Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2024

December 2024

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

07-14-2009, 04:33 PM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Location: SW Louisiana,

LA

Cobra Make, Engine: ERA FIA #2128

Posts: 55

|

|

Not Ranked

Not Ranked

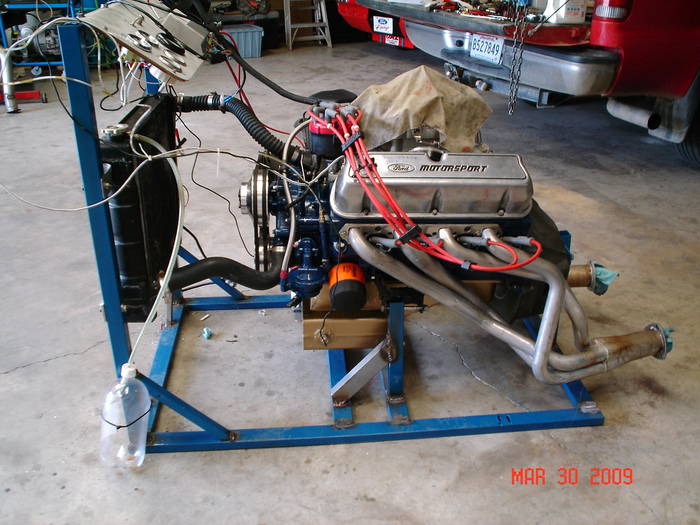

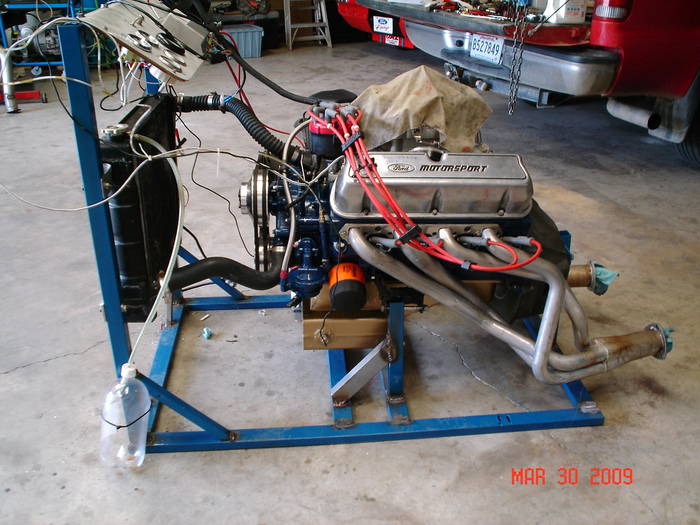

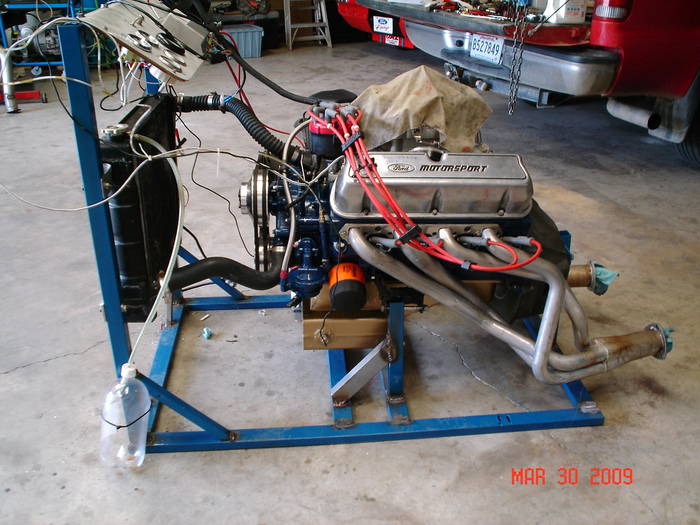

Engine Test Stand

Engine Test Stand

I bought these plans off of ebay and built this for a Jag project and for the 302 I'm putting in my ERA.

It's adjustable and from what I can tell, it would work for any make of engine. The pix are a V12 Jag. I'll just change the engine mounts and reset the spacings for my 302. It will easily hold +1500 lb and is well designed. Structural members are all .125" wall. The legs extend out for better support during testing. Plans have wiring diagrams for tach- oil pressure-water temp, materials list.

By not buying it retail, I was able to afford a Millermatic 180 with which to build it. $8.50 for the plans and about $225 for the materials (including gauges, although fuel pump for efi would be more)

The guys name on ebay is "fishermanruss" or you can email him at russ.green@comcast.net

|

-

Advertising

07-14-2009, 07:46 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

Doug;

I was looking at the ones from Jegs/Summit and decided I could build one for a ton less money,so I did,basically just form the pistures in the catalogs!!!!!!!!!!

