhere under the footbox before the line goes into the fuel filter and mechanical fuel pump. The Tee has a restrictor inside with a 1.2mm hole. This way y get the full fuel pressure to the webers, but as soon as I stop the engine the pressure drains away quickly through this "return" line. No need to feed a line back to the tank.

__________________

Nothing sounds better than a Cobra in a Tunnel !

|

04-06-2007, 08:45 AM

|

|

CC Member

|

|

|

Join Date: Nov 2000

Location: Tucson,

Az

Cobra Make, Engine: Superformance 427 Side-Oiler

Posts: 2,156

|

|

Not Ranked

Not Ranked

Fuel Injection is not comparable (do to pressure/volume differences)to the carb situation.

__________________

The rest of the world can have their opinion about the United States just as soon as WE give it to them.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 03:02 AM.

|

Linear Mode

Linear Mode