I did make a few changes to suit my needs. I had an extra radiator and some electric fans, have a bunch of square steel tubing of varouis sizes/lengths, a Harbor Frieght chop saw and a Lincoln Mig welder. I probably spent 2 days cutting it all out, they sand lbasting the tubing and welding it up. I used a spare 302 block for my mounts and measurements. Then I made the gauge panel out of an old STOP sign, bought some of the less expensive gauges at O'Rielly's, some I already had..... probably have less than a hundred bucks in it compared to 2 grand from Jegs/Summit.......

Be warned, when folks find out you got this stand, you'll have a lot of new friends!!!!!!!!!! I really don't mind though.....

It's real easy to test your engine for leaks and such as well as break it in and set timing/carb when you can walk around it and work on it.......

I plan to clean up mine this weekend and re-wire some of the gauges and make everything nice and neat..........

Here's a few pictures of mine......

David

__________________

DAVID GAGNARD

Last edited by DAVID GAGNARD; 07-14-2009 at 09:33 PM..

|

07-14-2009, 08:15 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2001

Location: Florence,

AL

Cobra Make, Engine: RCR GT 40 & 1966 Fairlane 390 5 speed

Posts: 4,511

|

|

Not Ranked

Not Ranked

engine stand

engine stand

We build this one for almost nothing. The radiator is sitting on a stool. We are going to add a frame to hold the radiator later. We have broke in a couple of motors on this stand. I have motor mount adapters for 302 or FE motors.

It great for finding leaks on an FE.

In the picture are Coach Mike and Colin breaking in a 390 FE.

Colin: "Coach, were are the leaks"? Coach: "everywhere"

__________________

''Life's tough.....it's even tougher if you're stupid.'' ~ John Wayne

"Happiness Is A Belt-Fed Weapon"

life's goal should be; "to be smarter than inanimate objects"

Last edited by Dwight; 07-14-2009 at 08:17 PM..

Reason: add pic

|

07-14-2009, 09:37 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

Well, the little red x's just ain't workng for me today, look in my gallery, there shoud be 3 or 4 pictures of the stand/gauge panel with an engine on it.........

Doug, I can take some "rough" measurements for you if you'd like........not sure exactly where in SW La. you are, maybe not too far from me.....come by and look at mine and come in a truck and I'll gladly give you all the steel tubing you need to make your stand!!!!!!!!!!!!! I got a bunch of it........

David

__________________

DAVID GAGNARD

Last edited by DAVID GAGNARD; 07-14-2009 at 09:47 PM..

|

07-14-2009, 09:55 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

__________________

DAVID GAGNARD

|

07-15-2009, 07:34 AM

|

|

CC Member

|

|

|

Join Date: Feb 2008

Location: SW Louisiana,

LA

Cobra Make, Engine: ERA FIA #2128

Posts: 55

|

|

Not Ranked

Not Ranked

Stand Made

Stand Made

David,

I made my stand already, but would like to see yours. That's the V12 I'm rebuilding right now. I live in Lafayette and Paragon is a client of mine, so I'm in your area at least once a month.

Next month or two is a little tight with vacation and all, but will definitely touch base.

DE

|

07-15-2009, 10:02 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

Doug;

Let me know when your in the area, Paragon is all of 5 minutes from my house!!!!!!!!!!!!!

Your welcome to come by anytime.........

David

__________________

DAVID GAGNARD

|

07-16-2009, 10:14 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2006

Location: Melbourne,

VIC

Cobra Make, Engine: RMC, carb 347 TopLoader and Jag running gear ~ so old school I time it with an hour-glass :D

Posts: 1,293

|

|

Not Ranked

Not Ranked

Could this be the stand?

hmmm...

looks like another project...

ta

LoBelly |

07-16-2009, 10:56 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

[quote=LoBelly;966831]Could this be the stand?

hmmm...

looks like another project...

ta

dat be the one I made, couldn't get the pictures on the post like I would've liked too.........

I have some more pics and can take a few more now that there's no engine on it right now........

It's really very simple and works great,easy to build if you can half-a$$ weld like ME!!!!!!!!!

The only thing I was worried about was if the whole thing would "walk" while running an engine on it, well, it didn't and doesn't!!!!!!!!

The stand and wiring is kinda "primative" as you see. Plans for this coming weekend are to re-wire the whole thing, nice and neatly with those corrugated wire cover things from factory cars and add a battery tray/box.

I have an extra 1-wire alternator and brackets I put on the motor which keeps the battery charged. Without the alternator, running the ignition and electric fan, you need to have a battery charger on the battery to keep it up for any running time over 20 minutes or so..... The motor on the stand in the picture is my 472hp race motor and I've run it for as long as one hour and fifteen minutes at one time... I like to get at least 2 hours of break-in and run time on it before putting it in the car.........

This is one of the best things I've made and have in my shop. It makes tuning and making adjustments a breeze when you can walk around the motor and get to it. Also, easier to find and fix any leaks before it's in the car.... The picture doesn't show it, but I run it with muffler, makes hearing "funny" noises easier and keeps the neighbors happy...........

David

__________________

DAVID GAGNARD

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 11:49 AM.

|

Doug;

Doug;

Linear Mode

Linear Mode